10

Warranty

Titan Trailers warrants the suspension systems manufactured by it to be free from defects in

material and workmanship under proper use, installation, application and maintenance for a

period of 3 years after delivery to the original buyer.

Written permission for any claim return must be first obtained from an authorized Titan Trailer

Personnel. All returns must have transportation charges prepaid by the customer and accompanied

with a complete written explanation of claimed defects and the circumstances of suspension

failure. On all parts not manufactured by Titan Trailers, their warranty is to the extent that the

manufacturer of such parts warrant them to Titan Trailers. In no event will Titan Trailers be liable

for business interruptions, loss of profits, personal injury, cost of delay or for other special, indirect,

incidental or consequential losses, costs or damages.

Subject to all the above conditions, if repair or replacement of any defective part is made by Titan

Trailers, Titan Trailers will return the repaired or replaced parts to the original purchaser with

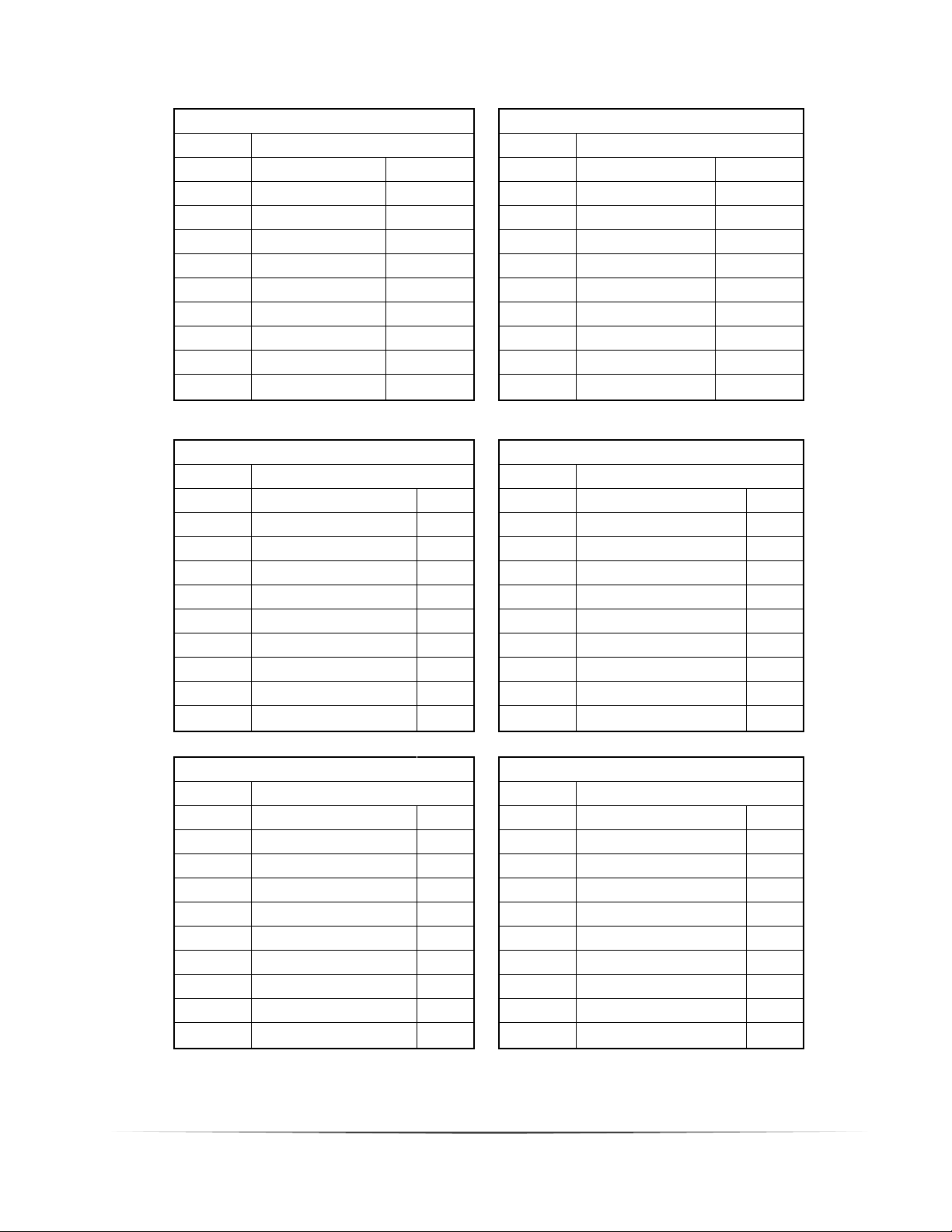

transportation charges prepaid. Table 6 below shows the timeline for warranties.

Table 6