Table of Contents

1. Important safeguards.............................................................................5

2. Transport, installation and connection.................................................6

2.1. Supply.................................................................................................................................6

2.2. Storage and conservation....................................................................................................6

2.3. Information on liability..........................................................................................................6

2.4. Transportation.....................................................................................................................6

2.4.1. Machine weight ...............................................................................................................6

2.4.2. Transporting the machine mounted on pallet, with a forklift or forklift truck ......................7

2.5. Installation...........................................................................................................................7

2.5.1. Preparations....................................................................................................................7

2.5.2. Place machine.................................................................................................................7

2.5.3. Procedure........................................................................................................................7

2.6. Changing the installation location........................................................................................9

2.7. Dismantling .........................................................................................................................9

2.7.1. Requisite qualifications....................................................................................................9

2.7.2. Scrapping and disposal...................................................................................................9

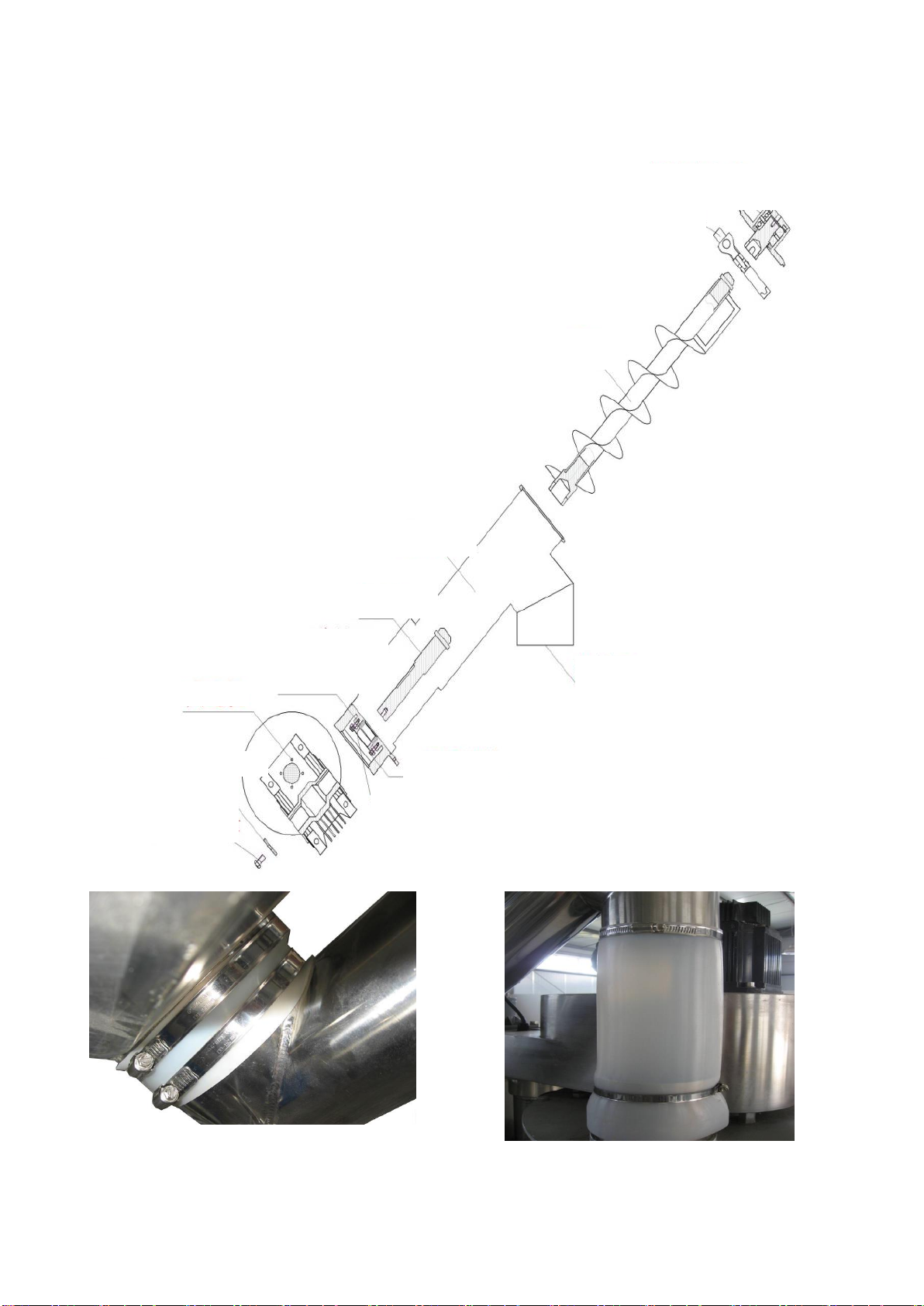

3. Description of the machine..................................................................10

3.1. Main items in the standard machine..................................................................................10

3.2. Working principle...............................................................................................................10

3.3. Machine specifications ......................................................................................................11

3.3.1. Specification of the delivered machine...........................................................................11

3.3.2. Specification of the standard machine...........................................................................11

4. Operation...............................................................................................12

4.1. Operating panel.................................................................................................................13

4.1.1. Operating switches, buttons and indications..................................................................13

4.2. Machine controls...............................................................................................................14

4.3. Settings at the machine.....................................................................................................14

4.3.1. Adjusting the incline angle.............................................................................................14

4.4. Cleaning and product changeover.....................................................................................14

5. Problem solving....................................................................................15

5.1. General.............................................................................................................................15

5.2. Operator observations-summary.......................................................................................16