OmniCure® LX500 Series

UV Curing Solutions

http://www.excelitas.com/omnicure

Excelitas Canada Inc. 2022

All rights reserved

Table of Contents

1Introduction ...................................................................................................................... 1

2Safety Precautions/ User Warnings...................................................................................... 2

2.1 Glossary of Symbols................................................................................................................................................2

2.2 Safety Precautions ..................................................................................................................................................2

3Optical Safety Data ............................................................................................................ 4

4Getting Started.................................................................................................................. 5

4.1 Package Contents ...................................................................................................................................................5

4.2 UV LED Controller and Head Images .....................................................................................................................8

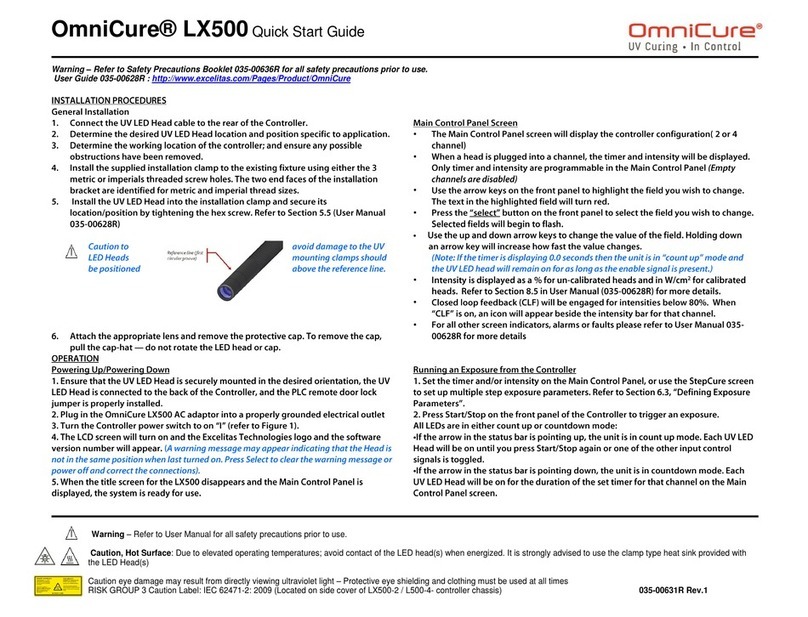

5Installing the Hardware ...................................................................................................... 9

5.1 General Installation .................................................................................................................................................9

5.2 Clamp Installation and Removal.............................................................................................................................9

5.3 Changing Lenses................................................................................................................................................... 10

5.4 Storing LED Head and Lens Assemblies .............................................................................................................. 10

5.5 Installation Component Images............................................................................................................................ 10

6Operation........................................................................................................................ 12

6.1 Powering Up and Powering Down........................................................................................................................ 12

6.2 Understanding the Controller Display.................................................................................................................. 13

6.3 Closed Loop Feedback.......................................................................................................................................... 16

6.4 Defining Exposure Parameters............................................................................................................................. 16

6.5 Running an Exposure from the Controller............................................................................................................ 19

6.6 Using the PC Interface with USB Connection ...................................................................................................... 19

6.7 Interfacing with a PLC........................................................................................................................................... 19

6.8 Using the Foot Pedal............................................................................................................................................. 21

7Troubleshooting ...............................................................................................................23

7.1 Symptoms and Possible Causes ...........................................................................................................................23

7.2 Error Codes............................................................................................................................................................24

8Care and Maintenance ...................................................................................................... 26

8.1 Cautions and Handling..........................................................................................................................................26

8.2 Cleaning Materials ................................................................................................................................................26

8.3 Cleaning the LED Head and Lens Assembly ........................................................................................................ 27

8.4 Cleaning the Controller......................................................................................................................................... 27

8.5 Calibrating a UV LED Head................................................................................................................................... 27

8.6 Viewing Log Files ..................................................................................................................................................28

8.7 SD Cards................................................................................................................................................................28

9Technical Specifications.....................................................................................................32

9.1 Environmental Conditions ....................................................................................................................................32

9.2 Controller Specifications.......................................................................................................................................32

9.3 UV LED Head Specifications................................................................................................................................. 33

10 Regulatory Compliance .................................................................................................... 34

10.1 Product Safety and Electromagnetic Compatibility: ........................................................................................... 34

10.2 China RoHS ........................................................................................................................................................... 35

10.3 WEEE Directive ......................................................................................................................................................37