Exclusiva BlueStar 55BT M User manual

BlueStar 55BT M

BlueStar 66BT M

BlueStar

Scrubber Dryer

Technical data plate.

PLEASE NOTE:

Before use, carefully read

the instructions.

3

A

3

1

4

8

7

6

2

5

4

B

2

3

56

8

4

9

7

1

10

5

D

C

1

4 5

6

33A 3B 3C 3D

2

A

B

34

5

1

67

89

2

6

F

E

1 2

3

123

7

H

G

I

123

2

1

8

4

3

6

5

4

3

6

2

7

75

1

1

2

1

L

M

N

25

CONTENTS

1. GENERAL INFORMATION

1.1. SCOPE OF THE MANUAL

1.2. TERMINOLOGY AND SYMBOL LEGEND

1.3. PRODUCT IDENTIFICATION

1.4. SPECIFIC USE

1.5. TECHNICAL MODIFICATIONS

2. SAFETY INFORMATION

2.1. BASIC RECOMMENDATIONS

2.2. NOISE AND VIBRATIONS

3. HANDLING INFORMATION

3.1. PACKING LIFTING AND TRANSPORT

3.2. CHECKS UPON DELIVERY

3.3. UNPACKING

3.4. LIFTING AND TRANSPORT: MACHINE,

BATTERY AND BATTERY CHARGER

4. TECHNICAL INFORMATION

4.1. GENERAL DESCRIPTION

4.1.1. MACHINE

4.1.2. BATTERY

4.1.3. BATTERY CHARGER

4.2. STRUCTURE AND FUNCTIONS

4.2.1. MACHINE

4.2.2. BATTERY

4.3. ACCESSORIES

5. INSTALLATION INFORMATION

5.1. BATTERY PREPARATION

5.2. BATTERY INSTALLATION AND PREPARATION

5.2.1. CIRCUIT BOARD SETTINGS CONFIGURATION

5.3. BATTERY CHARGER CONFIGURATION

5.4. MACHINE PREPARATION

6. OPERATING INFORMATION

6.1. BATTERY CHARGING

6.2. SQUEEGEE AND SPLASH GUARD ASSEMBLY,

DISASSEMBLY AND ADJUSTMENT

6.2.1. SQUEEGEE ASSEMBLY

6.2.2. SQUEEGEE DISASSEMBLY

6.2.3. SQUEEGEE BLADES DISASSEMBLY /

ASSEMBLY

6.2.4. SQUEEGEE ADJUSTMENT

6.2.5. SPLASH GUARD ASSEMBLY/ DISASSEMBLY

6.3. BRUSH ASSEMBLY / DISASSEMBLY

6.4. FILLING AND DRAINING THE DETERGENT

SOLUTION TANK

6.5. DRAINING THE RECOVERY TANK

6.6. DRIVING THE MACHINE

6.7. WORK METHOD

6.7.1. PREPARATION AND WARNINGS

6.7.2. OPERATING CONTROLS

6.7.3. DIRECT SCRUBBING OR FOR SLIGHTLY

DIRTY SURFACES

6.7.4. INDIRECT SCRUBBING OR FOR VERY

DIRTY SURFACES

6.7.5. POSTSCRUBBING OPERATIONS

6.8. SPECIFIC INSTRUCTIONS FOR THE USE OF

POWER MAINS AC 230V MODEL

7. MAINTENANCE INFORMATIONS

7.1. TANK S

7.2. SUCTION HOSE

7.3. SQUEEGEE

7.4. ACCESSORIES

7.5. MACHINE BODY

7.6. BAT TER IES

7.7. FUSES AND THERMAL BREAKERS

7.8. PERIODIC MAINTENANCE

7.9. RECOMMENDED SPARE PARTS

8. OPERATING CHECKS

8.1. THE MACHINE DOESN’T WORK

8.2. THE MACHINE DOESN’T MOVE FORWARD

8.3. THE BRUSHES DON’T ROTATE

8.4. NOT ENOUGH OR TOO MUCH DETERGENT

8.5. NO SUCTION

8.6. THE BRUSH MOTOR OR THE SUCTION

MOTOR DOESN’T STOP

8.7. THE SQUEEGEE DOESN’T CLEAN OR DRY

EFFICIENTLY

8.8. THE BATTERY CHARGER DOESN’T WORK

8.9. THE BATTERIES DO NOT CHARGE OR DO

NOT HOLD A CHARGE

9. CONDITIONS OF WARRANTY

9.1. SCRAPPING OF THE MACHINE

9.2. DISPOSAL WEEE

26

1. GENERAL INFORMATION

1.1. SCOPE OF THE MANUAL

To make it easier to read about and look up various

subjects, refer to the table of contents at the begin-

ning of the section in your language.

This manual has been prepared by the manufacturer

and is an integral part of the product. As such, it must

be kept in a safe place for the machine’s entire service

life until demolition.

The customer must ensure that machine operators

have read or are familiar with the contents of this

manual so that they strictly follow the instructions

described herein.

Constant compliance with the instructions provided

in this manual is the only way to guarantee the best

results in terms of safety, performance, efficiency and

service life of the product you now own. Non-com-

pliance with these rules may cause injuries to people

and damage to the machine, the scrubbed surface

and the environment: in no case can such injuries or

damage be attributed to the manufacturer.

This manual refers in detail to the machine and pro-

vides instructions and descriptions only about our

batteries and battery chargers (optional).

The batteries and the battery charger are basic com-

plementary machine parts and will affect its opera-

tion in terms of running time and performances.

Only the correct combination of the two accessories

(batteries and battery charger) will ensure the hi-

ghest possible performances and avoid wasting lots

of money. For more detailed information refer to the

special battery and battery charger manuals.

Our recommended battery chargers and batteries

(optionals) ensure the best combination with the

machine and offer outstanding versatility (battery

charger) as well as the category’s highest quality and

performance standards.

1.2. TERMINOLOGY AND SYMBOL LEGEND

For the sake of clarity and to efficiently highlight the

various aspects of the instructions provided, terms

and symbols were used that are defined and illustra-

ted here below:

- Machine. This definition replaces the commercial

name to which this manual refers.

- Operator. ‘operator’ means the person or persons

given the task of installing, operating, adjusting, main-

taining, cleaning, repairing or transporting machinery.

- Technician. A technician is considered a person

who has the experience, technical education, legi-

slative and regulatory knowledge that allows him to

carry out any type of required work, and the ability to

recognise and to avoid possible risks during machine

installation, and maintenance.

☞- INDICATION SYMBOL . Particularly important in-

formation to avoid machine malfunctions.

- ATTENTION SYMBOL . Very important informa-

tion to avoid serious damage to the machine and to

the environment in which it operates.

- DANGER SYMBOL Vital information to avoid se-

rious (or extreme) consequences affecting the health

of persons and causing damage to the product and

the environment in which it operates.

Total weight (ready to operate)

Max. working range incline 2%

(Max. transporting range incline 10%)

Rated power brush drive

Rated power suction turbine

1.3. PRODUCT IDENTIFICATION

The nameplate located under the dashboard, above

the battery connector, contains the information.

1.4. SPECIFIC USE

This appliance is suited for the commercial use,

e.g. in hotels, schools, hospitals, factories, shops,

oces, and rental companies.

This machine is a floor scrubber-drier: it must be used

to scrub and to vacuum liquids of flat, rigid, horizon-

tal, smooth or moderately rough and uniform floors

that are free from obstacles in both civic and indu-

strial environments. Any other use is prohibited.

Please refer very carefully to the safety information

reported in this manual.

The scrubber-drier distributes a quantity of a water

and detergent solution (adjustable) on the surface to

be cleaned, while the brushes remove any dirt on the

ground. The machine’s suction system, using a ground

squeegee, perfectly dries the liquids and the dirt just

removed from the front brushes in a single pass.

By efficiently combining a cleaning detergent with

various types of brushes (or abrasive disks), the ma-

chine can adapt to all the various combinations of

floors and dirt.

1.5. TECHNICAL MODIFICATIONS

The manufacturer reserves the right to make techni-

cal modifications to the product, without prior notice,

in order to make the necessary technical upgrades or

improvements. For this reason, some details of your

machine may be different from the information in the

sales catalogues or from the illustrations presented in

this booklet. However, this will not reduce safety or in-

validate the information supplied to this regard.

2. SAFETY INFORMATION

2.1. BASIC RECOMMENDATIONS

☞Carefully read the “instruction manual” before

starting, using, performing unscheduled or routi-

ne maintenance or any other work on the machine.

Rigorously comply with all the instructions pro-

vided in this manual and in those for the batteries

and battery chargers (with particular attention to

warnings and danger notices).

The manufacturer will not be held responsible for in-

juries to persons or damage to property due to non-

compliance with the aforementioned instructions.

This machine must be powered only with the safety

extra-low voltage indicated on the technical data plate.

☞Before using the machine, make sure that each

part is in the correct position.

The appliance is not intended for use by persons

(including children) with reduced physical, sensory or

mental capabilities, or lack of experience and knowl-

edge, unless they have been given supervision or in-

struction concerning use of the appliance by a person

responsible for their safety.

Children should be supervised to ensure that they do

not play with the appliance.

Do not operate this machine for any other purpo-

se except for the use for which it was specifically de-

signed. Evaluate the type of building where it will be

utilised and rigorously comply with the current safety

regulations and conditions.

Do not use the machine in places without adequa-

te lighting, in explosive environments, when harmful

dirt is present (dust, gas, etc.), on roads or public pas-

sage ways and in outdoor environments in general.

The machine operating temperature range is +4°C

to + 35°C; when not being used, store the machine in

a dry and non-corrosive environment within a tem-

perature range of between + 10°C and + 50°C.

When using the machine under any condition the hu-

midity must range between 30% and 95%.

Never use or vacuum liquids, gases, dry dust,

acids and solvents (e.g. paint thinners, acetone,

etc.), even if diluted, inflammables or explosives

(e.g. petrol, fuel oil, etc.); never vacuum flaming

or incandescent objects.

Do not use the machine on slopes or ramps ste-

eper than 2%;

for small slopes, do not use the machine sideways,

always handle it with caution and never move

backwards. When transporting (10% max) the ma-

chine on steeper ramps or slopes, be very careful to

avoid tipping and/or uncontrolled accelerations.

The machine can be handled on ramps and/or steps

only with the brush head and squeegee lifted off the

ground.

Never park the machine on a slope.

☞Never leave the machine unattended with the key

in and connected; it may be left only after having

disconnected it and taken the key out and guaran-

teeing against accidental movements and, if necessa-

ry, disconnecting it from the electrical power supply.

Make sure there are no other persons, and children in

particular, in the area where the machine is being used.

Do not use the machine to transport persons/

things or to tow objects. Do not tow the machine.

☞Do not use the machine as a support surface for

any weight for any reason.

Do not block the ventilation and heat dispersion ope-

nings.

Do not remove, modify or by-pass the safety devices.

Always use individual safety devices to ensure

operator safety: aprons or safety overalls, non-slip

and waterproof shoes, rubber gloves, goggles and

earphones, and masks to protect the respiratory tract.

Before starting to work, remove necklaces, watches,

ties and other objects that may cause serious injuries.

Do not insert hands between moving parts.

☞Do not use detergents that differ from those re-

quired and follow the instructions indicated on the

relative safety sheets. Detergents should be stored in

a place that is inaccessible to children. In case of con-

tact with the eyes, rinse immediately with copious

amounts of water and, if swallowed, immediately

consult a physician.

Make sure that the battery charger power sockets are

connected to an efficient earthing system and that

they are protected by magnetothermal and differen-

tial circuit-breakers.

Follow the battery manufacturer’s instructions and

comply with legal provisions. The batteries should

always be clean and dry to avoid surface leakage cur-

rents. Protect the batteries against impurities, such as

metallic dust.

If the machine is equipped with gel batteries it is

essential to make sure the run-down indicator (loca-

ted on the panel) is adjusted correctly. Contact your

dealer or refer to the specific paragraph.

Do not place tools on top of the batteries: they

may cause a short-circuit or an explosion.

When using battery acid, rigorously respect the

relative safety instructions. In the presence of parti-

cularly strong magnetic fields, evaluate the possible

effect on electronic control devices.

Never spray water on the machine to clean it.

☞Recovered fluids contain detergents, disinfectants,

water, as well as organic and inorganic material col-

lected during work operations: dispose of them in

accordance with current legal provisions.

If the machine malfunctions and/or operates inef-

ficiently, turn it off immediately (disconnecting it

from the electric power supply or from the batteries)

and do not tamper with it.

Contact one of the manufacturer’s technical service

centres.

All maintenance or accessory replacement opera-

tions must be carried out in environments with ade-

quate lighting and only after having disconnected

27

the machine from the electric power supply by deta-

ching the battery connector.

☞All work on the electrical system and all mainte-

nance and repair operations (especially those not

explicitly described in this manual) should be carried

out only by authorised service centres or by speciali-

sed technical personnel who are experts in the sector

and in the pertinent safety regulations.

☞The machine owner can only use original acces-

sories and spare parts supplied exclusively by the

manufacturer since such parts are the only ones that

guarantee that the equipment will operate safely wi-

thout any problems. Do not use parts disassembled

from other machines or other kits as spare parts.

☞Before each use, check the machine and, in parti-

cular, check that the battery charging cable and the

connector are in good condition and safe for use. If

they are not in perfect condition, do not use the ma-

chine for any reason until an authorised specialist re-

pairs the defective parts.

☞If foam or liquid is noted, immediately turn off the

suction motor.

☞Do not use the machine on textile flooring, such as

rugs, carpeting, etc.

Wax, foaming detergents or dispersions along the

hoses may cause serious problems for the machine

or clog the hoses.

2.2. NOISE AND VIBRATIONS

See last page.

3. HANDLING INFORMATION

3.1. PACKING LIFTING AND TRANSPORT

During all lifting or transport operations, make

sure that the packed machine is securely anchored

to prevent it from tipping over or falling accidentally.

Transport vehicle loading and unloading operations

must be carried out with adequate lighting.

The packed machine must be handled using ade-

quate devices, making sure not to damage/strike any

part of the packing, not to tip it over and to be very

careful when placing it on the ground.

☞All these instructions also apply to the batteries

and the battery charger.

3.2. CHECKS UPON DELIVERY

☞When the goods are delivered (machine, battery

or battery charger) by the transporter, carefully check

the condition of the packing and its contents. If the

contents have been damaged, notify the transporter

and reserve the right, in writing (select the word “re-

serve” on the document), to submit a claim for com-

pensation before accepting the goods.

3.3. UNPACKING

Wear safety clothing and use adequate tools to

limit the risks of accidents.

Carry out the following steps if the machine is packed

with a cardboard housing:

- Use scissors or clippers to cut and eliminate the pla-

stic straps.

- Slip off the cardboard housing from the top of the

packed machine.

- Remove the envelops inside and check their con-

tents (use and maintenance manual, battery charger

connector)

- Remove the metallic brackets or plastic straps that

secure the machine to the pallet.

- Release the brushes and the squeegee from the pa-

cking.

- Take the machine off the pallet (pushing it

backward) by using an inclined surface that is solidly

attached to the floor and to the pallet.

Take the same precautions and follow the same in-

structions to remove the optional battery charger

from the packing (holding the special handles to ex-

tract it from the top of the packing) and the optional

battery.

After moving the machine away from all the packing,

start mounting the accessories and the batteries as

per the instructions provided in the specific section.

Keep all the pieces of the packing since they might be

useful in the future to protect the machine and the

accessories during transport to another location or to

authorised service centres. If not, the packing can be

disposed in accordance with current disposal laws.

3.4. LIFTING AND TRANSPORT: MACHINE,

BATTERY AND BATTERY CHARGER

Never use a forklift truck to lift the machine. There

are no places on the frame that can be used to lift the

machine directly.

Before preparing the packing and transporting the

machine:

- Empty the recovery tank and the detergent solution

tank.

- Disassemble the squeegee and the brushes or scrapers.

- Disconnect and remove the batteries.

Place the machine on the original pallet (or an equi-

valent one that can bear the weight and is big enou-

gh for the machine’s overall dimensions) using an

inclined surface.

Solidly anchor the machine and the squeegee to the

pallet using metallic brackets or other elements that

can bear the weight of the parts.

Lift the pallet with the machine and load it on the

transport vehicle.

Secure the machine and the pallet using ropes con-

nected to the transport vehicle.

As an alternative, when using private transport vehi-

cles, use inclined ramps to push the machine without

the pallet, making sure to protect all parts and the

machine itself against violent impacts, humidity,

28

vibrations and accidental movements during tran-

sport.

The battery boxes have holes where tools can be ho-

oked for handling.

☞To lift or insert the battery (into the machine

compartment), use only suitable personnel and

equipment (cables, eyehooks, etc.) for the operation

and to bear the weight of the loads involved. When

transporting, take the same precautions and follow

the same instructions provided for the machine toge-

ther with those in the special manufacturer’s manual.

The battery charger can be transported on its sup-

ports, both vertically and horizontally. Take the same

precautions and follow the same instructions provi-

ded for the machine together with those in the spe-

cial manufacturer’s manual.

4. TECHNICAL INFORMATION

4.1. GENERAL DESCRIPTION

4.1.1. MACHINE

We can summarise the machine’s main features as

follows:

- The form of the squeegee, the air flows and the

specially designed rubber blades produce excellent

drying results even on tiled floors. Thanks to the par-

ticular balanced shape of the machine frame and the

squeegee support, no water residues are left behind

in a curve, and even when a smaller squeegee is used.

Excellent distribution of weights and dimensions

thanks also to the heavy weight of the brush plate

and batteries in the centre of the machine.

- A heavy weight on the brushes makes them work

efficiently on the floor. The pressure is generated by

the weight of the plate, without springs or additional

devices that lead to difficulties and inaccuracy. The

entire mass is generated by the hanging weight of a

15 mm steel ship’s plate.

- A large volume of water in the tanks reduces dead

time since fewer trips are needed to collect water and

dump dirt. There is no delicate flexible diaphragm

that, at a technical level, is difficult to clean.

- The dirty water tank leaves several litres for decan-

ting any foam

- Robust construction. The frame and squegee are

made in extra thick plate and aluminium 6 mm, 8 mm,

10 mm up to 20 mm – are laser cut and welded. The

brush plate is made from 15 mm ship’s sheet metal,

with a surface treatment that protects the plate and

the paint for thousands of hours in a saline fog. All

screws are made with stainless steel; the tanks (body)

are made with 7-8 mm thick shockproof polyethyle-

ne. Everything is simple and very strong, without any

other complicated designs.

- The battery compartment can house very large bat-

teries, which guarantees extended running time.

- The suction motor is housed inside the machine,

thus reducing operating noise to a minimum.

- The recovery tank is very easy to clean due to the

lack of the characteristic difficult access points of re-

covery tanks located in a lower position.

4.1.2. BATTERY

Regardless of the type of construction, battery per-

formances are indicated with the term capacity,

which always refers to a discharge period. Another

important value is the number of possible dischar-

ges. The capacity is expressed in amps per hour (Ah),

while the discharge period is generally indicated as

20 hours (C20 or 20h, or not expressly indicated) or

5 hours (C5 or 5h). The discharge/charge cycles indi-

cate the number of times that the battery can hold

a charge under the best conditions, i.e. they indicate

the useful battery service life complying with all the

necessary measures.

Therefore, the capacity of a battery varies depending

on how fast it uses energy (current). That’s why the-

re’s such a variation in the capacity values expres-

sed as C5 or C20. These factors must be taken into

account when comparing products available on the

market with our own.

This machine can be equipped with two types of bat-

teries that differ in terms of their construction and

features.

- Pb-Acid battery with tubular armoured modules:

the electrolyte level in each element must be perio-

dically checked!

If one element is no longer covered by the acid

solution it will oxidise in 24 hours, thus perma-

nently affecting that element’s performance.

Refer to the battery manual to avoid physical da-

mage and economic loss.

- Gel module battery: this type of battery is main-

tenance free and does not require special envi-

ronments for recharging (since it does not emit any

harmful gases); therefore, it is highly recommended.

It should not be taken for granted that batte-

ries and battery chargers with the same technical

features as those we offer will produce the same

results. Only perfect compatibility between the-

se elements (Pb-Acid batteries, gel batteries and

battery chargers) will safeguard the performan-

ces, the service life, the safety and the economic

value invested.

4.1.3. BATTERY CHARGER

This type of high-frequency battery charger efficien-

tly charges batteries, extending their operating and

service life. In addition, because they can be confi-

gured it is a very versatile solution that reduces the

number of chargers required in the warehouse. The

same battery charger can be used for both Pb-Acid

batteries and for gel batteries.

The information indicated on the digital display can

be used to always keep the charging process, the bat-

29

tery and the battery charger under control (read the

specific manual for more details).

It should not be taken for granted that batte-

ries and battery chargers with the same technical

features as those we offer will produce the same

results. Only perfect compatibility between the-

se elements (Pb-Acid batteries, gel batteries and

battery chargers) will safeguard the performan-

ces, the service life, the safety and the economic

value invested.

Refer to the relevant manufacturer’s manual provided.

4.2. STRUCTURE AND FUNCTIONS

4.2.1. MACHINE

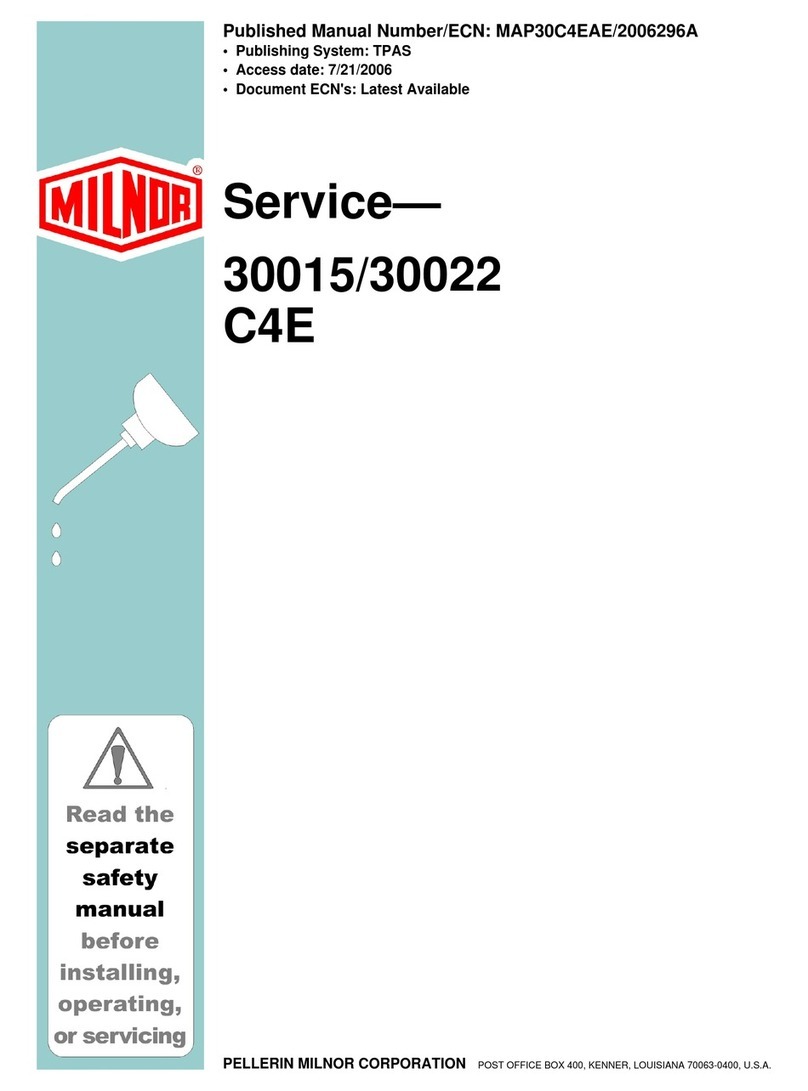

PHOTO A

1 BATTERY COMPARTMENT HOOD

2 RECOVERY WATER TANK

3 SOLUTION WATER TANK PLUG

4 SOLUTION WATER TANK

5 BRUSH MOTOR PROTECTIVE COVER

6 SPLASH GUARD

7 FRONT RIGHT BUMPER WHEEL

8 MACHINE RIGHT WHEEL

PHOTO B

1 CONTROL PANEL

2 GENERAL ON / OFF KEY SWITCH

3 SOLUTION WATER OUTLET ADJUSTING

LEVER

4 RECOVERY TANK DRAIN HOSE

5 SOLUTION WATER TANK DRAIN PLUG

6 BRUSH PLATE LIFT/LOWER PEDAL

7 RECOVERY TANK INSPECTION PLUG

8 SQUEEGEE LIFT/LOWER LEVER

9 BATTERY CHARGER CONNECTOR

10 FORWARD/REVERSE TRACTION LEVER

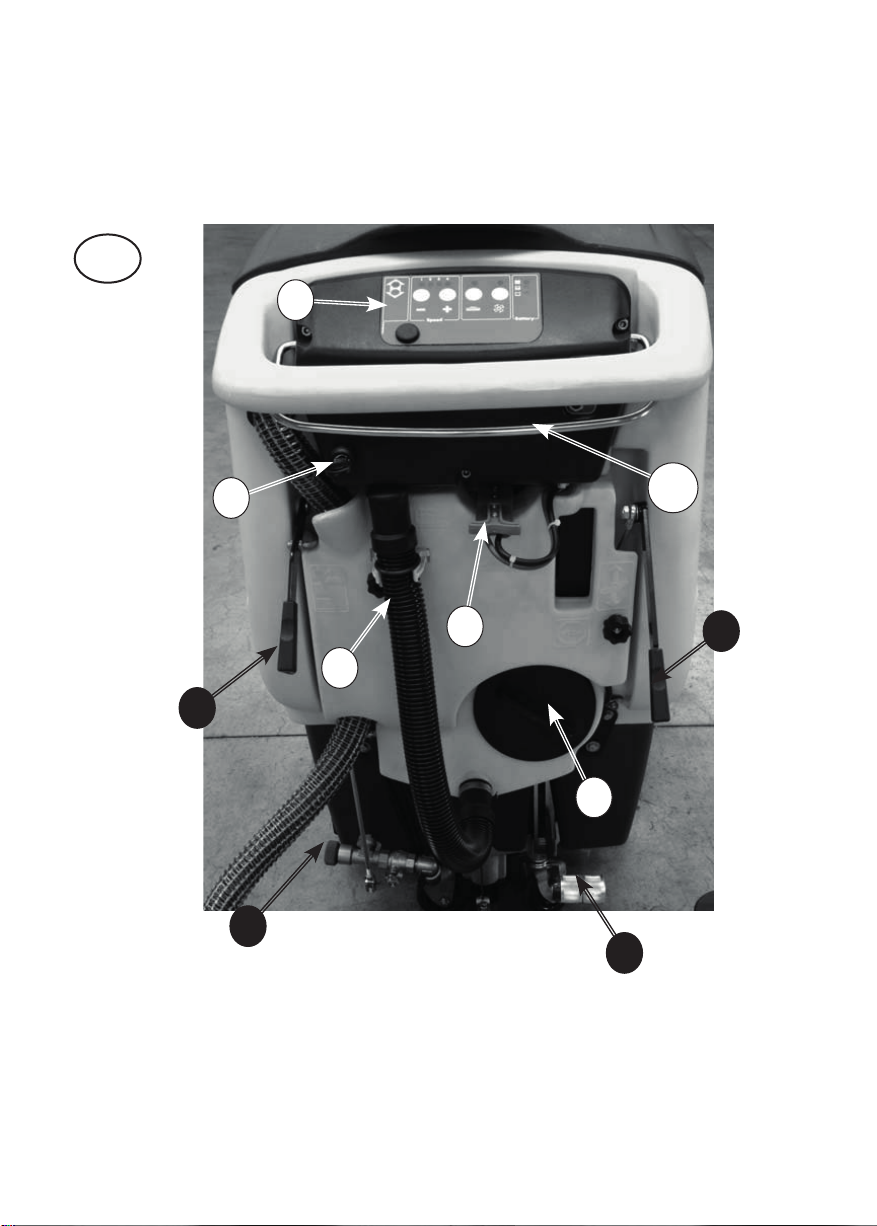

PHOTO C DC 24V MODEL WITH TRACTION

1 FORWARD/REVERSE LED INDICATORS

2 PUSH SWITCH FOR THE ADJUSTING OF

DRIVING SPEED

3 DRIVING SPEED LED INDICATORS

4 BRUSH MOTOR SWITCH

5 SUCTION MOTOR SWITCH

6 BATTERY POWER TEST

PHOTO D DC 24V MODEL WITH TRACTION

1 GENERAL ON / OFF KEY SWITCH

2 FORWARD/REVERSE TRACTION LEVER

2A FORWARD DRIVE

2B REVERSE DRIVE

3 HOUR METER

4 BRUSH MOTOR THERMAL BREAKER

5 TRACTION MOTOR THERMAL BREAKER

6 SOLUTION WATER OUTLET ADJUSTING

LEVER

7 RECOVERY TANK DRAIN HOSE

8 BATTERY CHARGER CONNECTOR

SQUEEGEE LIFT/LOWER LEVER

PHOTO E DC 24V MODEL WITHOUT TRACTION

1 BRUSH MOTOR SWITCH

2 SUCTION MOTOR SWITCH

3 BATTERY POWER TEST

PHOTO F AC 230V MODEL

1 GENERAL ON/OFF SWITCH

2 BRUSH MOTOR SWITCH

3 SUCTION MOTOR SWITCH

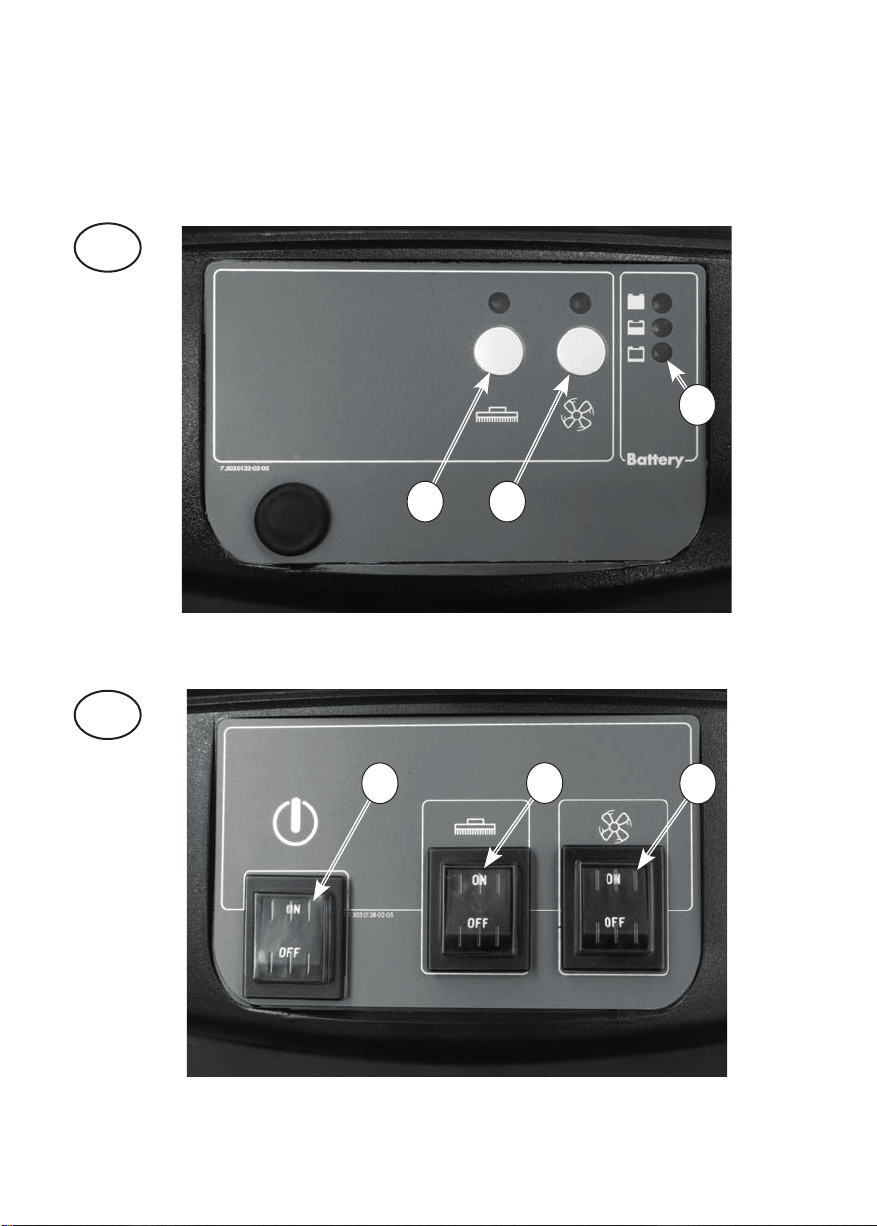

PHOTO G DC 24V MODEL

1 SUCTION COMPARTMENT HOOD

2 BATTERY COMPARTMENT WITH 12V

BATTERIES

3 BATTERY COMPARTMENT HOOD

PHOTO H DC 24V MODEL

1 SUCTION FILTER

2 VACUUM MOTOR COMPARTMENT

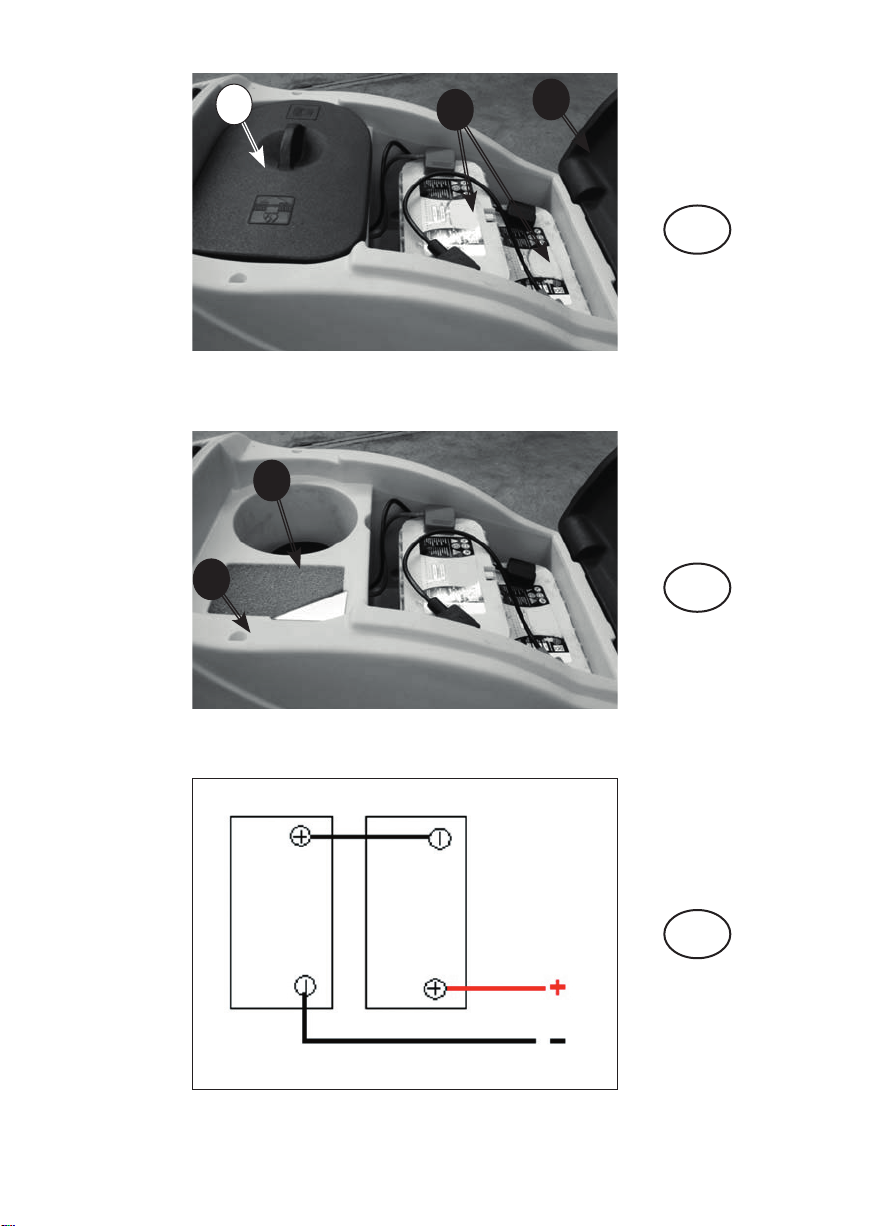

PHOTO I DC 24V MODEL

BATTERY CONNECTION DIAGRAM

PHOTO L

1 SUCTION HOSE CONNECTOR

2 SQUEEGEE INCLINATION ADJUSTING KNOB

3 SQUEEGEE BLADES REPLACEMENT KNOB

4 SQUEEGEE BUMPER WHEEL

5 SQUEEGEE PRESSURE ADJUSTING KNOB

6 SQUEEGEE WHEEL

7 SQUEEGEE FIXING KNOB

PHOTO M

1 SPLASH GUARD FIXING SPRING CLIP

2 SPLASH GUARD

PHOTO M

1 BRAKE LEVER

4.2.2. BATTERY

If supplied, the Pb-Acid (if not dry charged) or gel bat-

teries are ready to be installed:

Positive pole - red

Negative pole - black

4.3. ACCESSORIES

Your machine supplier can provide a complete and

updated list of all available accessories, such as

brushes, scrapers, disks, etc.

5. INSTALLATION INFORMATION

5.1. BATTERY PREPARATION

The technical features of the batteries used must

30

match those indicated in the technical features sec-

tion. Using different batteries may cause serious

damage to the machine or may require them to be

charged more frequently.

During installation or when performing any type of

battery maintenance, the operator must be equipped

with adequate safety accessories to prevent accidents.

Work far from open flames, do not short-circuit the bat-

tery poles, do not generate sparks and do not smoke.

The batteries are normally supplied full of acid solu-

tion (for the Pb-Acid type) and ready for use. In any

case, follow the steps indicated in the manual sup-

plied with the battery and carefully follow the instruc-

tions regarding safety and operating procedures.

5.2. BATTERY INSTALLATION AND

PREPARATION

These operations must be carried out by speciali-

sed personnel.

Disconnect the Anderson connector of the battery

wiring from the Anderson connector of the machine

wiring. Always hold the connectors with the hands

and never pull on the cables.

Attach the battery wiring to the battery, connec-

ting the terminals only on the poles marked with

the same symbol (red wiring “+”, black wiring “-“)!

A battery short-circuit may cause an explosion!

After checking that all the controls on the panel are in

position “0” or at rest, connect the battery connector

to the machine connector.

Close the battery compartment making sure not

to crush any wires.

5.2.1. CIRCUIT BOARD SETTINGS

CONFIGURATION

The machine is equipped to GEL battery circuit board

configured. If the operator whish to use e Pb-Acid bat-

tery, it is necessary to set the electronic circuit board

as follows:

Model “B” (DC 24V)

TO ENTER THE BATTERY THRESHOLD CONFIGURA-

TION MODE:

1) Press simultaneously the push buttons “BRUSH

MOTOR SWITCH” (Photo E - 1) and “SUCTION MOTOR

SWITCH”(Photo E - 2) within 2 seconds after switching

on the machine with the key switch (Photo D - 1). The

three LED of the battery power test (Photo E - 3) will

be ON.

2) Press “SUCTION MOTOR SWITCH” (Photo E - 2) key

within 5 seconds from the previous action; you have

now entered in the configuration mode: the green and

yellow LED of the battery power test (Photo E - 3) will

be ON.

CONFIGURATION SETTINGS ARE DISPLAYED ON

THE BRUSH LED (Photo E - 1) and on the SUCTION LED

(Photo E - 2):

Gel:

BRUSH LED (Photo E - 1) on.

SUCTION LED (Photo E - 2) off.

Pb-Acid:

BRUSH LED (Photo E - 1) off.

SUCTION LED (Photo E - 2) off.

Li-Lithium:

BRUSH LED (Photo E - 1) off.

SUCTION LED (Photo E - 2) on.

TO MODIFY CONFIGURATION SETTINGS:

Press the “BRUSH MOTOR SWITCH”(Photo E - 1)

TO SAVE THE SETTINGS AND EXIT THE MODE:

Press the“SUCTION MOTOR SWITCH”(Photo E - 2)

Once the settings have been set, we have different

battery discharge levels with differentiated interven-

tion on the machine functions as specified in the fol-

lowing table:

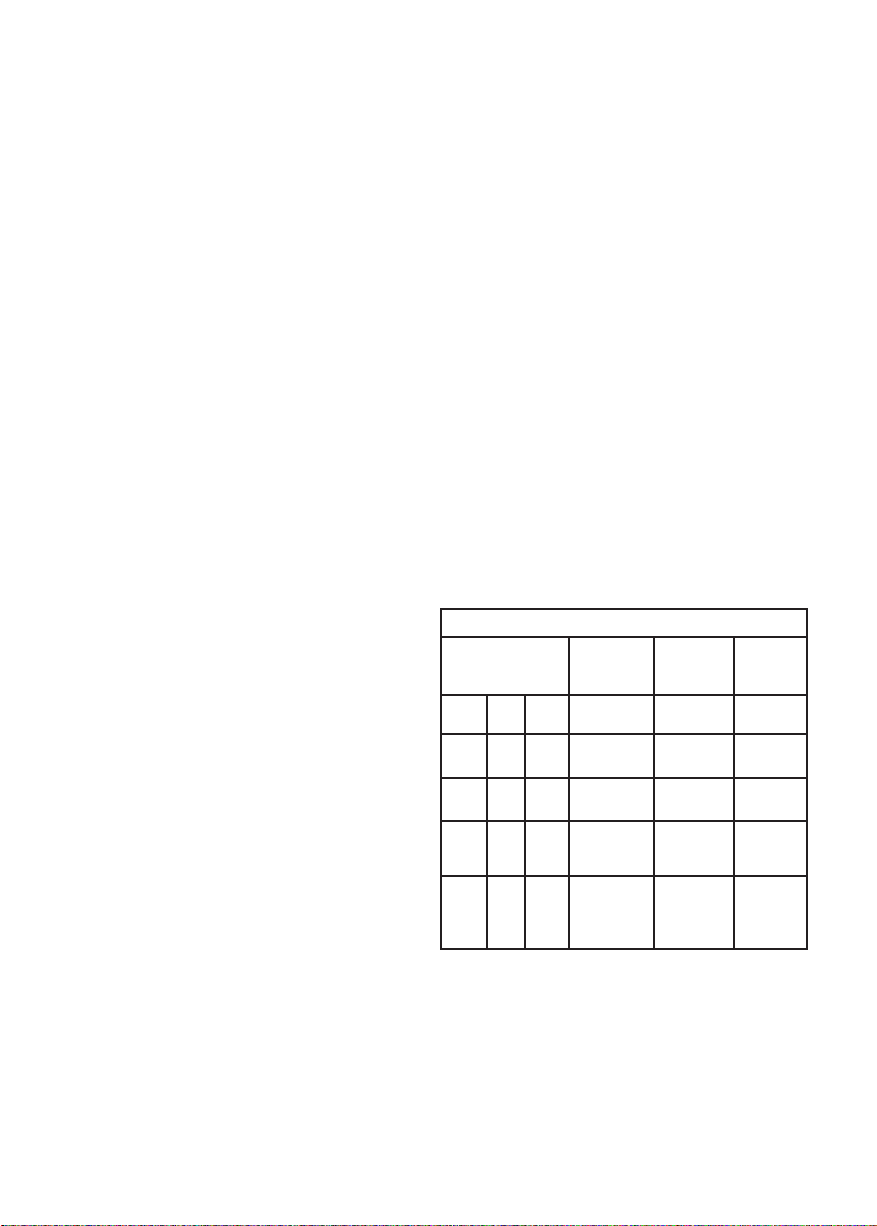

Battery discharge indicator and functions - Model “B”(DC 24V)

Volts

Battery Type

Battery power

test indicator

LED

Brush opera-

tion indica-

tor LED

Pb-

Acid

GEL Li Signaling Signaling Action

24,0 24,0 >25,4 Green

LED ON

LED ON All working

21,5 22,5 >23,5 Yellow

LED ON

LED ON All working

20,5 21,5 >22,6 Red LED ON LED

FLASHING

Brush motor

is not wor-

king

20,0 21,0 <22,6 Red LED

FLASHING

LED

FLASHING

Brush and

suction mo-

tors are not

working

Model “BT” (DC 24V with traction)

TO ENTER THE BATTERY THRESHOLD CONFIGURA-

TION MODE:

1) Press simultaneously the push buttons “REDUCE

SPEED” (Photo C - 2-) and“SUCTION MOTOR SWITCH”

(Photo C - 5) within 2 seconds after switching on the

machine with the key switch (Photo D - 1).The second

LED of the speed indicator (Photo C - 3B ) will be ON.

2) Press“INCREASE SPEED”(Photo C - 2+)”key within 5

31

seconds from the previous action; you have now en-

tered in the configuration mode.

THE CONFIGURATION SETTINGS ARE VISIBLE ON

THE SPEED INDICATOR LED:

1) The first two LEDs (Photo C - 3A, 3B) indicate the

type of setting of the indicator intervention threshold

an both must be ON;

2) The third and fourth LEDs (Photo C - 3C, 3D) indi-

cate the battery type: for the PB-Acid battery only the

third LED (Photo C - 3C ) should be ON, while for the

GEL battery both should be ON (Photo C - 3C, 3D)

3) To select Li batteries, press the “BRUSH ON”button

(Photo C - 4) for 2 seconds together with the “SUC-

TION ON” button (Photo C - 5) until the third LED

(Photo C - 2-C) and the fourth LED (Photo C - 3D)

switch off.

TO MODIFY CONFIGURATION SETTINGS:

1) The “INCREASE SPEED”(Photo C - 2+)”and“REDUCE

SPEED” (Photo C - 2-) keys are used to set the indica-

tor’s intervention threshold in such a way that the first

two speed indicators LEDs turn ON;

2) The “BRUSH MOTOR SWITCH” (Photo C - 4) is used

to set the PB-Acid battery type while the “SUCTION

MOTOR SWITCH” (Photo C - 5) is used to set the GEL

battery type

TO SAVE THE SETTINGS AND EXIT THE MODE:

Press the“REDUCE SPEED” (Photo C - 2-) switch and the

“SUCTION MOTOR SWITCH”(Photo C - 5) simultaneously.

Once the settings have been set, we have different

battery discharge levels with differentiated interven-

tion on the machine functions as specified in the fol-

lowing table:

Battery discharge indicator and functions - MODEL “BT”

(DC 24V with traction)

Volts

Battery Type

Battery

power test

indicator

LED

Brush

operation

indicator

LED

Pb-Acid GEL Li Signaling Signaling Action

24,0 24,0 >25,4 Green

LED ON

LED ON All working

21,5 22,5 >23,5 Yellow

LED ON

LED ON All working

20,5 21,5 >22,6 Red LED

ON

LED

FLASHING

Brush motor

is not work-

ing

Battery discharge indicator and functions - MODEL “BT”

(DC 24V with traction)

Volts

Battery Type

Battery

power test

indicator

LED

Brush

operation

indicator

LED

20,0 21,0 <22,6 Red LED

FLASHING

LED

FLASHING

Brush and

suction mo-

tors are not

working

If you do not complete the configuration procedure,

the settings remain as they were originally.

We recommend to call the assistance centre or a tech-

nician if you have problems with the settings given.

Do not open or tamper the electronic board.

5.3. BATTERY CHARGER CONFIGURATION

The machine is equipped with a battery charger con-

figurated for GEL batteries

To change the battery charger settings read the man-

ual provided by the battery charger manufacturer.

If the machine is supplied with a battery and a

charger, the setting of the machine and the charger

is carried out by the manufacturer.

In the event of changes to the equipment, i.e. the type

of battery and charger, we always recommend that

you contact your authorised service centre both for

the machine setting and the setting of the charger’s

charging curve.

As a general rule, the following criteria apply:

For Pb-acid and GEL batteries:

charging current of approx. 10-12% of the capacity in

Ah-C20

For lithium batteries:

current of approx. 40% of the capacity in Ah

Failure to comply may result in serious damage to

the battery and warranty invalidation.

5.4. MACHINE PREPARATION

Before starting to work, wear non-slip shoes, glo-

ves and any other personal protection device indica-

ted by the supplier of the detergent used or conside-

red necessary based on the operating environment.

☞Do the following before starting to work. Refer to

the relative sections for a detailed description of the-

se steps:

check the battery charge level and charge, if necessary.

Mount the brushes or scraper disks (with the abrasive

disks) that are suitable for the surface and work in-

volved.

Mount the squeegee, check that it is solidly attached

and connected to the suction hose and that the

drying blades are not too worn.

32

Make sure that the recovery tank is empty. If not,

empty it completely.

Check and completely close the detergent solution

release control.

Fill the detergent solution tank with a mix of clean water

and non-foaming detergent in an adequate concentra-

tion through the anterior hole. Leave 2 cm between the

mouth of the plug and the level of the liquid.

☞To avoid risks, become familiar with the machine

movements, carrying out test runs on a large surface

without obstacles.

To obtain the best results in terms of cleaning and

equipment service life, you should do the following

simple but important operations:

- Identify the work area, moving all possible obstacles

out of the way; if the surface is very extensive, work in

contiguous and parallel rectangular areas.

- Choose a straight work trajectory and begin wor-

king from the farthest area to avoid passing over are-

as that have already been cleaned.

6. OPERATING INFORMATION

6.1. BATTERY CHARGING

Prepare and check the battery charge according to

the instructions provided in the specific section.

Detach the battery connector from the machine po-

wer connector (the one with the gripping fins) and

connect the battery connector to the battery charger

connector.

Do not connect the battery charger to the scrub-

ber-drier’s main wiring connector.

Hold the connectors with the hands; do not pull them

using the cables.

If the machine is equipped with Pb-Acid batteries,

charge only in a well-ventilated area, lift the superior

cover and open the battery plugs.

Follow the steps indicated in the battery manufac-

turer’s operating and safety manual (see the battery

maintenance section).

If the machine is equipped with gel batteries (mainte-

nance free), follow the instructions indicated here below.

If the machine is used regularly:

Always keep the batteries connected to the battery

charger when the machine is not being used.

If the machine is not used for extended time periods:

Charge the battery during the night after the last

work period, then disconnect the battery from the

battery charger.

Charge the battery during the night before using the

machine again.

Intermediate or incomplete charging while working

should be avoided.

If the machine is equipped with Pb-Acid batteries,

use a hydrometer to check the element liquid inten-

sity on a regular basis: if one or more elements are

discharged and the others fully charged, the battery

has been damaged and should be replaced or repai-

red (refer to the battery service manual).

Close the element plugs and lower the superior cover.

Hold the connectors with the hands; don’t pull them

using the cables.

Reconnect the machine connectors.

6.2. SQUEEGEE AND SPLASH GUARD

ASSEMBLY, DISASSEMBLY AND

ADJUSTMENT

The squeegee is the main component that ensures

perfect drying.

6.2.1. SQUEEGEE ASSEMBLY

Slightly screw the two knobs ( Photo L - 7 ) into the

squeegee body and insert the squeegee into the

slots situated on the squeegee support.

Screw the two knobs ( Photo L - 7 ) in order to secure

the squeegee to the support.

Firmly insert the suction hose ( Photo L - 1 ) into the

pipe in the squeegee body.

6.2.2. SQUEEGEE DISASSEMBLY

Disconnect the suction hose from the squeegee

body.

Unscrew the two knobs ( Photo L - 7 ) that secure the

squeegee to its support and pull the squeegee to free it.

6.2.3. SQUEEGEE BLADES DISASSEMBLY /

ASSEMBLY

Disassemble the squeegee from its support (see 7.2.2)

Unscrew the knobs ( Photo L - 7 ) ( Photo L - 3 ) placed

on the squeegee body and apply some pressure on

their bolts in order to push out the plastic support of

the squeegee blades from the squeegee body.

Tear o the rubber blades from the plastic support.

Assemble the new blades on the plastic support by

the means of the plastic pins that have to be xed in

the holes placed the blades.

Push the plastic support of the squeegee blades into

the squeegee body and screw the knobs ( Photo L - 7 )

to secure it to the squeegee body.

Reassemble the squeegee to its support (see 7.2.1).

6.2.4. SQUEEGEE ADJUSTMENT

The knob screw on the squeegee support ( Photo L -

2 ) adjusts the squeegee’s inclination with respect to

the oor. The two red knobs on the sides, connected

to the rear wheels of the squeegee ( Photo L - 5 ) are

to adjust the pressure of the squeegee to the oor.

When the squeegee is perfectly adjusted, the rear

squeegee blade, sliding as it moves, bends in all

points forming an angle of 45° with the oor.

As the machine operates (advances), the knobs ( Photo

L - 2 ) ( Photo L - 5 ) can be used to adjust the inclination

and pressure of the squeegee blades on the oor.

Squeegee drying must be uniform along the entire

drying line: damp patches mean that drying is insu-

33

cient; turn the adjustment knobs to optimize drying.

6.2.5. SPLASH GUARD ASSEMBLY/ DISASSEMBLY

The splash guard is assembled to the brush plate with

a spring holder linked to the brush plate itself ( Photo

M - 1 ).

To disassemble the splash guard simply detach the

spring holder and pull the splash guard.

To reassemble, x the splash guard in the brush plate,

and then hook the steel cable to one side of the plate

and the spring holder to the other side of the brush

plate.

6.3. BRUSH ASSEMBLY / DISASSEMBLY

Never use the machine if brushes or scrapers and

abrasive disks are not perfectly installed.

Assembly:

Make sure that the brush plate is raised; otherwise lift

it by following the instructions provided in the spe-

cific section.

Make sure that the ignition key on the control panel

is in position “0”.

Bring the brushes (or the guide disks equipped with

abrasive disks) near the connections, under the brush

plate; lower the washing plate and start the brushes

turning: the brushes/discs couple automatically;

Do not allow the length of the rows of brushes to

become lower than 1 cm.

Do not allow the thickness of the abrasive disks to

become less than 1 cm.

Working with excessively worn brushes or excessi-

vely thin abrasive disks may damage the machine

and the floor.

Regularly check the wear on these parts before star-

ting to work.

Disassembly or replacement:

Make sure that the brush plate is raised; otherwise lift

it by following the instructions provided in the spe-

cific section.

Make sure that the ignition key on the control panel

is in position “0”.

While holding the brushes (or the guide disks) with

the hands under the plate, turn them in the rotation

direction while lowering to release them from the

guide plate.

6.4. FILLING AND DRAINING THE DETERGENT

SOLUTION TANK

☞The temperature of the water or the detergent

should never exceed 50°C.

• Always empty the detergent solution tank before

filling it up.

To fill:

• Remove the plug in the front of the machine .

• Leave 2 cm between the mouth of the plug and the

liquid level. Do not fill beyond this point!

• Add the required quantity of the chemical product,

considering the percentage indicated by the sup-

plier, with reference to the full tank capacity listed on

the product sheet.

• Use only those products suitable for the floor and

the dirt to be removed.

The machine was designed to be used with non-

foaming and biodegradable detergents made speci-

fically for scrubber-driers. The use of other chemical

products (such as sodium hypochlorite, oxidisers,

solvents or hydrocarbons) may damage or destroy

the machine.

• Follow the safety regulations specified in the relati-

ve section and indicated on the detergent container.

• Contact the machine manufacturer to obtain a com-

plete list of available and suitable detergents.

☞Always add the detergent after filling the tank with

water to prevent foam from being created inside.

• Do not leave the water hose unattended and insert

it completely into the tank: the hose might move and

get sensitive parts of the machine wet.

Close the tank with its plug…

To drain:

• Unscrew the cock.

• Close the drainage plug firmly.

6.5. DRAINING THE RECOVERY TANK

The dirty water must be drained in accordance with

national regulations.

The user is completely responsible for ensuring com-

pliance with such rules.

After the detergent solution is finished, always empty

the recovery tank before filling it again.

In general, the recovery tank can be emptied whene-

ver required, and even during intermediate phases of

the work cycle.

The recovery tank volume is higher than the deter-

gent solution volume, therefore a potentially dan-

gerous situation for the suction motor should never

occur. In any case, a safety float turns off the suction

motor if the dirty liquid level is too high.

If water or foam starts leaking from under the

tanks for any reason, immediately turn off the suction

motor and empty the recovery tank.

To drain the tank:

Drive the machine to a suitable location to drain the

dirty water and preferably near a toilet or a sewer

drain (comply with the national regulations for waste

water disposal).

Turn off the machine and remove the key from the

panel.

Detach the drain hose from the hook and, keeping it

high, unscrew the plug.

Lower the drain hose toward the selected drainage

point.

The emptying operation can be interrupted quickly

and whenever required just by raising the drain hose.

Check how much dirt is still in the tank and, if neces-

34

sary, wash it inside through the inspection hole by

unscrewing the rear window .

Fully tighten the drain hose with the screw plug and

hang it on the support behind the machine. The drain

hose plug must be airtight, otherwise the subsequent

pressure loss will reduce drying efficiency.

6.6. DRIVING THE MACHINE

Check connection between the power and battery

connectors, located under the control panel.

Put the ignition key in and turn it.

Check battery charge status via the control unit and,

if sufficient, select the running speed wanted, operate

the brush control key and the suction control key. Now

open the solution cock by lowering the detergent do-

sage lever which is at the back of the machine, lower

the suction unit by lowering the squeegee control le-

vel, lower the washing unit, levering with your foot on

the brush plate control lever.

Move forwards, pulling the forward lever up . Re-

member to lift the floor cleaner before reversing to

avoid damaging it.

6.7. WORK METHOD

6.7.1. PREPARATION AND WARNINGS

Remove any loose solid residue from the surface

to be treated (using suitable tools, such as vacuum

cleaners, sweepers, etc.). It this is not done, the solid

dirt might prevent the squeegee from operating cor-

rectly, reducing drying efficiency.

This machine can driven only by trained personnel.

6.7.2. OPERATING CONTROLS

• Battery charge control: the sequence of lights pro-

gressively turns off until the battery is discharged .

When the red light turns on, turn off the brush motor,

close the solution supply, finish drying the small resi-

dual moisture and go to the battery charging area to

charge the battery.

The batteries may be irreparably damaged if the

residual charge level drops too low (see the battery

operating manual). Do not force the battery dischar-

ge beyond the safety limits, turning the key off and

on or in any other manner.

When an abnormal situation occurs, such as when

the machine doesn’t have enough power and the

safety devices don’t trip, stop immediately: follow

the instructions in the troubleshooting section and

contact a specialised worker to check the discharge

control devices.

6.7.3. DIRECT SCRUBBING OR FOR SLIGHTLY

DIRTY SURFACES

Scrubbing and drying in a single pass.

Prepare the machine as previously described.

Check connection between the power and battery

connectors, located under the control panel.

Put the ignition key in and turn it.

Check battery charge status via the control unit and,

if sufficient, select the running speed wanted, opera-

te the brush control key and the suction control key.

Now open the solution cock by lowering the deter-

gent dosage lever which is at the back of the machi-

ne, lower the suction unit by lowering the squeegee

control level, lower the washing unit, levering with

your foot on the brush plate control lever .

Move forwards, pulling the forward lever up or push

it down to reverse . Remember to lift the floor cleaner

before reversing to avoid damaging it.

Never use the machine without the detergent solu-

tion: the floor might be damaged.

6.7.4. INDIRECT SCRUBBING OR FOR VERY

DIRTY SURFACES

Scrubbing and drying in various passes.

Prepare the machine as previously described.

First set of operations:

Check the connection between the power and batte-

ry connector, located under the control panel.

Put the ignition key in and turn it.

Check battery charge status via the control unit and,

if sufficient, operate the brush control key. Now open

the solution cock by lowering the detergent dosa-

ge lever which is at the back of the machine, lower

the brushing unit by levering with your foot on the

brush plate control lever. Move forwards, pulling the

forward lever up .

Allow the detergent solution to work on the dirt

according to what is indicated in the information

relative to the detergent used.

Second set of operations:

Proceed as explained in the previous “Direct Wa-

shing” paragraph (7.7.3) to also proceed with drying

the floor.

Never use the machine without the detergent solu-

tion: the floor might be damaged.

6.7.5. POST-SCRUBBING OPERATIONS

Cut off the supply of detergent.

Lift the brush unit and turn off the brush motor.

After having completely dried any traces of water

on the surface, wait a few seconds and then lift the

squeegee and turn off the suction motor.

Move to a suitable location to drain the tanks (as de-

scribed in 7.4 and 7.5).

Empty and clean the tanks (see sections 7.4 and 7.5).

Turn off the machine using the key and remove it

from the control panel.

If necessary, charge the battery (see the relative section).

6.8. SPECIFIC INSTRUCTIONS FOR THE USE OF

POWER MAINS AC 230V MODEL

The power mains AC 230V machine may be turned on

only if the voltage indicated on the tag corresponds

35

with the available voltage and that the electrical out-

let is grounded (earthed).

Do not damage the feed cable; do not crush or pull on it.

ATTENTION Make sure that the power cable does

not come into contact with the rotary brushes.

ATTENTION !!! - The power mains AC 230V ma-

chine has parts, which are connected to the cur-

rent; contact with these could cause grave injuries

or even death.

- Before executing any type of operation on the ma-

chine always disconnect it from the electrical source.

- Never touch electric cables that are defective or worn.

- Before gaining access to the electrical system it is

always necessary to disconnect the machine from

the electrical source by removing the plug from the

socket-outlet.

- In the case of defective, damaged, or cracked electric

cables, replace immediately with authentic replace-

ment parts.

- The network of connections must be protected from

water spray.

-The patch cord for the connection of the machine

to the mains power must conforms to current

safety rules.

- The electrical system to which the machine is con-

nected must be equipped with a cutout box.

- It is absolutely forbidden to use the machine in

proximity to swimming pools or stretches of water.

EMERGENCY SITUATIONS

In case of emergency:

- Immediately disconnect the machine from the

power mains.

- Immediately apply proper rst-aid.

If an accident should occur the machine must not be

put into operation until a technician authorized by

the manufacturer has examined it.

7. MAINTENANCE INFORMATIONS

36

When needed After every use Weekly Monthly

Remove and wash the squeegee X

Drain the recovery tank X

Drain, rinse with clean water or sanificate the recovery tank X

Charge the batteries X X

Check the acid level in the battery cells (if batteries are not mainte-

nance-free) X

Check the wear of the squeegee rubber blades X

Open and clean the suction filter X

Removebrushesandcheck for brush wear, foreign bodies and wrapped

belts X

Verify the machine general conditions. X

Open and clean the solution water filter X

Verify that suction hose and conduct are free from obstructions X

Check and clean the pivoting wheels X

Check wear and function of traction drive belt or chain; if necessary,

adjust belt or chain tension X

Clean the brush plate, squeegee support and squeegee X

Check the lifting/lowering of the brush plate. X

Check the lifting/lowering of the squeegee. X

Grease the moving parts. X

Check the control cable for the opening of the solution water tap. X

Descale water hoses. X

37

Turn the key, remove it from the control panel and

disconnect the battery from the machine wiring.

☞All work on the electrical system as well as all main-

tenance and repair operations (especially those not

explicitly described in this manual) should be carried

out only by authorised service centres or by speciali-

sed technical personnel who are experts in the sector

and in the pertinent safety regulations.

Performing regular maintenance on the machine,

and carefully following the manufacturer’s instruc-

tions, is the best guarantee for obtaining the best

performances and extended machine service life.

7.1. TANKS

Drain the two tanks as described in the relative sec-

tions.

Remove any solid dirt by filling and draining the

tanks until all dirt has been eliminated: use a washing

hose or similar tool to do this.

Water hotter than 50°, a high-pressure cleaner

or excessively powerful sprays may damage the

tanks and the machine.

Leave the plugs of the tanks open (only while the ma-

chine is not being used) so that they can dry and thus

prevent the formation of foul odours.

7.2. SUCTION HOSE

Detach the suction hose from the squeegee.

Now you can wash the hose and remove any obstruc-

tions.

Firmly insert the hose on the squeegee body.

7.3. SQUEEGEE

Do not handle the squeegee with bare hands:

wear gloves and any safety clothing needed to carry

out the operation.

Detach the squeegee from the machine and clean it

under running water using a sponge or a brush.

Check the efficiency and the wear on the strips in

contact with the floor. They are designed to scrape

the film of detergent and water on the floor and to

isolate that portion of the surface to enhance the

vacuum of the suction motor: this ensures that the

machine will dry very efficiently. Working constantly

in this manner tends to round or to deteriorate the

sharp edge of the strip, thus reducing drying efficien-

tly. This is why the squeegee strips must be replaced.

To replace the worn blades, follow the instructions in

the relative section. Turn the blades around to wear

down the other sharp corners or to install new ones.

7.4. ACCESSORIES

Remove and clean the brushes or the scraper disks.

To avoid damaging the floor and the machine, careful-

ly check if foreign matter, such as metallic parts, screws,

chips, cords or similar items, has become jammed.

Check that the brushes are flat as they work on the

surface (check for any irregular wear on the brushes

or on the abrasive disks). If necessary, adjust the slant

of the action on the floor.

Use only the accessories recommended by the manu-

facturer: other products may reduce operating safety.

7.5. MACHINE BODY

Use a sponge or a soft cloth to clean the exterior of

the machine and, if necessary, a soft brush to elimi-

nate tough dirt. The machine’s shockproof surface

is rough to make it harder to see scratches caused

during use. However, this does not make it easier to

remove tough stains on the surface. Steam machines

can be used but it’s prohibited to use hoses with run-

ning water or a high-pressure cleaner.

7.6. BATTERIES

PB-ACID

Carry out maintenance operations in accordance with

the manufacturer’s instructions and with all the other

instructions provided in this manual.

Exposing the element plates (not completely immersed

in the acid solution) will lead to rapid oxidation and irre-

parably reduce the element’s operating capacities.

An overflowing acid solution may corrode the machine.

Use battery chargers recommended by the manufac-

turer and, in any case, those that are suitable for the

type of battery to be charged.

Always charge batteries in well-ventilated rooms:

there is an explosion risk!

The use of gel or maintenance-free batteries is highly

recommended.

GEL

Carry out maintenance operations in accordance

with the manufacturer’s instructions and with all the

other instructions provided in this manual.

Use only those battery chargers recommended by

the manufacturer.

☞If the batteries are not used, in either case, for an

extended period of time, disconnect them and re-

store the charge within the time limits specified for

the type of battery used (generally and as a precau-

tion, no more than 3 months for Pb-acid/GEL/AGM

batteries, 6 months for Li-ion batteries).

The manufacturer accepts no liability for damage to

batteries caused by failure to follow this procedure.

7.7. FUSES AND THERMAL BREAKERS

The machine is equipped with electric protection

devices on the main operating components to avoid

costly malfunctions.

Thermal cutouts are installed to protect the drive mo-

tor wherever foreseen and the brush motor.

When one of these breakers trips automatically, the

disabled function can be reactivated by fully depres-

This manual suits for next models

2

Table of contents