EXE XDDL Series User manual

Rev. 03 del 17/09/2018 Pag. 1 / 40

USE AND MAINTENANCE MANUAL

Motor Controller XDDLxx LVC

Model: XDDL4 XDDL8 XDDL16 XDDL24

Serial Number: _ _ _ _ _ _ Years of Construction : 20 _ _

Official Language: ITALIAN Manual Language: ENGLISH

[ TRANSLATION OF THE ORIGINAL INSTRUCTIONS ]

Rev. 03 del 17/09/2018 Pag. 2 / 40

,

Keep this manual for future consultation.

Provide this manual to all Motor Controller operators and maintenance technicians.

For further information and clarifications or if there are any problems with this product, contact SRS or LITEC

ITALIA.

Before using the Motor Controller, fill out the following information. This information must be provided

whenever contacting technical support.

Company name and

address (1)

Date of purchase

Company name and

address (2)

Date of purchase

Company name and

address (3)

Date of purchase

Reproduction, transmission or computerized archiving as wells as translation into another language, in any

form, in whole or in part, are absolutely forbidden without prior written authorization from SRS.

Revision

Changes

Description

DATE

01

Entire Manual

First issue

2014

02

Entire Manual

Changes according to standards and decrees

05/10/2017

03

Entire Manual

Technical data and drawings updates

17/09/2018

MANUFACTURER

SRS LIGHT DESIGN s.r.o.

Rybnicna 36/D, SK-

83106 Bratislava, Slovak Republic

Tel: +421244681417

www.srslight.com

DISTRIBUTOR

LITEC ITALIA S.R.L.

Via Martin Luther King 70,

I-31032 Casale sul Sile (TV), Italy

Tel: +390422997300

www.exetechnology.com

www.litectruss.com

Rev. 03 del 17/09/2018 Pag. 3 / 40

TABLE OF CONTENTS

1. GENERAL INFORMATION................................................................................................................................5

1.1. SCOPE OF THE MANUAL..............................................................................................................................5

1.2. SAFETY SIGNS...............................................................................................................................................6

1.3. REPAIR - REPLACEMENT - WARRANTY POLICY.......................................................................................6

2. MACHINE PRESENTATION..............................................................................................................................8

2.1. INTENDED USE..............................................................................................................................................8

2.2. IDENTIFICATION OF EXE-DRIVE MOTOR CONTROLLER .........................................................................9

2.3. GENERAL DESCRIPTION..............................................................................................................................9

2.4. PRINCIPLE OF OPERATION .......................................................................................................................12

2.5. TECHNICAL DATA........................................................................................................................................14

2.5.1 EXE-Rise chain hoist link............................................................................................................15

2.6. AIRBORNE NOISE EMISSION.....................................................................................................................15

3. SAFETY WARNINGS.......................................................................................................................................16

3.1. GENERAL SAFETY WARNINGS..................................................................................................................16

3.2. SPECIAL SAFETY WARNINGS....................................................................................................................17

4. MOVEMENT AND INSTALLATION.................................................................................................................18

4.1. MOVEMENT & TRANSPORT .......................................................................................................................18

4.2. TRANSPORT AND STORAGE .....................................................................................................................18

5. USE...................................................................................................................................................................19

5.1. ELECTRIC WIRING.......................................................................................................................................19

5.2. CONNECTING THE XRH-C PUSHBUTTON PANEL...................................................................................19

5.3. CONTROL UNIT STARTUP..........................................................................................................................21

5.3.1. Using the equipment in individual mode.....................................................................................21

5.3.2. Using the equipment in individual mode with the XDRH pushbutton panel ...............................22

5.3.3. Use in “LINK” BETWEEN CONTROLLER mode........................................................................24

5.3.4. Use in “LINK” BETWEEN CONTROLLER mode with XDRH pushbutton panel ........................26

5.3.5. Use in PICKLE mode with the XCLH1 pushbutton panel...........................................................28

5.4. ERRORS .......................................................................................................................................................28

5.5. EMERGENCY INTERVENTIONS.................................................................................................................31

6. INSPECTIONS..................................................................................................................................................33

6.1 INITIAL INSPECTION AND AT EVERY USE ...............................................................................................33

6.2 PERIODIC INSPECTION ..............................................................................................................................33

6.3 EXTRAORDINARY INSPECTION.................................................................................................................34

7. DEMOLITION AND DISPOSAL.......................................................................................................................34

8. DECLARATION OF CONFORMITY ................................................................................................................35

9. MAINTENANCE AND REPAIRS REGISTRY..................................................................................................36

INDEX OF FIGURES

Rev. 03 del 17/09/2018 Pag. 4 / 40

Figure 1

EXE-Drive XDDL4 Low Voltage Control

8

Figure 2

EXE-Drive XDDL8 Low Voltage Control

8

Figure 3

EXE-Drive XDDL16 Low Voltage Control

8

Figure 4

EXE-Drive XDDL24 Low Voltage Control

8

Figure 5

EXE-Drive Motor Controller Plate

9

Figure 6

DL8-LVC Frontal and Rear View

9

Figure 7

DL8-LVC Frontal and Rear View

10

Figure 8

DL8-LVC Frontal and Rear View

10

Figure 9

DL8-LVC Frontal and Rear View

11

Figure 10

DDL4-LVC Front View Description

12

Figure 11

Pickle and Group Stop Function

13

Figure 12

DDL4-LVC Rear View Description

13

Figure 13

Spider

19

Figure 14

XRH-C Pushbutton panel

20

Figure 15

DL8 and RH8C

21

Figure 16

Declaratio of Conformity example

35

INDEX OF TABLES

Table 1

Connector

14

Table 2

Technical Data

15

Table 3

EXE-Rise chain hoist link

15

ATTACHED DOCUMENTATION

This manual is an integral part of the EXE-Drive Motor Controller and contains the EXE-Drive Motor Controller

Declaration of Conformity.

The Declaration of Conformity is an integral part of the manual, therefore it is also an integral

part of the EXE-Drive Motor Controller.

The Declaration of Conformity contains a list of directives and standards.

Rev. 03 del 17/09/2018 Pag. 5 / 40

1. GENERAL INFORMATION

Thank you for choosing a XDDL Motor Controller from the EXE-Drive line produced by SRS and distributed by

LITEC ITALIA.

Do not use the Motor Controller EXE-Drive until all operators have read this manual

thoroughly. Failure to follow these instructions could endanger the safety of individuals

and/or lead to injuries or even death.

The manual must be followed to insure safe, reliable, and proper operation of the Motor

Controller EXE-Drive in order to eliminate the possibility of injuries and/or damage to the

equipment.

This manual, along with the other documents included in the package, are an integral part of the equipment

and must accompany the product throughout its life cycle, even if it is transferred to another owner. The

manual must be kept clean and protected from rain, humidity and any other agent that could cause it to

deteriorate. It must be complete and intact in order to be legible for future consultation.

The information contained in this manual is correct as of the time it was printed but may be

subject to changes without notice or notification (the revision of the document shown in the

heading is essential for identifying the version you possess), when necessary, according to the

SRS continuous improvement policy.

Make sure this manual is always available to all operators and maintenance technicians.

The customer is responsible for supervising all staff involved and for making sure they are aware of the risks

and safety implications related to the use of the EXE-Drive Motor Controller.

1.1. SCOPE OF THE MANUAL

The purpose of this manual is to inform operators of proper installation and use of the EXE-Drive Motor

Controller to prevent and minimize risks during man-machine interaction. The manual also contains

information regarding maintenance operations that is intended solely for maintenance technicians.

The information provided in this manual includes important instructions on the safety of the machinery and all

individuals involved. Carefully follow all instructions before performing any installation and maintenance

operations and before using the Motor Controller.

Failure to follow these instructions could endanger the safety of individuals and/or cause material or other

damages.

Before using the EXE-Drive Motor Controller, each operator must become familiar with the warnings,

instructions, and recommendations contained in this manual. Implementation of all safety precautions

specified in this manual is required before performing these operations. If any steps are not clear, please

contact SRS or its distributor.

It is the sole responsibility of the customer (employer) to check with the local authorities to

determine whether the EXE-Drive Motor Controller is compliant with local legislation.

Lifting operations permitted by the manufacturer are for set up purposes without people

under or in proximity of moving loads.

Rev. 03 del 17/09/2018 Pag. 6 / 40

1.2. SAFETY SIGNS

This manual contains various safety signs in order to identify and indicate particular situations. The safety

signs are phrases that provide information on the potential risks and proper procedures, as reported below:

WARNING: indicates a very hazardous situation that, if not prevented, could lead to serious

injury or death.

CAUTION: indicates a hazardous situation that, if not prevented, could lead to slight or moderate

injury.

NOTE WELL: indicates the procedures not related to injury.

OPERATOR/S: Personnel in charge to the various activities related to the entire life cycle of the

machine, handling, to the installation and use.

MAINTENANCE TECHNICIANS: Personnel responsible for maintaining the machine and its safe

and satisfactory operation. It is required to carry out all necessary maintenance. He must be fully

acquainted with the equipment and the risks it presents and with the intervention procedures

envisaged.

EXPERTS TECHNICIAN: a person who, for his training and experience, possesses skills and

knowledge in the field of control systems and lifting equipment and sufficient familiarity with the

main regulations to determine any deviations from the conditions envisaged.

1.3. REPAIR - REPLACEMENT - WARRANTY POLICY

Before shipping, the performance of the EXE-Drive Motor Controller is checked by SRS or by authorized

service centres. The manufacturer guarantees that upon delivery to the customer, the goods is free of

manufacturing and material defects.

Upon receipt of the merchandise, quantitative and qualitative controls must be performed. If there is a

nonconformity, the merchandise must be immediately returned to the carrier.

The warranty is only valid for new equipment.

The purchaser must not remove or allow anyone to remove the tags and instructions from the product.

If a warranty claim must be made, or if there is a malfunction or parts are needed, contact SRS or its

distributor. This warranty may be replaced by all other express or implied warranties at the complete

responsibility of the purchaser.

Rev. 03 del 17/09/2018 Pag. 7 / 40

WARRANTY PERIOD

The EXE-Drive Motor Controller is provided with a limited warranty of one year from the date of purchase. The

warranty covers the mechanical parts, excluding the electrical and others parts subject to wear. The warranty

period starts on the day of delivery, substantiated by a purchase receipt such as an invoice or delivery note, or

copies of them.

In the event of injury or property damage due to use of the product, the purchaser must provide written

notification of the injury or damage to the manufacturer or one of its distributor within 48 hours.

Repairs under warranty do not renew or extend the warranty period.

REPAIR AND REPLACEMENT POLICY

If the properly maintained EXE-Drive Motor Controller has a performance problem due to material or

manufacturing defects, after inspection by SRS or an authorized operator, repair or replacement of the unit will

be without charge for the original purchaser.

The repair/replacement policy applies only to EXE-Drive Motor Controllers that have been properly used and

inspected/stored as shown in this manual. This policy does not apply to parts subject to normal wear, to

abuse, to insufficient and improper maintenance, to inadequate and improper use, and in the presence of

hostile environments.

WARRANTY LIMITATIONS

The warranty does not cover abuse and negligence. SRS shall not be liable for any damage

resulting from failure to follow the instructions in this manual.

The use of replacement parts not supplied by SRS or its distributor and changes made to SRS project by third

parties also make the warranty void. The warranty does not cover:

- damage due to transport;

- improper or inadequate use;

- negligent handling;

- chemical or abrasive actions;

- connection to voltages that differ from the

recommended ones;

- improper or inadequate maintenance;

- excessive heat;

- parts subject to normal wear and tear;

- use outdoors without appropriate measures;

- malfunction or defect due to the use of products

not supplied by SRS;

- abuse or damage resulting from an accident;

- failure to follow the instructions in this manual;

- not used, inspected, or maintained in compliance

with current laws and the instructions written by the

manufacturer;

- installed, repaired, tampered with, or changed

without following laws and instructions.

The limited warranty excludes electrical parts and consumables.

The manufacturer is in no way responsible for accidental or consequential damages as these terms are

defined in section 2-715 of the Uniform Commercial Code UCC. The purchaser must collaborate with SRS or

one of its distributors in investigating the injury or damage and in defence of any requests for compensation. If

the Purchaser does not comply with this section or if the injuries/damages are caused, in whole or in part, by

the Purchaser’s failure to comply with federal or state laws regarding safety, the Purchaser must indemnify

and hold the manufacturer harmless from any claim, loss, or expense for injuries or damages related to use of

the product.

Rev. 03 del 17/09/2018 Pag. 8 / 40

2. MACHINE PRESENTATION

The EXE-Drive Motor Controller is the result of years of experience in the structure moving sector for the

entertainment and events industry. The high level of technology applied has led to the creation of a product

that enhances the primary features of a Motor Controller combined with ease of use.

Like all products in the EXE-Technology brand, the Motor Controller is made according to the highest quality

standards, using high precision electronic and electromechanical components, which ensure long-term use of

the product without problems.

2.1. INTENDED USE

The EXE-Drive Motor Controller is only intended for the use for which it was expressly designed, namely to

control and move EXE-Rise electric chain hoists for the entertainment and events industry. To check the

compatibility between the EXE-Drive Motor Controller and EXE-Rise electric chain hoists, consult section 3.5

in this manual.

Any other use should be considered improper and therefore dangerous.

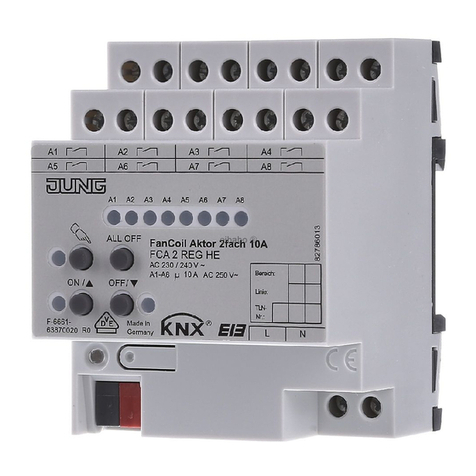

Figure 1: “EXE-Drive XDDL4 Low Voltage Control” Figure 2: “EXE-Drive XDDL8 Low Voltage Control”

Figure 3: “EXE-Drive XDDL16 Low Voltage Control” Figure 4: “EXE-Drive XDDL24 Low Voltage Control”

Rev. 03 del 17/09/2018 Pag. 9 / 40

2.2. IDENTIFICATION OF EXE-DRIVE MOTOR CONTROLLER

The information plate is in English. The translation of the content in other languages is provided in

this manual.

Figure 5: “EXE-Drive Motor Controller Plate”

EXE-Drive Motor Controllers have a visible, legible, and indelible plate that contains the following indications

(please see Figure 5 as example):

1. 965056: example of manufacturer product code;

2. Type: LT XDDL8-LV: commercial name;

3. Power: AC3-230V/400V / 50Hz, 3x32A max: power supply;

4. S/N: 170556: Serial Number;

5. MFC: 2017: Years of construction;

6. EXE-Technology Logo;

7. CE marked;

8. Waste Disposal Symbol;

9. Made by: Company name and address of the manufacturer.

2.3. GENERAL DESCRIPTION

The EXE-Drive Motor Controller was designed to meet safety standards. In fact, the device is equipped with:

- A general differential magnetothermic switch for protecting the entire machine.

- Adjustable magnetothermic protection for each motor output.

- Protection on the control circuit through fuses located inside the device.

- Release system coupled to the general differential magnetothermic switch.

DL4-LVC

Figure 6: “DL4-LVC Front and Rear View”

FRONT VIEW

REAR VIEW

Rev. 03 del 17/09/2018 Pag. 10 / 40

DL8-LVC

Figure 7: “DL8-LVC Front and Rear View”

DL16-LVC

Figure 8: “DL16-LVC Front and Rear View”

REAR VIEW

FRONT VIEW

FRONT VIEW

REAR VIEW

Rev. 03 del 17/09/2018 Pag. 11 / 40

DL24-LVC

Figure 9: “DL24-LVC Front and Rear View”

The EXE-Drive Motor Controller was designed to manage up to 4/8/16/24 chain hoists that are electrically

compatible, either separately or simultaneously, which are controlled through switches located on the front

panel or using a wireless pushbutton panel. The GO/STOP buttons can be connected with a link connector.

The unit is equipped with automatic cyclic sequence control of the input supply phases. This module controls

the main voltage of 400V ±10% AC and the star configuration. If there is a problem with the voltage, the user

will be warned and the unit will not move with any hoist. Plus, if a cable is disconnected, the Motor Controller

will stop to insure maximum safety.

The Motor Controller does not work in the following situations:

A phase is missing

There is an under-voltage situation on the power lines

There is an over-voltage situation on the power lines

All electrical components have UL/CSA and CE certification and are compliant with European Directives. The

components are housed in a 19 inch Rack powder coated robust steel case. The complete unit has CE

marking and is compliant with the standards/directives shown in the Declaration of Conformity attached to this

manual.

FRONT VIEW

REAR VIEW

Rev. 03 del 17/09/2018 Pag. 12 / 40

2.4. PRINCIPLE OF OPERATION

The Motor Controller was designed and built to simultaneously or individually manage from 1 to a maximum of

4/8/16/24 electric chain hoists that are electrically compatible. It can be operated in two modes:

DIRECT: the Motor Controller will only operate with the commands located on the front of it.

REMOTE: the Motor Controller will only operate with the commands located on the pushbutton panel.

On the Motor Controller, only the emergency STOP button is enabled in both modes. In the event of a

failure or emergency, this button allows you to shut off the voltage to the Motor Controller command

circuit and, at the same time thanks to a release coil coupled to the main switch, to move the switch to the

OFF position and completely shut off the system, putting it in safe mode.

PICKLE: the Motor Controller supplies power but does not operate the electric chain hoists. In PICKLE

mode, operation occurs locally and only on a single hoist using a PICKLE XCLH1 pushbutton panel.

Never use the up-down selectors to invert the direction of the motors while pressing the GO button. This could

be very dangerous to yourself and others.

An example of the front panel of the Motor Controller XDDL4-LVC is shown below. The model XDDL8-LVC

differs only in the number of chain hoists that can be connected to them.

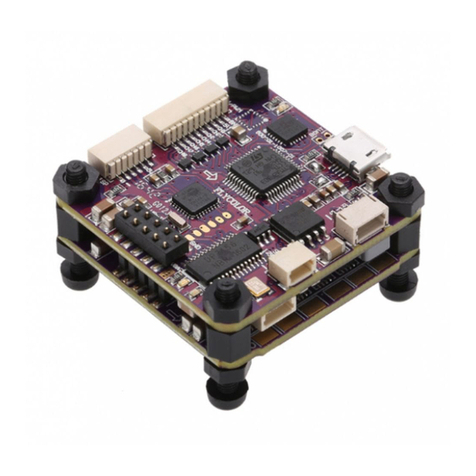

Figure 10: “XDDL4-LVC Front View Description”

POWER (ELECTRIC SUPPLY): indicates the status of the power supply.

- RED: phase misalignment, missing phase, undervoltage or over voltage - check the network.

- GREEN: there are no power supply problems, the Motor Controller is functioning.

STATUS: indicates the status of the LEDs on the Motor Controller and remote unit.

ORANGE: indicates that the Direction switches are active on the remote unit.

RED: the GO button is pressed on the front panel or on the RC-x remote digital unit.

GREEN: the unit is functioning normally / E-stop and RESET are not necessary.

E-STOP: indicates the state of the LEDs for the E-stop functions:

- ORANGE: state after the E-stop of the loading cell - press/release the E-STOP to reset the state

- RED: E-STOP condition received from the line

Rev. 03 del 17/09/2018 Pag. 13 / 40

- RED FLASHING: The emergency STOP button is active on the base unit

- GREEN: The unit is functioning normally / E-stop and RESET are not necessary.

EMERGENCY STOP: is a red button. After the STOP button has been pressed, the system is locked in an

inactive position and to restart it, the button must be turned clockwise. The system must also be RESET.

GO: is a white button. When it is pressed, it runs all of the selected channels and the related electric chain

hoists move. When the GO button is pressed again, power to the motors is cut off.

DIRECTION SWITCHES: allow you to change the direction of each electric chain hoist individually or in a

group. The movement direction is signalled by a LED located near the switch.

PICKLE POWER: lets you power and not run the electric chain hoists. With the switch set to ON, operation

occurs locally and only on a single hoist using a PICKLE XCLH1 pushbutton panel. Local operation is useful

for taking up the slack on the chains of the individual hoists before running them simultaneously.

The XDDL16 / 24-LVC models differ from the XDDL4 / 8-LVC for the following functions:

PICKLE: This function is activated via a key selector as shown in Figure 10-b. The selector must be placed in

the Pickle position.

GROUP STOP: This function is activated / deactivated with the GROUP STOP DISABLE button (Figure 10-b).

The color is orange when the function is off.

Figure 11: “Pickle e Group Stop function”

An example of the rear panel of the XDDL4-LVC is shown below. The other models differ only in the number

of electric chain hoists that can be connected to them.

Figure 12 “XDDL4-LVC Rear View Description”

Rev. 03 del 17/09/2018 Pag. 14 / 40

REMOTE/LINK CONNECTOR - Neutrik NC5-MAH/FAH: These are for connecting the electric chain hoists or

an RCx remote digital connection. They can be controlled using a GO and STOP emergency button with an

RH remote digital unit.

Poles

Function

NOTE

1

CMN data

Common data

2

Data-

Less Data

3

Data+

More Data

4

DC1

Power supply for RC-X

DC12-36V

5

DC2

Power supply for RC-X

DC12-36V

Table 1: “Connector”

POWER SUPPLY CABLE: For the main input, a 5G6mm2 cable is used with a CEE 32/5p connector. The

cable has an MPA end to easily change the phase alignment. The fuse for the electronic transformer is type

T2.5A.

2.5. TECHNICAL DATA

GENERAL INFORMATION

Model and Type

XDDL4/8/16/24 Low Voltage Controller

Case

Steel with grey powder coating.

MAIN CHARACTERISTICS

RCD Protection for input power supply

MCB protection for channel

4/8/16/24 x Inverter Contactor for direct control

4/8/16/24 x 3 - Channel position switches (UP-OFF-DOWN)

4/8/16/24 x green LEDS that indicate the channel UP selection

4/8/16/24 x white LEDS that indicate the channel DOWN selection

3 x Red Neon Voltage presence indicators (L1-L2-L3)

XLR 5-pin male/female OUT Link panel connector

XLR 5-pin IN Link + REMOTE panel connector

2x XLR 4-pin for E-stop link function.

1 metre of XLR 5-pin link cable is supplied

Emergency Button

White GO button (which requires the presence of an operator) with flashing light indication

Phase recognition safety function - The unit will not function if the three-phase sequence

supply is not direct.

2 Pickle function switches (ON-OFF)

TECHNICAL DATA

Input - Y power supply connector - Δ 230

VAC: Only upon request, please contact

us for more information.

Pin with CEE 400VAC ± 10% –32A (XDDL4/8)/ 63A (XDDL16/24) –3 P+N+E 6h - @ 50-

60Hz mechanical phase inverter

Output

2 x female connectors from the Socapex 19-pin panel - crimped connector.

1-2 power supply channels 3-5-400VAC+PE Channel control (UP-DOWN-COMMON)

Linked systems

Up to 9 XDDL units of any type or 8 XDDL units of any type plus a remote control

pushbutton panel

Miniature Circuit Breaker (MCB)

4 x 10A

Residual Current Device (RCD)

30mA

Cable length

1.5m

Operating temperature

-20°C +40°C

Protection Class Ip

P20

Rev. 03 del 17/09/2018 Pag. 15 / 40

Compatible with EXE-Rise electric chain

hoists

EXE-Rise D8 250/500/1000/2000 kg DC

EXE-Rise D8+ 150/300/600/800/1200 kg DC

EXE-Rise D8 310/620/1120/2000 kg DC

EXE-Rise D8+ 160/310/610/1000 kg DC

EXE-Drive compatible accessories

EXE-Drive Remote Emergency Button XDRHG

EXE-Drive Remote Emergency Button XDRHGR

EXE-Drive Digital Remote Control XDRH4/8/12/16C

Connection with all XDDL4/8/16/24

DIMENSIONS

XDDL4

XDLL8

XDDL16

XDDL24

Rack Unit

5U

5U

12U

14U

Net weight

21 kg

25 kg

44 kg

47 kg

Frame width

483mm

483mm

483mm

483mm

Frame depth

300mm

300mm

300mm

300mm

Frame height

222mm

222mm

535mm

620mm

Packaging

dimensions

530x441x250mm

530x441x250mm

530x600x560mm

530x470x760mm

Table 2: “Data sheet”

2.5.1 EXE-Rise chain hoist link

PARANCHI EXE-RISE D8 DC/LVC

PARANCHI EXE-RISE D8+ DC/LVC

EXE-DRIVE

MOTOR

CONTROLLER

250kg

500kg

1000kg

2000kg

150kg

300kg

600kg

800kg

1200kg

LT XDDL4

DC/LVC

v

v

v

v

v

v

v

v

v

LT XDDL8

DC/LVC

v

v

v

x

v

v

v

v

v

LT XDDL16

DC/LVC

v

v

v

x

v

v

v

v

v

LT XDDL24

DC/LVC

v

v

v

x

v

v

v

x

x

Table 3: “EXE-Rise chain hoist link”

The values in the table refer to the standard EXE-Drive Motor Controllers.

On request it is possible to request a personalization.

2.6. AIRBORNE NOISE EMISSION

The airborne noise emitted by the machine has sound power lower than 70dBA.

The values quoted for the noise emission levels are related to one machine. They are therefore not

representative of exposure levels to which operators are exposed. These levels will have to be evaluated in

the use environment to determine whether or not protection measures are required for operators.

Rev. 03 del 17/09/2018 Pag. 16 / 40

3. SAFETY WARNINGS

The EXE-Drive Motor Controller should be used for the intended use by the manufacturer, as described in

Chapter 2.

Any modification that is unauthorized by the manufacturer or its distributor, which alters

the functionality or is prohibited in the following manual, will be fully responsible for

whoever performs them.

These modifications, if carried out without the manufacturer's approval, will also invalidate

any form of warranty issued and invalidate the Declaration of Conformity provided for in the

2006/42 / EC Machinery Directive and subsequent amendments.

3.1. GENERAL SAFETY WARNINGS

The equipment must be installed by authorized operator according to the following instructions. Erroneous

installation may lead to low performance, injury to persons or animals, or damage to property for which the

manufacturer shall not be liable.

Before connecting the EXE-Drive Motor Controller, make sure the data of power supply on

the plate correspond with those of the electrical mains.

The equipment must be connected to the electrical system in compliance with current industrial standards.

The system must be adequately sized compared to the nominal power of the EXE-Drive Motor Controller and

must have a earthing.

After removing the packaging, check the integrity of the EXE-Drive Motor Controller. The packaging elements

(plastic bags, styrofoam, metal points, etc.) must not be left within the reach of children as they can be

potential sources of danger.

This equipment must only be used for the purpose for which it was specifically designed. Any other use should

be considered improper and therefore dangerous. The manufacturer cannot be considered responsible for any

damage from improper, incorrect, or unreasonable use.

The use of any electrical device (included EXE-Drive Motor Controller) requires the observance of certain

fundamental rules, in particular:

- Don’t touch the Motor Controller with wet or damp hands or feet;

- Don’t expose the Motor Controller to weather.

Before performing any cleaning operation maintenance and inspection, turn off the equipment and disconnect

it from the power supply, removing the plug from the power outlet or turning off the switch.

In the event of a failure and/or poor operation of the Motor Controller, turn off the machine and disconnect it

from the power supply by removing the plug from the power outlet or turning off the switch and do not tamper

with it. For repairs, contact only SRS or its distributor. Failure to comply with the above may compromise the

safety and warranty of the EXE-Drive Motor Controller.

If you decide to stop using the Motor Controller, please make it inoperative by disconnecting it from the power

supply after having shut off the switch to the system.

Rev. 03 del 17/09/2018 Pag. 17 / 40

3.2. SPECIAL SAFETY WARNINGS

Although the EXE-Drive Motor Controller is compliant with all European safety standards,

using it isn’t without potential hazards. Check the operation procedures and warnings

before using the Motor Controller.

In this way, you will avoid jeopardizing your safety and that of others. Don’t improvise when faced with a

question or unexpected occurrence. Read the manual carefully or consult SRS or its distributor.

- Do not allow unauthorized staff use the Motor Controller.

- Do not use the Motor Controller if it is damaged, malfunctioning, or functioning abnormally.

- Do not use the Motor Controller if it is not functioning perfectly.

- Do not use the Motor Controller outside or in locations exposed to jets of water or in particular

environmental conditions without adequate protection.

- Use in explosive atmospheres or those with a high concentration of dust or oily substances suspended

in the air is prohibited. Electrical devices produce arcs and sparks that can cause a fire or explosion.

- Do not use the Motor Controller at temperatures greater than +40°C or less than -20°C.

- Do not operate Motor Controller if visibility is reduced or compromised.

- Do not operate the Motor Controller in a horizontal or upside down position.

- Avoid impacts or shocks to the Motor Controller during movement and transport.

- NEVER connect the Motor Controller to a number of chain hoists that’s greater than the established

outputs.

- Do not use the Motor Controller for purposes that are not compliant with the nature of its use.

- Do not connect chain hoists of dubious origin for which the absorption and electrical power are

unknown to the Motor Controller.

- Do not change the gear selection during operation of chain hoists.

- Do not connect the Motor Controller to multiple outlets.

- Do not scratch or twist the power cord.

- Do not place heavy items on the power cord.

- Do not heat the cable, it could be damaged and cause a fire or electrical shock.

- Do not disconnect the Motor Controller from the mains when it is on.

- Do not insert fingers or pointed objects in the air vents.

- Do not block the air vents.

- If you do not intend to use the Motor Controller for a long period of time, pull the plug after shutting off

the main switch.

- Do not operate this device near water sources, in areas with wet floors, or in humid areas where

condensation forms on the equipment.

- It must not be located near or above heat sources.

- It must not be installed or operated without adequate ventilation.

Do not operate the device in the presence of gas or flammable fumes.

Operation of any electrical instrument in those areas would be a serious safety hazard.

Rev. 03 del 17/09/2018 Pag. 18 / 40

4. MOVEMENT AND INSTALLATION

During movement and package removal of the EXE-Drive Motor Controller, safe handling techniques must be

used. Motor Controllers must be assembled by qualified technician. Always consult the local directives and the

use and maintenance manual. Whenever the Motor Controller is intended to be used outdoors, a protective

covering must be used to protect it from the weather. This cover may also be protection against fine sand.

4.1. MOVEMENT & TRANSPORT

The customer must perform a careful quantitative check of the Motor Controller and its components at the time

of delivery and make sure no parts were damaged. Any damage that occurred during transport is the

courier/shipper’s responsibility. The packaging must be disposed of in an ecological manner. Make sure all of

the paths and areas intended for handling are free of obstacles.

4.2. TRANSPORT AND STORAGE

We recommend transporting the Motor Controller in its original package or in a custom-made flight case.

Before positioning the Motor Controller in storage, make sure all parts are dry.

Use flight cases with vents for all compartments and do not pile more than two cardboard boxes containing the

Motor Controllers coming from the factory.

A operator must be present when moving the merchandise using machinery such as a forklift. The packaging

materials such as plastic bags and styrofoam must not be disposed of in the environment but must be saved

to repackage the Motor Controller after use.

STORAGE

The merchandise is packaged in such a way as to ensure protection against possible damage. This packaging

must be stored in a dry area away from humidity and heat, with temperatures between -20°C and +40°C. If the

Motor Controller does not work at the first startup, immediately put it back in its packaging and keep it in a

covered, dry, and clean area away from heat sources that could compromise its integrity.

UNPACKING AND MOVING THE MOTOR CONTROLLER ON THE FLOOR

Remove the EXE-Drive Motor Controller from its package and make sure the information shown on the data

plate are the same as on the transport document and that no damage was caused by inadequate transport.

Perform the following checks:

- make sure the connectors and cables are not damaged;

- check the integrity of the body of the Motor Controller;

- make sure there are no dents or cracks;

- make sure there are no water infiltrations.

If damage due to shipping is found, return the transport document along with the box or flight case containing

the damaged Motor Controller in order to be able to open the claim.

Any claims related to damaged Motor Controllers must be presented within 48 hours of receipt of the

merchandise. In any case, it must be stressed that every part of the Motor Controller is checked thoroughly

before it is packaged and shipped to the customer.

Rev. 03 del 17/09/2018 Pag. 19 / 40

5. USE

Electric chain hoists connected to an EXE-Drive Motor Controller may be activated individually or

simultaneously using the GO button located on the front panel or wirelessly by remote or in pickle mode. The

units may be connected together to create larger systems.

5.1. ELECTRIC WIRING

Before connecting the EXE-Drive Motor Controller to electric power distribution, make sure

the voltage and power of the mains corresponds with what is stated on the data plate. Also

make sure the earthing system is efficient.

Operators must have a derivation circuit with a earthing system to ensure protection against current overloads

and short circuits and that meet the requirements set forth in the safety laws and protection of health in the

workplace in the country in which the EXE-Drive Motor Controller is installed.

In order to prevent the risk of electrocution or malfunction, make sure all of the power supply cables to the

EXE-Drive Motor Controller are protected from any external dangers.

The IP20 protection rating indicates that when the EXE-Drive Motor Controller is used in open areas it is not

protected, therefore adequate protection of the entire body of the Motor Controller is necessary.

Changes, adjustments, and electrical and technical regulations may only be performed by

authorized, skilled staff.

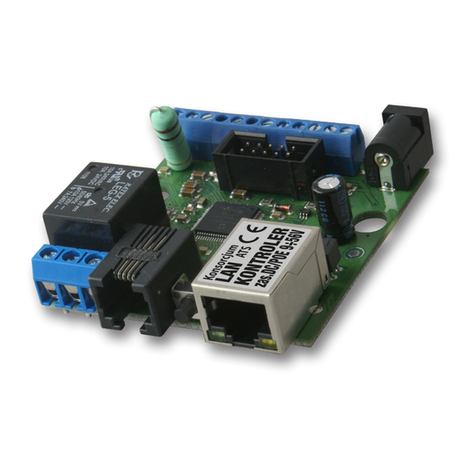

Figure 13: “Spider”

SOCAPEX 19 LV wiring:

M1:135 - M2:246 - 7:M1UP - 8:M1DW - 9:M2UP - 10:M2DW - 11:M1C - 12:M2C - 13+14:PE - 15...19:NC

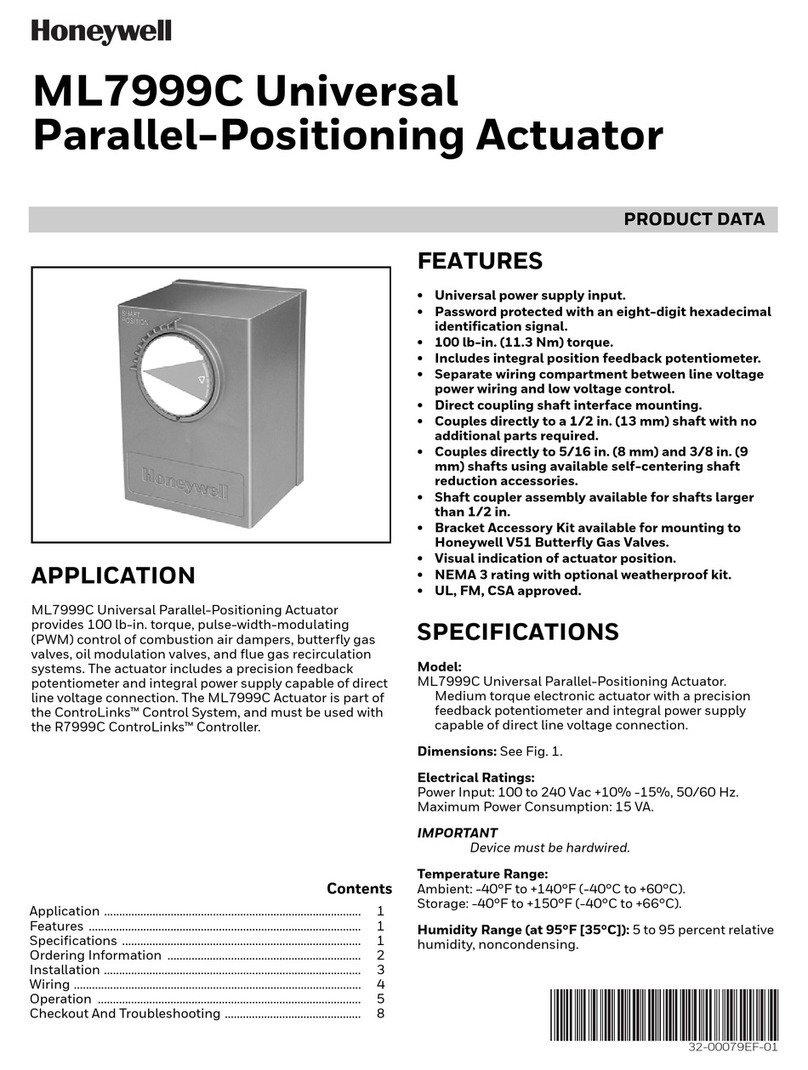

5.2. CONNECTING THE XRH-C PUSHBUTTON PANEL

The LT RC-x pushbutton panel allows you to control the LT XDDLxx unit using a 5-pole cable. To use the

controller and the XRH-C pushbutton panel you must have a 5-pole cable with Neutrik connectors. The

maximum length of the cable is 100m. The data connection is through an RS485 communication line. A list of

the types of cable supported can be requested from the manufacturer.

Rev. 03 del 17/09/2018 Pag. 20 / 40

Figure 14: “XRH-C pushbutton panel”

STOP: the switch protects the Motor Controller from undesired operations and makes it inactive. STOP is

identified with a red button. As soon as the STOP button is pressed, the system locks in the inactive position

and the button must be turned clockwise to continue the operation. After releasing the STOP button, both the

controller and pushbutton panel must be reset by pressing and releasing the STOP/E-STOP mushroom

button.

GO: this white button sets the selected channels of the control system ON when it is pressed. If the GO button

is pressed again, power to the hoists is shut off.

DIRECTION SWITCHES: allow you to change the direction of each electric chain hoist controlled individually

or in a group. Preselection of the direction of the hoists is shown by the corresponding LED being lit.

Direction LED indications:

Green light - UP

Yellow light - DOWN

No light - INACTIVE

STATUS LED INDICATIONS

-ORANGE: the operator is using the direction switches

-RED: the GO button was pressed on the front panel of the Motor Controller or the pushbutton panel

-GREEN: the unit is operating normally; no E-stop or RESET is necessary.

E-STOP LED for E-stop operation:

-ORANGE: press/release E-STOP to reset this state

-RED: E-STOP was pressed on the pushbutton panel

-Flashing RED: the E-STOP mushroom button was pressed on the Motor Controller

-GREEN: The unit is functioning normally / E-stop and RESET are not necessary.

CONNECTING THE EXE-DRIVE MOTOR CONTROLLER

Using a link connector located on the front panel 9 EXE-Drive Motor Controllers or 8 EXE-Drive Motor

Controllers + 1 XRH-C pushbutton panel can be connected. For connection, a 5-pole DMX data cable with 1,

2, 3 assembled pins is indispensable. For safety reasons, a single master and all other slaves must be set up

in line. When a remote pushbutton panel is connected you can create a group of controllers connected in line

This manual suits for next models

4

Table of contents