Danfoss W894A User manual

Other Danfoss Controllers manuals

Danfoss

Danfoss VLT FC 322 Guide

Danfoss

Danfoss AIPA User manual

Danfoss

Danfoss ADAP-KOOL Drive User manual

Danfoss

Danfoss MCI 25 User manual

Danfoss

Danfoss EKC 202 User manual

Danfoss

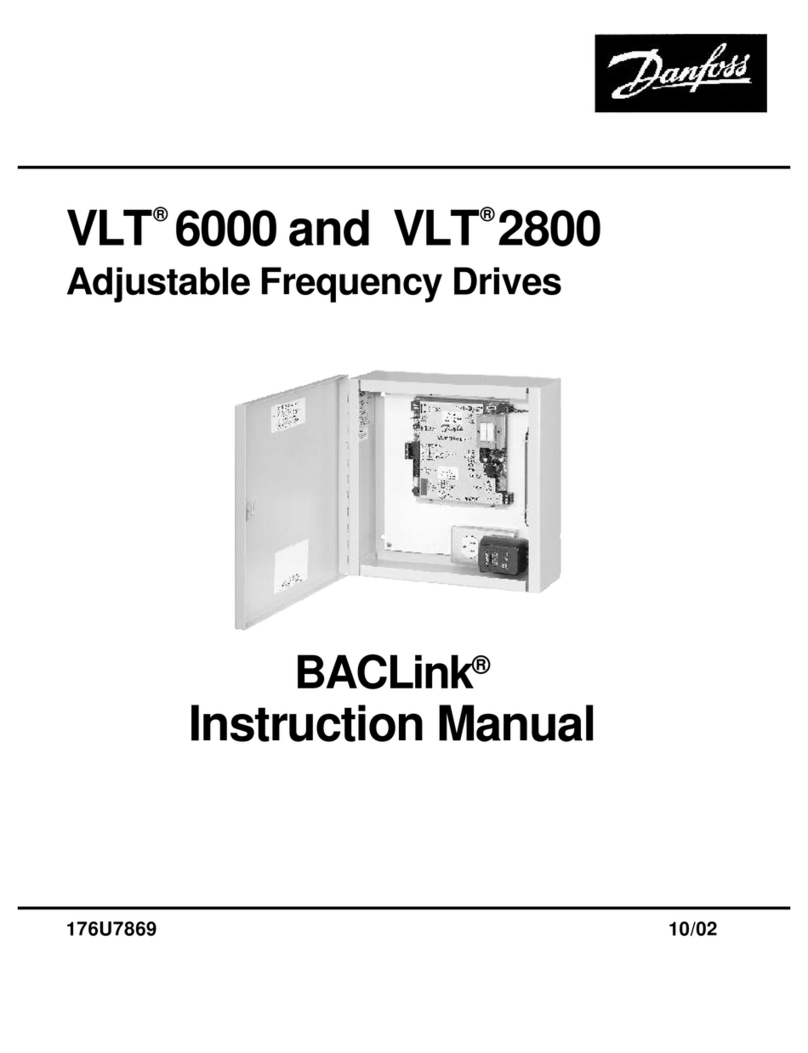

Danfoss VLT 6000 series User manual

Danfoss

Danfoss 51 Series User manual

Danfoss

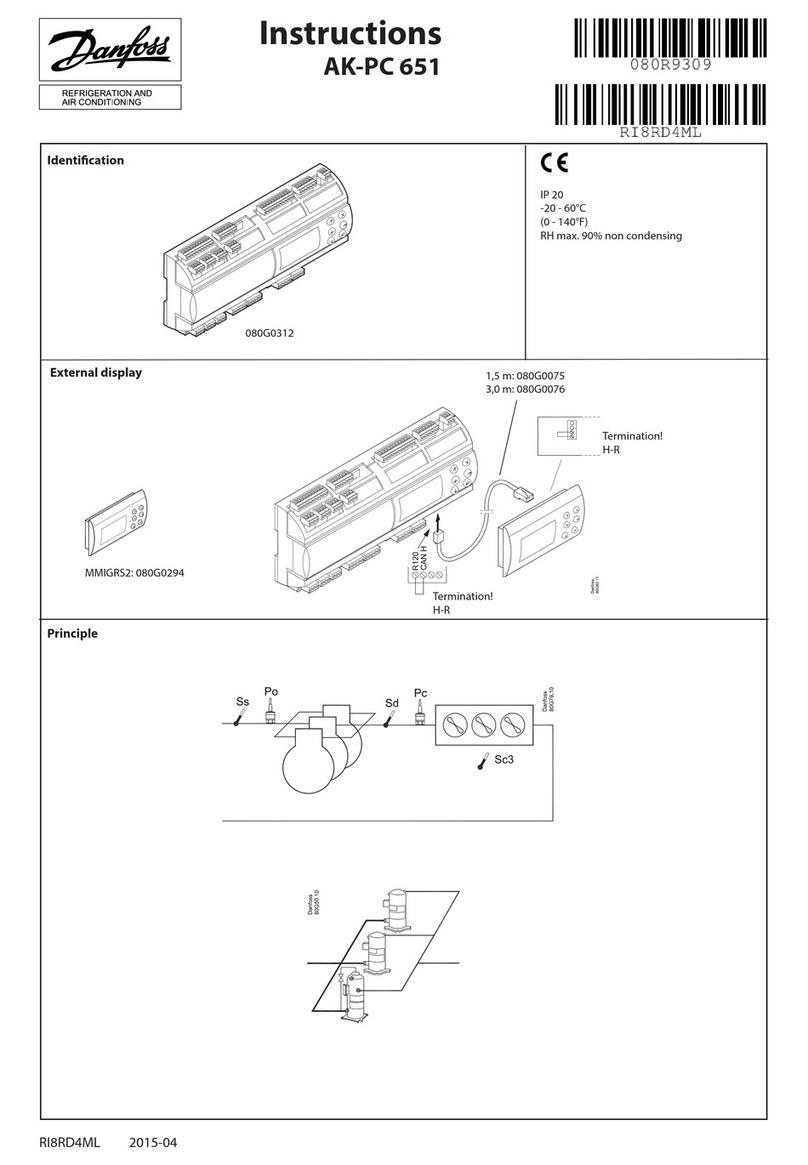

Danfoss ADAP-KOOL AK-PC 651 User manual

Danfoss

Danfoss ERC 112D VSC User manual

Danfoss

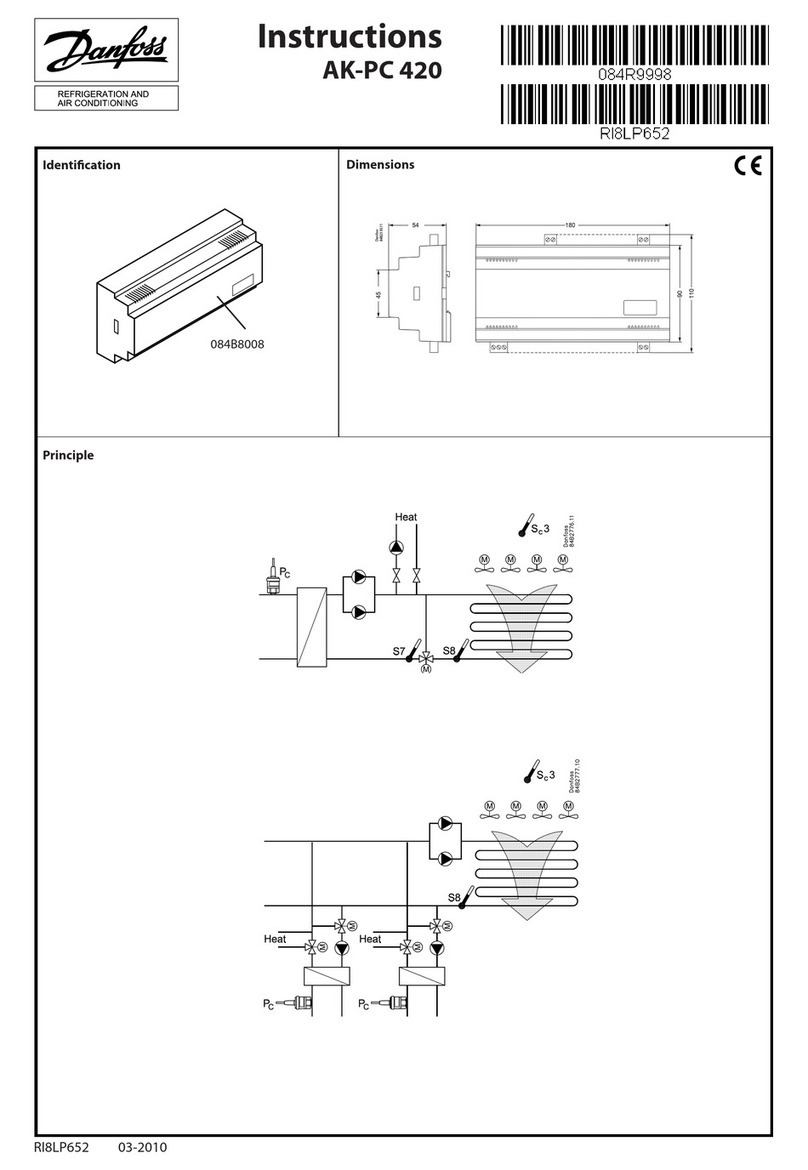

Danfoss AK-PC 420 User manual

Danfoss

Danfoss Old ICAD 600 series User manual

Danfoss

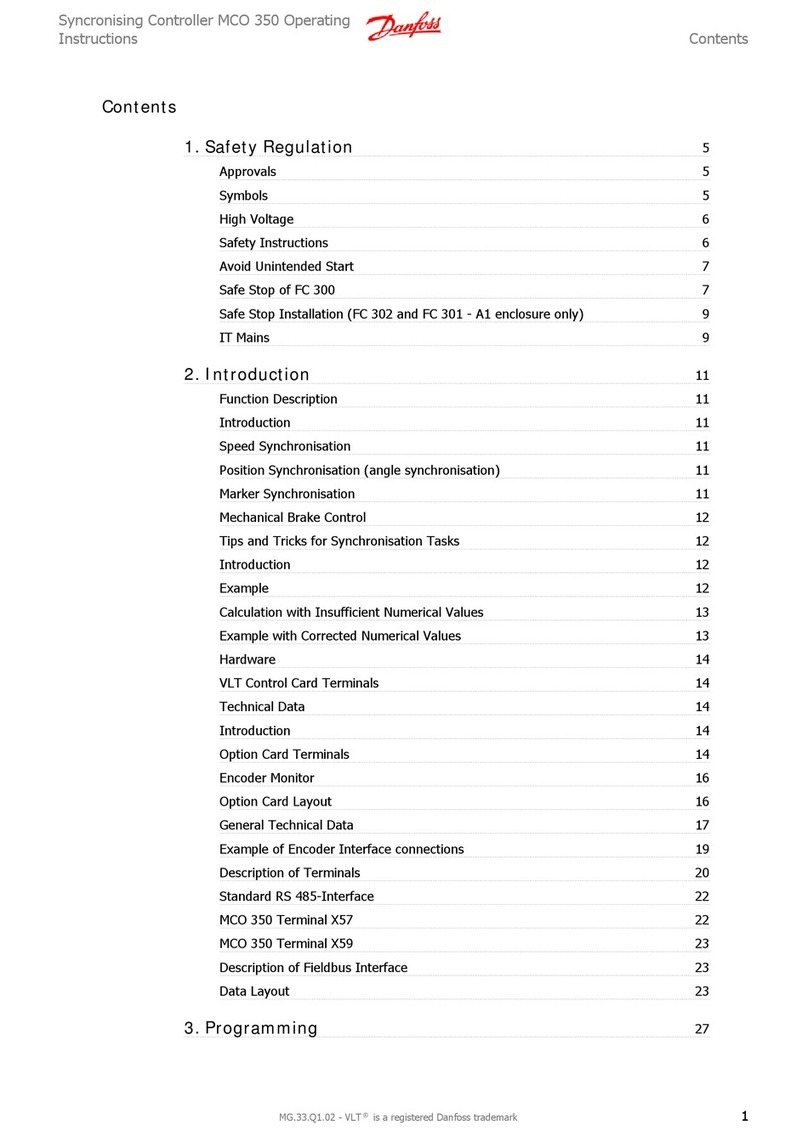

Danfoss MCO 350 User manual

Danfoss

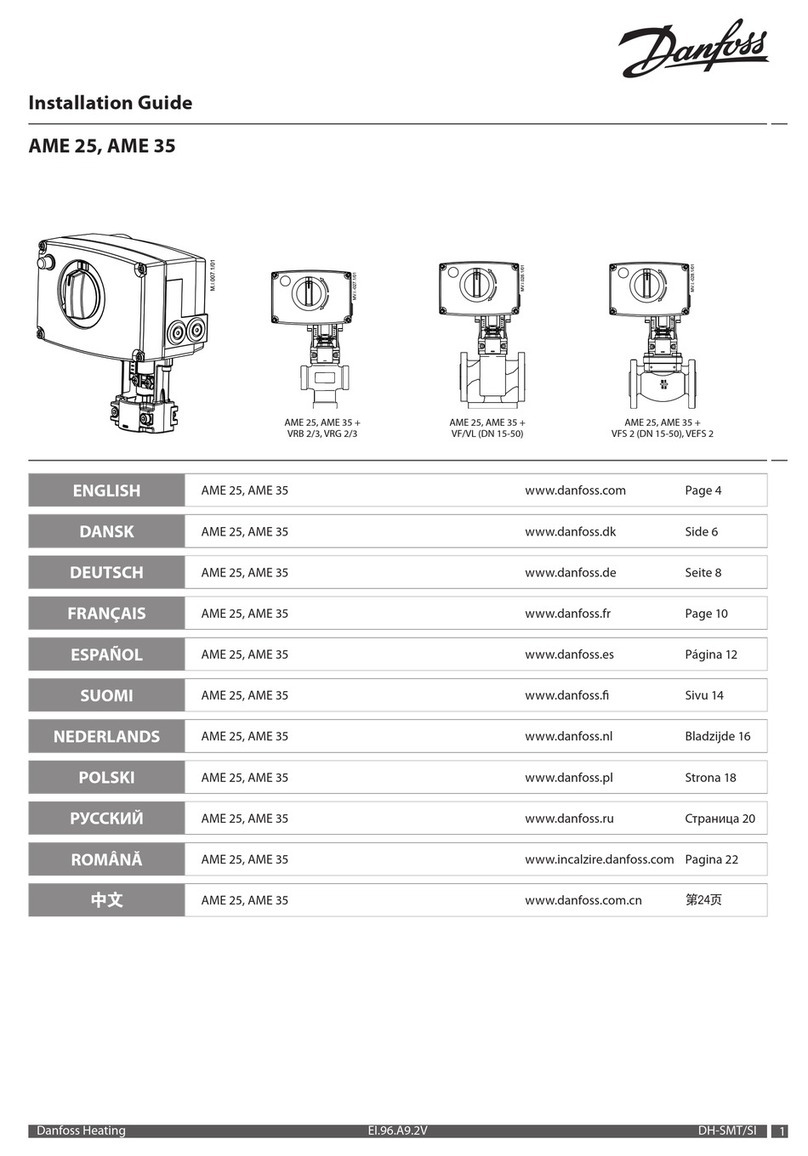

Danfoss AME 25 User manual

Danfoss

Danfoss MCD Series User manual

Danfoss

Danfoss EKD 316 User manual

Danfoss

Danfoss DEVI DEVIreg Hotwater User manual

Danfoss

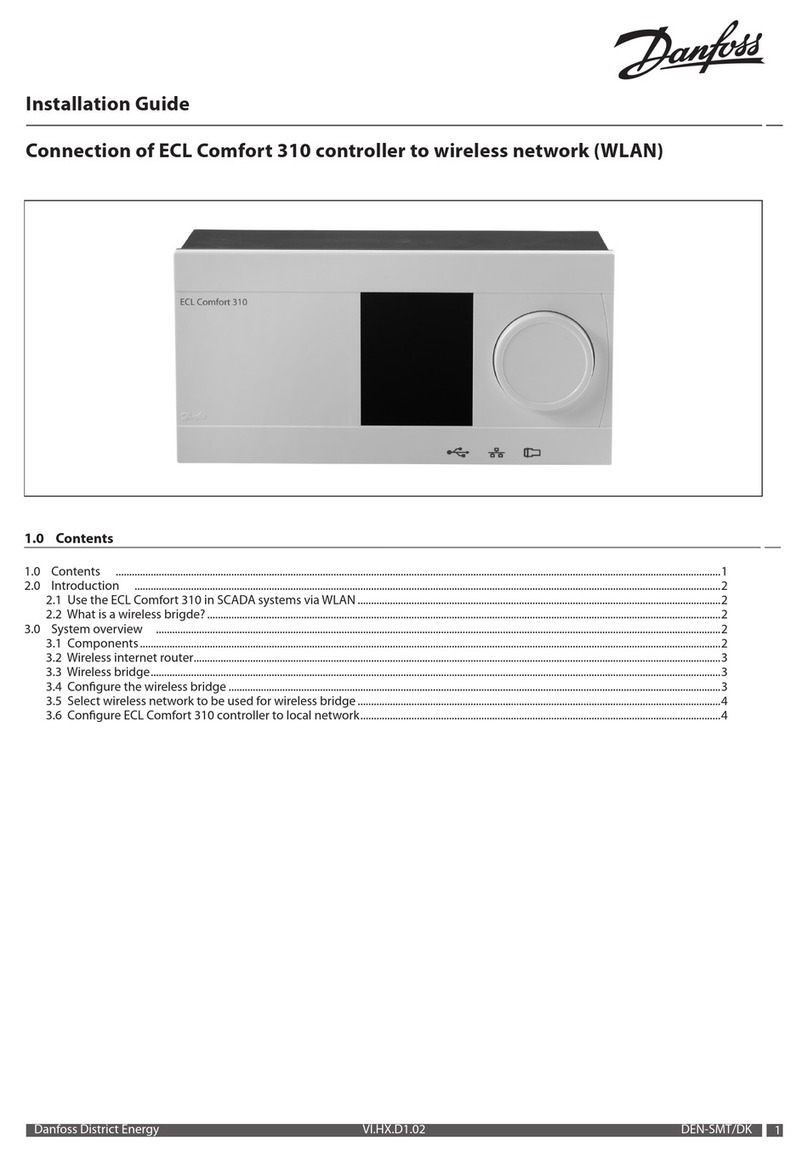

Danfoss ECL Comfort 310 User manual

Danfoss

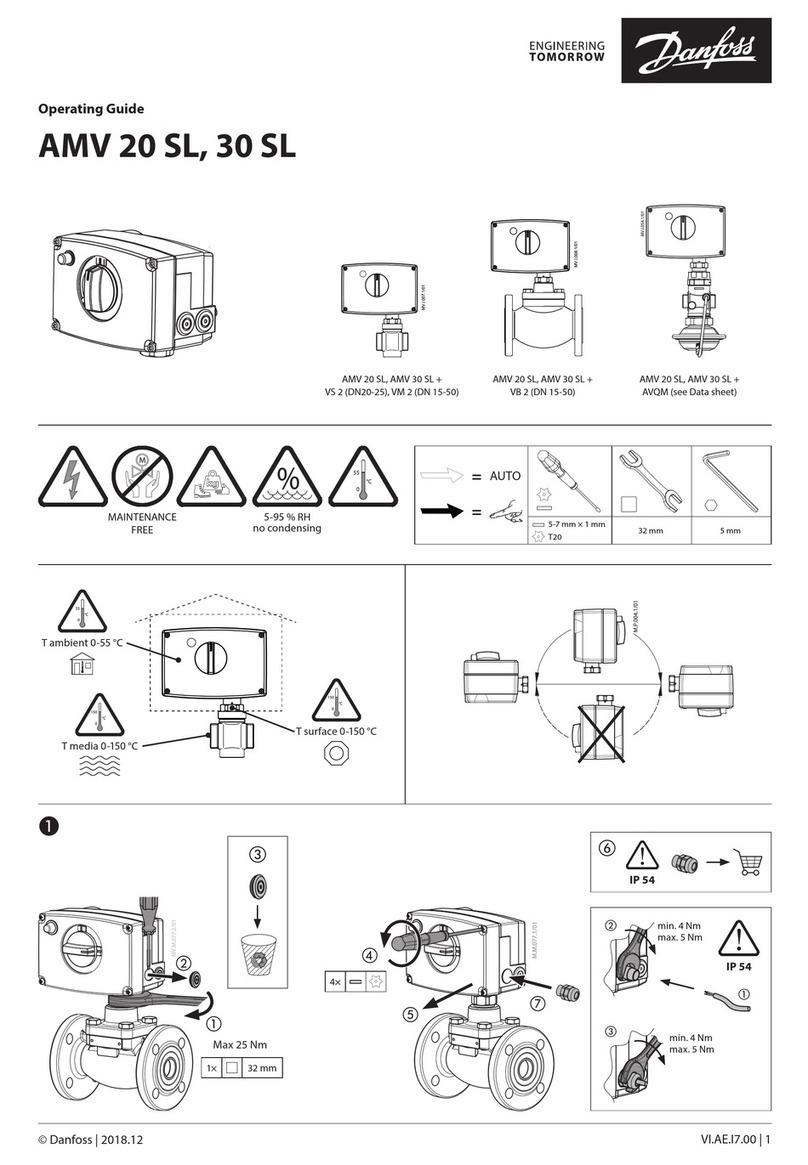

Danfoss AMV 20 SL User manual

Danfoss

Danfoss ADAP-KOOL AK-CC 750 User manual

Danfoss

Danfoss AMD 413 User manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions