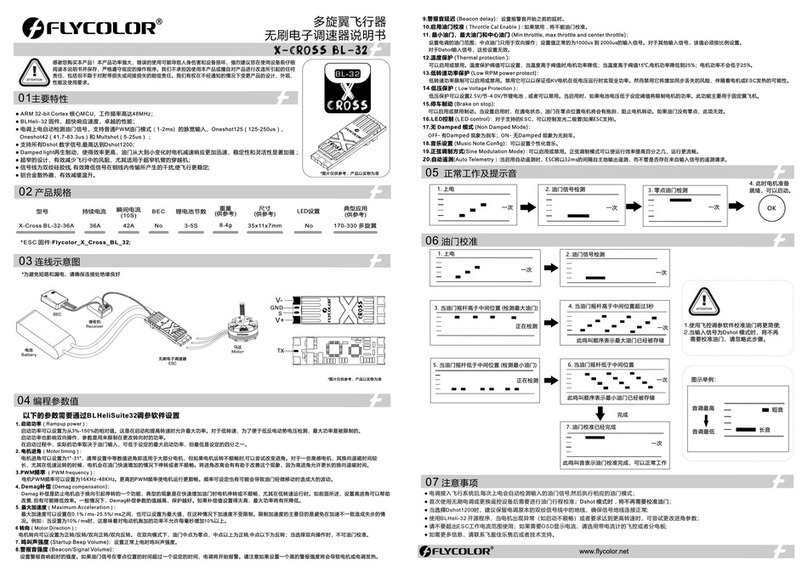

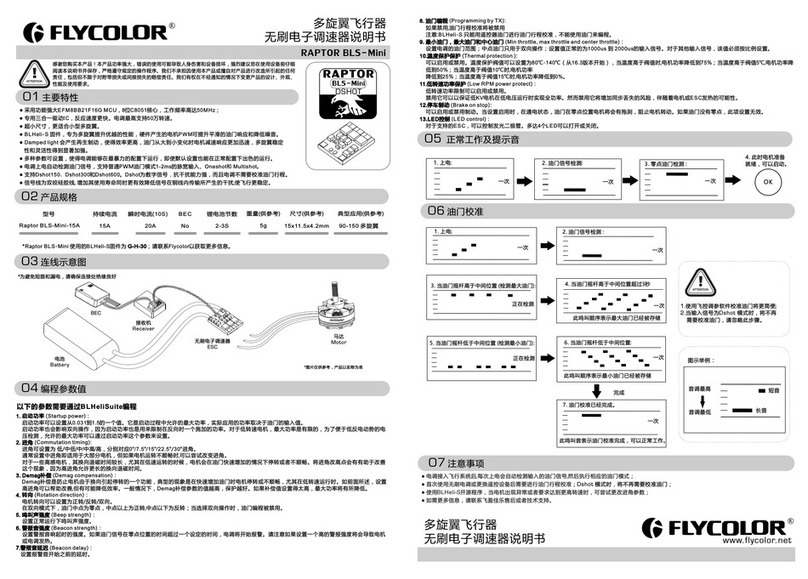

05 ESC Programming parameter

www.flycolor.net

251400-1058-EN,V 1.2

Default values are marked in dark gray.

*:Only enabled for some ESCs. From code rev 14.4, damped light is default on the E S Cs that support it. For prior code revisions, high is default.

**: Default startup power varies by ESC. Generally the default power is lower for larger ESCs.

***:For code revs 14.4 and before, dither range was 7/15/31/63.

1. Closed loop P gain sets the proportional gain for the rpm control loop. This setting controls the gain from speed error to motor power.

2. Closed loop I gain sets the integral gain for the rpm control loop. This setting controls the gain from integrated speed error (summed over time) to motor power.

3. Closed loop mode sets the range of speeds that the control loop can operate on.

- For the high range, throttle values from 0% to 100% linearly correspond to rpm targets from 0 to 200000 electrical rpm

- For the middle range, throttle values from 0% to 100% linearly correspond to rpm targets from 0 to 100000 electrical rpm

- For the low range, throttle values from 0% to 100% linearly correspond to rpm targets from 0 to 50000 electrical rpm

- When closed loop mode is set to off, the control loop is disabled.

4.Multi gain scales the power applied to the motor for a given input. Note that this is only for P W M input, for PPM input it has no effect. Beware that a low multi gain will also limit the maximum power to the motor.

5. Startup is always done with the direct startup method, which runs the motor using back emf detection from the very start. In this mode power is given by the throttle used, but limited to a maximum level.

This maximum level can be controlled with the startup power parameter. Beware that setting startup power too high can cause excessive loading on E S C or motor!

6. Commutation timing can be adjusted in three steps. Low is about 0°, mediumlow 8°, medium 15°, mediumhigh 23° and high 30°. Typically a medium setting will work fine, but if the motor stutters it can be

beneficial to change timing.

7.Pwm frequency:

-High: High pwm frequency is around 20kHz.

-Low: Low pwm frequency is around 8kHz.

-Damped light : This mode adds loss to the motor for faster retardation. Damped light mode always uses high pwm frequency. This mode is only supported on some ESCs (where fet switching is sufficiently fast).

8.Pwm dither is a parameter that adds some variation to the motor pwm off cycle length. This can reduce problems (like throttle steps or vibration) in rpm regions where the pwm frequency is equal to harmonics of

the motor commutation frequency, and it can reduce the step to full throttle. It is primarily beneficial when running damped light mode. Dither is not applied in closed loop mode.

9.Demag compensation is a feature to protect from motor stalls caused by long winding demagnetization time after commutation. The typical symptom is motor stop or stutter upon quick throttle increase,

particularly when running at a low rpm. As described earlier, setting high commutation timing normally helps, but at the cost of efficiency.

Generally, a higher value of the compensation parameter gives better protection. If demag compensation is set too high, maximum power can be somewhat reduced.

10. The rotation direction setting can be used to reverse motor rotation.

11.The input pwm polarity setting can be used to inverse the throttle behaviour. This is intended to be used with receivers that provide negative pwm. When using PPM input it must be set to positive.

Programming parameters that can only be accessed from configuration software (BLHeliSuite):

- Throttle minimum and maximum values for PPM input (will also be changed by doing a throttle calibration).

- Throttle center value for bidirectional operation with PPM.

- Beep strength, beacon strength and beacon delay.

- Programming by TX. If disabled, the TX can not be used to change parameter values (default is enabled).

- Thermal protection can be enabled or disabled (default is enabled).

Temperature is above 140℃, motor power is limited to 75%;Above 145℃, motor power is limited to 50%;Above 150℃, motor power is limited to 25%.Above 155℃, motor power is limited to 0%.

- PWM input can be enabled or disabled (default is disabled). If disabled, only 1-2ms PPM and 125-250us OneShot125 are accepted as valid

input signals.

- Power limiting for low R P Ms can be enabled or disabled (default is enabled). Disabling it can be necessary in order to achieve full power on some low kV motors running on a low supply voltage. However, disabling

it increases the risk of toasting motor or ESC.

- Brake on stop can be enabled or disabled (from rev14.5 ,default is disabled),When enabled, brake will be applied when throttle is zero. For nonzero throttle, this setting has no effect.

Programming parameters below in table that can be accessed from the configuration software (BLHeliSuite) via connect the flight controller :

Function

1 - Closed loop P gain

2 - Closed loop I gain

3 - Closed loop mode

4 - Multi gain

5 - Startup power**

6 - Commutation timing

7 - Pwm frequency

8 - Pwm dither***

9 - Demag compensation

10 - Rotation direction

11 - Input pwm polarity

0.13

0.13

HiRange

0.75

0.031

Low

High

Off

Off

Normal

Positive

0.17

0.17

MidRange

0.88

0.047

MediumLow

Low

3

Low

Reversed

Negative

0.25

0.25

LowRange

1.00

0.063

Medium

*DampedLight

7

High

Bidirectional

0.38

0.38

Off

1.12

0.094

MediumHigh

/

15

/

/

//

0.50

0.50

1.25

0.125

High

31

/

/

/

/

/

0.75

0.75

0.188

1.00

1.00

0.25

1.5

1.5

0.38

2.0

2.0

0.50

3.0

3.0

0.75

4.0

4.0

1.00

6.0

6.0

1.25

8.0

8.0

1.50

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

123456789 10 11 12 13

● User need to calibrate the throttle range when starting to use a new ESC or another transmitter.

● BLHeli open-source firmware, when some abnormality occurs in E S C driving the motor or need the motor to reach a higher R P M, user can try to change the timing.

● User also can connect the flight control to the computer to update the firmware or change the setup via .configuration software (BLHeliSuite)

● Please contact Flycolor sales or technical support for more information.

User Manual

Multi-Rotor Brushless ESC

06 Attention

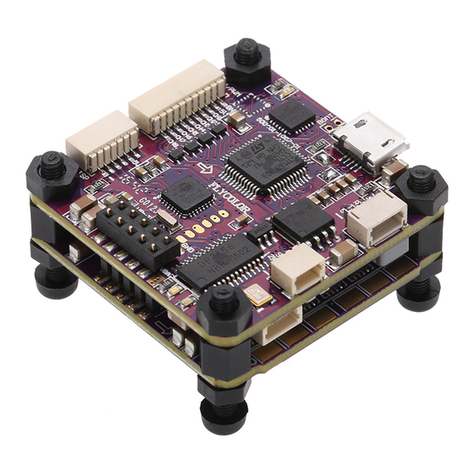

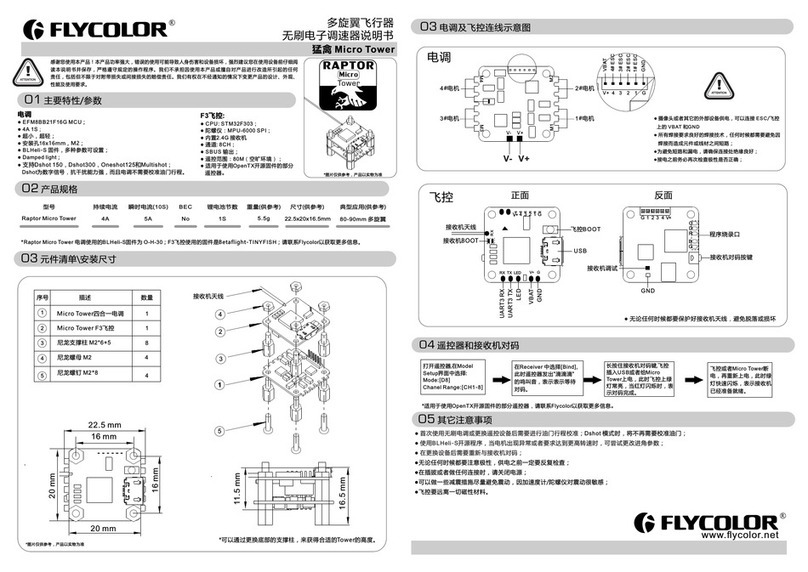

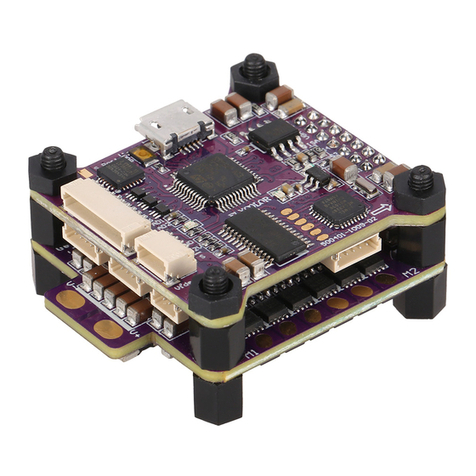

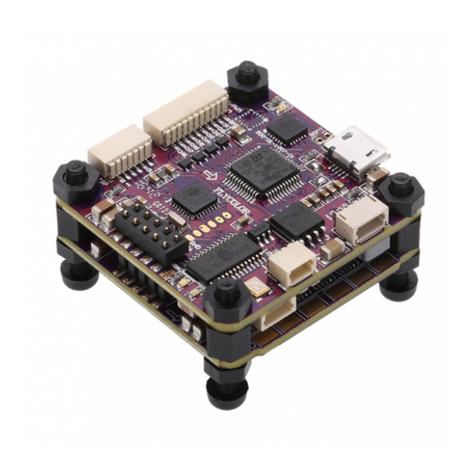

BOTTOM

GND

VBAT

GND

S

LED

LED

5V

GND

Buzzer

Buzzer

5V

Buzzer

5V

GND

LED

5V

GND

1

3

5

6

Image

transmitter

VBAT-

VBAT+

GND

S

2

12V

Camera

S

12V

GND

GN D

5V

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

RX

TX

5V

GN D

OS D O UT

12V

GN D

PWM

Receiver

GND

5V

CH1

CH2

CH3

CH4

CH5

CH6

1

2

3

4

5

6

7

8

BOOT

9

10

Data

transmission CH8

C H 7

GPS

RX

TX

5V

GND

1

2

4

3

Bridged “BOOT”

for recovering firmware

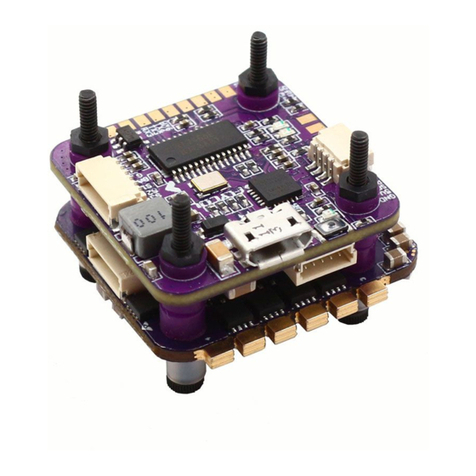

TOP PWM Mode

ISP programming

connector

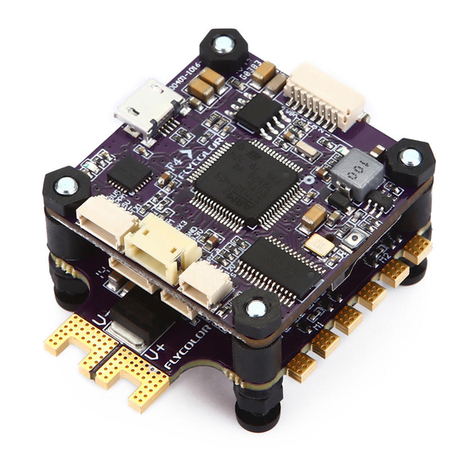

PPM Mode BO TTOM

GND

VBAT

GND

S

LED

LED

5V

GND

Buzzer

Buzzer

5V

Buzzer

5V

GND

LED

5V

GND

1

3

5

6

Image

transmitter

VBAT-

VBAT+

GND

S

2

GND

5V

CH1

GPS

RX

TX

5V

GND

1

2

4

3

PPM

Receiver

1

2

3

GN D

5V

CH1

CH2

CH3

CH4

CH5

CH6

CH7

CH8

RX

TX

5V

GN D

S

12V

GN D

12V

Camera

S

12V

GND

BOOT

9

10

Data

transmission CH8

C H 7

Bridged “BOOT”

for recovering firmware

TOP

ISP programming

connector