Exel Orbital EPS-2000 User manual

Page

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Version 1.01

Date: June 2005

Page 2

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

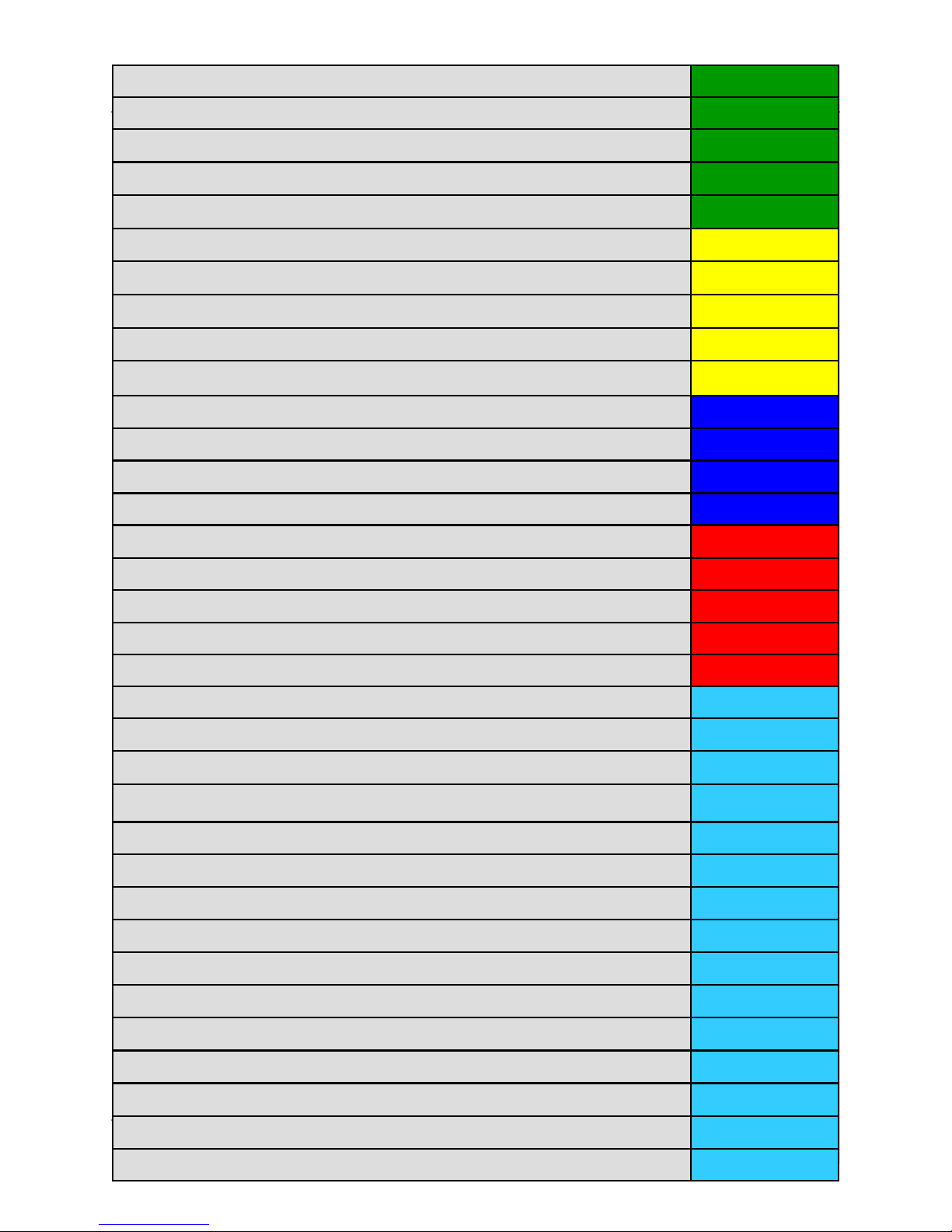

Unpacking the Power Supply Page 4

Required Peripherals Page 5

Power Supply Hook Up Page 6

Power-Up Page 7

Chapter 2, Library and Memory

Chapter 2, Library and Memory

Chapter 2, Library and Memory

Page 8

Loading a Weld Schedule from the Main Memory

Loading a Weld Schedule from the Main Memory

Loading a Weld Schedule from the Main Memory

Page 9

Loading a Weld Schedule from the CF Card

Loading a Weld Schedule from the CF Card

Loading a Weld Schedule from the CF Card

Page 10

Moving a Weld Schedule from CF Card to Main Memory

Moving a Weld Schedule from CF Card to Main Memory

Moving a Weld Schedule from CF Card to Main Memory

Page 11

Moving a Weld Schedule from Main Memory to CF Card

Moving a Weld Schedule from Main Memory to CF Card

Moving a Weld Schedule from Main Memory to CF Card

Page 12

Creating a Weld Schedule -4 Level Weld Page 14

Creating a Weld Schedule -S3Page 17

Viewing or Modifying a Weld Schedule Page 18

Chapter 4, Making a Weld Page 19

Weld Tracking Information Page 20

Calibrating the Rotor Driver Page 21

Making a Weld Page 23

Jog, Home, Purge and Stop Page 24

Chapter 5, Utility, Passwords, Printing, Reports and Faults Page 25

Utility Page 26

Alarm Settings Page 27

Passwords Page 28

Alarms and Faults Page 29

Zero the Pressure Transducer Page 31

Weld Report on Microsoft Excel Page 33

Chapter 1, Start Up Page 3

Chapter 3, Create a Weld Schedule Page 13

Making a Test Weld Page 22

Page 3

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

C Copyright 2001 Exel Orbital Systems All Rights Reserved

EPS-2000 Power Supply

Chapter1,Start

Chapter1,Start

Chapter1,Start-

-

-Up

Up

Up

Version 1.11.01

Revision Date: November 2001

Page 4

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Unpacking the Power Supply

Chapter 1 Start Up

The EPS-2000 Power Supply comes in

a water tight, rolling carrying case. This

case is suitable for shipment.

Open the case by unlatching the 6

latches.

Open the lid of the case. If the lid does not open readily, there

may be a vacuum inside due to air

travel. Push the pressure release button

then open the lid.

In the bottom of the case is the power

supply operations manual, the line cord

and a purge connector.

Place the power supply on a stable work

surface.

Page 5

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

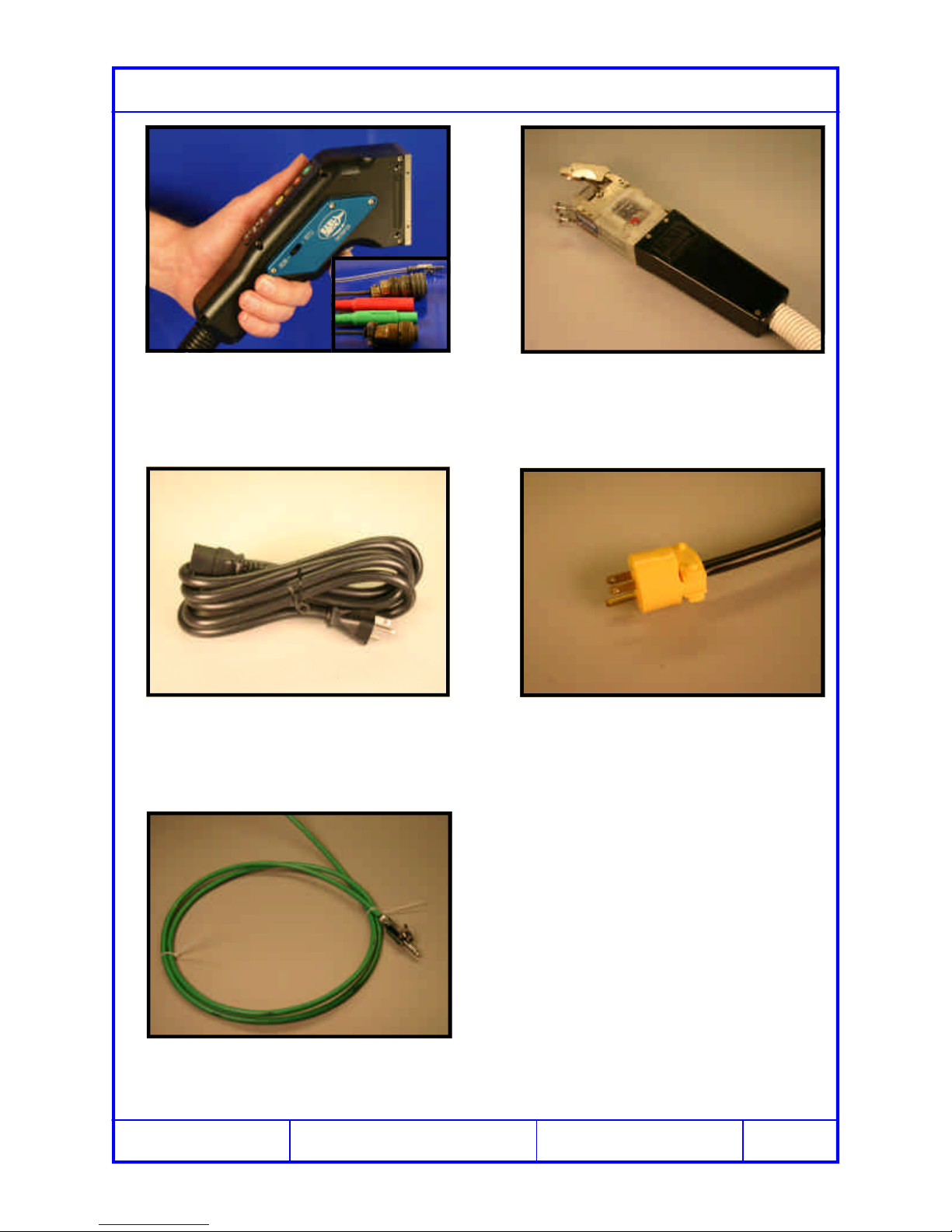

Required Peripherals

C Copyright 2001 Exel Orbital

All Rights Reserved

Chapter 1 Start Up

A welding head is required to operate

the EPS-2000 Power Supply. Above is

the Exel RDR-05 Rotor Driver.

The line cord provided is 20 amp rated

for 250 volt service.

The EPS-2000 Power Supply can oper-

ate Arc Machines orbital welding heads

as well.

A source of purge for the power supply

is required. Use the purge connector

provided.

It may be necessary to cut off the plug

provided on the line cord and replace it

with one suitable for the outlet intended.

Page 6

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Power Supply Hook Up

Start by inserting the A/C line plug into

power ranging from 85 to 265 volts and

from 47 to 63 hertz single phase.

Connect the power, ground, motor, gas

and remote (if applicable) of the welding

head to the power supply.

Chapter 1 Start Up

Notes:

1. The EPS-1000 does not require a

dedicated circuit.

2. Power Input: 85 to 265 volts and

47 to 63 hertz.

3. Purge Input: 15 to 80 psi or 100

to 530 Kpa.

Above is a view of the back of the EPS-

2000 Power Supply with all necessary

connectors visible.

Connect the Argon or mixed gas purge

inlet from the source to the power sup-

ply.

Page 7

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

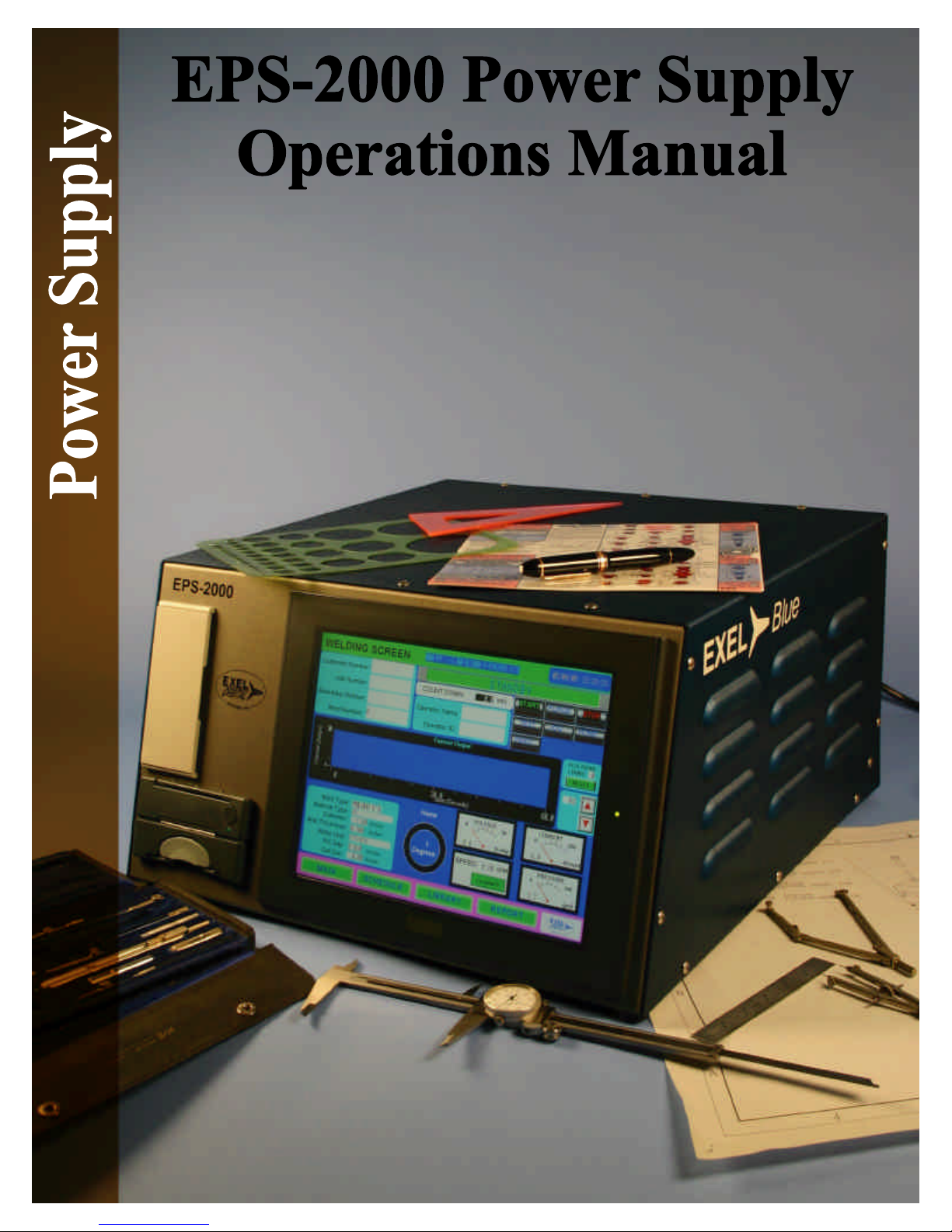

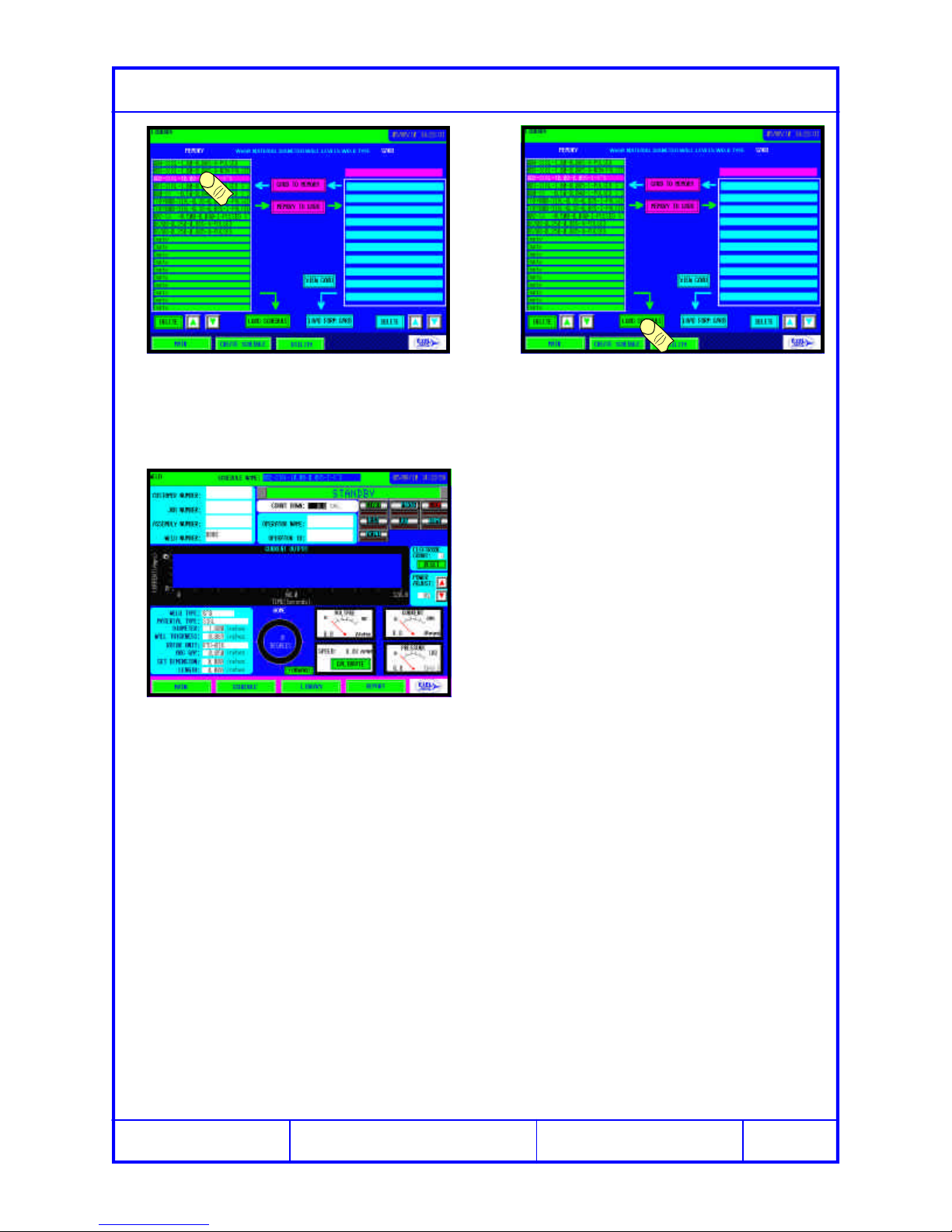

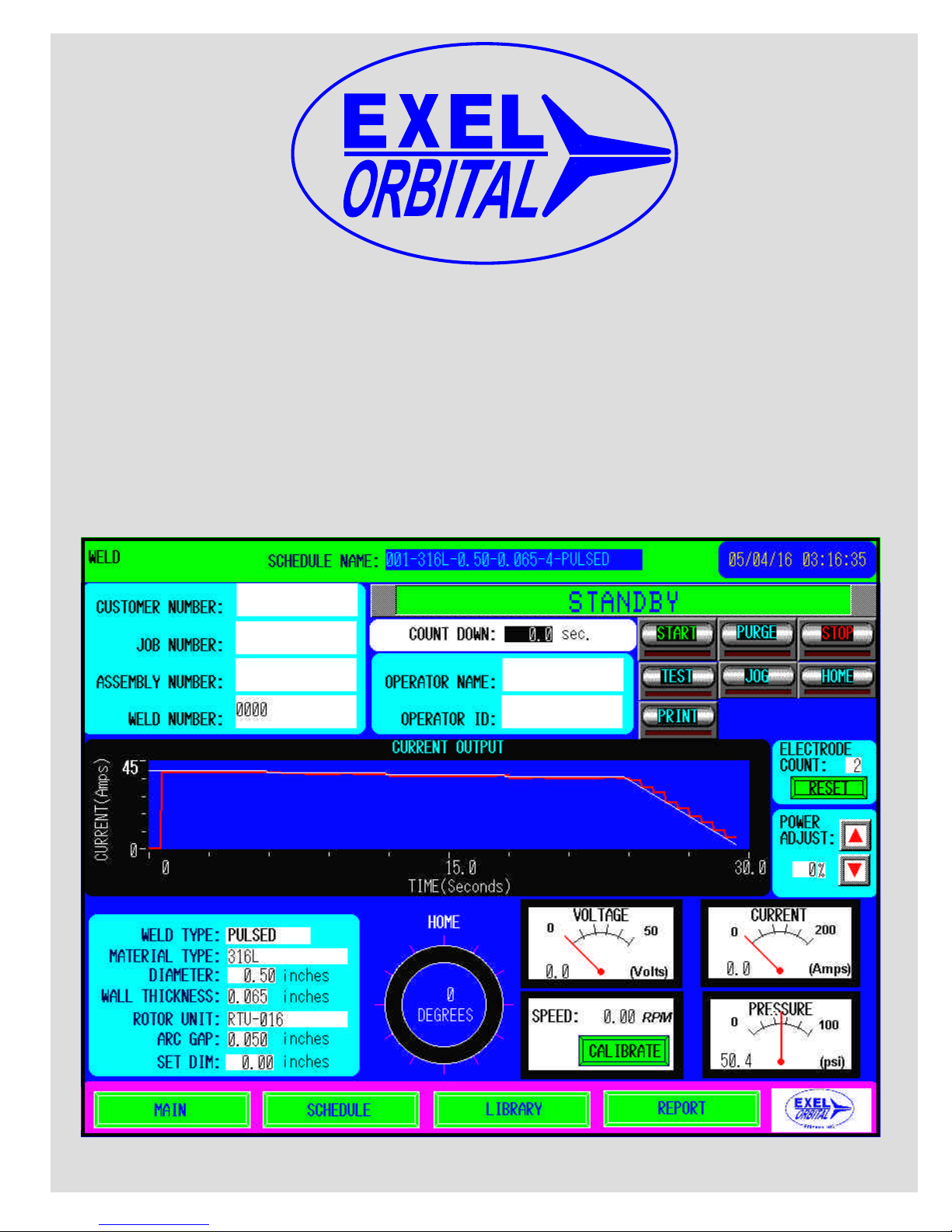

Power-Up

Turn the main power switch on.

Chapter 1 Start Up

The Main Screen will appear on the touch

screen. Select the desired Language then

touch any spot on the screen to continue.

The Library Screen above appears so

that a weld schedule may be created or

loaded from memory.

If Password protection selected enter

that password here.

1

2

Page 8

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

C Copyright 2001 Exel Orbital Systems All Rights Reserved

EPS-2000 Power Supply

Chapter2,Libraryand Memory

Chapter2,Libraryand Memory

Chapter2,Libraryand Memory

Version 1.11.01

Revision Date: June 2005

Page 9

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

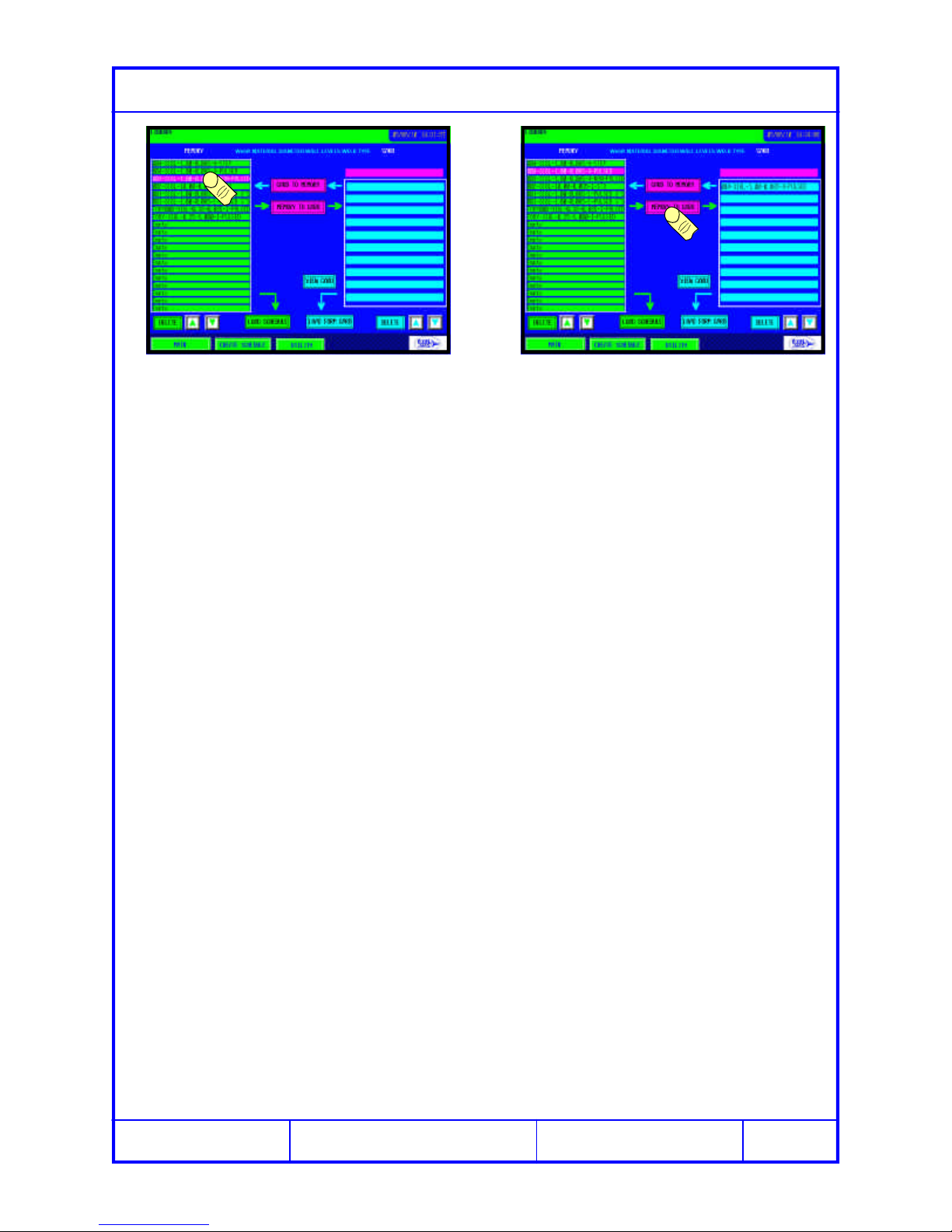

Loading a Weld Schedule from the Main Memory

Select the desired weld schedule from

the Main Memory in the left column. Select Load Schedule.

The selected weld schedule appears on

the screen.

Page 10

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Loading a Weld Schedule from the CF Card

Orient the CF Card as shown. Insert the CF Card, being sure that it is

seated completely into the slot. The

eject button should pop up.

Eject

Button

Touch the VIEW CARD button and all

weld schedules in the card will be dis-

played in the right column.

Select the desired schedule and the

name will appear in the pink window

above the right column.

Touch LOAD FROM CARD and the weld

schedule will load

Page 11

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

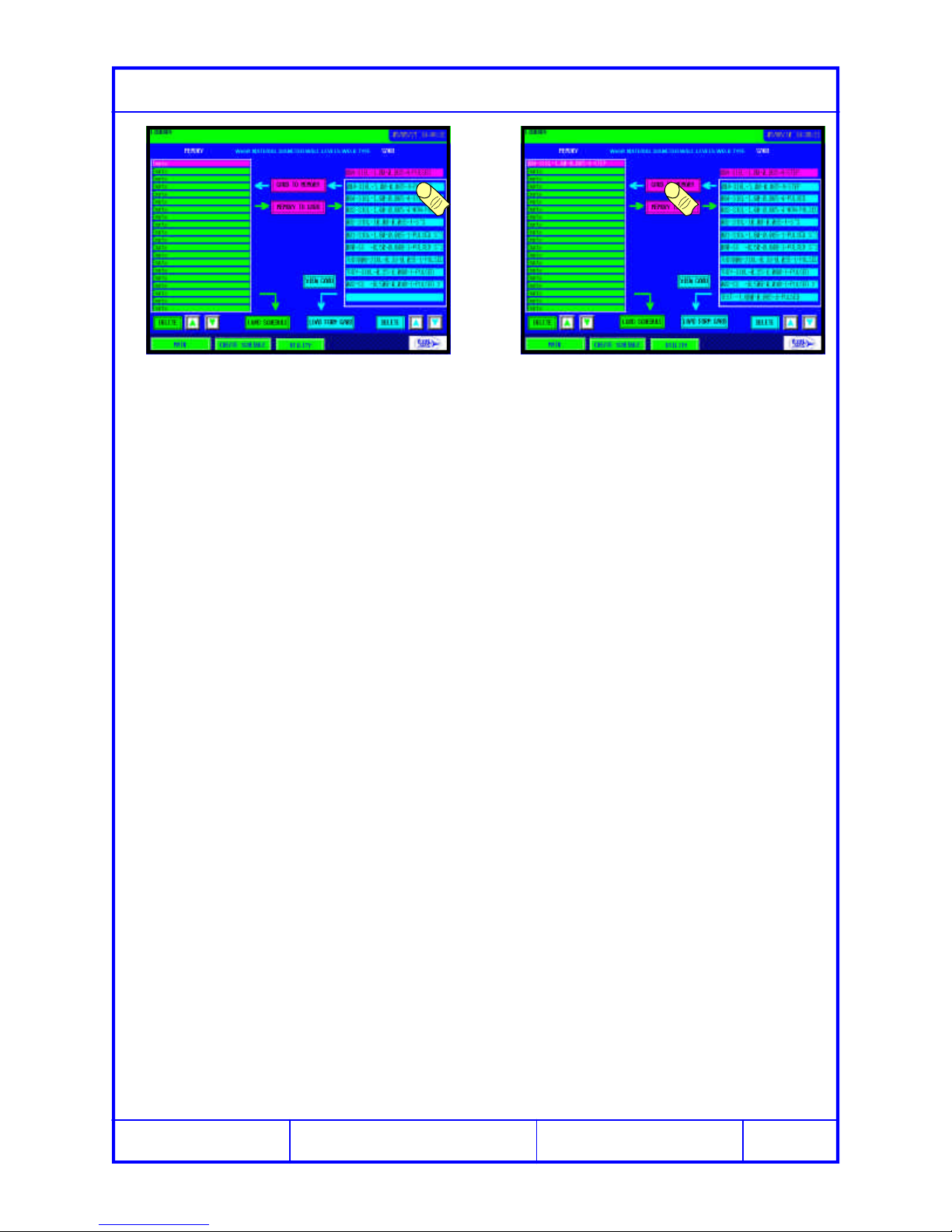

Moving a Weld Schedule from CF Card to Main Memory

Select the desired weld schedule to

transfer to main memory and it will ap-

pear in the pink window.

Select CARD TO MEMORY and the

weld schedule will be copied to the Main

Memory in the left column.

Page 12

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Moving a Weld Schedule from Main Memory to CF Card

Select the desired weld schedule to

transfer to the CF Card. Select MEMORY TO CARD and the

weld schedule will be copied to the CF

Card in the right column.

Page 13

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

C Copyright 2001 Exel Orbital Systems All Rights Reserved

EPS-2000 Power Supply

Chapter3,CreateaWeld

Chapter3,CreateaWeld

Chapter3,CreateaWeld

Schedule,

Schedule,

Schedule,

Version 1.11.01

Revision Date: June 2005

Page 14

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

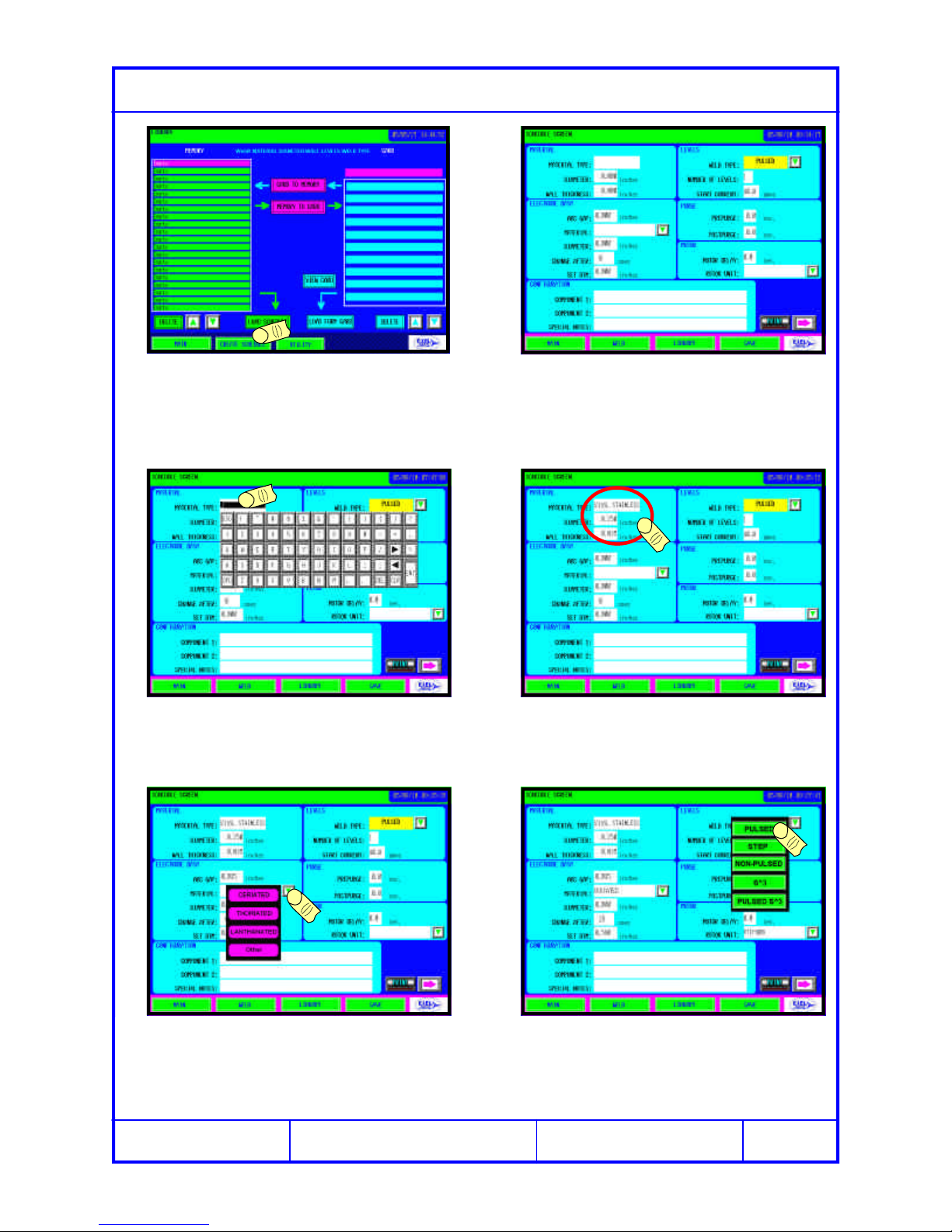

Creating a Weld Schedule -4 Level Weld

From the LIBRARY screen touch CRE-

ATE SCHEDULE. The above screen appears.

Enter the Material Type that will be

welded by touching the field and using

the QWRTY keypad that appears.

Fill in all the Material Fields.

Enter the Electrode Data and select the

electrode material from the pull down

menu. CHANGE AFTER alarms the op-

erator to change the electrode.

In the Levels category select the Weld

Type to be made.

Page 15

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Creating a Weld Schedule -4 Level Weld

After entering the data on the first screen

push the right arrow to move to the sec-

ond Schedule Screen

The above screen appears.

Enter Level 1 data and click UPDATE

GRAPH, both the polar and linear graph

of time, current and rotation are shown.

With a multi level weld it is convenient to

click the fill button to copy Level 1 infor-

mation to all subsequent levels.

Level 2 contains the same information as

level 1. Change the relevant field, in this

case 41 High amps. UPDATE GRAPH.

1

2

1

2

1

2

Edit Level 3 in the same manner as

Level 2 and UPDATE GRAPH to con-

form changes.

Page 16

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Creating a Weld Schedule -4 Level Weld

Edit Level 4 and UPDATE GRAPH. Enter a Down Slope and UPDATE

GRAPH. The 4 Level Pulsed Weld

Schedule is now complete.

1

212

To save the newly created weld sched-

ule touch SAVE. The Library Menu appears in Save As

mode. Displaying a default name in the

Schedule Name field.

Click SAVE TO MEMORY to save the

schedule in internal memory or SAVE

TO CARD to save to the CF Card.

If the default name is undesired touch

the SCHEDULE NAME field and a

KWRTY keypad appears to rename.

Page 17

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Creating a Weld Schedule -S3

In SCHEDULE SCREEN 1 select

PULSED S3as the Weld Type. When PULSED S

3is selected, notice

that Number of Levels shows INF. This

denotes that there are infinite levels.

Referring back to the multi-level weld de-

veloped on the previous pages, use the

settings for Level 1 and Level 4

Input Level 1 High amps for Point 1 and

Level 4 High amps for Point 2. Time is

the total of Level 1,2,3 & 4 time from the

Multi-Level weld.

Lev Time High Low Freq % High

11.9 42 10.5 650

21.9 41 10.5 650

31.9 40 10.5 650

41.9 38 10.5 650

Speed

8

8

8

8The S3Weld is complete

Note: Below are the values en-

tered for a 4 Level weld for 1/4” di-

ameter, .035 wall 316L Stainless

Steel.

Page 18

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Viewing or Modifying a Schedule

From the WELD Screen touch the

SCHEDULE button Enter the Programmer Password which

gives access to the weld schedule. See

Pass Words in the Utility Section.

The first screen to appear is Schedule

Screen 1. Click the Right Arrow to move

to Schedule Screen 2

Click the Left Arrow to move back to

Schedule Screen 1

Page 19

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

C Copyright 2001 Exel Orbital Systems All Rights Reserved

EPS-2000 Power Supply

Chapter4,Making AWeld

Chapter4,Making AWeld

Chapter4,Making AWeld

Version 1.11.01

Revision Date: June 2005

Page 20

C Copyright 2005 Exel Orbital

All Rights Reserved

1.2.

3.4.

5.6.

Weld Tracking Information

When a weld schedule loads there are

several fields that can be filled which al-

low tracking of a weld in the REPORT.

Touch the field where information is to

be entered and a QRTY keypad appears

Press ENTER when complete and the

QRTY keypad disappears. Continue filling in all remaining fields.

This information will now appear on the

Weld Report making tracking easier.

Note:

1. To open or create a weld sched-

ule see Library and Memory

Library and Memory

Library and Memory or Cre-

Cre-

Cre-

ate a Weld Schedule

ate a Weld Schedule

ate a Weld Schedule

Table of contents