Exepd AB1 3 Series User manual

Operation Manual

dpe

Control and Signal Devices

AB1-[D/E/K/M/N/P/W]3-

******

Exepd GmbH

i_PARK TAUBERFRANKEN 23

97922 Lauda-Königshofen

Germany

Phone: ++49 (0) 9343 627055-0

Fax: ++49 (0) 9343 627055-99

Operation Manual

Control and Signal Devices

AB1-[D/E/K/M/N/P/W]3-******

AB1-X3-YB002eng 31.07.2023 www.exepd.de

page 2 of 8

1. Product Description ....................................................................................... 3

2. Intended Use ................................................................................................ 3

3. Applied Standards ......................................................................................... 3

4. Type key...................................................................................................... 4

5. Technical data .............................................................................................. 4

5.1. Technical data indicator light AB1-M3… ...................................................... 5

5.2. Technical data pushbutton type AB1-D3… ................................................... 5

5.3. Technical data Mushroom pushbutton M22 AB1-N3….................................... 5

5.4. Technical data Mushroom pushbutton M30 AB1-E3… .................................... 5

5.5. Technical data key switch AB1-K3… ........................................................... 6

5.6. Technical data selector switch/potentiometer AB1-P/W3…............................. 6

6. Safety Instructions ........................................................................................ 6

7. Special Conditions ......................................................................................... 6

8. Assembly and installation ............................................................................... 7

9. Commissioning ............................................................................................. 7

10. Operation, maintenance and troubleshooting .................................................... 7

11. Installation in a housing/device of the type of protection increased safety "e" and

protection by housing "t" ........................................................................................ 8

12. Accessories, spare parts................................................................................. 8

13. Service address ............................................................................................ 8

Operation Manual

Control and Signal Devices

AB1-[D/E/K/M/N/P/W]3-******

AB1-X3-YB002eng 31.07.2023 www.exepd.de

page 3 of 8

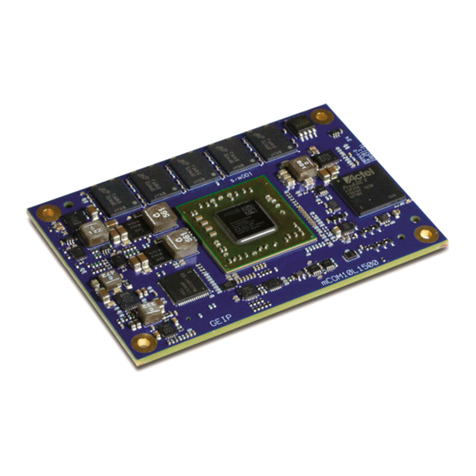

1. Product Description

The manually operated control and signal devices are used to display, control, and trigger

electrical functions with a button, rotary knob, switch or as an emergency stop.

The control and signal devices are suitable for use in category II 2G/D and are intended

for fixed installation.

2. Intended Use

The control and signal devices can be used as a device without additional testing in

potentially explosive environments of device category II 2G/D (for use in Ex zones 1/2

and 21/22).

When installed in a housing/device with the type of protection increased safety "e" and

protection by housing "t", this must be checked separately with the housing (device). The

operating temperature of the housing/device must not exceed 80°C.

The conditions for using the device remain the same.

The command signalling devices are actuated by hand.

The values specified on the type plate, as well as electrical data and the device category

for the place of use must be observed.

The control and signal devices are suitable for the ambient temperature range from -

20°C to +60°C.

The maximum permissible surface temperature is 80°C.

Changes to the control and signal devices are not permitted. (It is not possible to open

the equipment without destroying it, the existing internal Ex d gaps cannot be changed).

3. Applied Standards

EN IEC 60079-0 / General requirements

EN 60079-1/ Flameproof enclosure

EN IEC 60079-7 / Increased safety

EN 60079-31 / Protection by housing

Operation Manual

Control and Signal Devices

AB1-[D/E/K/M/N/P/W]3-******

AB1-X3-YB002eng 31.07.2023 www.exepd.de

page 4 of 8

4. Type key

A

B

1

-

*1

*2

-

*3

*3

*3

*3

*3

*3

*1

Type

D

=

Pushbutton

E

=

Mushroom Pushbutton M30

K

=

Key Switch

M

=

Signalling Lamp

N

=

Mushroom Pushbutton M22

P

=

Potentiometer

W

=

Selector Switch

*2

Main Material

3

=

1.4301/1.4305 Stainless Steel

*3

Device specific breakdown**

**as an alternative to 3, a unique 6-digit article number can be used. All relevant data

are contained in the item designation or the product documentation.

The device-specific breakdown can be found in the associated data sheets.

5. Technical data

Mechanically

Material: stainless steel 1.4301/1.4305

Impact resistance front: 7 Nm; (calotte) 4 Nm

The connection side must be protected against the risk of mechanical damage.

Mounting hole max. Ø22.0 +0.3 mm

thread M22x1.5

hole max. Ø30.0 +0.3 mm

thread M30x1.5

Ambient temperature range max. -20 °C ≤ T ≤ +60 °C

Maximum operating temperature +80 °C

Temperature class (G) T6

Surface temperature (D) T85 °C

Nominal voltage standard 24 V - device-specific

Rated current max. 1 A - device-specific

Rated power (potentiometer) max. 1 Watt - device-specific

Power loss PV max. 1 Watt

For further dimensions and data on the built-in parts, see the following device-specific:

Degree of protection according to EN 60079-0 (EN 60529): housing IP66

Explosion protection: (Exact data see type plate / information plate)

II 2G Ex db eb IIC T6 Gb

II 2D Ex db IIIC T85 °C Db

Associated EU Declaration of Conformity: AB1-X3-YC0001

Type examination certificate: IBExU22ATEX1083 X

Operation Manual

Control and Signal Devices

AB1-[D/E/K/M/N/P/W]3-******

AB1-X3-YB002eng 31.07.2023 www.exepd.de

page 5 of 8

5.1. Technical data indicator light AB1-M3…

Outer diameter head: Ø 27 mm

Length: 41 mm

Electrical characteristics:

Rated voltage: 24 VDC

Current consumption: IN<15 mA

Rated power consumption: <0.4 W

Connecting cable: single color 2x 0.5 mm²

Two-tone 3x 0.5 mm²

Recommended back-up fuse: max. 63 mA F

5.2. Technical data pushbutton type AB1-D3…

Outer diameter head: Ø 27 mm

Length: 53 mm

Electrical characteristics:

1-2 switching elements (changeover)

Mechanical life: min. 10^7

Rated voltage: 24 VDC/230 VAC

Permissible rated current: ≤1 A

Connecting cable: 2-6x0.5 mm²

Protection class II (protective insulation)

5.3. Technical data Mushroom pushbutton M22 AB1-N3…

Outer diameter head: Ø 27 mm

Length: 90mm (with mushroom print attachment)

Electrical characteristics:

1 switching elements (break contact positively separated, auxiliary contact changeover)

Rated voltage: 24 VDC/230 VAC

Permissible rated current: ≤1 A

Connecting cable: max. 4x0.5 mm²

Protection class II (protective insulation)

5.4. Technical data Mushroom pushbutton M30 AB1-E3…

Outer diameter head: Ø 35 mm

Length: 92mm (with mushroom print attachment)

Electrical metrics

1-3 switching elements (break contact positively separated, auxiliary contact

changeover)

Rated voltage: 24 VDC/230 VAC

Permissible rated current: ≤1 A

Connecting cable: max.7x0.5 mm²

Protection class II (protective insulation)

Operation Manual

Control and Signal Devices

AB1-[D/E/K/M/N/P/W]3-******

AB1-X3-YB002eng 31.07.2023 www.exepd.de

page 6 of 8

5.5. Technical data key switch AB1-K3…

Outer diameter head: Ø 27 mm

Length: 74 mm

Electrical metrics

Rated voltage: 24 VDC

Permissible rated current: ≤150 mA

Connection cable: max.13Gx0.5 mm²

The internal protective conductor (wire line) must be integrated into a suitable

equipotential bonding/grounding measure.

5.6. Technical data selector switch/potentiometer AB1-W/P3…

Outer diameter head: Ø 27 mm

Length: 58mm (excluding actuator button)

Electrical characteristics:

Rated voltage: 24 VDC

Rated current: ≤150 mA

Rated power (potentiometer): 1 W max

Connection cable: max.13Gx0.5 mm²

The internal protective conductor (wire line) must be integrated into a suitable

equipotential bonding/grounding measure.

6. Safety Instructions

The equipment in an electrical system in a potentially explosive environment must be

kept in good condition, operated, and monitored properly by the operator. This also

includes checking the equipment for any transport damage before it is put into operation.

Assembly and disassembly may only be carried out by trained specialists.

All generally applicable legal rules and other binding guidelines on occupational safety,

accident prevention and environmental protection must be observed.

Damaged components must not be put into operation.

7. Special Conditions

The cable must be connected in a safe area or in a suitable connection area (e.g. Ex e or

Ex t terminal box).

Dust deposits > 5 mm must be removed.

A defective device must not be operated.

The head area is adequately protected against the risk of a mechanical hazard, the

connection side must be protected against the risk of a mechanical hazard, e.g., by

mounting in a housing/device with the type of protection increased safety "e" and

protection by housing "t" or by a suitable device Attachment/installation location.

The metal housing of the control and signal device must be included in a suitable

grounding/potential equalization dimension, e.g., through suitable installation or using

grounding lugs.

Operation Manual

Control and Signal Devices

AB1-[D/E/K/M/N/P/W]3-******

AB1-X3-YB002eng 31.07.2023 www.exepd.de

page 7 of 8

The control and signal device must not be exposed to any charge carrier-generating

processes and charge mechanisms (applies to emergency stop and mushroom

pushbutton).

(e.g., particles moving fast along a surface, pneumatic transport of dust and the spraying

of charges in an electrostatic coating process).

8. Assembly and installation

The control and signal device must be installed in a fixed location and secured against

loosening and twisting.

The line must be mechanically protected and firmly laid, the

Bending radii (4 x cable diameter) must be observed during installation.

The connection must be made in a safe area or in a suitable connection area (e.g. Ex e or

Ex t terminal box). The connecting cable may be shortened for the installation.

Observe the maximum connection data on the type plate.

The head area is adequately protected against the risk of a mechanical hazard, the

connection side must be protected against the risk of a mechanical hazard, e.g. by

mounting in a housing/device with the type of protection increased safety "e" and

protection by housing "t" or by a suitable device Installation in a panel, etc.

In order to discharge electrostatic charges, the control and signalling device requires a

connection to earth of max. 100 MΩ (measured with 1 kV at 50% relative humidity). This

can be done simply by installing it on conductive or dissipative bases, which in turn are

grounded. In the case of insulated installation, equipotential bonding/grounding can be

established with a lug.

The installation requirements according to EN 60079-14 must be taken into account.

9. Commissioning

Before the first start-up, the control and signal device must be checked for suitability in

the relevant zone. The values specified on the type plate must not be exceeded. If the

device is used in areas where there is a risk of dust explosion, dust deposits larger than

5mm on the top of the control and signal device are not permitted.

The installation of the control and signal device and the functional arrangement within

the system must be checked before commissioning.

It may only be used if it is undamaged and clean.

10. Operation, maintenance, and troubleshooting

The operator of an electrical system in a potentially explosive environment must keep the

equipment in good condition, operate it properly, monitor it and carry out maintenance

and repair work. See also EN 60079-17.

Maintenance work and work to eliminate faults may only be carried out by trained

specialist personnel.

Before maintenance and/or troubleshooting, the specified safety regulations must be

observed. The warnings on the devices must be observed!

Before recommissioning, the applicable laws and guidelines must be observed.

Operation Manual

Control and Signal Devices

AB1-[D/E/K/M/N/P/W]3-******

AB1-X3-YB002eng 31.07.2023 www.exepd.de

page 8 of 8

11. Installation in a housing/device of the type of

protection increased safety "e" and protection by

housing "t"

The control and signal device is suitable and approved for installation in a housing

(device) with the type of protection increased safety "eb" and protection by housing "tb".

It meets the following standards:

EN 60079-7 / device protection through increased safety "e"

EN 60079-31 / Protection by housing "t"

Use/installation must be checked separately with the housing (device) (use of the control

and signal device analogous to a component).

The operating temperature of the equipment (housing/device) must not exceed 80°C.

The conditions for using the device remain the same.

Installation in an Ex e or t housing/device

The control and signal device can be installed in a suitably approved Ex e or t housing of

Category II 2G/D.

The control and signal device must be drilled through a hole in the housing

max. Ø22.0 +0.3 mm or Ø30.0 +0.3 mm, with a suitable nut and protected against self-

loosening by the applied torque of 8Nm.

Alternatively, the control and signal device can be fastened in a metric ISO thread

M22x1.5 or M30x1.5 that is inserted in the housing/device. The tightening torque is

8Nm.

The height of the nut or the depth of the threaded hole must be dimensioned so that at

least 2 full threads are engaged (depending on the housing material, a higher number of

threads may be engaged with threaded holes).

The mounting surface of the housing must be closed and sufficiently level to be able to

ensure the IP degree of protection (at least IP64) through the installation.

The seal used has been tested for use and must not be replaced.

Thread form: metric ISO thread M22x1.5 or M30x1.5

Bore diameter: max. Ø22.0 +0.3 mm / Ø30.0 +0.3 mm

Tightening torque: 8 Nm

12. Accessories, spare parts

Locking screw

Grounding set (tab with nut)

metal nut

13. Service address

Exepd GmbH

i_PARK TAUBERFRANKEN 23

97922 Lauda-Königshofen

Germany

Phone: ++49 (0) 9343 627055-0

Fax: ++49 (0) 9343 627055-99

www.exepd.de

Table of contents