EXFO XTM-50 Series User manual

User Guide

XTM-50

Optical Tunable Filter

www.EXFO.com

Copyright Information

ii XTM-50

Copyright Information

Copyright © 2021–2023 EXFO Inc. All rights reserved. No part of this publication may be

reproduced, stored in a retrieval system or transmitted in any form, be it electronically,

mechanically, or by any other means such as photocopying, recording or otherwise,

without the prior written permission of EXFO Inc.(EXFO).

Information provided by EXFO is believed to be accurate and reliable. However, no

responsibility is assumed by EXFO for its use nor for any infringements of patents or other

rights of third parties that may result from its use. No license is granted by implication or

otherwise under any patent rights of EXFO.

EXFO’s Commerce And Government Entities (CAGE) code under the North Atlantic Treaty

Organization (NATO) is 0L8C3.

The information contained in this publication is subject to change without notice.

Trademarks

EXFO’s trademarks have been identified as such. However, the presence or absence of

such identification does not affect the legal status of any trademark.

Units of Measurement

Units of measurement in this publication conform to SI standards and practices.

Patents

The exhaustive list of patents is available at www.EXFO.com/patent.

Version number: 3.0.0.1

Information in this document applies to the XTM-50 version B.

Contents

Optical Tunable Filter iii

Contents

Copyright Information .........................................................................................................................................ii

1 Introducing the XTM-50 ........................................................................................................1

Technical Specifications .......................................................................................................................................1

XTM-50 Overview ................................................................................................................................................3

Conventions .........................................................................................................................................................5

2 Safety Information ................................................................................................................7

3 Getting Started with Your XTM-50 .......................................................................................9

Unpacking and Installing the XTM-50 ..................................................................................................................9

Connecting an Optical Source to the XTM-50 ....................................................................................................10

4 Setting the Wavelength/Frequency and FWHM Values .....................................................11

Adjusting the Central Wavelength .....................................................................................................................11

Adjusting the FWHM .........................................................................................................................................14

Reaching a Position on the Bandwidth or Wavelength Tuning Actuator ............................................................16

5 Maintenance ........................................................................................................................17

Cleaning Optical Connectors ..............................................................................................................................18

Cleaning the Cover of the XTM-50 .....................................................................................................................20

Recycling and Disposal ......................................................................................................................................20

6 Troubleshooting ..................................................................................................................21

Displaying the User Documentation ..................................................................................................................21

Contacting the Technical Support Group ...........................................................................................................21

Transportation ...................................................................................................................................................21

7 Warranty ..............................................................................................................................23

General Information ..........................................................................................................................................23

Gray Market and Gray Market Products .............................................................................................................23

Liability ..............................................................................................................................................................24

Exclusions ..........................................................................................................................................................24

Certification .......................................................................................................................................................24

Service and Repairs ............................................................................................................................................25

EXFO Service Centers Worldwide .......................................................................................................................26

Optical Tunable Filter 1

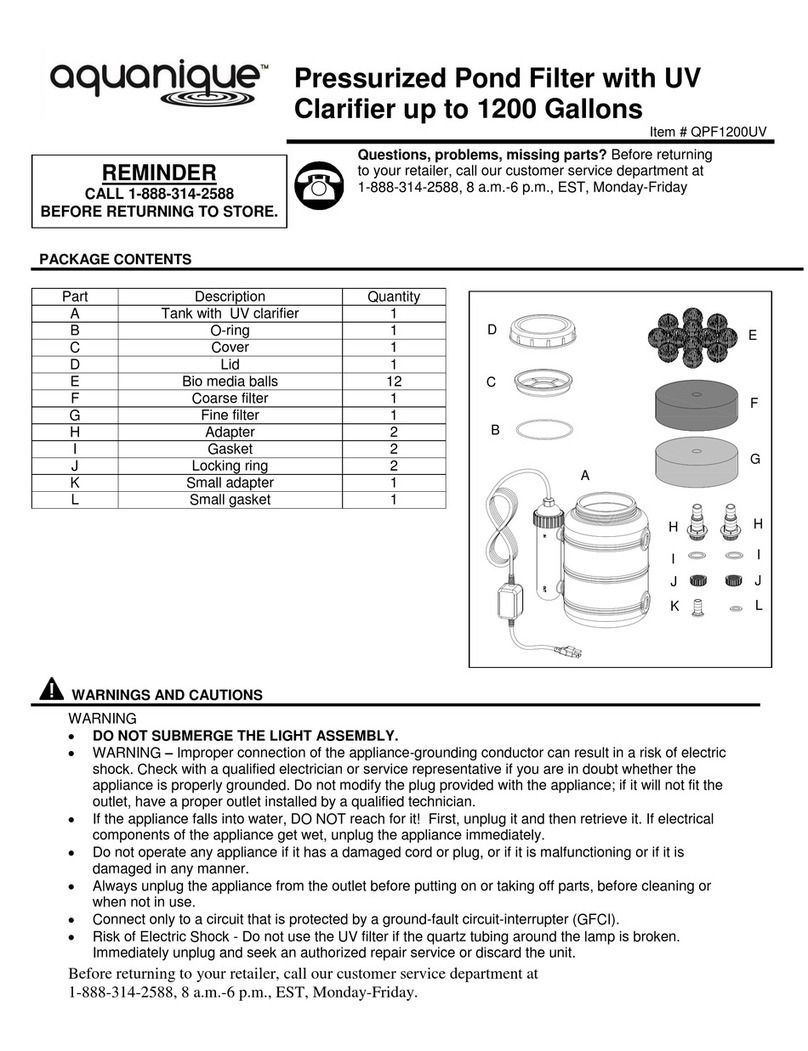

1 Introducing the XTM-50

The XTM-50 is a reliable optical tunable filter that features wavelength and bandwidth

tuning. The large wavelength range, the narrow FWHM and the flat-top shape ensure a

clean extraction of the optical signal. It is designed for closely-spaced channel selection and

extraction in DWDM applications.

The XTM-50 is based on the use of a reflection diffraction grating mounted in a

Littman-Metcalf configuration.

When an optical signal is detected at the XTM-50 input port, the input wave is directed

towards the output port after passing through the XTM-50 monochromator.

Technical Specifications

The following table lists the technical specifications of the XTM-50 models.

All optical specifications apply at constant temperature.

IMPORTANT

The following technical specifications can change without notice. The information

presented in this section is provided as a reference only. To obtain this product’s

most recent technical specifications, visit the EXFO Web site at www.exfo.com.

Standard Ultrafine O-bandaWide

Optical specifications

Wavelength range 1450–1650 nm 1480–1620 nm 1260–1360 nm 1525–1610 nm

Wavelength resolution 5 pmb5 pmb5 pmb5 pmb

Minimum bandwidth

(FWHM)

50 pm

(6.25 GHz)

32 pm

(4 GHz)

50 pm

(8 GHz)

50 pm

(6.25 GHz)

Maximum bandwidth

(FWHM)

950 pm

(120 GHz)

650 pm

(80 GHz)

900 pm

(160 GHz)

5000 pm

(625 GHz)

Bandwidth resolution 1 pm 1 pm 1 pm 0.3 % of FWHM

typical

Filter edge gradient 500 dB/nm

typicalc

800 dB/nm

typical

500 dB/nm

typicalc

500 dB/nm

typicald

Insertion loss 5 dB (4.5 dB

typical)e,f

5 dB (4.0 dB

typical)f,g

5 dB (4.5 dB

typical)f,h

5 dB (4.5 dB

typical)i,j

Flatness 0.2 dBk0.2 dBl0.3 dBk,m 0.2 dBn

Polarization dependent

loss ±0.2 dBe±0.2 dBg±0.2 dBh±0.2 dBi

Out-of-band

suppression (crosstalk)

40 dB (60 dB

typical)o

40 dB (50 dB

typical)o

40 dB (60 dB

typical)o

40 dB (45 dB

typical)o

Introducing the XTM-50

2XTM-50

Technical Specifications

Interfaces

Optical fiber type SMF or PMF SMF

Connector type FC/PC or FC/APC

Operating conditions

Maximum optical input

power

30 dBm 27 dBm

Temperature range 15° to 35°C, indoor use only

Storage temperature -20°C to 60°C

Maximum relative

humidity

80 % for temperatures up to 31°C decreasing linearly to 50 %

relative humidity at 40°C

Altitude 2000 m (maximum operating)

Size and Weight

Dimensions (W x D x H) 193 mm x 231 mm x 164 mm (7.6 in x 9.1 in x 6.4 in)

Weight 3.5 kg (7.7 lbs)

a Specifications apply for wavelengths not equal to any water absorption line.

b Typical, related to user dexterity.

c From -3 and -40 dB for FWHM <800 pm.

d Between -3 and -40 dB. Typically 550 dB/nm @ FWHM = 50 pm,

450 dB/nm @ FWHM = 1 nm, 225 dB/nm @ FWHM = 5 nm.

e From 1500 to 1600 nm & FWHM >100 pm.

f At lowest FWHM the insertion loss is 7 dB typical.

g From 1500 to 1600 nm & FWHM >60 pm.

h From 1280 to 1340 nm & FWHM >100 pm.

iForFWHM>100pm.

j At lowest FWHM the insertion loss is < 7.0 dB.

k Centered width of FWHM - 150 pm. For 150 pm < FWHM < 650 pm.

l Centered width of FWHM - 100 pm. For 100 pm < FWHM < 500 pm.

m From 1280 to 1340 nm.

n Centered width of FWHM - 150 pm. For 150 pm < FWHM < 2000 pm.

o Measured 1 nm away from the -3 dB points.

Standard Ultrafine O-bandaWide

Introducing the XTM-50

Optical Tunable Filter 3

XTM-50 Overview

XTM-50 Overview

Handle

The handle bar enables you to carry the XTM-50.

Micrometer Actuators

Two high resolution micrometer actuators enable you to perform wavelength and

bandwidth tuning.

The screw located on top of the actuators enable you to lock the actuator at the wanted

setting.

³The bandwidth actuator is composed of two graduated scales:

³On the sleeve: 13 mm stroke with 0.5 mm graduation interval.

³On the thimble (rotary part): 250 μm by turn, with 5 μm graduation interval.

³The wavelength actuator includes coarse and fine position adjustments, with four

graduated scales:

³Coarse adjustment:

On the sleeve: 13 mm stroke with 0.5 mm graduation interval.

On the thimble (rotary part): 0.5 mm by turn, with 0.01 mm graduation interval.

³Fine adjustment:

On the sleeve: 200 μm stroke with 25 μm graduation interval.

On the thimble: 25 μm by turn, with 0.5 μm graduation interval.

For more details on how to adjust wavelength and FWHM, see Setting the

Wavelength/Frequency and FWHM Values on page 11.

Connector’s

drawer

Handle

Drawer screw

Lock

Wavelength actuator:

Fine adjustment

Wavelength actuator:

Coarse adjustment

Bandwidth

actuator

Optical

connectors

Introducing the XTM-50

4XTM-50

XTM-50 Overview

Optical Connectors

The two following optical connectors, protected by a dust cap, are located on the front

panel:

³Input: channel filter input port.

³Output: channel filter output port.

The two optical connectors are mounted on a drawer, which enables you to access the

internal optical connectors for cleaning (see Cleaning Optical Connectors on page 18).

Retractable Leg

The retractable leg enable you to tilt the XTM-50 upward for convenient purpose, so that it

stands on both front legs and the rear feet (see Unpacking and Installing the XTM-50 on

page 9).

Labels and markings

Label Description

Identification of the product.

Indicates serial number, model, options (if any) and date

of manufacture.

Warranty seal.

The XTM-50 cover must not be open, otherwise the

warranty is not valid anymore.

MANUFACTURED / FABRIQUE

OPTIONS

MODEL / MODELE

Made in France

xxxx-xx

XTM-50

xxxxxxxxxxxx

SERIAL NUMBER / NUMERO DE SERIE

Introducing the XTM-50

Optical Tunable Filter 5

Conventions

Conventions

Before using the product described in this guide, you should understand the following

conventions:

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury. Do not proceed unless you understand and meet the

required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. Do not proceed unless you understand and meet the

required conditions.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in

component damage. Do not proceed unless you understand and meet the required

conditions.

IMPORTANT

Refers to information about this product you should not overlook.

XTM-50 7

2 Safety Information

WARNING

Do not install or terminate fibers while a light source is active. Never look directly

into a live fiber and ensure that your eyes are protected at all times.

WARNING

The use of controls, adjustments and procedures, namely for operation and

maintenance, other than those specified herein may result in hazardous radiation

exposure or impair the protection provided by this unit.

WARNING

If the equipment is used in a manner not specified by the manufacturer, the

protection provided by the equipment may be impaired.

WARNING

Use only accessories designed for your unit and approved by EXFO. For a complete

list of accessories available for your unit, refer to its technical specifications or

contact EXFO.

IMPORTANT

Refer to the documentation provided by the manufacturers of any accessories used

with your EXFO product. It may contain environmental and/or operating conditions

limiting their use.

IMPORTANT

When you see the following symbol on your unit , make sure that you refer

to the instructions provided in your user documentation. Ensure that you

understand and meet the required conditions before using your product.

IMPORTANT

When you see the following symbol on your unit , it indicates that the unit is

equipped with a laser source, or that it can be used with instruments equipped

with a laser source. These instruments include, but are not limited to, modules and

external optical units.

IMPORTANT

Other safety instructions relevant for your product are located throughout this

documentation, depending on the action to perform. Make sure to read them

carefully when they apply to your situation.

Optical Tunable Filter 9

3 Getting Started with Your XTM-50

This section explains how to properly install and connect your XTM-50.

Unpacking and Installing the XTM-50

The XTM-50 is a bench-top instrument designed for indoor use only, and is not dedicated to

wet locations. It is designed for use either in the horizontal or tilted position.

To unpack and install the XTM-50:

1. Open the package with care and remove the protective foam.

2. Pull out the XTM-50 vertically from its packaging.

3. Set the XTM-50 on a flat stable surface free of excessive vibration.

4. Place the XTM-50 in the wanted operating position as illustrated in the following figure:

5. To tilt the XTM-50 upward, deploy the two retractable legs located underneath it.

CAUTION

³Do not expose the XTM-50 to rain or excessive moisture.

³Do not install the XTM-50 near flammable gases or fumes.

IMPORTANT

When unpacking, handle the device with care and do not damage the original

shipping container in case the XTM-50 needs to be returned to EXFO.

Getting Started with Your XTM-50

10 XTM-50

Connecting an Optical Source to the XTM-50

Connecting an Optical Source to the XTM-50

To connect an optical source to the XTM-50:

Remove the protective cap from the IN and OUT connectors and connect the appropriate

jumper corresponding to the connector type mounted on your product, as indicated next to

the connectors (see XTM-50 Overview on page 3).

CAUTION

³Make sure you use the appropriate connector type, corresponding to the one

mounted on your XTM-50 (see Technical Specifications on page 1 for available

models).

³Make sure optical connectors are perfectly clean. It is essential to achieve

optimum system performance (see Cleaning Optical Connectors on page 18).

³To prevent premature failure of the XTM-50 optical connectors due to frequent

connections, always keep a fiber-optic jumper cable connected to the XTM-50

optical port while you use the jumper's free end to connect to other devices.

IMPORTANT

Keep protective caps on optical connectors when not in use.

Optical Tunable Filter 11

4 Setting the Wavelength/Frequency

and FWHM Values

Adjusting the Central Wavelength

The wavelength actuator enables you to adjust the wavelength with coarse and fine

adjustment positions.

³Coarse adjustment:

On the coarse adjustment screw, the scale on the thimble is graduated from 0 to 500.

One complete revolution of the thimble reaches one graduated marking on the sleeve.

³On the sleeve: 13 mm stroke with 0.5 mm graduation interval.

1 scale graduation corresponds to:

XTM-50 Standard: 11 nm (typ.)

XTM-50 Ultrafine: 6.5 nm (typ.)

XTM-50 O-band: 12 nm (typ.)

XTM-50 Wide: 11 nm (typ.)

³On the thimble (rotary part): 0.5 mm by turn, with 0.01 mm graduation interval.

1 scale graduation corresponds to:

XTM-50 Standard: 220 pm (typ.)

XTM-50 Ultrafine: 130 pm (typ.)

XTM-50 O-band: 240 pm (typ.)

XTM-50 Wide: 220 pm (typ.)

IMPORTANT

When using thimbles, account for any backlash in the system: always use the

thimble in the same rotating direction.

Coarse adjustment, thimble scale

Coarse adjustment, sleeve scale

Fine adjustment, sleeve scale

Fine adjustment, thimble scale

Setting the Wavelength/Frequency and FWHM Values

12 XTM-50

Adjusting the Central Wavelength

³Fine adjustment:

On the fine adjustment screw, the scale on the thimble is graduated from 0 to 30. One

complete revolution of the thimble reaches one graduated marking on the sleeve.

³On the sleeve: 200 μm stroke with 25 μm graduation interval.

1 scale graduation corresponds to:

XTM-50 Standard: 550 pm (typ.)

XTM-50 Ultrafine: 325 pm (typ.)

XTM-50 O-band: 600 pm (typ.)

XTM-50 Wide: 550 pm (typ.)

³On the thimble: 25 μm by turn, with 0.5 μm graduation interval.

1 scale graduation corresponds to:

XTM-50 Standard: 11 pm (typ.)

XTM-50 Ultrafine: 6.5 pm (typ.)

XTM-50 O-band: 12 pm (typ.)

XTM-50 Wide: 11 pm (typ.)

IMPORTANT

Modifying the FWHM can slightly alter the central wavelength setting. So you may

need to re-adjust the central wavelength after FWHM change.

Setting the Wavelength/Frequency and FWHM Values

Optical Tunable Filter 13

Adjusting the Central Wavelength

To tune the central wavelength:

1. Move the Wavelength tuning coarse thimble as follows:

³To increase the central wavelength from lower wavelength to higher wavelengths,

turn the thimble clockwise (from high to low values).

³To decrease the central wavelength from higher wavelength to lower wavelengths,

turn the thimble counterclockwise (from low to high values).

2. To finely adjust the central wavelength value, move the Wavelength tuning fine thimble

as follows:

³To increase the central wavelength from lower wavelength to higher wavelengths,

turn the thimble clockwise (from high to low values).

³To decrease the central wavelength from higher wavelength to lower wavelengths,

turn the thimble counterclockwise (from low to high values).

3. Tighten the lock screw (see XTM-50 Overview on page 3) to lock the central

wavelength setting.

4. If you had previously adjusted the FWHM, re-adjust it as it may have been slightly

altered by the central wavelength change.

Setting the Wavelength/Frequency and FWHM Values

14 XTM-50

Adjusting the FWHM

Adjusting the FWHM

The bandwidth actuator is graduated from 0 to 250. Two complete revolution of the thimble

reach one graduated marking on the sleeve.

³On the sleeve: 13 mm stroke with 0.5 mm graduation interval.

1 scale graduation corresponds to:

³XTM-50 Standard: 105 pm (typ.)

³XTM-50 Ultrafine: 68 pm (typ.)

³XTM-50 O-band: 96 pm (typ.)

³XTM-50 Wide: not linear, see the following figure.

³On the thimble (rotary part): 250 μm by turn, with 5 μm graduation interval.

1 scale graduation corresponds to:

³XTM-50 Standard: 0.21 pm (typ.)

³XTM-50 Ultrafine: 0.14 pm (typ.)

³XTM-50 O-band: 0.19 pm (typ.)

³XTM-50 Wide: not linear, see the following figure

IMPORTANT

Modifying the central wavelength can slightly alter the FWHM. So you may need to

re-adjust the FWHM after central wavelength change.

Thimble scale

Sleeve scale

FWHM (pm)

Actuator Graduation (sleeve scale, typical values) - Model: XTM-50 Wide only

Setting the Wavelength/Frequency and FWHM Values

Optical Tunable Filter 15

Adjusting the FWHM

To tune the bandwith:

1. Move the Bandwidth tuning actuator as follows:

³To increase the FWHM, turn the actuator clockwise (from high to low values)

³To decrease the FWHM, turn the actuator counterclockwise (from low to high

values).

2. Tighten the lock screw (see XTM-50 Overview on page 3) to lock the FWHM setting.

3. If you had previously adjusted the central wavelength, re-adjust it as it may have been

slightly altered by the FWHM change.

CAUTION

To avoid damaging your XTM-50, do not turn the bandwidth actuator beyond the 0

graduation marked on the sleeve.

Setting the Wavelength/Frequency and FWHM Values

16 XTM-50

Reaching a Position on the Bandwidth or Wavelength Tuning Actuator

Reaching a Position on the Bandwidth or Wavelength

Tuning Actuator

The Acceptance Test Report delivered with your instrument indicates the actuator position

(in mm) of the central wavelength and FWHM on your XTM-50.

This section explains how to adjust the actuators to reach the wanted position.

Reaching a Position on the Bandwidth Tuning Actuator

The bandwidth actuator is composed of two graduated scales:

³On the sleeve: 13 mm stroke with 0.5 mm graduation interval.

³On the thimble (rotary part): 250 μm by turn, with 5 μm graduation interval.

To reach a graduated position on the actuator, you must add both scale values.

Example:

To reach the value of 7.275 mm, proceed as follows:

1. Align value 0 of the thimble to value 7 of the scale on the sleeve.

2. Make a full counterclockwise revolution of the thimble to add 0.250 mm.

3. Turn the thimble counterclockwise to add 0.005 mm.

Reaching a Position on the Wavelength Tuning Actuator

The wavelength actuator enables coarse and fine adjustments.

³Coarse adjustment:

³On the sleeve: 13 mm stroke with 0.5 mm graduation interval.

³On the thimble (rotary part): 0.5 mm by turn, with 0.01 mm graduation interval.

³Fine adjustment:

³On the sleeve: 200 μm stroke with 25 μm graduation interval.

³On the thimble: 25 μm by turn, with 0.5 μm graduation interval.

To reach a graduated position on the actuator, you must add all four scale values.

Example:

To reach the value of 8.852 mm you can use different combinations; the following

procedure explains the "8.7+0.152" combination:

1. On the fine adjustment screw, align value 0 of the rotary thimble to value 100 of the

sleeve scale.

2. On the coarse screw:

2a. Align value 0 of the thimble to value 8.5 of the sleeve scale.

2b. Turn the thimble counterclockwise to reach value 200, which adds 0.200 mm.

3. On the fine screw:

3a. Align value 0 of the thimble to value 150 of the of the sleeve scale.

3b. Turn the thimble counterclockwise to add 4 graduations on the thimble scale

(which is 0.002 mm).

Other manuals for XTM-50 Series

2

Table of contents

Other EXFO Water Filtration System manuals

Popular Water Filtration System manuals by other brands

NSF

NSF RinseWell Smart Eco Rinse 4000 Series User manual and installation guide

Culligan

Culligan Iron-Cleer owner's guide

BWT

BWT Infinity M Installation and operating manual

Crystal Quest

Crystal Quest 200 Installation and maintenance instructions

First Water

First Water FW-120-M Operation manual

AquaSure

AquaSure Nano Ro user manual