Exhausto NFO Sinus Optimal User manual

NFODrivesAB20211201016‐2QuickInstallationGuide

Quick Installation Guide

NFO Sinus Optimal

1 Mechanical installation

When unpacking the inverter, carefully inspect the product and make sure it has not been damaged during

transportation. An inverter with cracks, dents or other visual damage shall not be installed.

The inverter must not be installed so that outlet air from another inverter or other equipment blows directly

into the inverter air intake. A minimum of 80 mm clearance must be kept above and below the inverter.

All terminals are accessed by opening the plastic cover. To be able to use the snap-and-hold-open

functionality of the cover, a free space of 200 mm is required above the inverter.

During installation it is important that no foreign objects, such as cable strands or screws, fall into the

inverter as a short circuit may occur. Drilling in chassis or cover is not allowed.

After installation, make sure all grommets at the cable entries are mounted and that the cover is closed and

secured with its screws to avoid access to dangerous voltages.

1.1 Mounting

Unscrew the two lower captive screws and loosen the inverter from the backplate.

Fasten backplate to a vertical surface using four screws. Make sure that the top mounting screws are

sufficiently strong to hold the entire weight of the inverter.

Place the inverter on the backplate by mating the chassis cut-out to the backplate hooks. Tighten the lower

captive screws on both sides.

3006468-2022-04

NFODrivesAB20212201016‐2QuickInstallationGuide

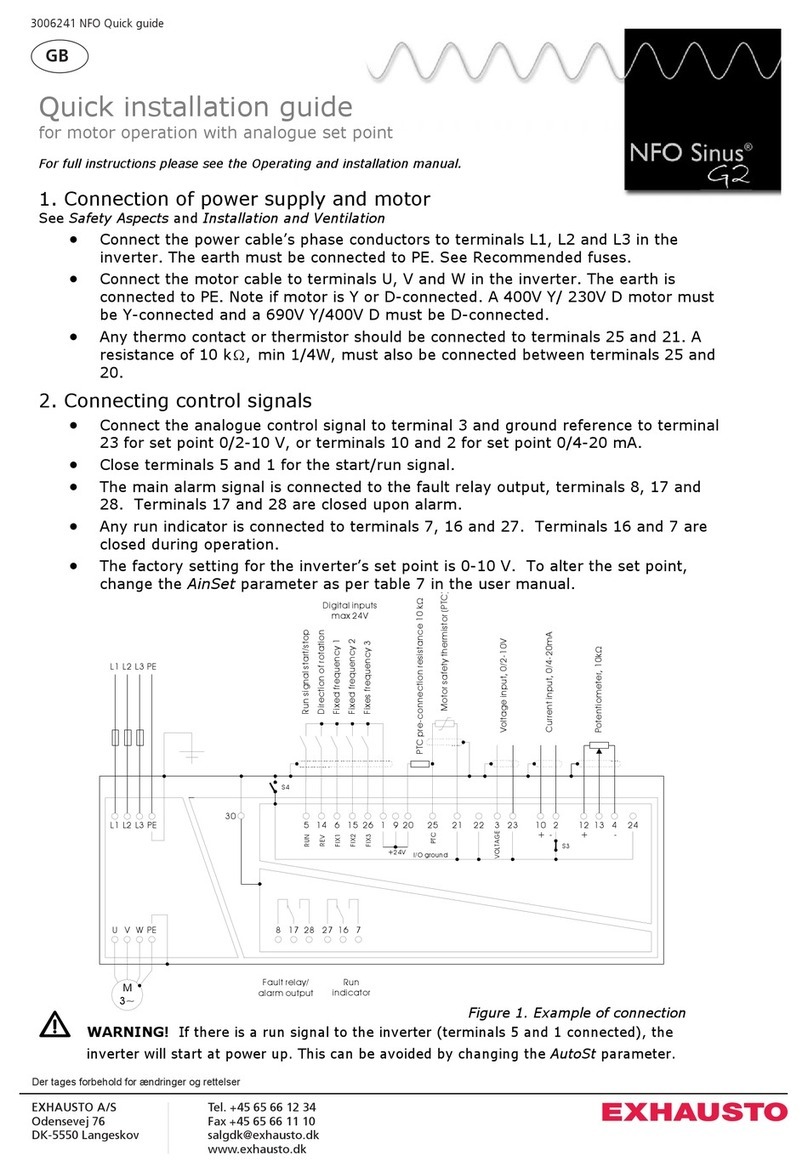

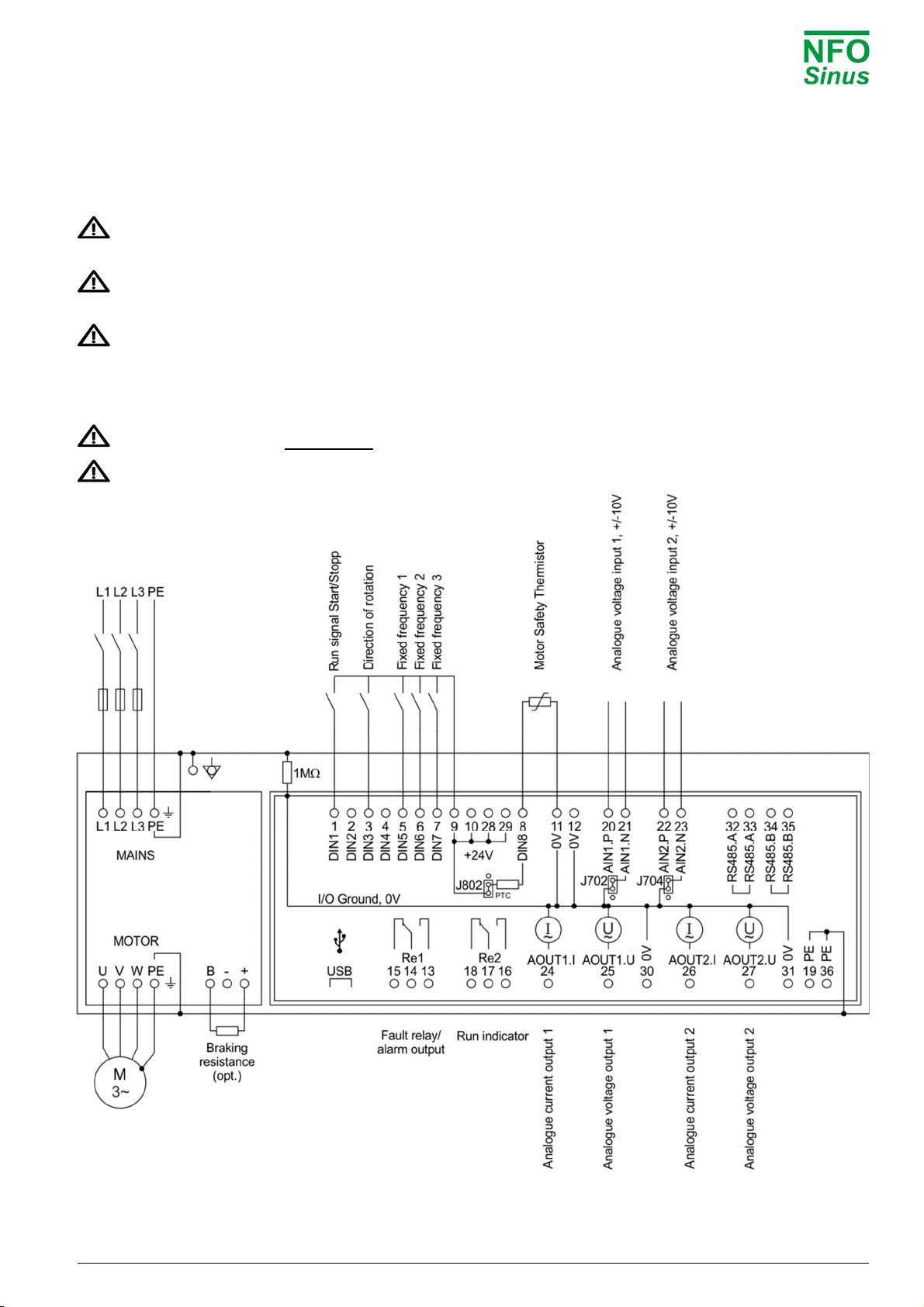

2 Electrical installation

Connect mains power to terminals L1, L2, L3 and PE.

Connect motor cable to terminals U, V, W and PE using standard unshielded cable.

Never install contactors or switches between the inverter (terminals U, V and W) and the motor that

intentionally or unintentionally may be used to disconnect the motor from inverter output.

A motor safety switch can be mounted between the inverter (terminals U, V and W) and the motor, but it

must only be operated when the motor is not running.

First time powered up, the installer must select application, enter motor name plate data, and perform a

motor tuning (see next section).

Connect/install the necessary low voltage signalling that is required for your application, e.g. a run signal

for start/stop, analog input for setpoint, communication, etc.

Make sure run signal is not activated until installer has completed the setup of the inverter.

Make sure the low voltage signal wires have sufficient isolation when passing nearby power cables.

3006468-2022-04

NFODrivesAB20213201016‐2QuickInstallationGuide

3 Initial setup and tuning

3.1 Select application

First time powered up after installation, or after performing a factory reset of parameters, the installer will be

prompted to select application type for the inverter.

The purpose of selecting application is to preset acceleration and deceleration ramps to a value suitable for

the application in question.

Please note that the preset values are a merely suggested general values. Depending on other operating

conditions, the installer may have to further adjust the accel/decel ramps.

Application Description

Pump Set acceleration and deceleration ramps suitable for general pump applications

Ventilation / other Set acceleration and deceleration ramps suitable for ventilation fan applications

OEM vacuum pump To be used only with OEM vacuum pump application

3.2 Enter motor data and perform tuning

First time powered up after installation, or after performing a factory reset of parameters, the installer must

enter the motor name plate data. The motor data is entered in the parameter group Motor and consists of

P-nom, U-nom, f-nom, N-nom, I-nom and cos . The data can be read from the motor name plate.

After motor data is entered, the installer must perform a motor tuning during which the inverter measures

and calculates the electrical properties of the motor. The tuning command is located in parameter group

Motor, adjacent to the motor data values. Select ‘Full’ tuning for most thorough measurement.

Until a correct tuning is performed, the inverter will toggle the status message ‘Not Tuned’ on the display.

Please refer to the Operating and Installation Manual for a complete description of the tuning commands.

3.3 Check rotation direction

After selecting application, entering motor data and performed tuning, it may be necessary to check/verify

correct rotation direction of the rotor.

This can be done by starting the motor at a low speed in manual mode.

Manual mode is selected when lower right corner of display reads ‘Manual’.

Pressing the ‘MAN / AUTO’ button toggles between manual and auto mode.

Pressing ‘START’ button in manual mode starts the motor.

Direction of rotation can be changed by changing the parameter ‘Phase order’ in parameter group ‘Run’.

The motor must be stopped when changing this parameter.

Default setpoint frequency in manual mode is 10.0 Hz. If necessary, increment or decrement setpoint using

the arrow up/down buttons.

When ready, press ‘STOP’ and then press the ‘MAN / AUTO’ button to select ‘Auto’mode. The inverter is

now ready to start operating according to the connected control signals.

3006468-2022-04

NFODrivesAB20214201016‐2QuickInstallationGuide

Keyboard and menu summary

Button Function

Enter into parameter or parameter-group.

Save parameter.

Enter/toggle between normal screen and setup

menu tree.

Leave parameter, parameter-group or leave

parameter unsaved.

Toggle Operating mode between Manual and Auto.

Starts motor in Auto mode if Run signal active.

Starts motor in Manual mode.

Stops motor in all modes.

NOTE: A bus master may start motor at any time

Increase parameter when changing.

Moves between parameter-groups or parameters.

Decrease parameter when changing.

Moves between parameter-groups or parameters.

Motor Ramp Run Control Freq. Speed PI-reg Output Comm. Status Temp. Display Count. Version Error

P-Nom Accel

Time

Phase

orde

r

Control

mode

Operate

mode

Operate

mode

Operate

mode

Relay 1

Mode

RS485

bustype U-rms Motor

temp

Display

par.1

Operate

time

CoProc

version Error-log

U-Nom Decel

Time

Stop

mode

Auto-

start FixFrq1 FixSpd1 FixReg1 Relay 1

Freq

RS485

add

r

I-rms Power

module

Display

par.2

Run

time

DSP

version

Restart

Delay

f-Nom Ramp

Brkpoint

Energy

save

A.input

1 type FixFrq2 FixSpd2 FixReg2 Relay 2

Mode

RS485

baud P-out COP

temp

Display

par.3

Brake

time

GUI

version

Reset

Time

N-Nom Alt.

Accel

Pwr On

delay

A.input

2 type FixFrq3 FixSpd3 FixReg3 Relay 2

Freq

RS485

cha

r

PF Heat

sink 1

Bklight

level

Cur.lim

time

Prod

date AC Fail

I-Nom Alt.

Decel

Run

delay

D.input

config FixFrq4 FixSpd4 FixReg4 Aout 1

Mode

RS485

timeout DC Link Heat

sink 2

Bklight

timeout

DC low

time

Serial

numbe

r

Temp Hi

cos Stop

delay FixFrq5 FixSpd5 FixReg5

Aout 1

Max

RS485

autostop

Brake

chop

Heat

sink 3

Menu

readonly

Start

count

PTC

Temp

Tuning DC

brake FixFrq6 FixSpd6 FixReg6

Aout 2

Mode

RS485

failsafe

Stator

freq.

Heat

sink 4

Alarm

count

Over

load

R-stator Kp

speed FixFrq7 FixSpd7 FixReg7

Aout 2

Max

USB

bustype

Rotor

freq.

Fan 1

volt

Output

Energy Ain Fail

R-rotor Ti

speed

A.input

min freq

A.input

min rpm

Setpoint

min

Analog

1 out

USB

add

r

Control

freq.

Fan 2

volt

Total

Energy DC Low

L-main Sleep

freq.

A.input

max freq

A.input

max rpm

Setpoint

max

Analog

2 out

USB

timeout

Rotor

speed

Fan 3

volt DC High

Sigma Bypass

freq.

Actual

min

USB

autostop

Control

speed

Fan 4

volt

GND

Fail

I-magn Bypass

bandw.

Actual

max

ABCC

interface

Actual

Torque

EXT

24V

Short

Circuit

I-limit Boost

time

Setp

min limit

ABCC

bustype

Control

Torque

USB

5V

Imagn

Low

Pole

Count

Boost

level

Setp

max limit

ABCC

add

r

Actual

PI-reg

Current

Low

T-nom Reg

sign

ABCC

timeout

Setpoint

Pi-reg

Current

High

Tuned

status

Reg

Kp

ABCC

autostop Ain 1 V Current

Limit

Reg

Ti

Auto

reset Ain1 mA Run Fail

Min freq Ain 2 V

Max freq Ain2 mA

Unit Keybrd.

Off limit Terminal

On limit

3006468-2022-04

Other Exhausto DC Drive manuals

Popular DC Drive manuals by other brands

Seagate

Seagate ST3780A product manual

YASKAWA

YASKAWA LA500 Installation and operation instruction

SEW-Eurodrive

SEW-Eurodrive Movidrive MDX61B System manual

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 750 Series Reference manual

Rockwell Automation

Rockwell Automation Allen-Bradley 1397 user manual

VST

VST SuperDisk Drive user guide