QUICK START COMMISSIONING GUIDE

UNIDRIVE SP

Winding/unwinding solution with analogue references

4

3787 en - 03.2006 / a

LEROY-SOMER

1 - GENERAL INFORMATION

The SP EDL ANA solution offers all winding/

unwinding functions maintaining a constant

tension of the product.

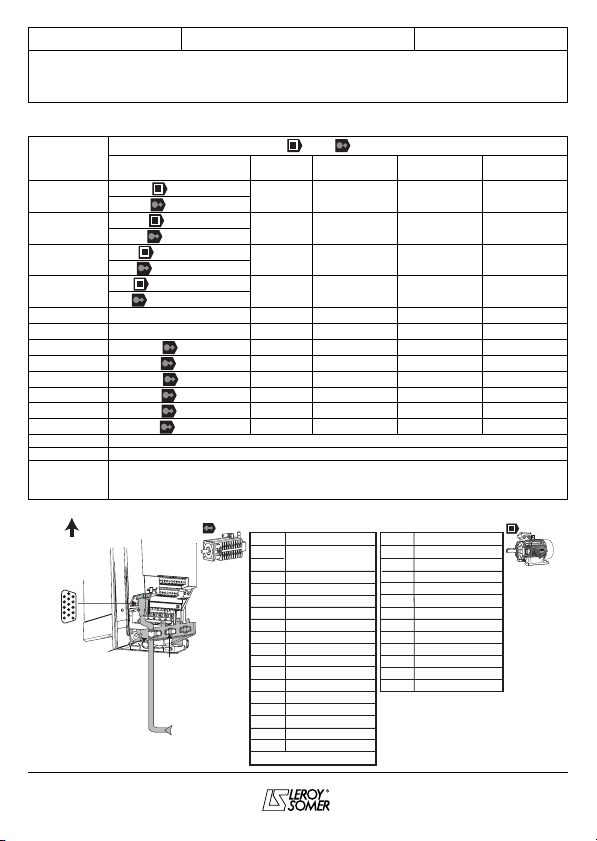

It comprises :

- a UNIDRIVE SP variable speed drive,

- a SM-EDL ANA module.

Note : If the Winding-unwinding solution is

managed by a field bus (use of a SM-Field

bus module), see the complete manual that

may be created from the CD Rom supplied

together with the drive.

1.1 - Operating principle

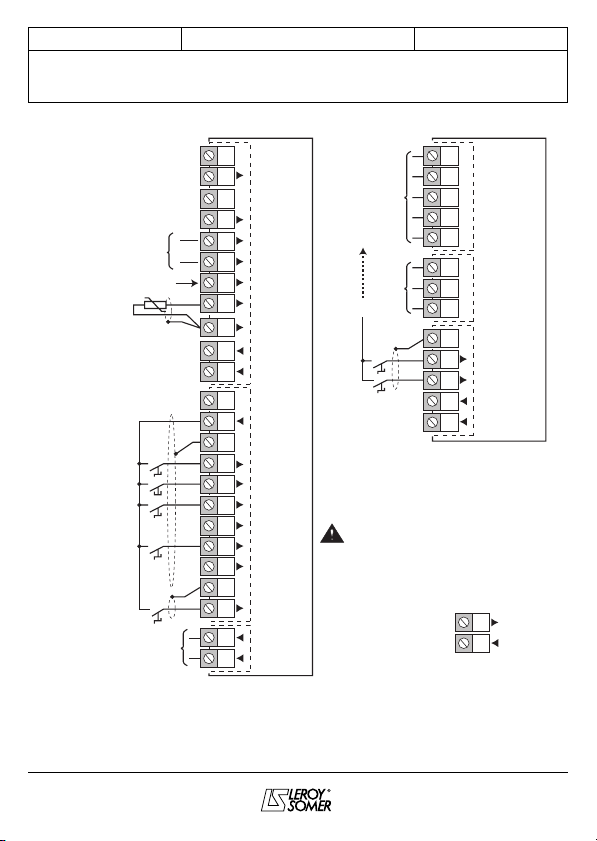

The system operates exclusively in closed

loop and it must be used with an asynchro-

nous or with a synchronous motor with all ty-

pes of encoders.

With an axial drive, in order to preserve a

constant tension on the product, irrespective

of the coil diameter, it is necessary that the

torque produced by the motor increases pro-

portionally to the radius.

The tension reference given by a potentio-

meter is applied through an analogue input.

By means of the line speed applied on ano-

ther analogue input and of the angular speed

issued from the encoder, a radius calculation

is made.

The tension reference multiplied by the ra-

dius determines the torque that the motor

must supply.

To refine the adjustment of the tension on the

product, it is possible to compensate the los-

ses without load (mechanical losses) and the

inertia during the transient periods.

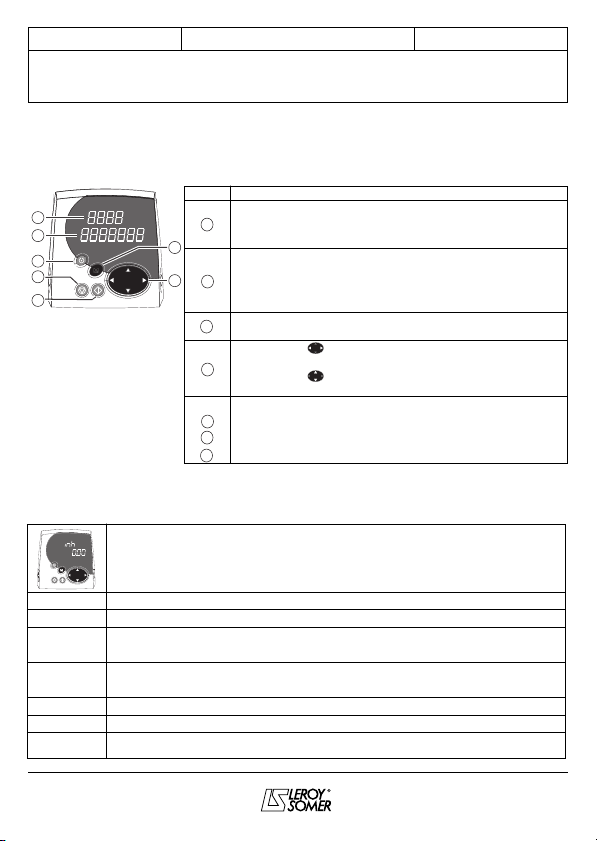

1.2 - Operating modes :

- speed adjustment : product threading,

- traction adjustment : winding or unwinding.