UnitswithoutROPSskiptothe“AllUnits”section

tocontinueinstructions.

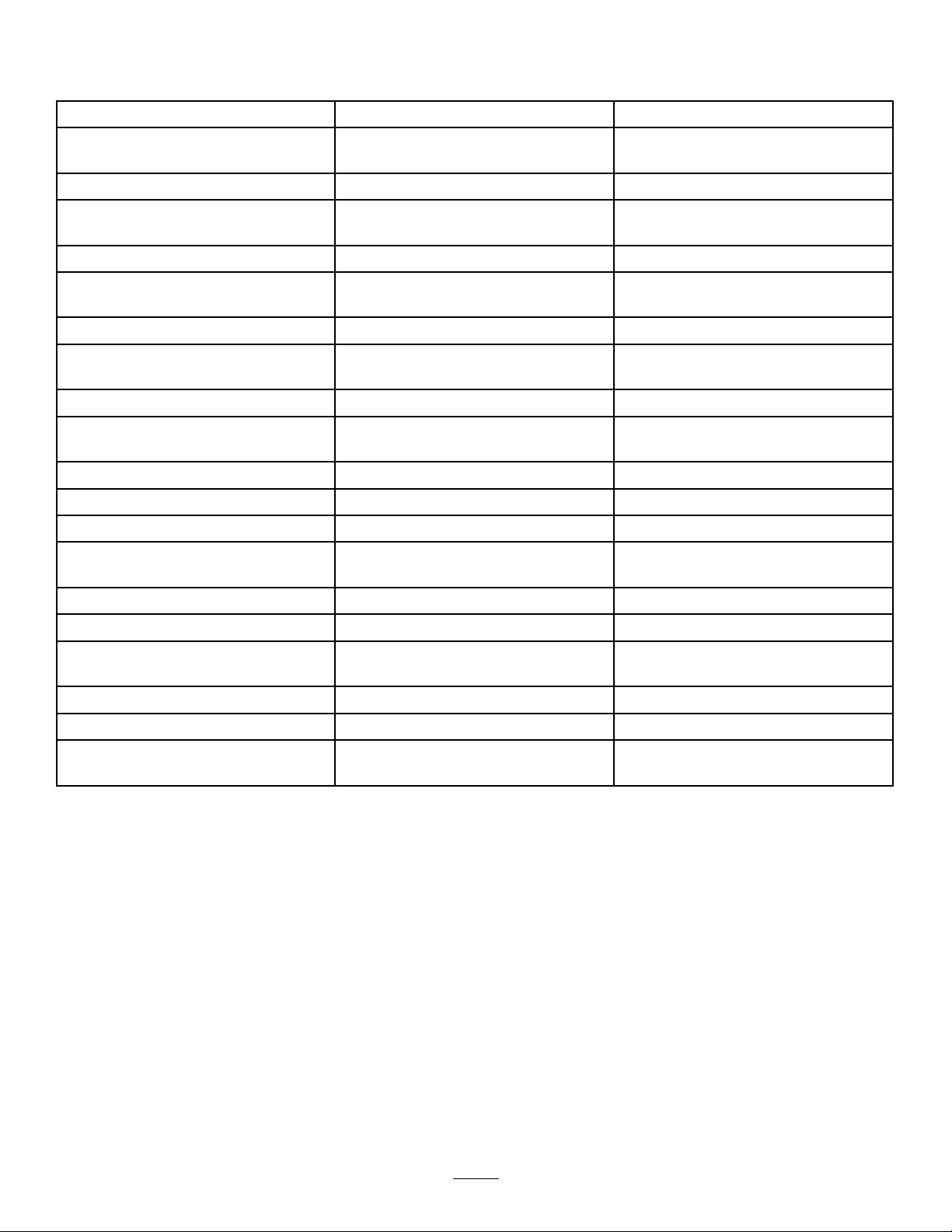

Figure7

1.Lowerrollbartubes5.3/8-16inchthinnylocnut

(item46)

2.Alignspacersandtapeto

frame.

6.3/8-16x41/2inch

capscrew

3.Raiserearofunithereand

supportwithjackstands.

7.3/8-16x11/2inch

capscrew

4.Wheelnuts

8.Alignlowerrollbartubesalongwheelmotor

channelsasshowninFigure7.

9.Looselyinstallthelowerrollbarhardwaretothe

tubesinthefollowingorder(referenceFigure7for

alignmentandinstallationinstructionsbelow).

10.Discardthe3/8-16inchregularnylocnutprovided

withtheLazerZunitorROPSkitandreplacewith

the3/8-16inchthinnylocnut(item46)provided

withthisUltraVac.

11.Installthe3/8-16inchthinnylocnut(item46)anda

springdiscwashertotheboltprotrudingfromthe

wheelmotorchannelasshown.

Note:Besurethespringdiscwasherconeis

installedtowardsthenylocnut.

UnitswithSerialNumber399,999andlowerrequire

useofa3/8-16x11/2inchscrew,springdisc

washerandwhizlocknut.Theseitemsareincluded

withROPSkitnumberFRPSLZ.

Note:On60inchunits,thelowerboltonthe

wheelchannelisbestinstalledbypositioningthenut

behindtheholeusingadeepsocketandturningthe

boltthroughtheholeintothenut.

12.Installone3/8-16x11/2inchhexcapscrew,spring

discwasherand3/8-16inchwhizlocknuttothetop

frontholeasshown(itwillbenecessarytopushthe

capscrewthroughthemaskingtapeappliedinstep

7).

13.Installone3/8-16x11/2hexcapscrew,springdisc

washerand3/8-16inchwhizlocknuttothetop

rearholeasshown(itwillbenecessarytopushthe

capscrewthroughthemaskingtapeappliedinstep

7).

Installone3/8-16x41/2hexcapscrew,springdisc

washerand3/8-16inchwhizlocknutthroughthe

toptubeasshown(itwillbenecessarytopushthe

capscrewthroughthemaskingtapeappliedinstep

7).

Note:Besurethespringdiscwasherconeis

installedtowardstheheadofallcapscrews.

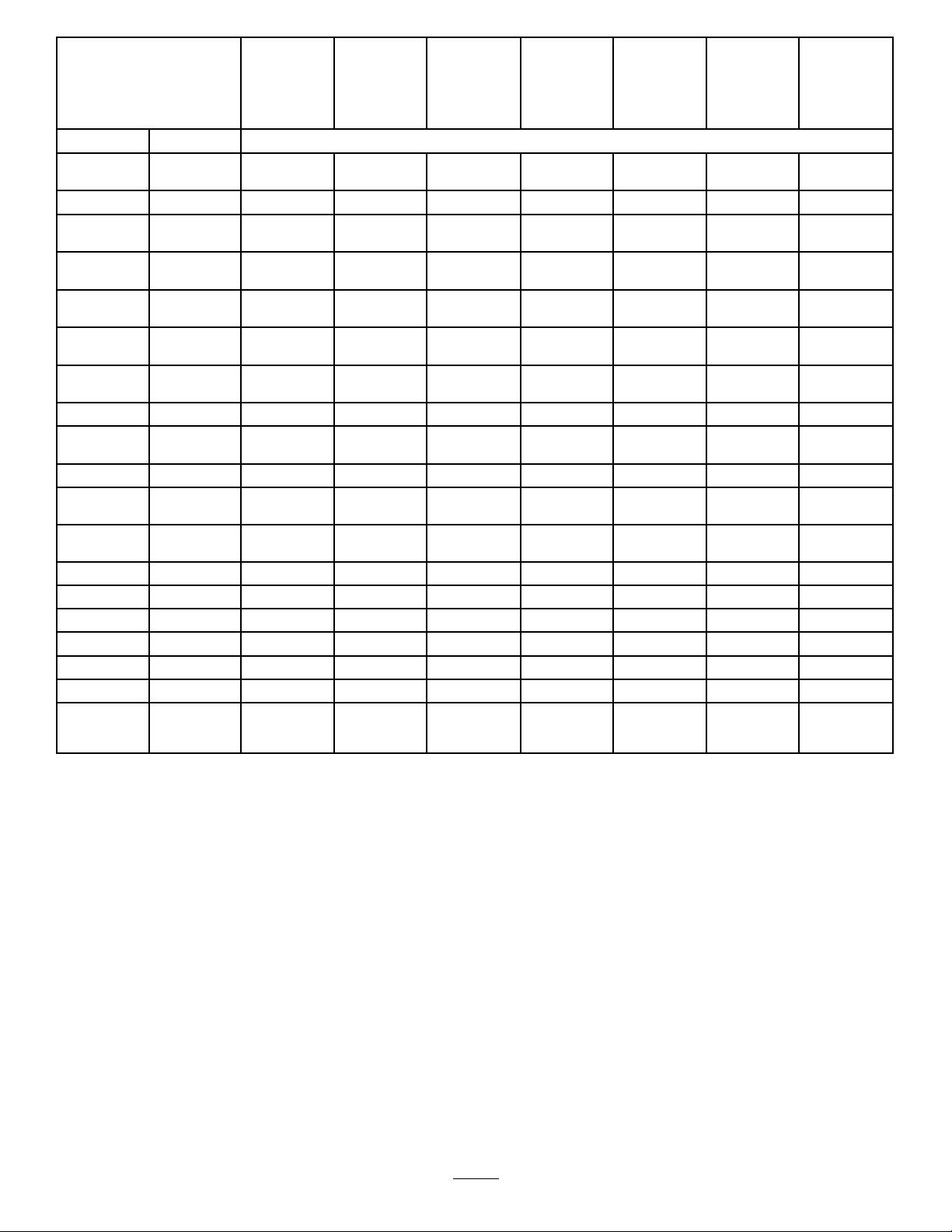

AllLazerZXPandLazerZXSUnits:

1.TemporarilyremovetheROPStoallowfor

installationoftheUltraVac.Retainthehardware

forreuse.

2.Installmountweldment(item9)looselytotherear

bumperusingthetwoholesprovided.Secureusing

four3/8-16x11/4inchscrews(item23),four3/8

springdiscwashers(item25)andfour3/8-16inch

whizlocknuts(item24).

3.Installtheframebrackets(item16)andspacers

(item17)looselytothemountweldment(item9)

asshown.Secureusingtwo3/8-16x11/4inch

screws(item23),two3/8springdiscwashers(item

25)andtwo3/8-16inchwhizlocknuts(item24).

Makesurethattheraisedportionofthespringdisc

washerfacestheheadofthescrew .

•ForLazerZXPUnitsseeFigure4.

•ForLazerZXSUnitsseeFigure8.

Figure8

4.Installtheframebrackets(item16),andROPSlower

rollbartubeslooselytothemountingpadsonboth

sidesoftheLazerframe.UsetheROPSmounting

hardware,eight3/8-16x11/2inchscrews,eight

3/8springdiscwashersandeight3/8-16inch

whizlocknuts.Makesurethattheraisedportionof

thespringdiscwasherfacestheheadofthescrew

(seeFigure5).

8