4www.exte.se

Before you start using your ExTe product, it is impor-

tant that you read and understand the content of

these operating instructions, especially the sections

that describe Safety.

The operating instructions are primarily intended to

teach you about the product’s functions and prop-

erties and how to best use them. They also contain

important safety and maintenance information and

describe any problems that may occur during use.

Keep the operating instructions with the product,

as important information regarding use, safety and

maintenance may be required. It is also possible

to obtain information about our products through

our website on the internet. You can nd us at

www.exte.se.

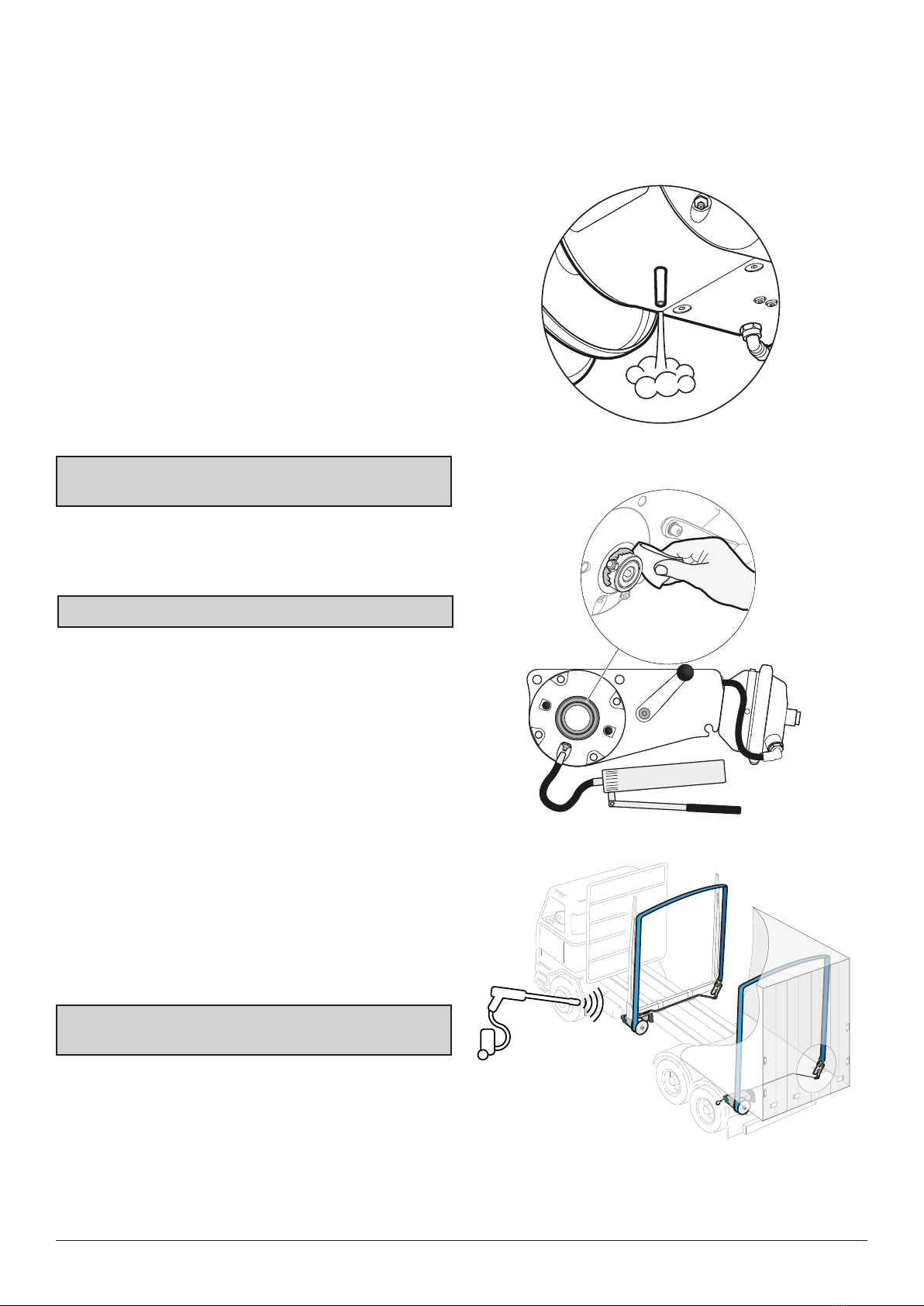

All information, all images, illustrations and speci-

cations are based on the product information that

was available at the time of publication of these

operating instructions. Images and illustrations

found in the operating instructions are type exam-

ples and are not intended to be exact depictions of

dierent parts of the product.

ExTe reserves the right to make changes in design

without prior notice. We cannot be held responsible

for misprints and changes.

Technical support

If you need support or service, please contact in the

rst place the ExTe dealer in your area. You can also

contact ExTe’s technical support at

Tel +46 (0)651-175 30 or email support@exte.se

More information at www.exte.se/support

Spare parts

Only original ExTe spare parts should be used.

The use of other parts could invalidate the product

guarantee.

Scrapping

TU is manufactured from recyclable materials or

materials that can be reused. Specialist companies

handle worn out products, dismantle them and

recycle materials that can be reused.

Modication

Warranty

TU is supplied with a 1 year warranty or according

to the actual agreement. The warranty covers

functional faults, faulty material and manufacturing

faults that may arise during the guarantee period

during normal use.

The warranty does not cover:

• Normal wear.

• Faults caused by insucient maintenance.

• Faults caused by improper or negligent

operation.

Repairs under warranty shall be carried out

by ExTe Fabriks AB or by ExTe Fabriks AB’s con-

tracted partner.

Please refer to our website www.exte.se for more

information.

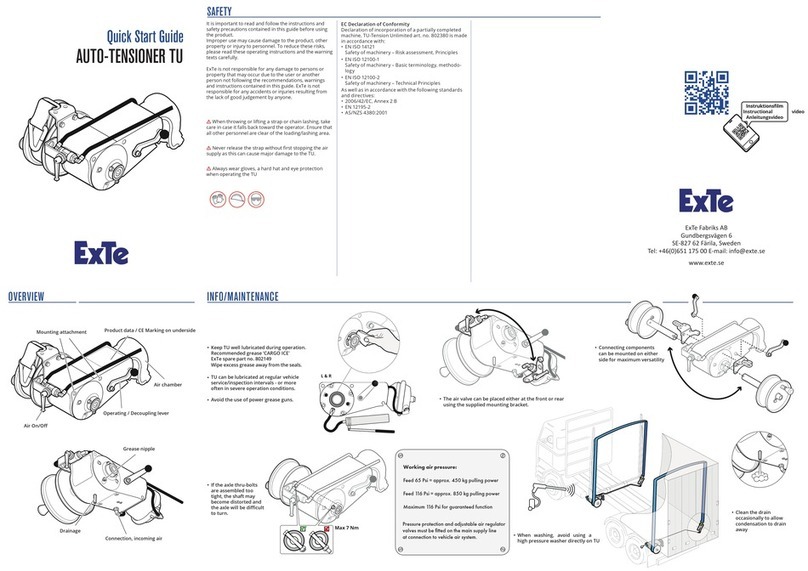

Accessories

TU has a number of accessories which make it

adaptable to most needs. Accessories are constantly

being developed; please see the current product

catalogue.

Contact information

ExTe Fabriks AB

Gundbergsvägen 6

Box 18

SE-827 62 Färila, Sweden

Tel: +46 (0)651-175 00

sales@exte.se

support@exte.se

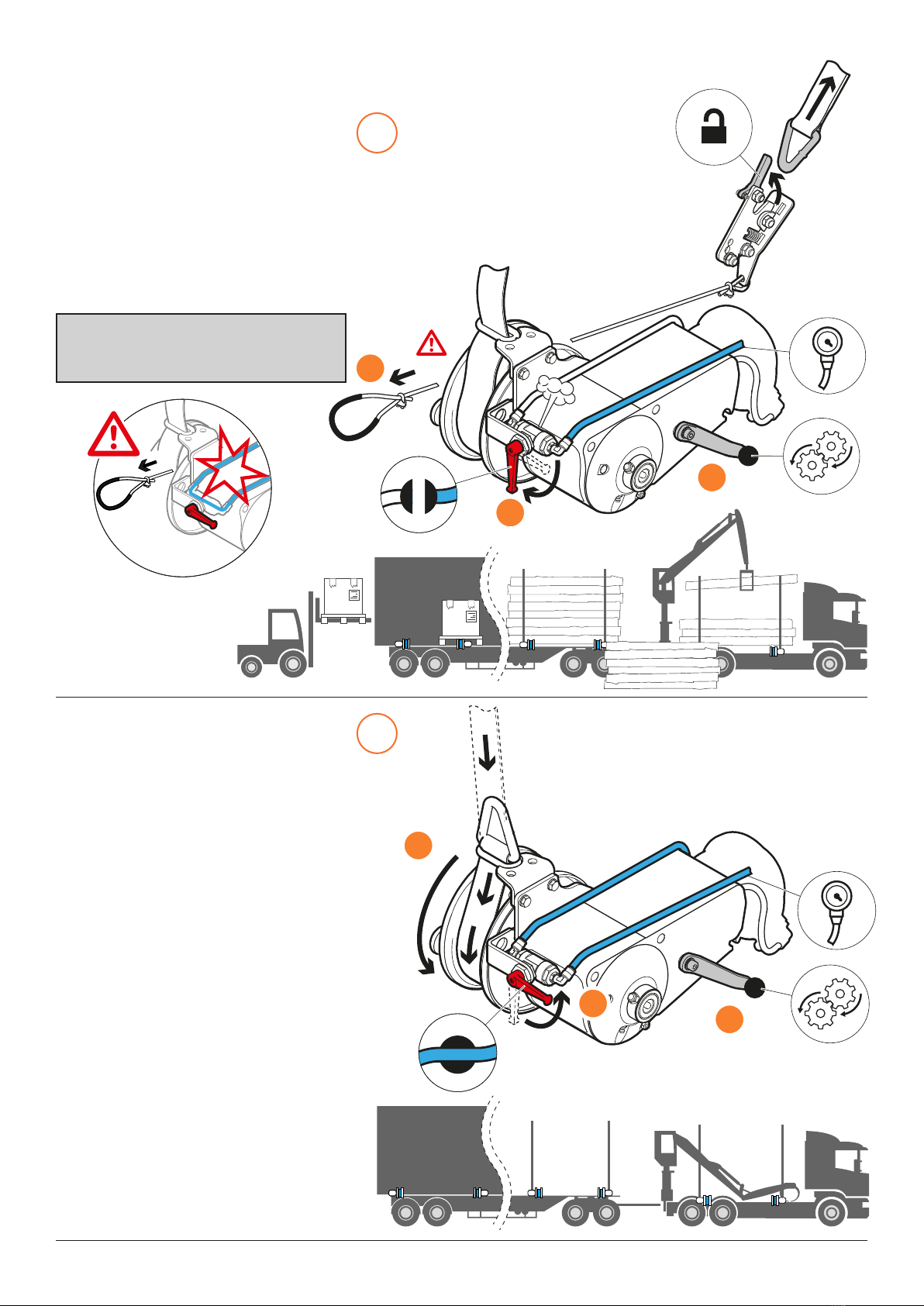

m Warning!

Modication is not permitted. If the equipment

has been modied, the product guarantee will be

void. Risk of injury!

IMPORTANT INFORMATION