Detroit Speed Selecta-Speed 121633 User manual

DSE F501-300 (Rev 06/28/19) Page 1 of 15

Detroit Speed, Inc.

Selecta-Speed Wiper Kit

1973-83 C10 GM Truck

P/N: 121633 & 121634

A downpour of rain will no longer hinder your ability to clearly see the road. The Detroit Speed

Selecta-Speed Wiper Kit provides you with the performance and convenience of a late model

wiper system in a package that easily and cleanly mounts in your 1973-83 C10 GM Truck.

Figure 1 –PN 121634 Shown

Item #

Description

Quantity

1

Wiper Motor Assembly

1

2

Wiper Control Module w/Mounting Plate

1

3

Wiper Harness

1

4

Wiper Switch Assembly

1

5

Hardware Kit

1

6

Instructions

1

DSE F501-300 (Rev 06/28/19) Page 2 of 15

This kit features a seven speed wiper system with five delays, low speed, and high speed. The

new pitman arm, included in the kit, connects directly to your existing wiper linkage. A rotary

switch is also included, along with a complete wiring harness.

This kit does feature a washer pump option as the wiper switch does have a push button

function. The wiring harness/control module is equipped with a power and ground wire to install

an inline electric washer pump. Detroit Speed does offer a washer pump kit available as part

number 121102.

Hardware Kit Checklist –Detroit Speed 1973-83 C10 Wiper Kit

Part Number

Description

Quantity

Check

9312209

1973-74 C10 Hardware Bag

1

9312206

Wiper Switch Adapter Assembly

1

9912060

1-1/4” Firewall Grommet

1

9912244

Billet Aluminum Wiper Switch Knob

1

9912044

3/8” AN Stainless Steel Washer

1

950054FS

10-24 x 3/4”L Button Head Screw

3

980096FS

5/16”-18 x 1”L Hex Head Flange Bolt

1

970043FS

5/16” SAE Washer

1

960033FS

5/16”-18 Nylock Nut

1

9312212

1975-83 C10 Hardware Bag

1

9312210

Wiper Switch LED Light Box Assembly

1

9912365

Acrylic Wiper Cover Plate

1

9912367

LED Dimmer

1

9912364

Pre-Wired White LED

1

9912366

2-Wire Lever Terminal Block

4

9912060

1-1/4” Firewall Grommet

1

9912244

Billet Aluminum Wiper Switch Knob

1

950128FS

No. 8 x 5/8”L Sheet Metal Screw

2

950054FS

10-24 x 3/4”L Button Head Screw

3

980096FS

5/16”-18 x 1”L Hex Head Flange Bolt

1

970043FS

5/16” SAE Washer

1

960033FS

5/16”-18 Nylock Nut

1

Installation Instructions:

1. Before beginning, please ensure that the parts included with your kit match the parts list

above. Ensure that the factory wiper system is in its “Parked” position. Disconnect the

battery power by removing the negative battery lead from the battery.

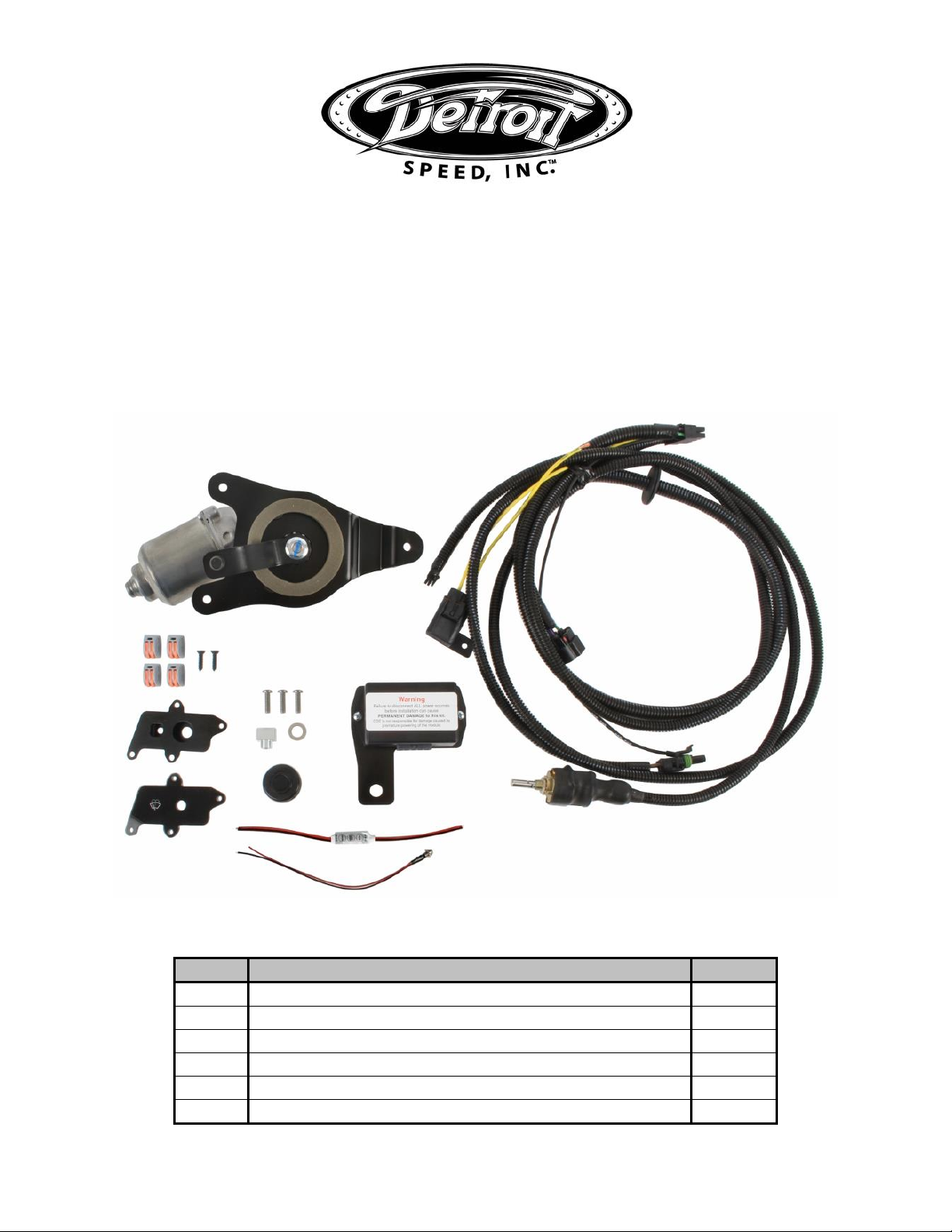

2. Mark the wiper arms’ parked location with masking tape for reference (Figure 2 on the next

page). It will be easier to access the wiper linkage with the wiper arms midway through their

travel.

DSE F501-300 (Rev 06/28/19) Page 3 of 15

Figure 2 –Parked Location

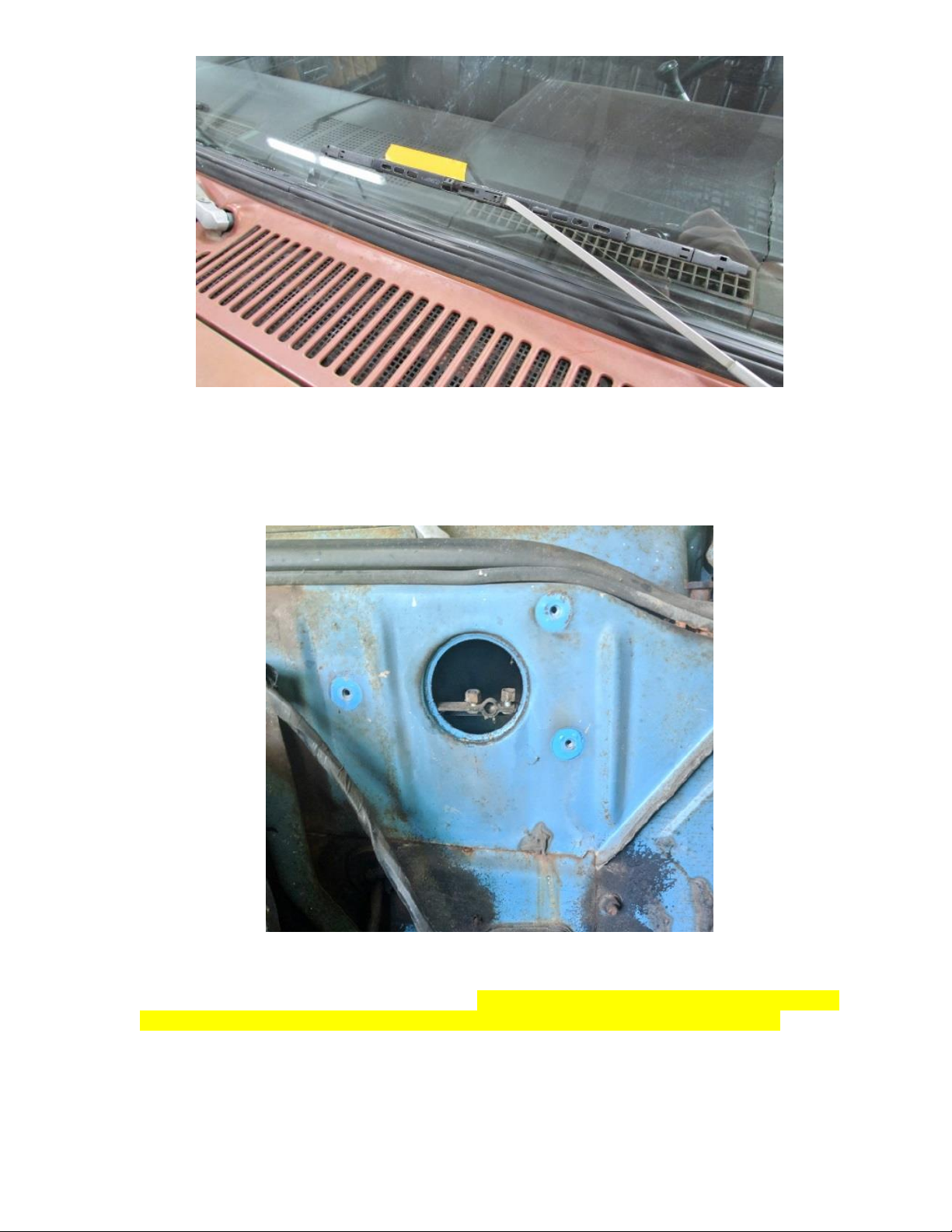

3. Remove the 3 bolts holding the stock wiper motor to the firewall.

4. Disconnect the wiper linkage from the wiper motor pitman arm and remove the stock wiper

motor from the firewall (Figure 3).

Figure 3 –Remove Stock Wiper Motor

5. The original wiring will not be used with the new Selecta-Speed Wiper Kit. A custom harness

is provided to replace the original harness. NOTE: If you decide to cut the old wires please

pay special attention to properly terminate the wire ends to avoid possible shorting.

6. Mount the new wiper motor assembly to the firewall. Use the three supplied 10-24 x 3/4”L

button head screws to mount the wiper motor assembly to the firewall. The adapter plate

will mount to the firewall using the original wiper motor firewall weld nuts (Figure 4 on the

next page).

DSE F501-300 (Rev 06/28/19) Page 4 of 15

Figure 4 –Attach Wiper Motor to Firewall

7. Attach the new pitman arm to the original wiper linkage. NOTE: The Selecta-Speed wiper kit

is shipped with the pitman arm in the “parked” postion. Do not move the pitman arm by hand

to attach the wiper linkage. If the pitman arm is moved from the original “parked” position

from Detroit Speed, it may result in the wiper blades stopping in the wrong spot on the

windshield.

8. The Selecta-Speed switch will replace the stock switch. Remove the screws holding the

gauge panel to the dash and remove. CAUTION: The gauge panel can flex a little, but on

certain trucks, it is necessary to remove the headlight knob first in order to remove the

gauge panel. Pull the headlight switch out as far as it will go. Press down on the release

button and pull out the headlight knob (Figure 5).

Figure 5 –Remove Headlight Knob

9. Remove the 2 screws holding the stock wiper switch to the dash (Figure 6 on the next page).

Disconnect the wiper switch connector from the back of the wiper switch and remove the

switch. For 1973-74 vehicles, tie up the original wiring under the dash and skip to Step 23.

For 1975-77 vehicles, proceed to the next step. For 1978-83 vehicles, skip to Step 11.

Push to

Remove Knob

DSE F501-300 (Rev 06/28/19) Page 5 of 15

Figure 6 –Remove Factory Wiper Switch (1973-74 shown)

10.Once the switch is removed from the dash, remove the light bulb housing by turning it

counter clock-wise in the switch housing. In order to use the LED light for the new wiper

switch, you will need to cut the wires from the original light bulb housing. Cut the gray

(positive) and black (ground) wires as close to the terminals as possible. Skip to Step 12.

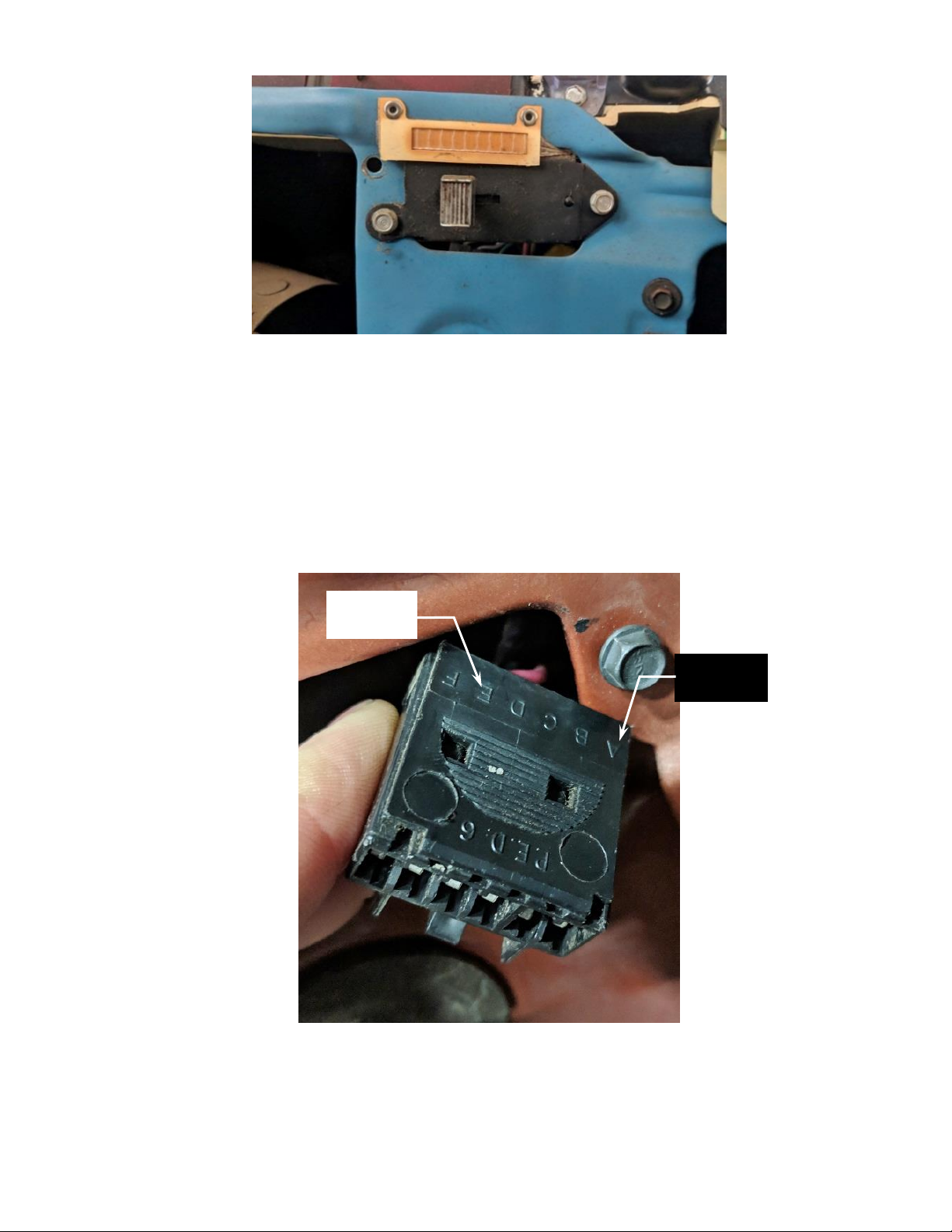

11.Once the wiper switch is removed from the dash, you will need to cut the “A” and “E” wires

from the back of the original wiper switch connector in order to use the LED light bulb (Figure

7). NOTE: The “A” wire is gray (positive) and the “E” wire is black (ground). Cut the wires as

close to the terminals as possible.

Figure 7 –Cut “A” & “E” Wires

12.Strip the wires in the vehicle that were cut for the light bulb, the wires on the provided

dimmer, and LED wires for the provided two-wire T-junction connector. Use the indicator on

the bottom of the T-junction connector to ensure that enough wire is stripped (Figure 8 on

the next page).

“E” – Black

Wire

“A” – Gray

Wire

This manual suits for next models

1

Popular Automobile Accessories manuals by other brands

ULTIMATE SPEED

ULTIMATE SPEED 279746 Assembly and Safety Advice

SSV Works

SSV Works DF-F65 manual

ULTIMATE SPEED

ULTIMATE SPEED CARBON Assembly and Safety Advice

Witter

Witter F174 Fitting instructions

WeatherTech

WeatherTech No-Drill installation instructions

TAUBENREUTHER

TAUBENREUTHER 1-336050 Installation instruction