20 Waterside Fancoil Units – Type PWX (12/2022)

6.0 Initial commissioning

Personnel:

Skilled qualified electrician

HVAC technician

Protective equipment:

Industrial safety helmet Safety shoes

Protective gloves Safety glasses

6.1 Unit inspection

6.1.1 Before initial commissioning:

Once the equipment has been installed and prior to the functional

testing and commissioning phase taking place, the following checks

should be completed;

General

Remove protective film, wrapping, if any. Ensure that the unit is

clean. If necessary, clean the faces of the inlet filter and heat

exchanger and drip tray.

Inlet filters are installed, clean, and are of the correct grade.

Check filters for correct fit and contamination ‘Checking and

replacing the filter’. Should the filters have been contaminated

even before commissioning, replace them.

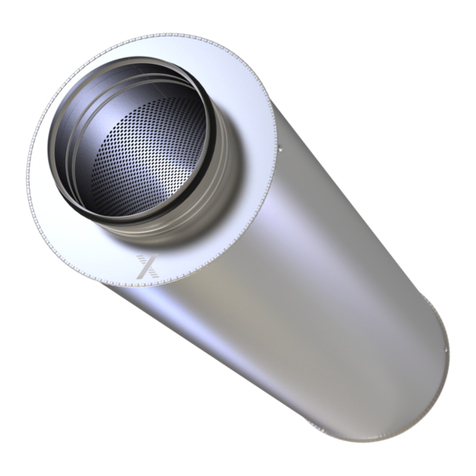

Fan/motor rotates in the correct direction with no obstructions (by

hand) to ensure free rotation and to check impeller is not rubbing

on the inlet ring or on any part of the scroll housing. Fan, blades,

and motors are clean and dust-free.

Heat exchanger is clean, in good condition, and the fins

undamaged.

Pipework is connected correctly (flow, return, heating, cooling

etc.) and does not put stress on the fancoil connections or create

vibrations.

The mains water system has been hydraulically balanced.

Pipework is insulated, vapor sealed and labelled.

All valves/control valves, commissioning devices and strainers

are installed, and the correct direction and strainers are clean.

Ensure actuators are installed before energising.

Ensure condensate pipework is installed to the correct fall (refer

to local regulations or guides). If condensate pumps are

installed, ensure these are primed according to the

manufacturer’s instructions before energising.

Electrical General

Unit and components are fully earthed in line with the TROX

wiring diagram and earthing has been tested.

All wiring must comply with local wiring regulations. PWX internal

wiring complies with BS 7671: IET wiring regulations.

Isolation switch / fused spur installed for each unit in line with

local regulations to enable isolation of the unit control panel from

the mains supply.

Electrical voltage from the site matches the unit required voltage

(230Vac, 1ph 50 - 60Hz) and correct protection fuse size is

installed (refer to TROX wiring diagram).

All cabling is installed & connected according to TROX wiring

diagram and is not damaged and has been tested/torque tested.

Operation of the electric heating element is fan controlled and

interlocked with the control system.

Fan delay incorporated into the control's logic, allowing the fan to

run [10 mins] after the heater has deactivated/switched off.

All safety components are connected and operational, including

all thermostats to cut power to the heater if needed.

Check that the controls enclosure lid is installed and securely

fastened.

Comms / BMS wiring should be separated from power, controls

and signal wiring.

6.2 Initial start-up

Once all unit inspection checks have been completed and any issues

identified are rectified, the unit can be energised.

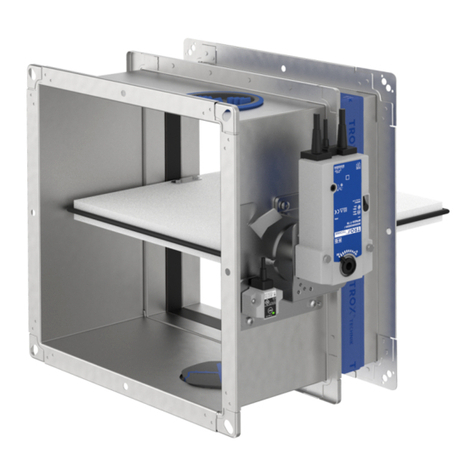

1. ▶ Ensure all volume control dampers connected within the

secondary ductwork are fully open.

2. ▶ Switch on the mains power supply to the fancoil and switch

on the fancoil using the switch located on the control panel.

The fancoil unit is ON

3. ▶ To start the fan, the correct control voltage must be applied

to the fan. Refer to TROX technical schedule for

confirmation of guide control voltage.

Appendix C: Local setting of fan speed

The control voltage (0-10Vdc) can be applied to the fan

from the integrated controller (BMS) or from a

potentiometer (if fitted). The typical control voltage should

be between 4 – 7.5Vdc.

Danger of injury from sharp edges, sharp corners and thin

sheet metal parts!

Sharp edges, sharp corners and thin sheet metal parts may cause

cuts or grazes.

– Be careful when carrying out any work.

– Wear protective gloves, safety shoes, hard hat and safety

Electric shock hazard! Electrical equipment carries a

dangerous electrical voltage!

– Only skilled qualified electricians are allowed to work on the

electrical system and to connect the unit to the mains

– Isolate the unit from the mains (all phases) and secure the unit

against inadvertently being energized on again.

– Verify that no voltage is present using an approved voltage

indicator.

– Carry out assembly or connection jobs only as long as no