Förster-Technik VARIO smart 2.0 User manual

Original Service Manual

Automatic calf feeder

Type VARIO smart 2.0 Powder

TAP5-VS2-50

Program version 2.00 and higher

15. May 2018

2 Table of contents

Table of contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Overview of the automatic feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.1 Front and right side view of automatic feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.2.2 Rear view of automatic feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.3 Left side view of the automatic feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.2.4 Boiler with heating circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.1 Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3.2 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.3 Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.4 Water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.5 Boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.3.6 Milk powder container. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.3.7 Number of feeding stations and animals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.4 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.6 Abbreviations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2. Important safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.1 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.2 Required qualifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 Residual risks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.4 How am I warned of hazards? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.1 What are the components of a hazard description? . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.2 Potentially fatal hazards or health hazards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4.3 Material damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.4.4 Safety signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.5 Safety devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.6 Structural alterations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .21

3. Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1 Setting up the feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.2 Electrical connection provided by the customer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.3 Water connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4 Installing feeding stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.1 Installing feeding station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.2 Installing stand partitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.5 Attaching the pushbutton/remote control for manual feed start . . . . . . . . . . . . . . . . . . . . 25

3.6 Connecting the antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6.1 Installing the antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6.2 Squelch values and identification ranges . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.6.3 Connecting antenna cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Table of contents 3

3.6.4 Connecting the Ethernet cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.7 Installing the safety grid for the powder hopper attachment . . . . . . . . . . . . . . . . . . . . . . . 29

3.8 Switching on the vapor barrier for powder discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.9 Filling the powder container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.10 Installing external cleaning agent supply pipework (optional). . . . . . . . . . . . . . . . . . . . . . 31

3.11 Switching on the automatic feeder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.12 Setting the date/time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .33

3.13 Filling the boiler. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.14 New installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.15 Setup settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.16 Adjusting the calibration scales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.17 Setting offline mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .34

3.18 Setting portion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.19 Drain time station parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.20 Function keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.21 Animal list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.22 Checking components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.23 Calibrating feed components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.24 Checking or setting cleaning settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.25 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.26 Reading in and creating transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.27 Registering animals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.28 Entering correction days . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

4. Programming and control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1 Hand terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4.1.1 The keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.1.2 The Auto LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.2 Offline mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.3 Automatic mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4 Menu structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

4.4.1 Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

4.5 Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5.1 Animal control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4.5.2 Main menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.5.3 Manual functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.6 Device data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.6.1 Setting operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.6.2 Checking and setting time/date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.6.3 Setting portion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.6.4 Drain time station parameters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.6.5 Function keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.6.6 Animal list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

4.6.7 Backing up and restoring data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4.6.8 Cloud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4 Table of contents

4.6.9 New installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4.7 Software updates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.7.1 Software update via SD card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.7.2 Software update via cloud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

4.7.3 Software update via internal (automatic) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.8 Reinstallation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

5. Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

5.1 Overview of the Setup menus. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

5.2 Language . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.3 Time/date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.4 Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.4.1 Feeder type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.4.2 Automatic feeder number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

5.4.3 Automatic feeder address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.4.4 Feeder operating modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.4.5 Base size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.4.6 Heating system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.4.7 Boiler valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.5 Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.5.1 Mixer drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.5.2 Additive dispenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.5.3 Flushing agent 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.5.4 Flushing agent 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5.5 Flushing agent sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5.6 Powder sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5.7 Circulation valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5.8 Gully valve 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

5.5.9 Air valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.10 Mixer temperature sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.11 Water meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.5.12 Supply and point electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.6 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

5.7 ID chip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.8 Calibration scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

5.9 Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.9.1 Feed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

5.10 Terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.10.1 Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.10.2 Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.10.3 Sleep mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

5.11 Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. .69

5.11.1 Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.11.2 Network configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

5.11.3 Cloud . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

Table of contents 5

5.11.4 Gateway . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.11.5 MultiReader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

5.11.6 Restart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

6. Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.1 Calibrating without calibration scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

6.2 Calibrating with calibration scales. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7. Transmitter and animal management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.1 Managing the transmitters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.1.1 Basics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.1.2 Creating transmitter numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

7.1.3 Reading transmitter numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.1.4 Manually entering transmitter numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.1.5 Assigning animal numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

7.1.6 Editing transmitters or animal numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

7.1.7 Deleting the transmitter number when canceling an animal . . . . . . . . . . . . . . . . . 78

7.1.8 Calling up the transmitter statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.2 Registering animals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.2.1 Manual registration of animals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

7.2.2 Automatically registering animals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

7.3 Canceling animals or animal groups. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.3.1 Canceling individual animals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.3.2 Canceling a group. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.3.3 Canceling weaned animals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

7.4 Changing the registration of animals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

8. Shutdown and recommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.1 Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.1.1 Temporary shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8.1.2 Permanent shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.2 Recommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.2.1 Recommissioning after temporary shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.2.2 Recommissioning after processor card replacement . . . . . . . . . . . . . . . . . . . . . . 88

9. Faults and warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

9.1 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

9.1.1 Calibration scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

9.1.2 Heating up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

9.1.3 Temperature too high . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.1.4 Boiler not filled . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.1.5 Shortage of water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

9.1.6 Water meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.7 Emptying the mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

9.1.8 Heating system. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

9.1.9 Boiler temperature sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

6 Table of contents

9.1.10 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.1.11 ID chip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

9.1.12 Station/drain valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

9.1.13 Uncontrolled output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

9.2 Warnings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

9.2.1 Emptying the mixer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

9.2.2 Mixer temperature sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

9.2.3 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

9.2.4 Incorrect ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

9.2.5 Address used twice. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

9.2.6 Unknown transmitter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9.2.7 Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

9.2.8 Fill up the MP container . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9.2.9 Calibration scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9.2.10 ID chip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9.2.11 Duplicate animal number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

9.2.12 Machine capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.2.13 Check SD card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

9.3 Other faults and messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.3.1 Automatic feeder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.3.2 Hand terminal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

9.3.3 Boot loader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

9.4 Service messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.4.1 Service work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

9.5 Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.5.1 Checking valves/motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

9.5.2 Checking the heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

9.5.3 Checking sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

9.5.4 Calibration scales . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

9.5.5 Checking stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

9.5.6 Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

9.5.7 Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

9.5.8 Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

9.5.9 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

9.5.10 Remote maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

10. Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.1 Checklist for commissioning and recommissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

10.2 Materials list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

10.3 Shutdown checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

10.4 Standard feeding plans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

10.5 CAN bus addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

10.6 Checking components for compliance with national regulations . . . . . . . . . . . . . . . . . . 125

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Introduction 7

1. Introduction

This operating manual enables you to operate this automatic feeder machine safely as intend-

ed.

• Have the end user provide you with the operating manual for the automatic feeder, the op-

erating manuals of all additional equipment to be connected and the safety data sheets for

cleaning agents.

• Carefully read all operating manuals and safety data sheets before starting up the automatic

feeder for the first time or restarting it.

• Observe all of the warnings and safety instructions in these operating manuals and safety

data sheets at all times.

1.1 Models

The following automatic feeder versions are available:

•Powder - for the use of milk substitute (MP).

•Combi - for the use of milk substitute and fresh milk.

•Fresh milk - for the use of fresh milk.

All automatic feeder versions can be equipped with a variety of pieces of peripheral equipment

and options.

8 Introduction

1.2 Overview of the automatic feeder

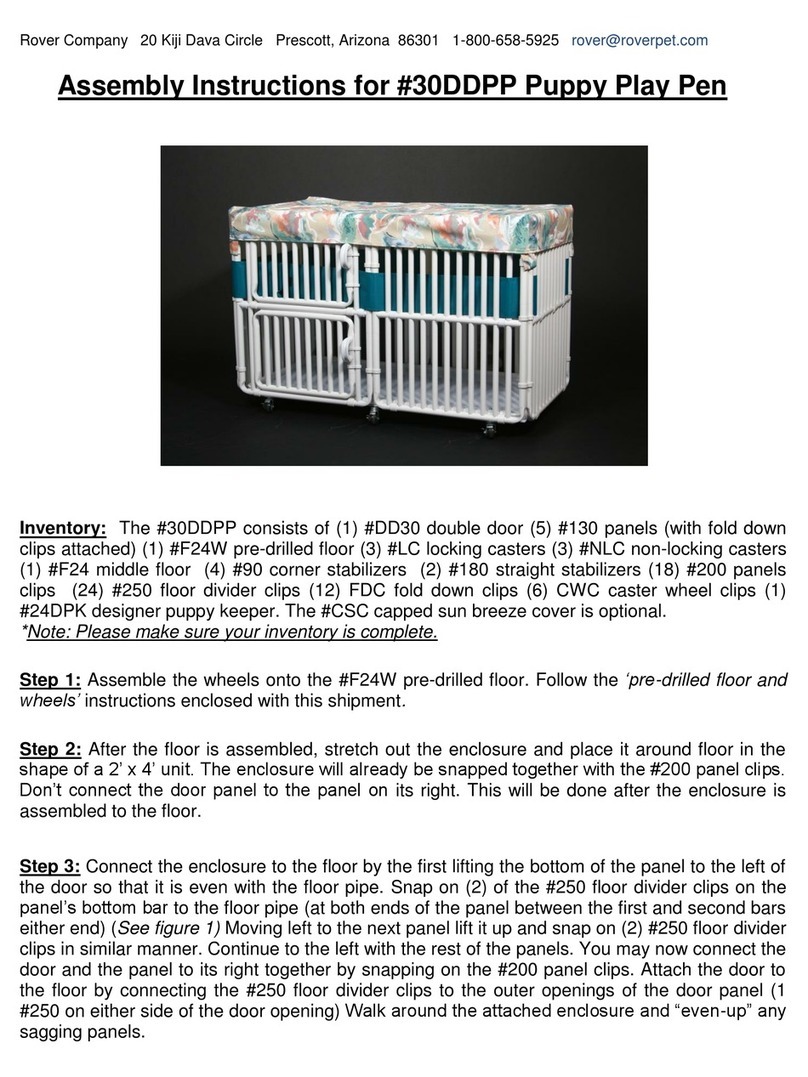

1.2.1 Front and right side view of automatic feeder

1 Milk powder container

2 Outlet valve (not shown here)

3 Milk powder discharge

4 Water supply

5 Mixer beaker

6 Rod electrode

7 Hose connection from mixer to the feeding pump

8 Mixer motor

9 Wing nut for transport restraint

10 Water connection

11 Temperature sensor

12 Point electrode for 500 ml portion

13 Right door

14 Ground connection screw

15 Main switch

16 Hand terminal

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

9

Introduction 9

1.2.2 Rear view of automatic feeder

1 Processor and power circuit board

2 Outlet valve for hose cleaning

1.2.3 Left side view of the automatic feeder

The Name plate is located above the left side door on the outside of the automatic feeder. It

contains information about the manufacturer, type and number of the automatic feeder, informa-

tion about connecting the feeder to the power supply as well as its certification. An example of

a name plate is shown below.

1 Name and address of the manufacturer

2 Type and number of the automatic feeder

3 Information on the connection to the power supply

4 Certification of the automatic feeder

1

2

3

4

10 Introduction

Rear left side door

1 Cleaning agent dosing pump 2 (acid)

2 Mixer drain valve

3 Feeding box valves (optional)

4 Drain hose (not shown here)

5 Drain hose to gully 2

6 Hose connection from mixer to the feeding pump

7 Cleaning agent dosing pump 1 (alkaline)

8 Dosing device for liquid additives (optional)

1

2

3

4

5

6

7

8

Introduction 11

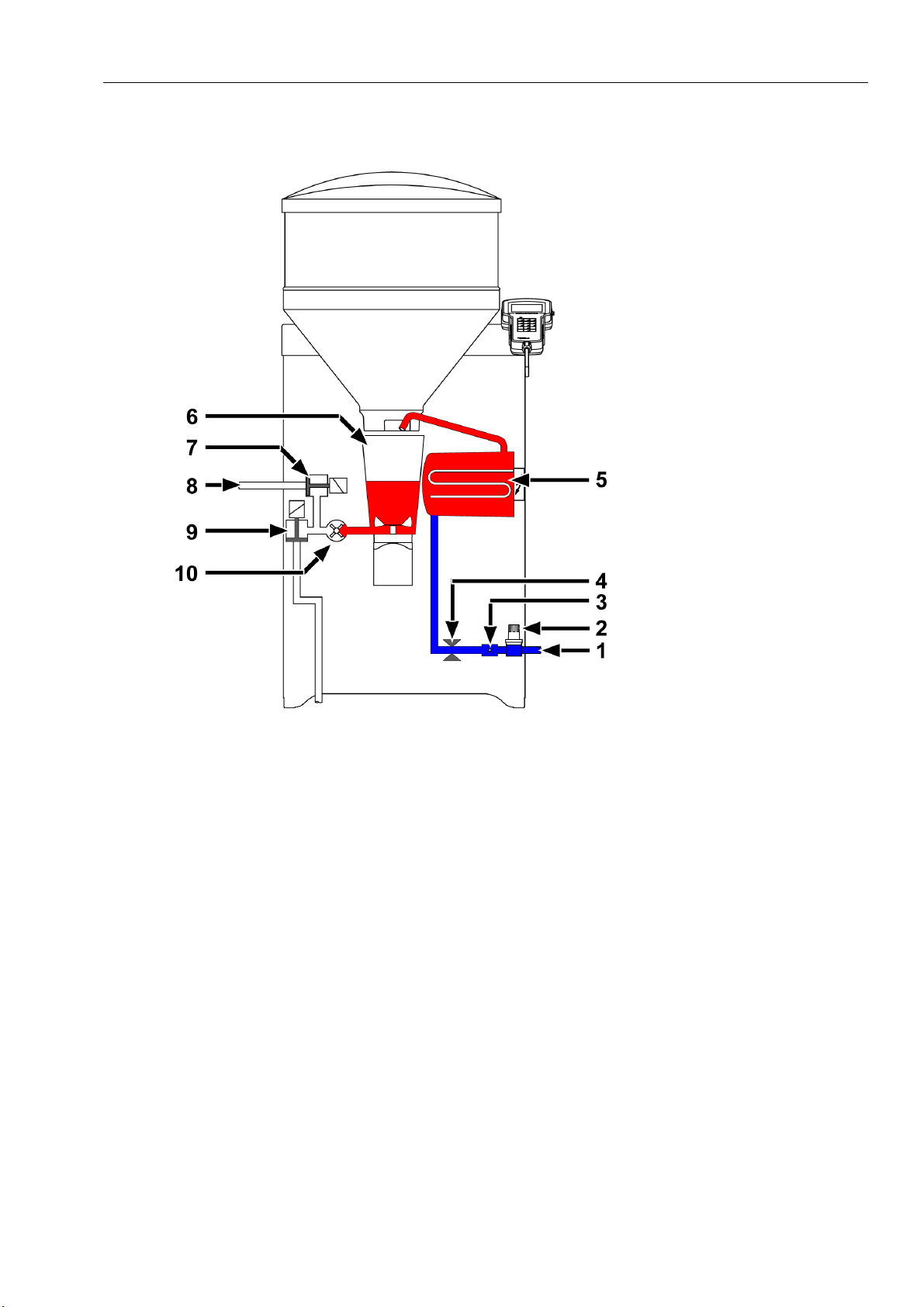

1.2.4 Boiler with heating circuit

1 Hose connection for water pipe

2 Pressure-reducing valve

3 Water meter

4 Boiler water valve

5 Boiler

6 Mixer

7 Valve unit (optional)

8 Hose connection between valve unit and teat

9 Mixer drain valve

10 Feeding pump

1.3 Technical data

1.3.1 Electrical connection

Note: The specifications for the electrical connection to your automatic feeder are on its name

plate above the left side door on the outside (see 1.2.3 "Left side view of the automatic feeder"

-9).

12 Introduction

1.3.2 Dimensions

Depth when the fly screen door is opened ~ 690mm

1.3.3 Weight

Approx. 80kg.

1.3.4 Water connection

Water is connected via a 3/4 inch hose and with a 3/4 inch screwed connection.

NOTICE!

The water must be of drinking water quality.

►Please bear in mind that high calcium, iron and manganese concentrations can cause pre-

mature wear of the components. In such cases it makes sense to install appropriate filtration

systems.

The water pressure on site must be between 1 and 6 bar or between 100000 and 600000 Pas-

cal.

1.3.5 Boiler

The boiler holds approximately 7 ltr of water.

Introduction 13

1.3.6 Milk powder container

The milk power container with attachment holds approximately 35 kg of milk substitute.

1.3.7 Number of feeding stations and animals

1.4 Disposal

All components, liquids and solids must be disposed of in compliance with the applicable official

regulations for proper waste recycling and disposal in your country. Also comply with the corre-

sponding safety data sheets.

1.5 Symbols

1.6 Abbreviations

Feeding stations: max. 4

Calves per feeding station max. 30

Calves per device max. 120

Optional: A white plus sign on a black background indicates that optional functions or

equipment are being described.

Abbreviation Meaning

Call ltr. t. or Call t. Call-off today in liters

Call ltr. y. or Call y. Call-off yesterday in liters

abs. absolute

Adli Ad lib

save amt. Amount saved up

feed.pump Feeding pump

out. pause Dispensing pause

sw.off del. Switch-off delay

dr. time Drink-out time

bo Boiler

dos. Dosage

El Electrode

electrol. Electrolyte

sw. on del. Switch-on delay

F 40 FIT feeding

f 40 FIT periods

gradient Gradient control

gr. A (B) Group A (B)

IFS TR Intelligent feeding station feed

IFS-4 Intelligent feeding station feed, quadruple unit

14 Introduction

IFS KF Intelligent feeding station concentrate

IV Interval feeding program

C Concentrate

Conc. concentr. Concentration

dra.v. N. Drain via teat

w. entitle. With entitlement

w/add. or w/addiv. With additive

MAP Manual feeding pump

MP Milk substitute

max maximum

Min. temp. Minimum temperature

mix. full Mixer full

mixer cl. Cleaning the mixer

mixer dr.valve Mixer drain valve

n. not

No. Number

Clean teat Clean teat

w/o entitlement Without entitlement

w/o add. or w/o add. Without additive

P 1-5 Periods 1-5

R rationed feeding principle

rel. relative

Drnk spd. Drinking speed

ho. Hose

clo.? close

servo Servo control

det. pump Flushing agent pump

Temp. Temperature

TR Feeding box

fd.sensor Feeding sensor

Bo. water Boiler water

Incr./Red. Increase/reduction

add. disp. Additive dispenser

Important safety instructions 15

2. Important safety instructions

This chapter outlines:

• The hazards caused by your automatic feeder and how to avoid them.

• The safety labels attached to the automatic feeder and what they mean.

• How to safely install the automatic feeder.

The automatic feeder is state of the art and is produced in compliance with recognized safety

regulations. However, hazards and adverse effects may arise when using it. Both warning signs

directly on the automatic feeder and warning notices in this manual provide warning of these

hazards.

2.1 Intended use

The automatic feeder may only be used to prepare, heat, and dispense liquid feeds, for example

milk, for calves.

2.2 Required qualifications

Only trained service technicians are authorized to install the automatic feeder, put it into service

and perform maintenance and repairs on it.

Service technicians are specialists with appropriate qualifications. They are able to assess the

work assigned to them and detect potential risks on the basis of their technical training as well

as their knowledge of the relevant standards. They have knowledge of relevant accident pre-

vention regulations, generally accepted safety regulations and country-specific standards and

provisions.

2.3 Residual risks

Hazards to health caused by the automatic feeder:

WARNING!

Danger from electric current

The automatic feeder is powered by electricity.

►You must observe the general precautions for handling electrical equipment.

• Read the operating manual before operating the automatic feeder.

• Keep children away from the automatic feeder.

• Do not touch any moving parts of the automatic feeder, for example the mixer blades.

• Only use genuine spare parts from the manufacturer.

• Switch the automatic feeder off and disconnect the power plug before carrying out any main-

tenance or cleaning work on the automatic feeder.

• If the end user intends to operate the automatic feeder outside of closed spaces, inform the

user that he/she must protect the automatic feeder from rain and moisture, for example with

a roof.

16 Important safety instructions

• Do not install the automatic feeder outdoors, in the open.

• If there is a connection to a drinking water system, then the system must be protected from

back siphoning.

• The following specific hazards are associated with the automatic feeder's electrical system:

•Electrical discharge. If there is an electrical or voltage discharge, electric current flows

through parts of the automatic feeder that are normally insulated. Touching the unit can

cause a fatal electric shock. The automatic feeder must be checked regularly for electri-

cal safety in compliance with national regulations (repeated inspection). Make sure that

a 30 mA residual current device (RCD) is installed.

•Short circuit, indirect contact. If there is a short circuit, current at many times the level

of the operating current can flow. Touching the unit can cause a fatal electric shock.

Make sure you install a fuse (provided by the customer) corresponding to the rating on

the name plate and a 30 mA residual current device (RCD) in compliance with local reg-

ulations.

• The solenoid valves and the pipes to the valves can reach temperatures of up to 70°C.

Touching it can cause burns. Do not touch the solenoid valves and pipes during operation.

• Liquid at temperatures of up to 70°C can spray out of the pipes to the valves. This can cause

scalding. Do not touch the pipes during operation. Carry out the recommended maintenance

on the hoses.

• The mixer and powder supply may start up unexpectedly if a calf which is entitled to feed

approaches the unit. This can crush or chop off fingers or hands. Never reach into the area

of the mixer or powder supply while the automatic feeder is in operation. Use only the scrap-

er supplied to clean the powder discharge opening.

•Poisoning. Additives that are fed to the calves may contain substances that are hazardous

to human health. Avoid direct contact and always wear protective gloves and goggles when

handling these substances.

•Chemical burns. The cleaning agent used to clean the automatic feeder contains caustic

substances. They can cause severe injuries to your hands or eyes. Avoid direct contact and

always wear chemical-proof protective gloves and goggles when handling the cleaning

agent.

•Excessive physical strain. The automatic feeder weighs 80kg. Never attempt to carry it by

yourself as this can cause excessive physical strain.

Material damage caused by the automatic feeder

The automatic feeder can cause the following types of material damage:

•Infection. Improper cleaning or incorrect operation can result in calves becoming infected

by pathogens from the automatic feeder. This can lead to medical costs or cause the death

of the calves.

•Corrosion. Improper cleaning or maintenance can result in the automatic feeder ceasing to

function correctly.

•Loss of stability. The automatic feeder must be set up on a level surface. Otherwise, the

automatic feeder can tip over and suffer damage.

Important safety instructions 17

2.4 How am I warned of hazards?

Hazards are indicated directly on the automatic feeder by safety labels (warning signs, instruc-

tion and prohibition notices), and in the operating manual by specially marked hazard descrip-

tions.

The warnings for hazards that can cause death or injury to people are emphasized more than

those for material damage, for example through the colors, hazard words or symbols used.

Safety labels are an important element of the overall automatic feeder safety concept. They pro-

vide warnings about hazards and explain how to avoid them.

Make sure that all the specified safety labels are fitted to your automatic feeder and that they

are in a legible condition. If the safety labels are difficult to read, replace them immediately. New

safety labels are available from Förster-Technik GmbH.

2.4.1 What are the components of a hazard description?

A hazard description always consists of the following elements:

• Hazard word (danger, warning, caution, attention)

• Type of hazard (what can happen?)

• Location of hazard (where can it happen?)

• Actions necessary for preventing the hazard (what should I do?).

2.4.2 Potentially fatal hazards or health hazards

Depending on their severity and the probability of them occurring, hazards that can cause death

or injury to people are indicated by a hazard symbol (warning triangle with exclamation

mark) and the following hazard words:

DANGER!

The word DANGER indicates an imminent hazard that will lead to death or serious injury.

Warning signs in the operating manual: DANGER (white text on red background).

WARNING!

The word WARNING indicates a potentially hazardous situation that could lead to death

or serious injury.

Warning signs in the operating manual: WARNING (black text on orange background).

CAUTION!

The word CAUTION indicates a potentially hazardous situation that could lead to minor

injury.

Warning signs in the operating manual: CAUTION (black text on yellow background).

18 Important safety instructions

2.4.3 Material damage

NOTICE!

The word NOTICE indicates possible material damage. The automatic feeder or an object

in its vicinity may be damaged, for example a calf.

Prohibition notice on the automatic feeder: a pictogram crossed out in red in a white circle with

a red border indicates something you are not allowed to do.

Operating manual: white text on blue background

2.4.4 Safety signs

Different safety notices are attached at the hazardous points on the automatic feeder. Warning

signs, prohibition and instruction notices.

What are warning signs?

Warning signs consist of:

• A pictogram in a yellow triangle illustrating the potential hazard.

What are prohibitory signs?

Prohibitory signs have a pictogram of the prohibited action in a red circle with a line

through it. See the adjacent example. They graphically depict the prohibited ac-

tion. In this example, the hose with a line through it means that you may not use

high-pressure cleaners.

What are instruction notices?

Instruction notices show a pictogram of what you are being instructed to do in a

blue circle. They illustrate what you have to do. In the example, the pictogram

means that you must always disconnect the plug first.

Other signs

Grounding symbol. This symbol is placed in the locations where you must perform

potential equalization.

2.4.4.1 Warning signs on the machine

Danger of death by electric shock

Important safety instructions 19

Burning/scalding

Health hazards caused by additives and cleaning agents

Automatic startup

No spraying

Grounding symbol

20 Important safety instructions

2.5 Safety devices

The automatic feeder may only be operated if the safety equipment is complete and intact. The

automatic feeder has the following safety equipment:

• Safety signs (warning signs, instruction and prohibition signs).

• The heater's safety temperature limiter. This shuts down the heater in the event of overheat-

ing (temperature rises above 70°C). The heater may only be reactivated by a service engi-

neer.

• Safety grid for the powder hopper attachment. The safety grid prevents people from being

injured by the rotating tools in the hopper, for example when adding milk powder. It must al-

ways be installed when the unit is operating.

• The scraper next to milk powder discharge. The powder discharge opening may only be

cleaned with the scraper. This prevents finger and hand injuries caused by the powder con-

veyor starting up automatically.

The safety devices at the machine are an important part of the safety concept and help prevent

accidents.

• Do not remove or change the safety devices unless the corresponding safety instructions

have been complied with.

• Put the machine into service only once all safety devices have been fitted and are in the

guard position!

Safety temperature limiter

The automatic feeder's heater is equipped with a safety temperature limiter which will be trig-

gered in the event of overheating (70°C) and which will then shut down the heater.

The safety temperature limiter is triggered if the water gets too hot or if the heater is running dry.

It can be found behind the cover illustrated below.

1 Cover of the safety temperature limiter

Protective grid for powder hopper attachment

The protective grid for the powder hopper attachment prevents you from being injured by the

rotating tools in the powder hopper, for example, when filling in milk powder.

1

This manual suits for next models

1

Table of contents