1

DAILY SAFETY CHECK LIST

Before use each day and at the beginning of each shift the aerial

platform shall be given a visual inspection and functional test

including, but not limited to, the following:

1) Read and fully understand Operating and Safety Manual.

2) Check safety belts and hard hats.

3) Check all decals and placards to see if in place and legible.

4) Check platform is securely fastened to platform support.

5) Check wheels and tyres.

6) Check outriggers (if applicable) for condition, microswitch

operation and security.

7) Check batteries for condition, cleanliness, connections and

electrolyte levels.

8) Check engine oil, fuel and coolant levels (if applicable).

9) Check installation of all guards, covers and boom clamps.

10) Check for loose, missing or damaged parts.

11) Check all hydraulic hoses and electrical cables and wiring.

12) Check hydraulic, fuel and air systems for leaks.

13) Do not exceed rated platform capacity 440 lbs (200kgs).

14) Check foot pedal for proper operation (if applicable).

15) Check all operating emergency controls – Select an area

free from obstructions and hazards. Exercise extreme

caution throughout the checking procedure especially when

checking brakes

16) Check operation of emergency system and jack recovery

17) Check brakes and all lights.

18) Check tilt sensor/alarm horn and beacons (if fitted).

19) Check high engine and/or high drive limit switches.

20) Check and refer to Operating and Safety Manual for further

daily/periodic checks and inspections.

SETTING UP PROCEDURES

FAILURE TO DEPLOY THE OUTRIGGERS CORRECTLY

COULD RESULT IN DEATH OR SERIOUS INJURY.

ALL MODELS

1) Read and fully comply with all safety precautions and

operating instructions in the Operating and Safety manual

and the warning decals on the machine.

2) Position Niftylift on firm, level ground. NEVER work with

base across or adjacent to any slope.

3) Position Niftylift, bearing in mind range of boom movement

so that any overhead obstruction or possible hazards such

as, but not limited to, power cables, telephone lines, drains,

man-hole covers, etc.

4) If the load bearing capacity of the ground is in any doubt

the machine must not be used.

5) Check wheels and cordon off area using appropriate

cones, barriers and flags.

6) Release boom travelling clamp.

7) Check all red emergency stops are not engaged i.e. fully out.

8) Ensure selector handvalve adjacent to ground control

station is turned fully down to outrigger/drive position.(for

four wheel drive machine grasp and hold duty selector.

Power will be available automatically).

9) From the cage control station depress and hold the green

power button or footswitch to give hydraulic power to the

outriggers and select the appropriate control lever. Note: No

power will be available if the booms are not in the boom rest.

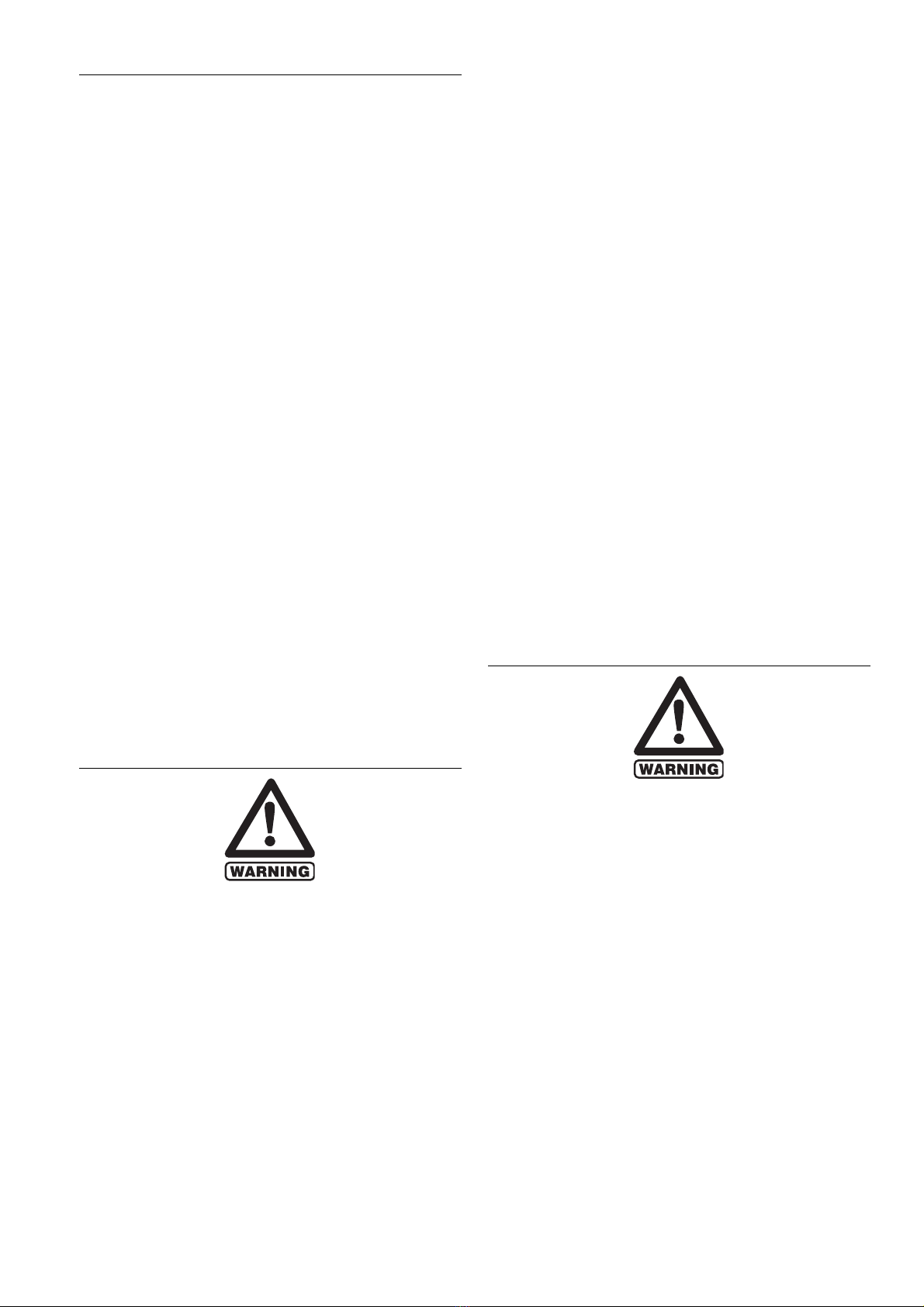

10) Using the four outrigger control levers, (toggle switches on

4WD), lower each outrigger onto a firm level surface and

level machine base ensuring each outrigger foot is taking

equal weight with the wheels clear of the ground.

11) Check machine is level using spirit level on the base, visible

from the cage.

12) Change selector valve at drive/outrigger control station to

platform, i.e. turn fully up. (On four wheel drive machines

releasing the duty selector handle automatically returns the

machine to ‘platform’ operation).

13) The booms can now be operated from the ground or cage

control station by depressing and holding the green power

button. Note: If no power is available check each outrigger

is lowered and each footpad is taking weight.

14) Always lower booms before adjusting, raising, retracting or

moving outriggers in any way.

15) Never alter, modify or block any of the safety circuits on

the Niftylift.

GROUND CONTROL OPERATION

ALWAYS ALLOW THE ENGINE TO

WARM UP BEFORE OPERATING.

ALL MODELS

1) Ensure all red emergency stops are out.

2) Turn key switch at ground control station to ground (i.e.

fully down).

3) Ensure selector hand valve (if applicable) is turned to

platform position i.e. fully up.

4) Battery electric models go to step 10).

DIESEL ENGINE OR BI ENERGY MODELS

5) Turn duty selector in platform to BATT (Battery) or

ENG (Engine).

6) If BATT (Battery) is selected go to step 10).

7) If ENG (Engine) is selected go to step 8). for a COLD

ENGINE or step 9). for a WARM ENGINE.

8) COLD ENGINE. turn the main engine ignition switch (located

in RHS engine canopy) through ON to GL. This engages the

glow plug pre-heat system. Hold for 3-5 seconds then turn

key fully to ST (start) position and the engine will fire.