®

6

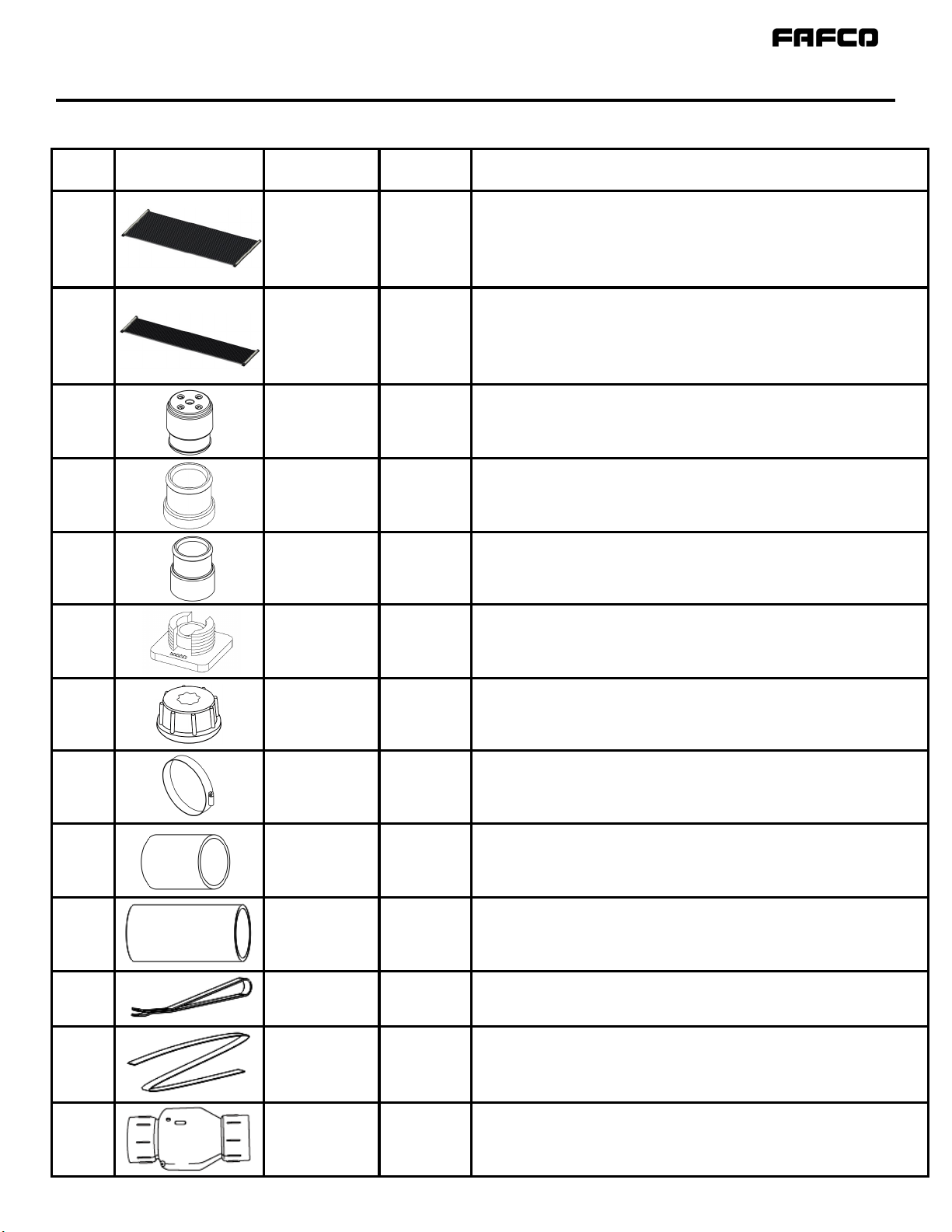

Item Image Name P/N Description

1

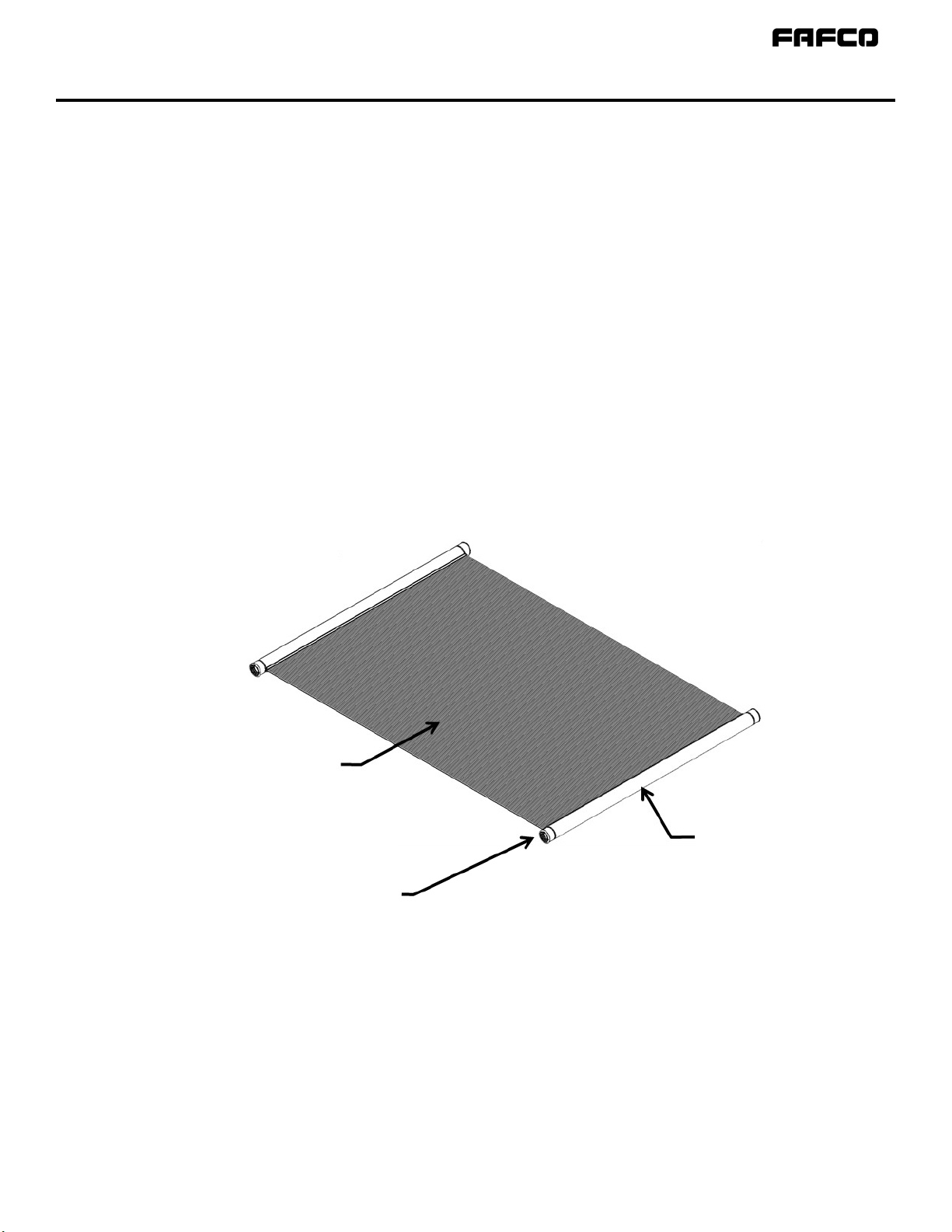

SunSaver®

(4ft x 12 ft)

(4ft x 10 ft)

(4ft x 8 ft)

822 (12ft)

820 (10ft)

818 (8ft)

4ft SunSaver®Collectors. These 4ft wide Collectors are available in three

different lengths, 12ft (48 sq.ft.), 10ft (40 sq.ft.) and 8ft (32 sq.ft.)

2

SunSaver®

(2ft x 12 ft)

(2ft x 10 ft)

(2ft x 8 ft)

09523 (12ft)

09524 (10ft)

09525 (8ft)

2ft SunSaver®Collectors. These 2ft wide Collectors are available in three

different lengths, 12ft (24 sq.ft.), 10ft (20 sq.ft.) and 8ft (16 sq.ft.)

3

Vacuum Relief

Valve (VRV) 188

Black, weather resistant CPVC, 2” PVC pipe size, barbed. Seals system

when pressurized and allows collectors to drain when the system is off.

Adapts to Solar Collector using Short Rubber Coupler.

4

End Cap 05380

Black, weather resistant CPVC, 2˝PVC pipe size, barbed. Adapts to solar

collector using Short Rubber Coupler.

5

Pipe Adapter 05381

Black, weather resistant CPVC, 2” PVC pipe size, barbed female slip.

Used with a Rubber Coupler to adapt the VRV to PVC.

6

Base 06918

Black, weather resistant polymer. Mounts solar collector header and

body straps to a roof or rack using a 1/4˝lag bolt and cap.

7

Cap 06919

Black, weather resistant polymer. Threads onto base to secure strap.

8

21/2” Hose

Clamp 02031

Stainless steel 21/2” hose clamp. Secures Rubber Couplers to barbed

fittings. Tighten using flat head or 5/16” socket driver.

9

Rubber Coupler

(3-1/2”) 02033

31/2” long, 23/8” inner diameter reinforced EPDM used to join the barbed

fittings on a VRV with those on the Pipe Adapter.

10

Rubber Coupler

(5”) 02035

5˝long X 2-3/8˝inner diameter reinforced EPDM used to join the

collectors to the barbed pipe adapters. Allows for flexibility between

collectors and hard piping.

11 Header Strap

(32”) 03431 Black, weather resistant braided polyester. Anchors top solar collector

header to cap and base.

12

Body Strap 03430

Black, weather resistant braided polyester. Anchors solar collector body

to cap and base. (150ft Roll)

13

Check Valve 02046

White, PVC 2˝female slip check valve prevents water from flowing

backward through the filter and backflushing debris into the pool when

the collectors drain.

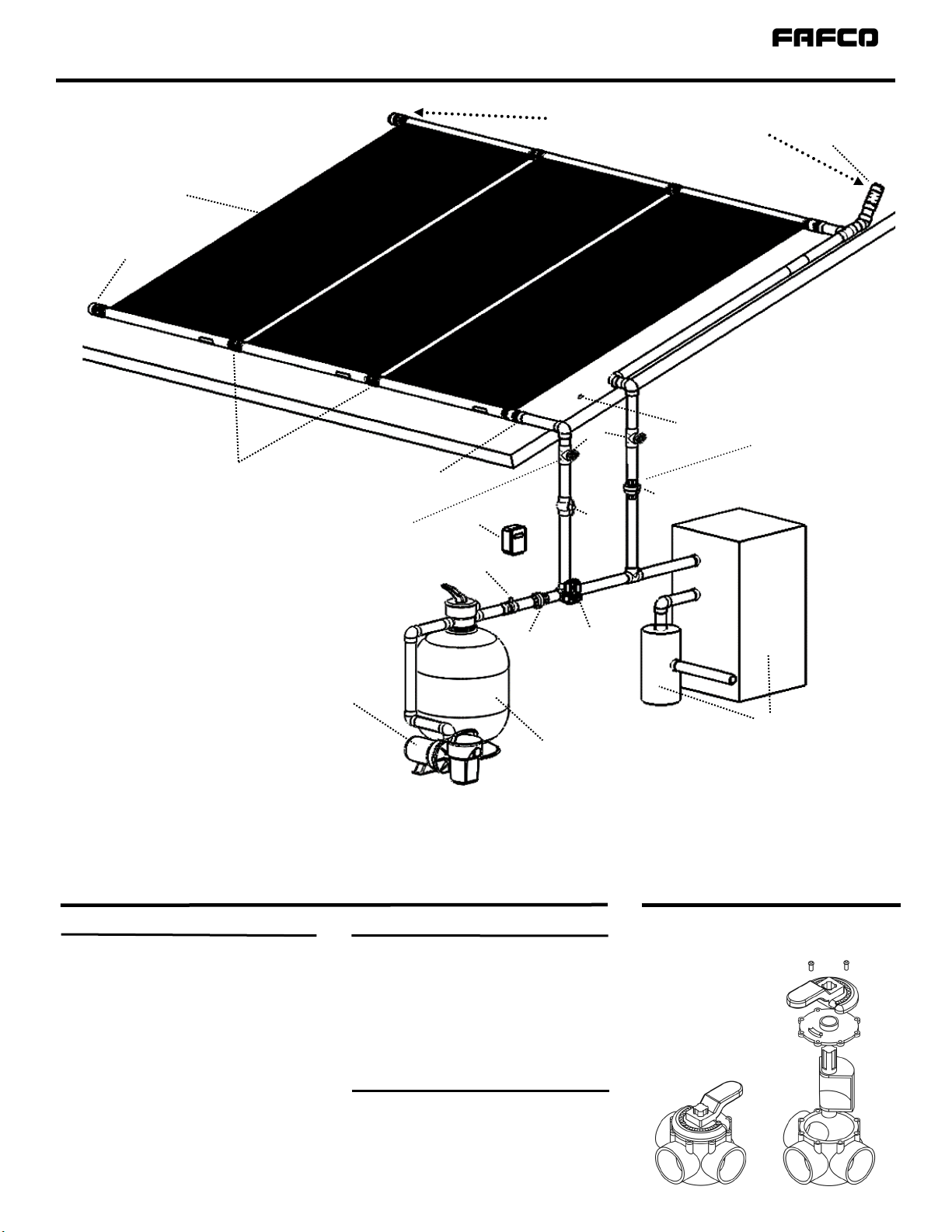

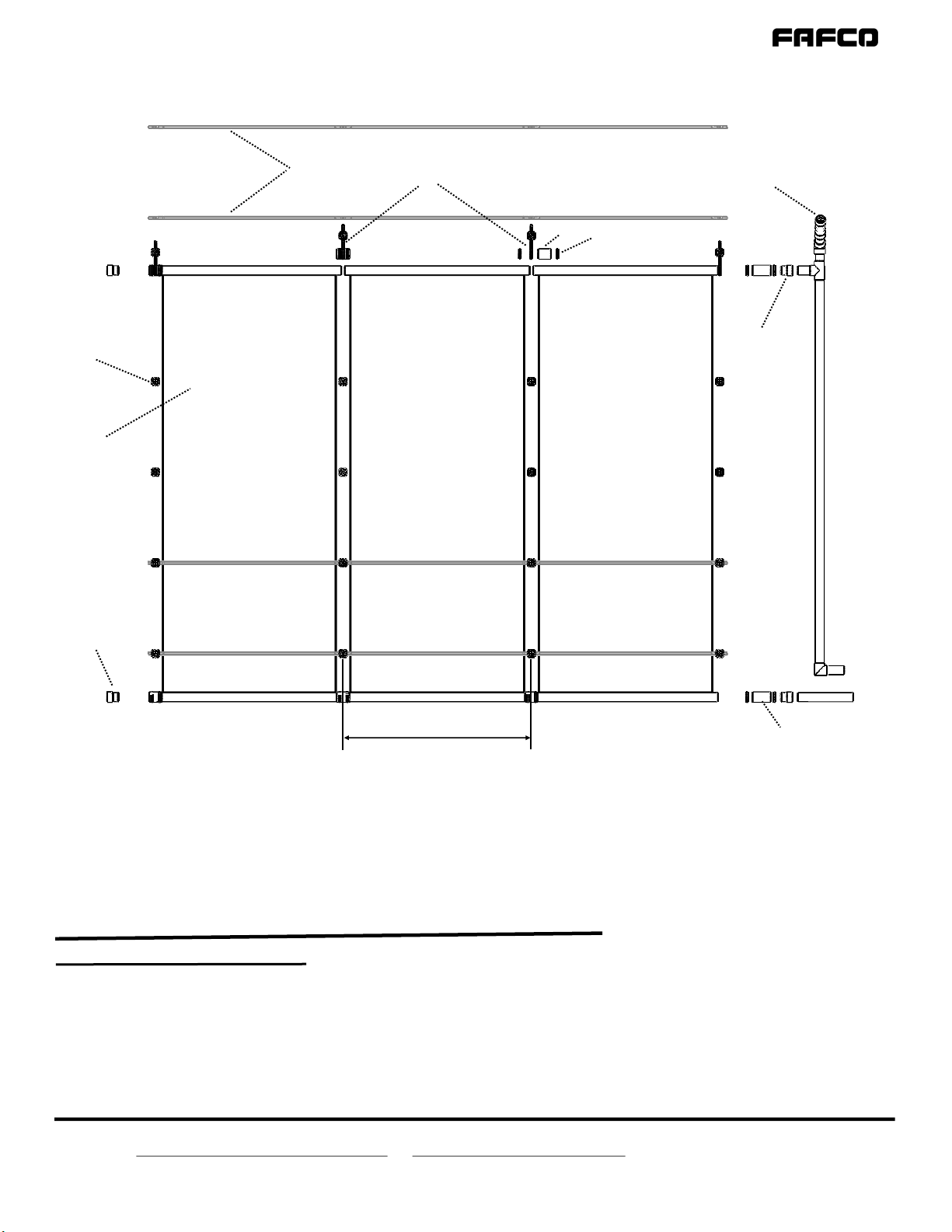

Array Components

Components & Parts List