Chapter: 1 Section: Page

CONFIGURATIONOFTHEDROMODELVNP400 5

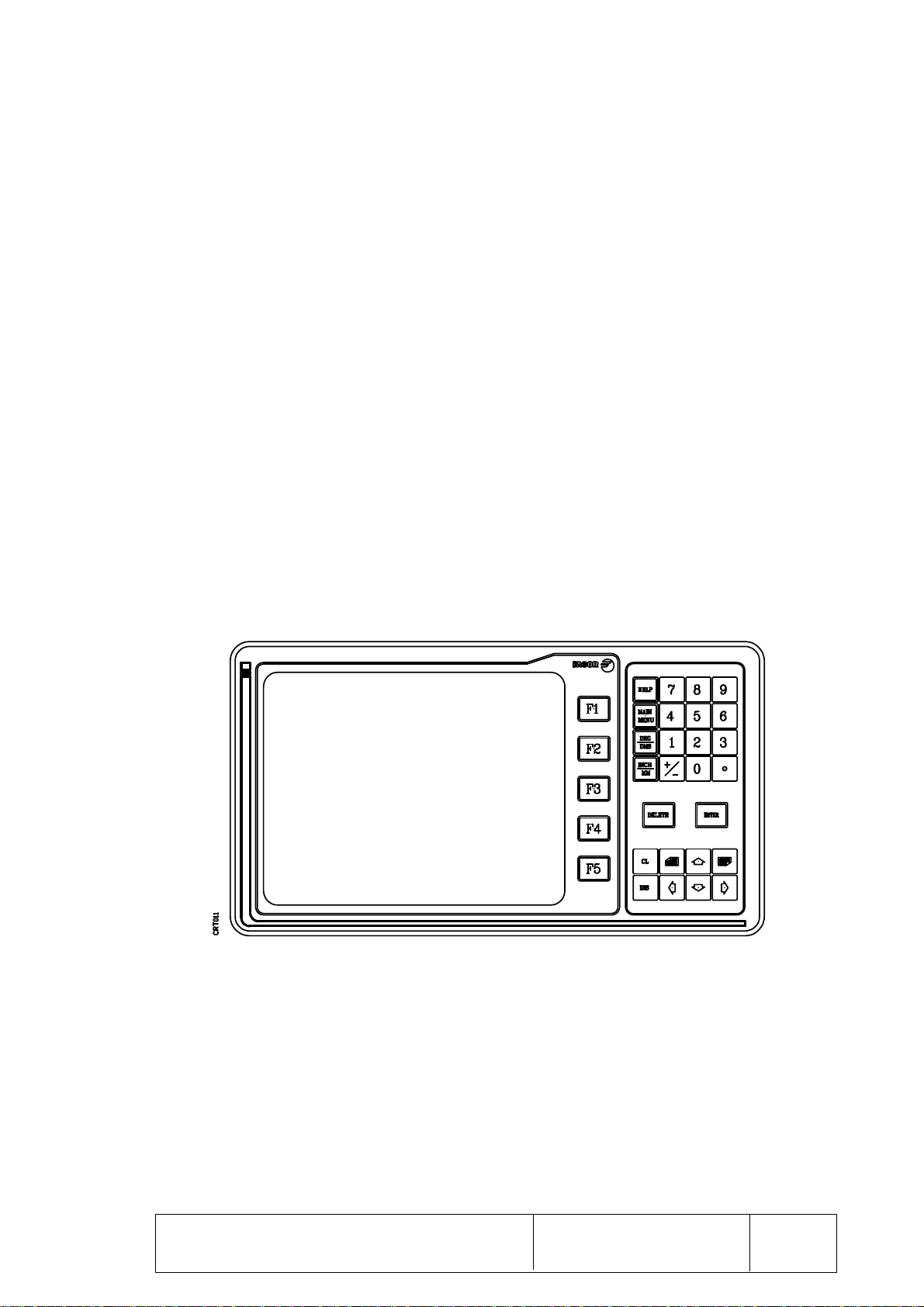

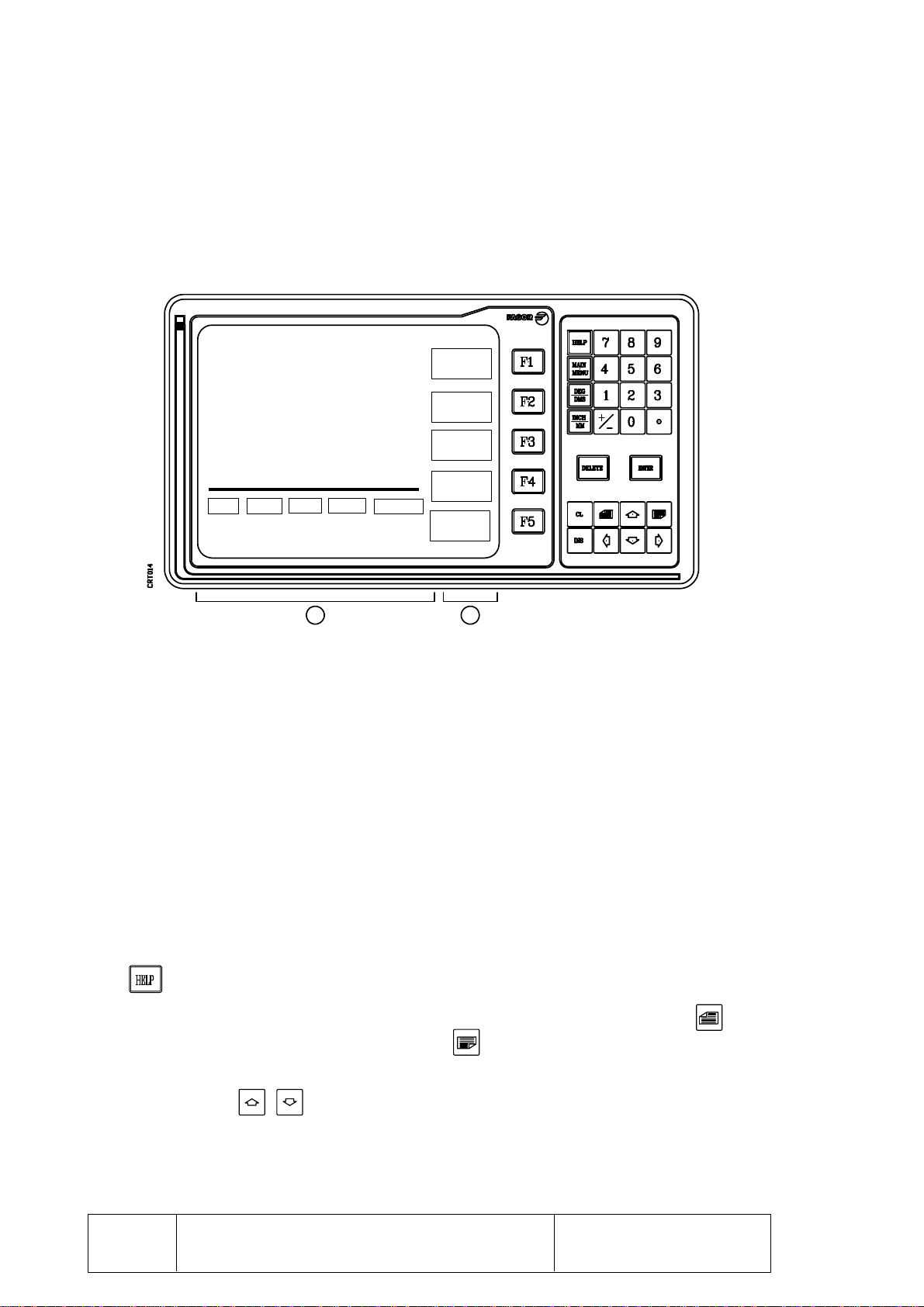

FRONTPANEL

Press again to exit from the help mode.

To access the main menu anytime.

Toggles the display of the work units of the rotary axes.

DEG Displays the positions in 0.0001 degree units. ie: 129.3900°

DMS Displays the positions in degrees, minutes and seconds. i.e: 120° 23' 24'’

Toggles the display of the work units of the linear axes.

Cancels the last character sequence entered.

Used to validate commands and data previously altered or generated.

Cancelsthe last character entered.

It is used to enter a position value directly when in TEACH-IN mode and when

assigningvaluestospecifictables.

To access the previous option, function or table.

To access the next option, function or table.

When pressing one of these keys and depending on the selected

operatingmode,theDROwilldisplaythepreviousornextfield,option,parameter

or block being edited.

SOFT-KEYS or function keys to select the different options shown on the screen.