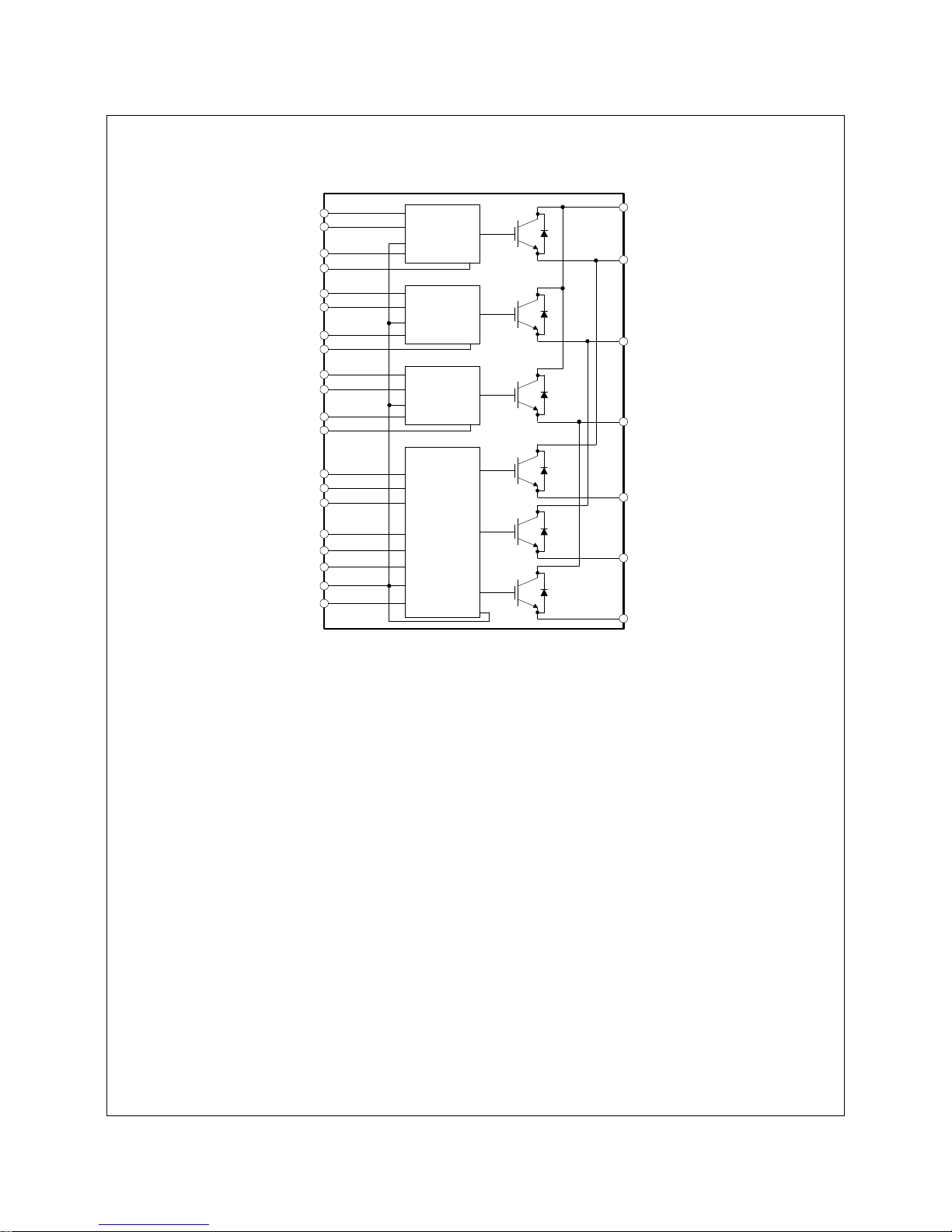

FSBB15CH60 Motion SPM® 3 Series

©2006 Fairchild Semiconductor Corporation 7www.fairchildsemi.com

FSBB15CH60 Rev. C6

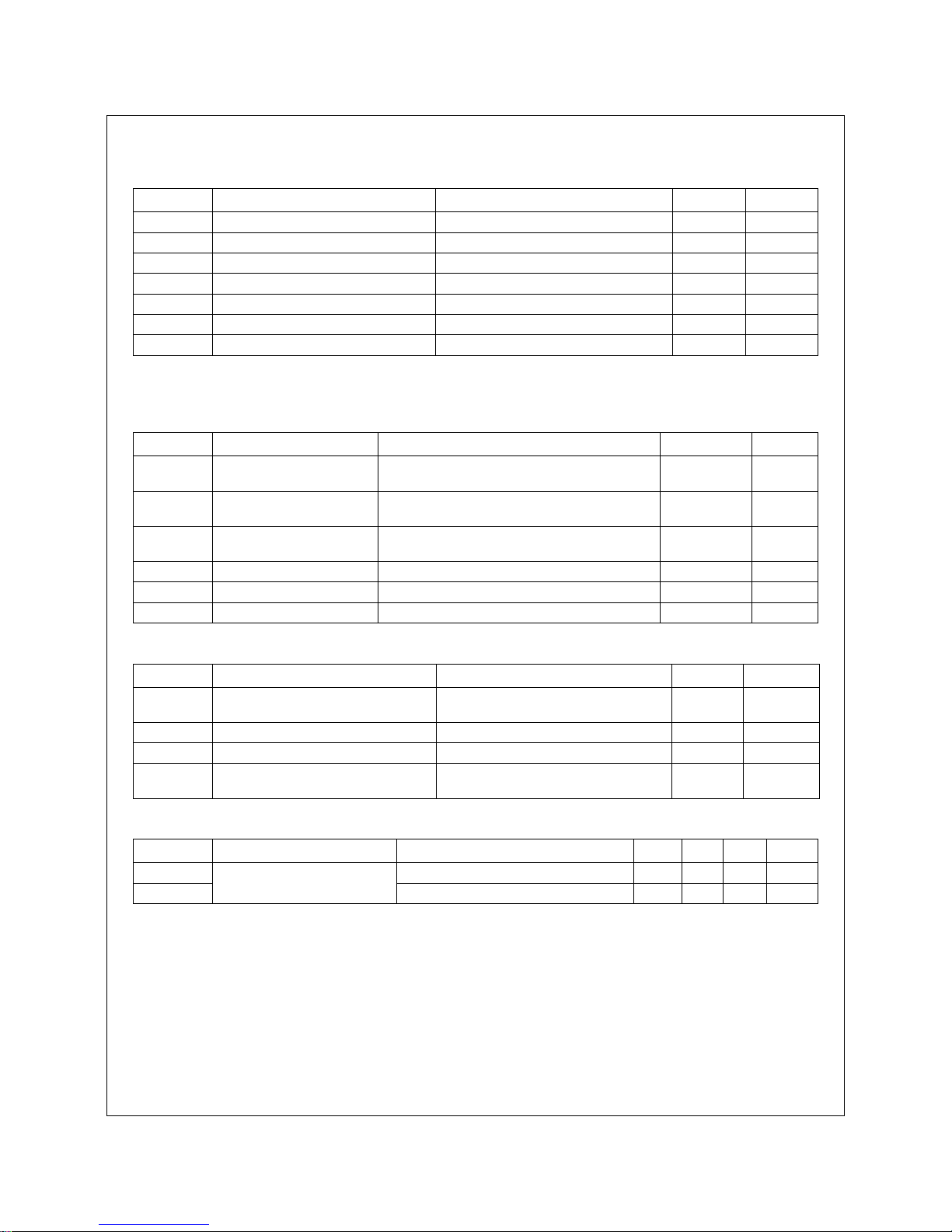

Electrical Characteristics (TJ= 25°C, unless otherwise specified.)

Control Part

2nd Notes:

4. Short-circuit protection is functioning only at the low-sides.

5. The fault-out pulse width tFOD depends on the capacitance value of CFOD according to the following approximate equation: CFOD = 18.3 x 10-6 x tFOD [F]

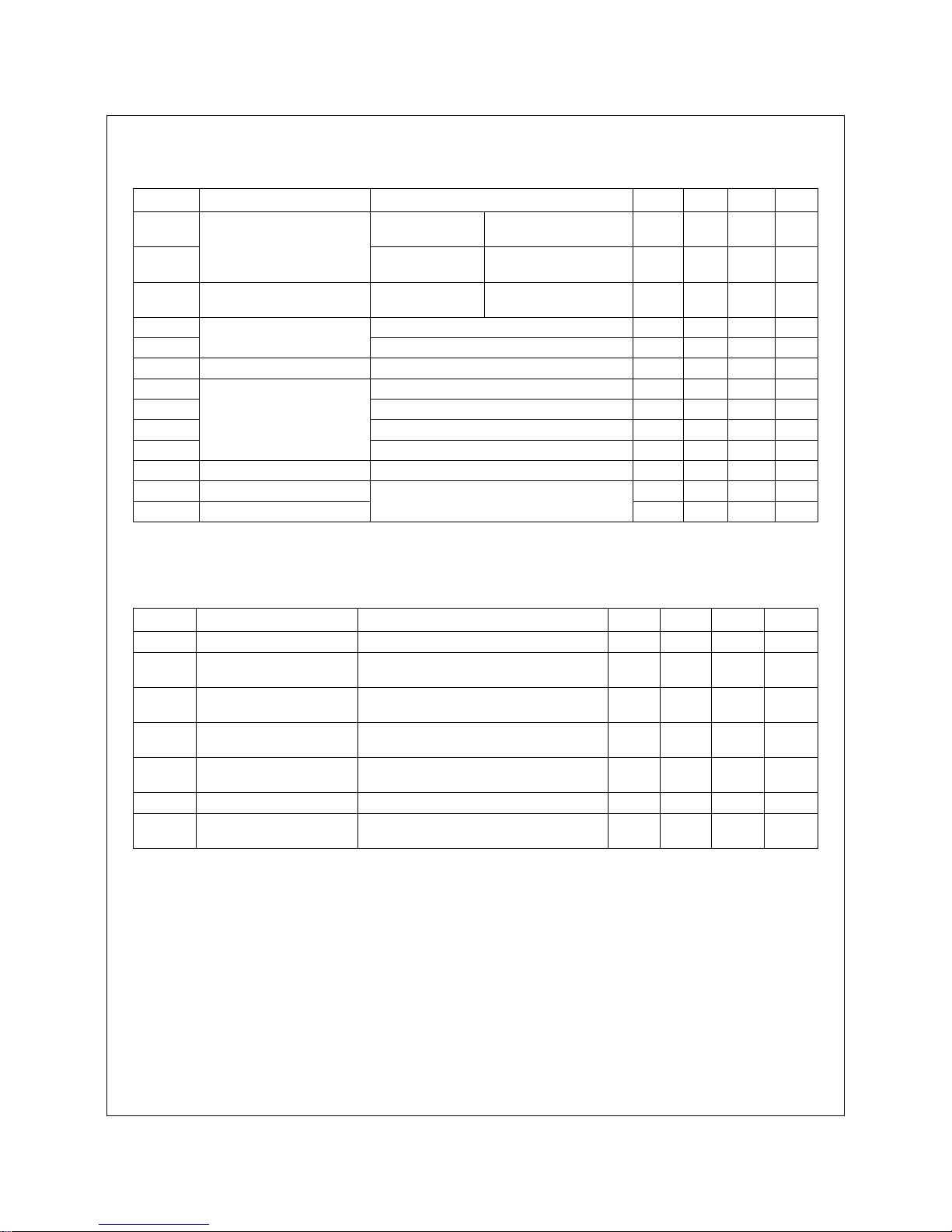

Recommended Operating Conditions

Symbol Parameter Conditions Min. Typ. Max. Unit

IQCCL Quiescent VCC Supply

Current VCC = 15 V

IN(UL, VL, WL) = 0 V VCC(L) - COM - - 23 mA

IQCCH VCC = 15 V

IN(UH, VH, WH) = 0 V VCC(UH), VCC(VH), VCC(WH)

- COM - - 100 A

IQBS Quiescent VBS Supply Current VBS = 15 V

IN(UH, VH, WH) = 0 V VB(U) - VS(U), VB(V) - VS(V),

VB(W) - VS(W)

- - 500 A

VFOH Fault Output Voltage VSC = 0 V, VFO Circuit: 4.7 kto 5 V Pull-up 4.5 - - V

VFOL VSC = 1 V, VFO Circuit: 4.7 kto 5 V Pull-up - - 0.8 V

VSC(ref) Short Circuit Current Trip Level VCC = 15 V (2nd Note 4) 0.45 0.50 0.55 V

UVCCD Supply Circuit Under-Voltage

Protection Detection Level 10.7 11.9 13.0 V

UVCCR Reset Level 11.2 12.4 13.2 V

UVBSD Detection Level 10.1 11.3 12.5 V

UVBSR Reset Level 10.5 11.7 12.9 V

tFOD Fault-out Pulse Width CFOD = 33 nF (2nd Note 5) 1.0 1.8 - ms

VIN(ON) ON Threshold Voltage Applied between IN(UH), IN(VH), IN(WH), IN(UL),

IN(VL), IN(WL) - COM 3.0 - - V

VIN(OFF) OFF Threshold Voltage - - 0.8 V

Symbol Parameter Conditions Min. Typ. Max. Unit

VPN Supply Voltage Applied between P - NU, NV, NW- 300 400 V

VCC Control Supply Voltage Applied between VCC(UH), VCC(VH), VCC(WH),

VCC(L) - COM 13.5 15 16.5 V

VBS High-Side Bias Voltage Applied between VB(U) - VS(U), VB(V) - VS(V),

VB(W) - VS(W)

13.0 15 18.5 V

dVCC / dt,

dVBS / dt Control Supply Variation -1 - 1 V / s

tdead Blanking Time for Preventing

Arm-Short For Each Input Signal 2.0 - - s

fPWM PWM Input Signal -20C TC100°C, -20C TJ125°C - - 20 kHz

VSEN Voltage for Current Sensing Applied between NU, NV, NW - COM

(Including Surge Voltage) -4 4 V