FSDH321, FSDL321

9

Functional Description

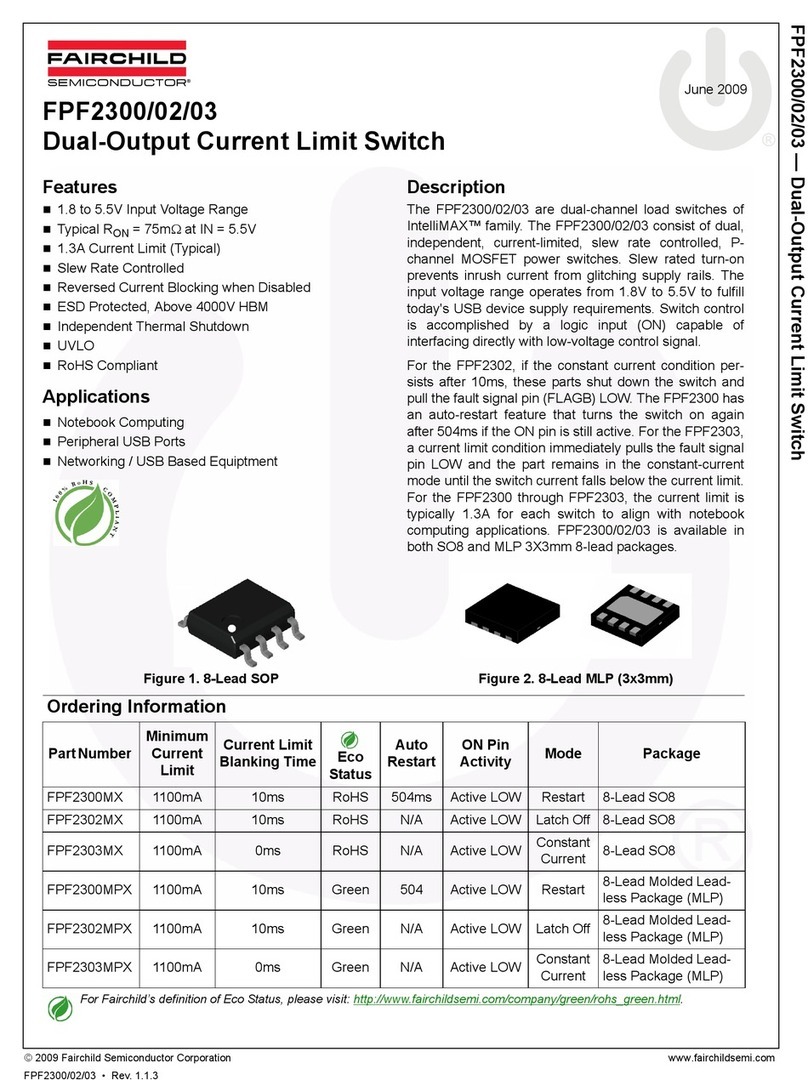

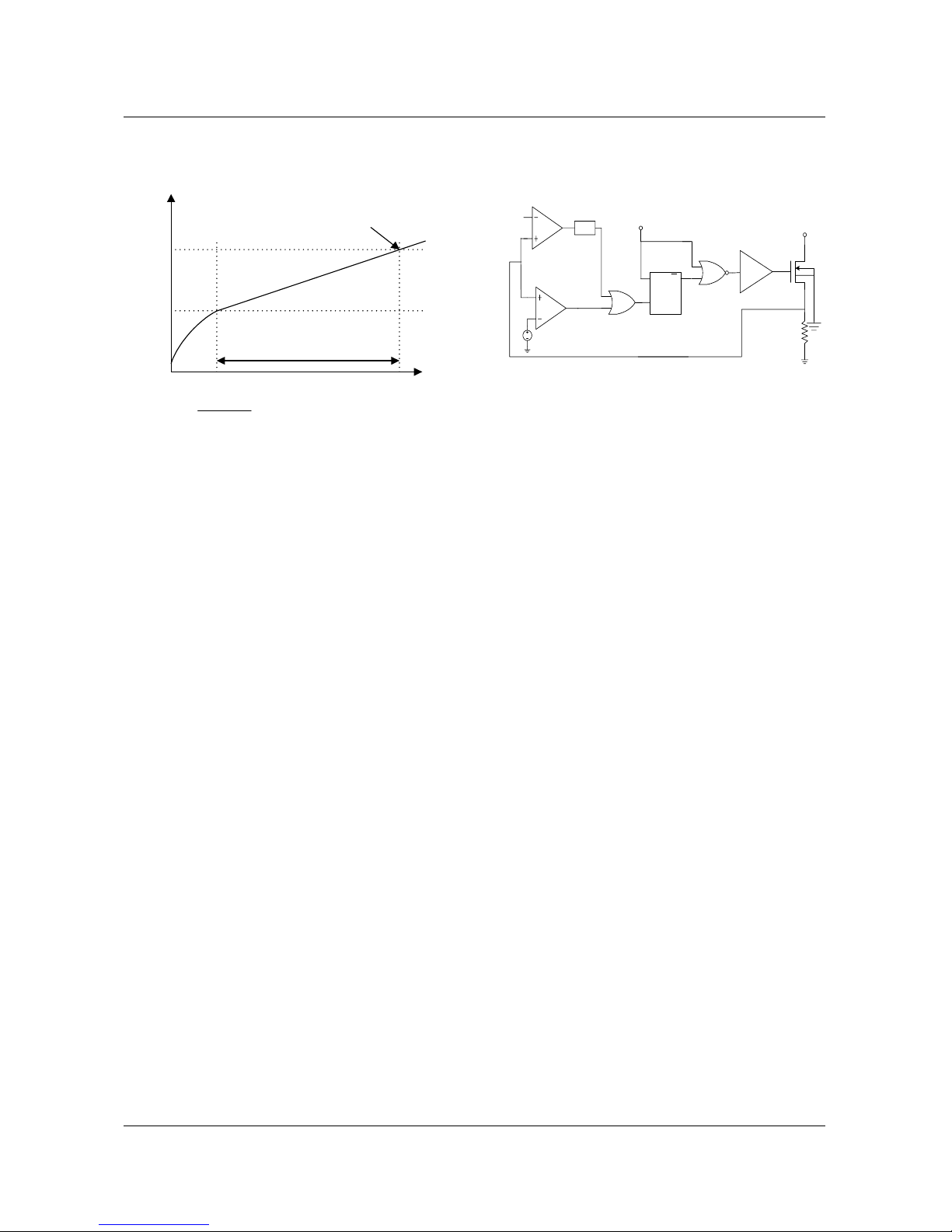

1. Startup : In previous generations of Fairchild Power

Switches (FPSTM) the Vstr pin had an external resistor to the

DC input voltage line. In this generation the startup resistor

is replaced by an internal high voltage current source and a

switch that shuts off when 15ms goes by after the supply

voltage, Vcc, gets above 12V. The source turns back on if

Vcc drops below 8V.

Figure 4. High Voltage Current Source

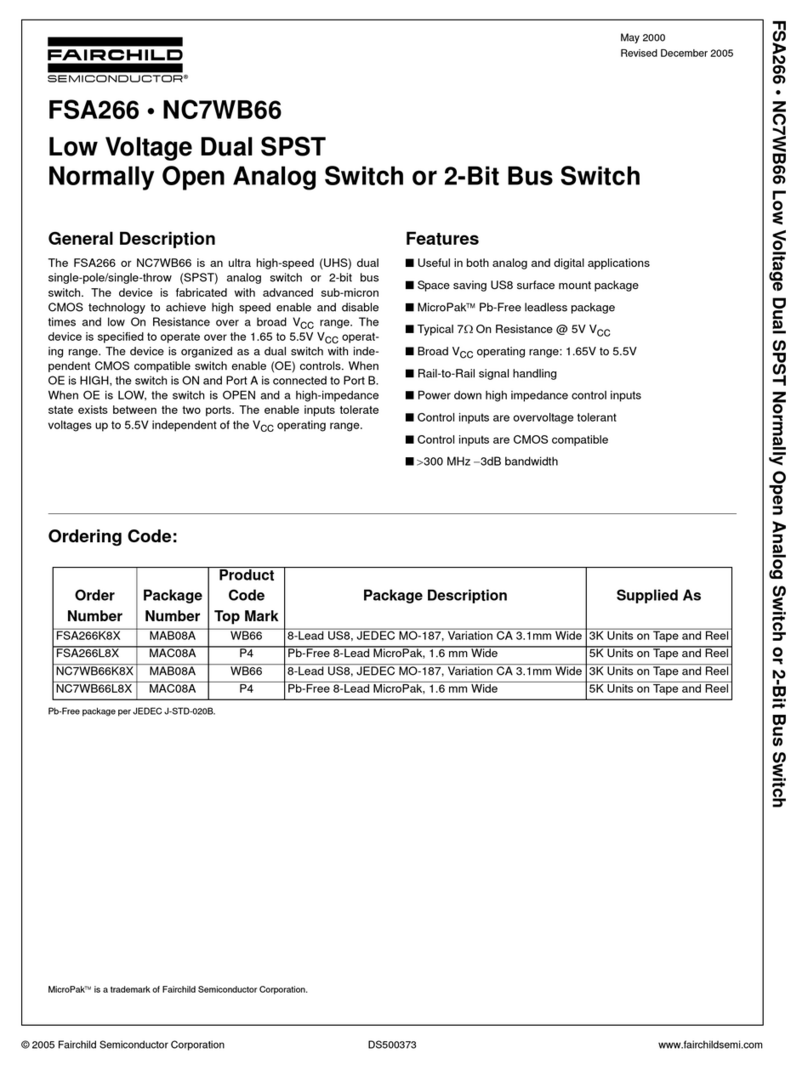

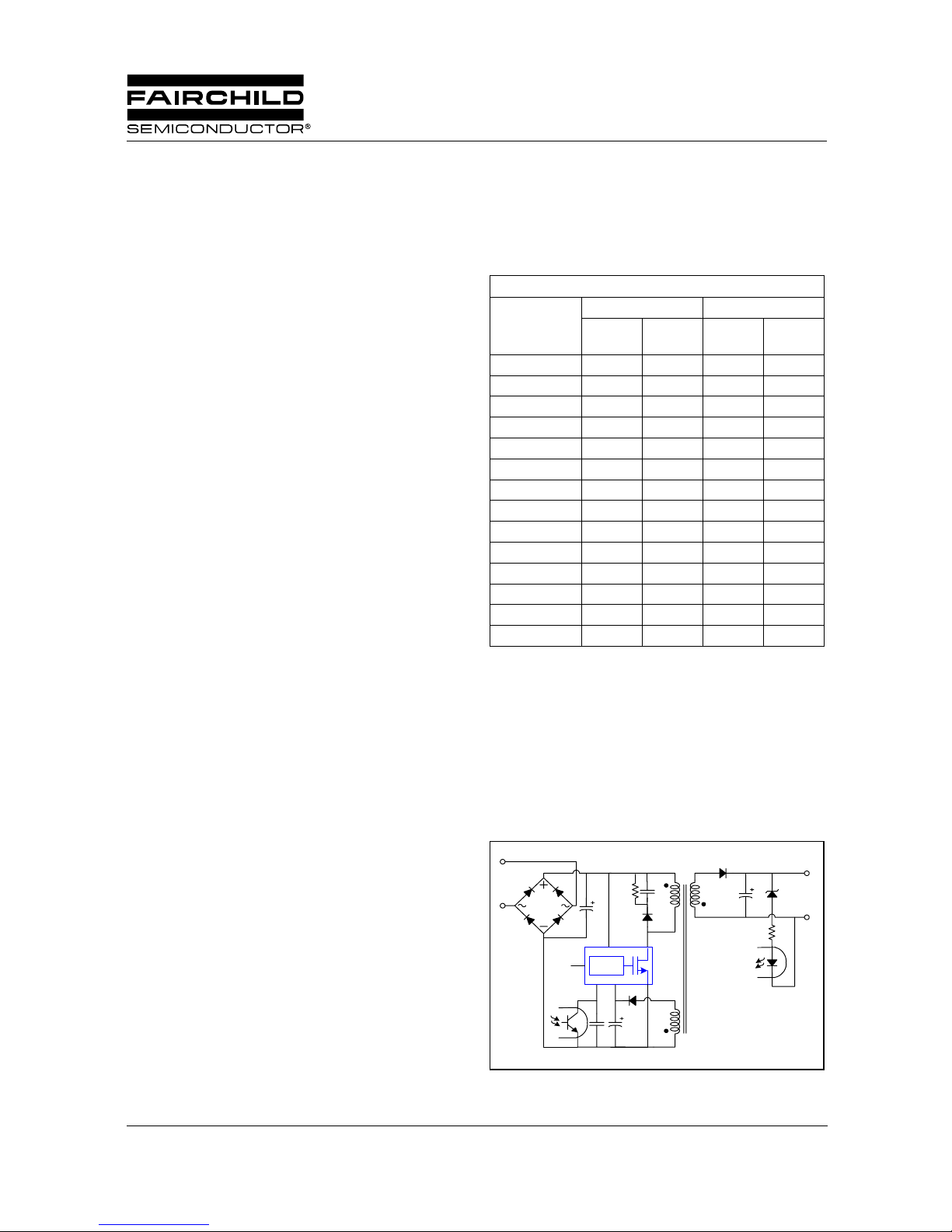

2. Feedback Control : The FSDx321 employs current mode

control, as shown in Figure 5. An opto-coupler (such as the

H11A817A) and shunt regulator (such as the KA431) are

typically used to implement the feedback network. Compar-

ing the feedback voltage with the voltage across the Rsense

resistor plus an offset voltage makes it possible to control the

switching duty cycle. When the KA431 reference pin volt-

age exceeds the internal reference voltage of 2.5V, the opto-

coupler LED current increases, the feedback voltage Vfb is

pulled down and it reduces the duty cycle. This event typi-

cally happens when the input voltage is increased or the out-

put load is decreased.

Figure 5. Pulse Width Modulation (PWM) Circuit

3. Leading Edge Blanking (LEB) : At the instant the inter-

nal Sense FET is turned on, the primary side capacitance and

secondary side rectifier diode reverse recovery typically

cause a high current spike through the Sense FET. Excessive

voltage across the Rsense resistor leads to incorrect feedback

operation in the current mode PWM control. To counter this

effect, the FPS employs a leading edge blanking (LEB) cir-

cuit. This circuit inhibits the PWM comparator for a short

time (tLEB) after the Sense FET is turned on.

4. Protection Circuits : The FPS has several protective

functions such as over load protection (OLP), over voltage

protection (OVP), abnormal over current protection

(AOCP), under voltage lock out (UVLO) and thermal shut-

down (TSD). Because these protection circuits are fully inte-

grated inside the IC without external components, the

reliability is improved without increasing cost. Once a fault

condition occurs, switching is terminated and the Sense FET

remains off. This causes Vcc to fall. When Vcc reaches the

UVLO stop voltage VSTOP (8V), the protection is reset and

the internal high voltage current source charges the Vcc

capacitor via the Vstr pin. When Vcc reaches the UVLO

start voltage VSTART (12V), the FPS resumes its normal

operation. In this manner, the auto-restart can alternately

enable and disable the switching of the power Sense FET

until the fault condition is eliminated.

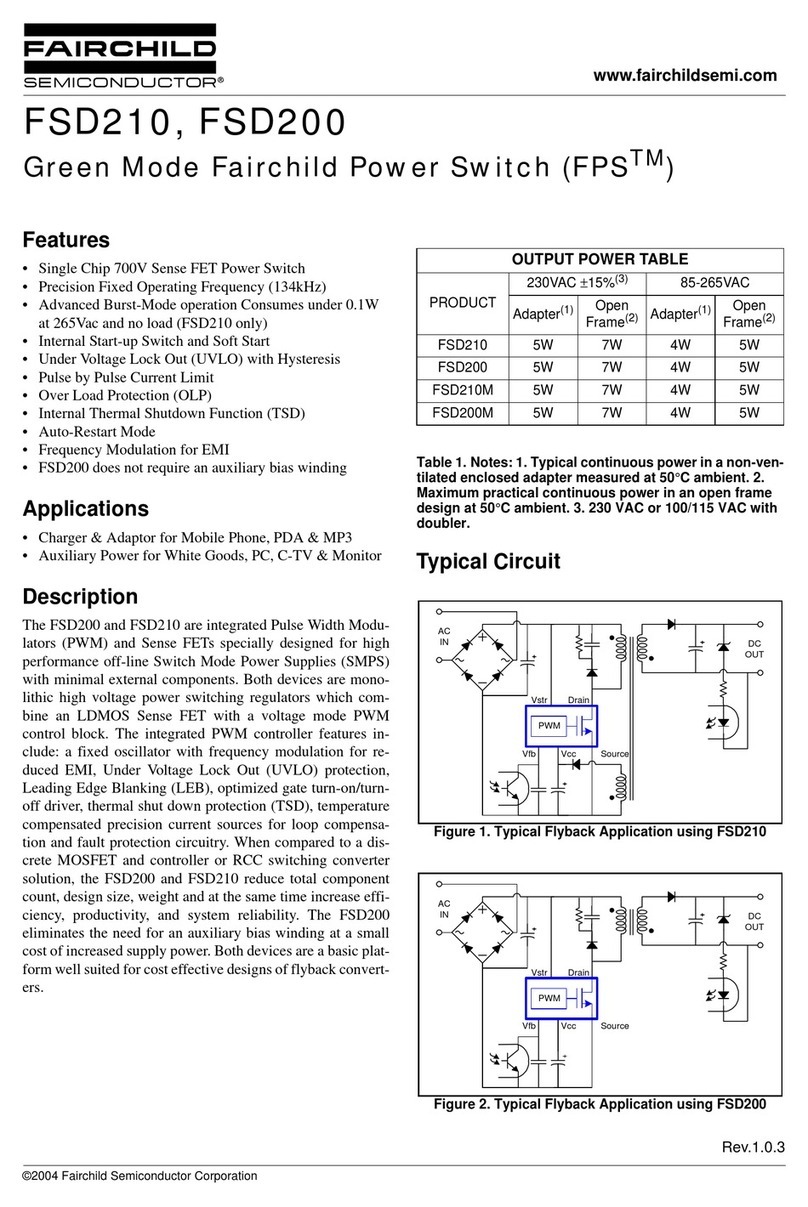

4.1 Over Load Protection (OLP) :Overload is defined as

the load current exceeding a pre-set level due to an unex-

pected event. In this situation, the protection circuit should

be activated in order to protect the SMPS. However, even

when the SMPS is operating normally, the over load protec-

tion (OLP) circuit can be activated during the load transition.

In order to avoid this undesired operation, the OLP circuit is

designed to be activated after a specified time to determine

whether it is a transient situation or an overload situation. In

conjunction with the Ipk current limit pin (if used) the cur-

rent mode feedback path would limit the current in the Sense

FET when the maximum PWM duty cycle is attained. If the

output consumes more than this maximum power, the output

voltage (Vo) decreases below its rating voltage. This reduces

the current through the opto-coupler LED, which also

reduces the opto-coupler transistor current, thus increasing

the feedback voltage (VFB). If VFB exceeds 3V, the feed-

back input diode is blocked and the 5uA current source (IDE-

LAY) starts to charge Cfb slowly up to Vcc. In this condition,

VFB increases until it reaches 6V, when the switching opera-

tion is terminated as shown in Figure 6. The shutdown delay

time is the time required to charge Cfb from 3V to 6V with

5uA current source.

Vin,dc

Vstr

Vcc

15ms after

Vcc≥12V

UVLO off

Vcc<8V

UVLO on

ISTR

J-FET

ICH

3OSC

Vcc Vcc

5uA 0.9mA

VSD

R

2.5R

Gate

driver

OLP

D1 D2

VFB

Vfb

431

CFB

Vo

+

-

VFB,in