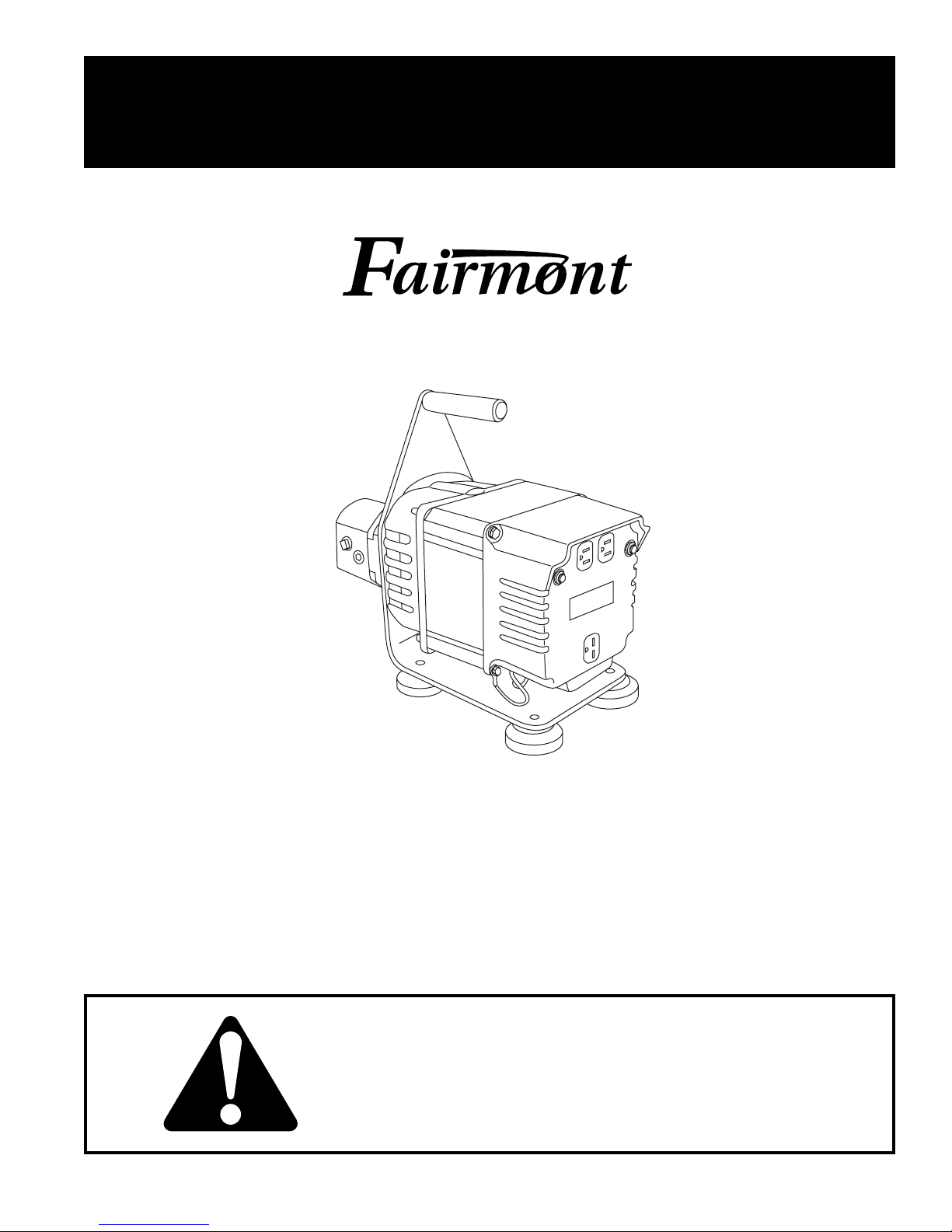

H6635 / 42276 Portable Alternator

Greenlee / A Textron Company 24455 Boeing Dr. • Rockford, IL 61109-2988 USA • 815-397-7070

Description ..................................................................... 2

Important Safety Instructions ......................................3-4

Identification ................................................................... 5

Specifications

Alternator ................................................................... 6

Hydraulic Power Source .........................................6-7

Recommended Hydraulic Fluids ................................ 7

Hoses and Fittings ..................................................... 8

Unit / Hose Connections ............................................ 8

Operation ..................................................................9-10

Maintenance............................................................11-12

Troubleshooting ........................................................... 13

Disassembly ................................................................. 14

Inspection ..................................................................... 15

Assembly...................................................................... 15

Illustration and Parts ...............................................16-17

Accessories (Optional) ................................................. 18

Table of Contents

Description

The H6635/42276 Portable Alternator provides instant

electric power for lighting, heaters and other electrical

equipment. It is driven by a hydraulic gear motor and is

able to operate from hydraulic systems with flow rates

from 30-45 l/min (8-12 gpm). The alternator, a 60-cycle,

single-phase unit, is capable of delivering up to 3500

watts of electrical power through its 120 and 240 volt AC

outlets.

The 120 volt duplex receptacle is split so that 15 amps

of current may be drawn from either half of the receptacle.

These outlets may be used along with the 240 volt

receptacle provided the alternator is not overloaded.

A maximum of 14.6 amps may be drawn from the 240

volt receptacle provided it is the only receptacle used.

When using the unit, current must be limited to the

ratings on the nameplates of the equipment being

used. If the 240 volt receptacle is used along with the

120 volt receptacles, the total load drawn must not

exceed the equipment’s nameplate ratings.

Purpose

This instruction manual is intended to familiarize

personnel with the safe operation and maintenance

procedures for the following Fairmont tool:

H6635/42276 Portable Alternator

Keep this manual available to all personnel.

Replacement manuals are available upon request

at no charge.

Safety is essential in the use and maintenance of

Fairmont tools and equipment. This instruction manual

and any markings on the tool provide information for

avoiding hazards and unsafe practices related to the use

of this tool. Observe all of the safety information provided.

KEEP THIS MANUAL

Outlet 1 120 Volts x Amps Draw = Watts #1

Outlet 2 120 Volts x Amps Draw = Watts #2

Outlet 3 240 Volts x Amps Draw = Watts #3

Outlet 4 240 Volts x Amps Draw = Watts #4

Total of all outlets used

must not exceed 3500 watts.

All specifications are nominal and may change as design improve-

ments occur. Greenlee Textron Inc. shall not be liable for damages

resulting from misapplication or misuse of its products.

Safety

Do not discard this product or throw away!

For recycling information, go to

www.greenlee.com.