1

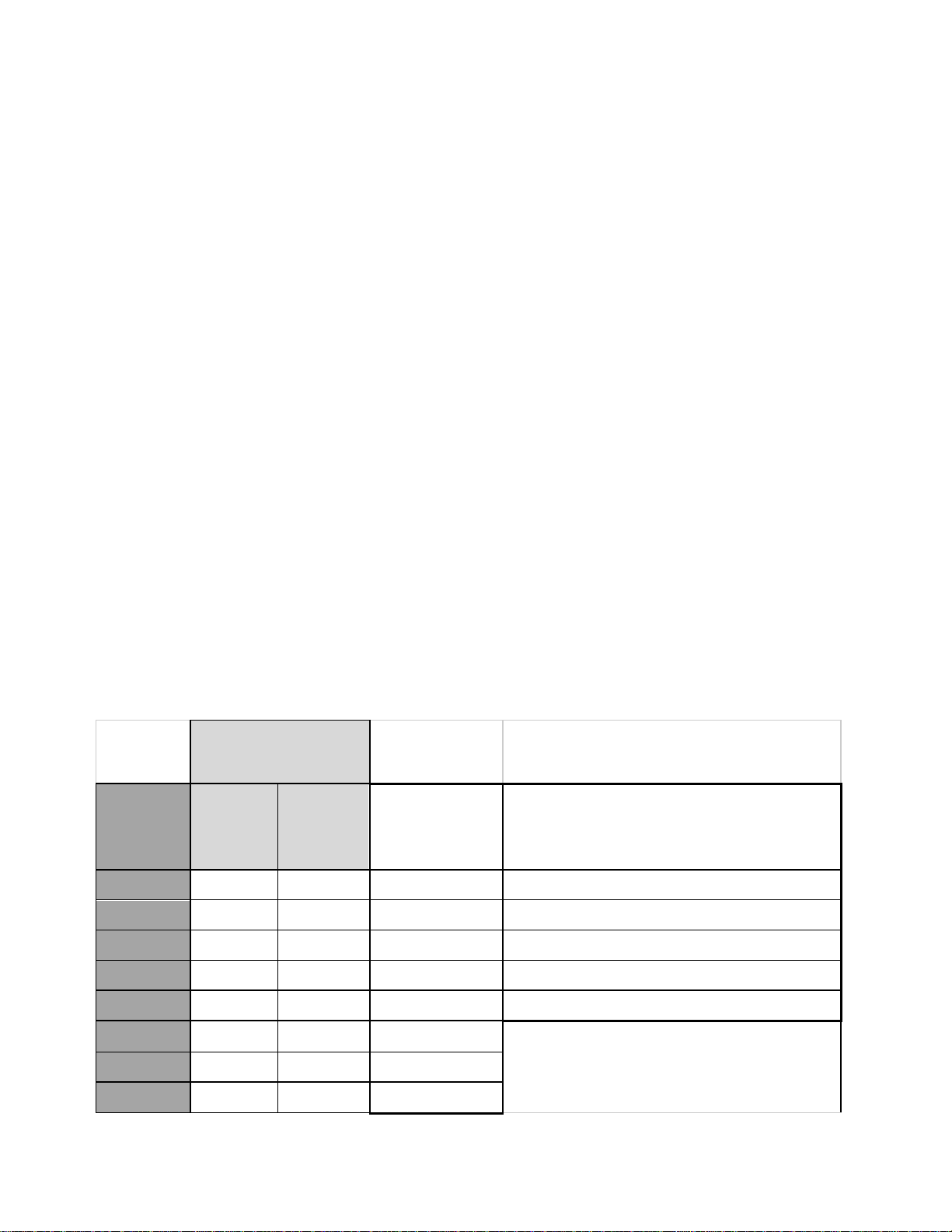

Table of content

1Copyright ............................................................................................................................ 3

2Trademarks......................................................................................................................... 3

3Warnings and safety notices............................................................................................... 3

4Limitation of liability............................................................................................................. 3

5About this manual............................................................................................................... 4

6Device layout...................................................................................................................... 4

7Accessories ........................................................................................................................ 5

7.1 AC adapter .................................................................................................................. 5

7.2 Battery......................................................................................................................... 5

8Getting started.................................................................................................................... 6

8.1 Product Content........................................................................................................... 6

8.2 How to install FX9 validators........................................................................................ 6

8.2.1 Electrical recommendations.................................................................................. 6

8.2.2 How to install Back Casings Wall.......................................................................... 7

8.2.3 How to install a Back Casing Pole........................................................................14

8.2.4 How to install the front casing..............................................................................27

8.2.5 Troubleshooting & Maintenance ..........................................................................27

8.3 How to clean plastic surfaces......................................................................................28

8.4 How to store FX915SC-ASK.......................................................................................28

8.5 How to switch the device ON or OFF..........................................................................29

8.6 Home screen and synchronization..............................................................................29

8.7 How to read an NFC card ...........................................................................................30

8.8 How to read a barcode (1D/2D) ..................................................................................31

8.9 About the SIM/SAM slots............................................................................................31

9Technical specifications.....................................................................................................32

10 Warranty information......................................................................................................34

11 Safety and general information.......................................................................................34

12 Declaration of Conformity...............................................................................................35

13 Band and power.............................................................................................................36

13.1 Support band information and power ..........................................................................36