Two post hydraulic lift QJY3.0-E

2

CONTENTS

1 Safety............................................................................................................................................................3

1.1 Introduction.........................................................................................................................................3

1.2 Symbols..............................................................................................................................................3

1.3 Intended Use ......................................................................................................................................3

1.4 Safety Instructions for Commissioning...............................................................................................3

1.5 Safety Instructions for Operation........................................................................................................4

1.6 Safety Instructions for Servicing.........................................................................................................4

1.7 Safety Features..................................................................................................................................4

2 Production information..................................................................................................................................5

2.1 Specifications......................................................................................................................................5

2.2 Safety warnings..................................................................................................................................6

3. Packing, transport and storage....................................................................................................................7

3.1 Packing...............................................................................................................................................7

3.2 Lifting and handling ............................................................................................................................7

3.3 Storage and stacking of packages.....................................................................................................7

3.4 Delivery and check of packages.........................................................................................................7

4 Installation.....................................................................................................................................................7

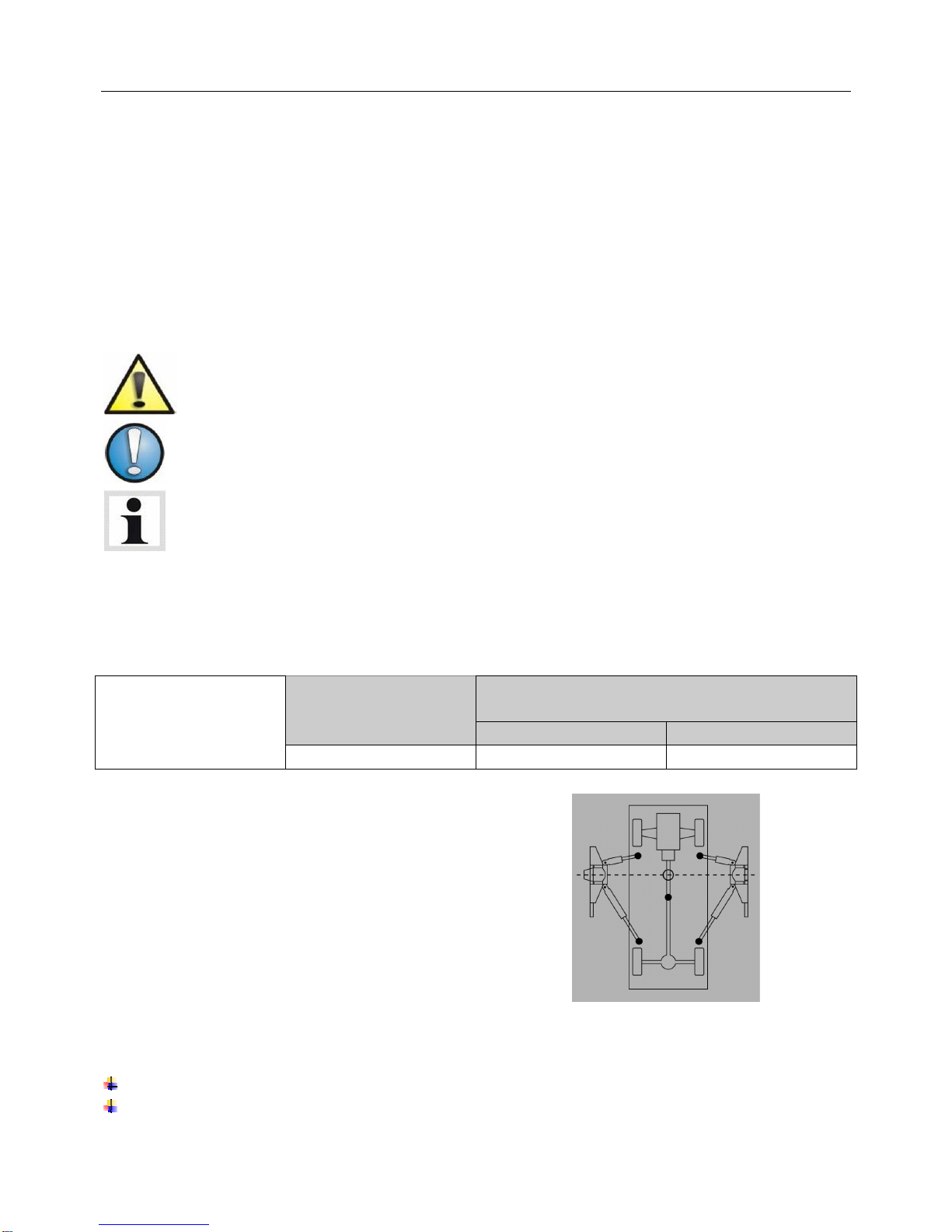

4.1 Space required ...................................................................................................................................7

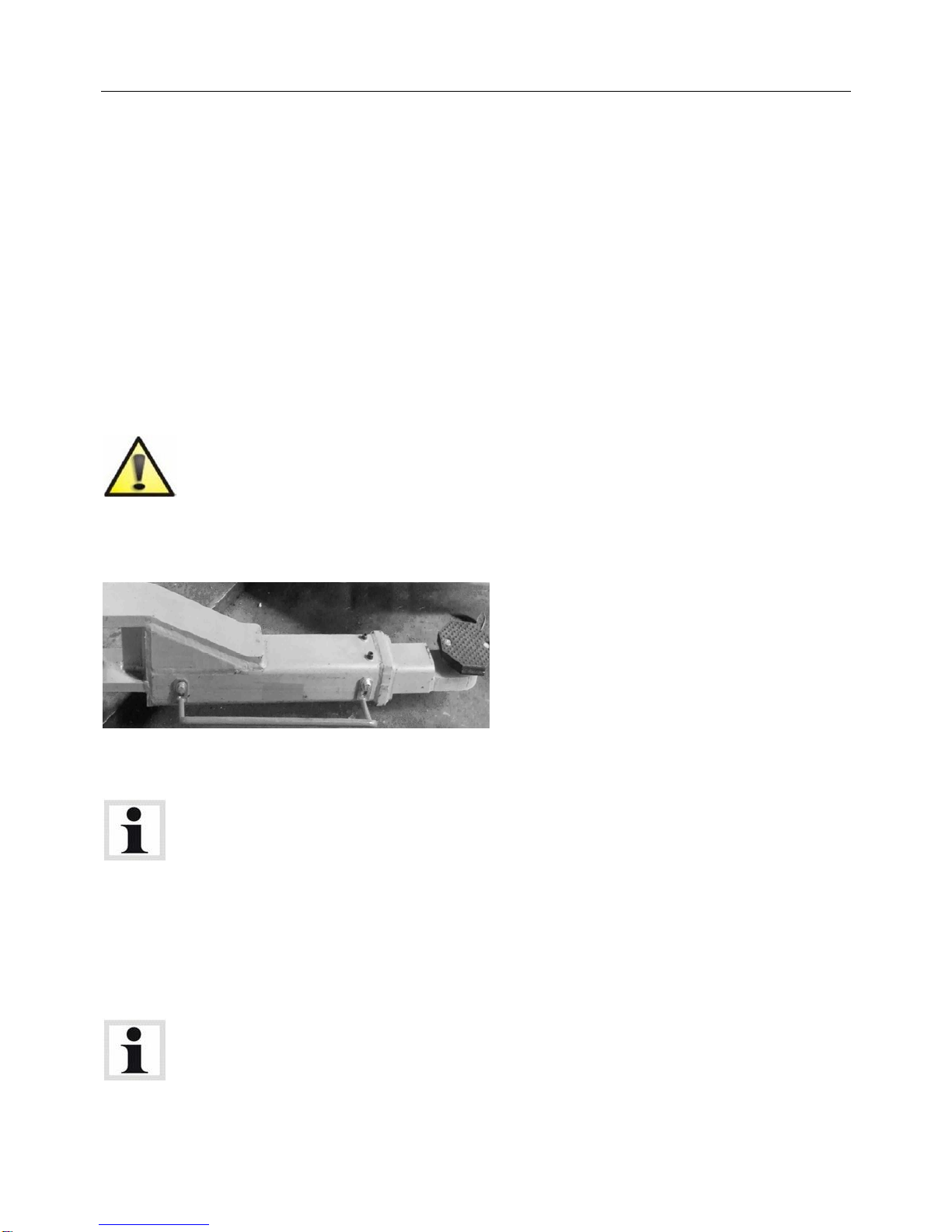

4.2 Installation steps.................................................................................................................................8

5 Operation ......................................................................................................................................................9

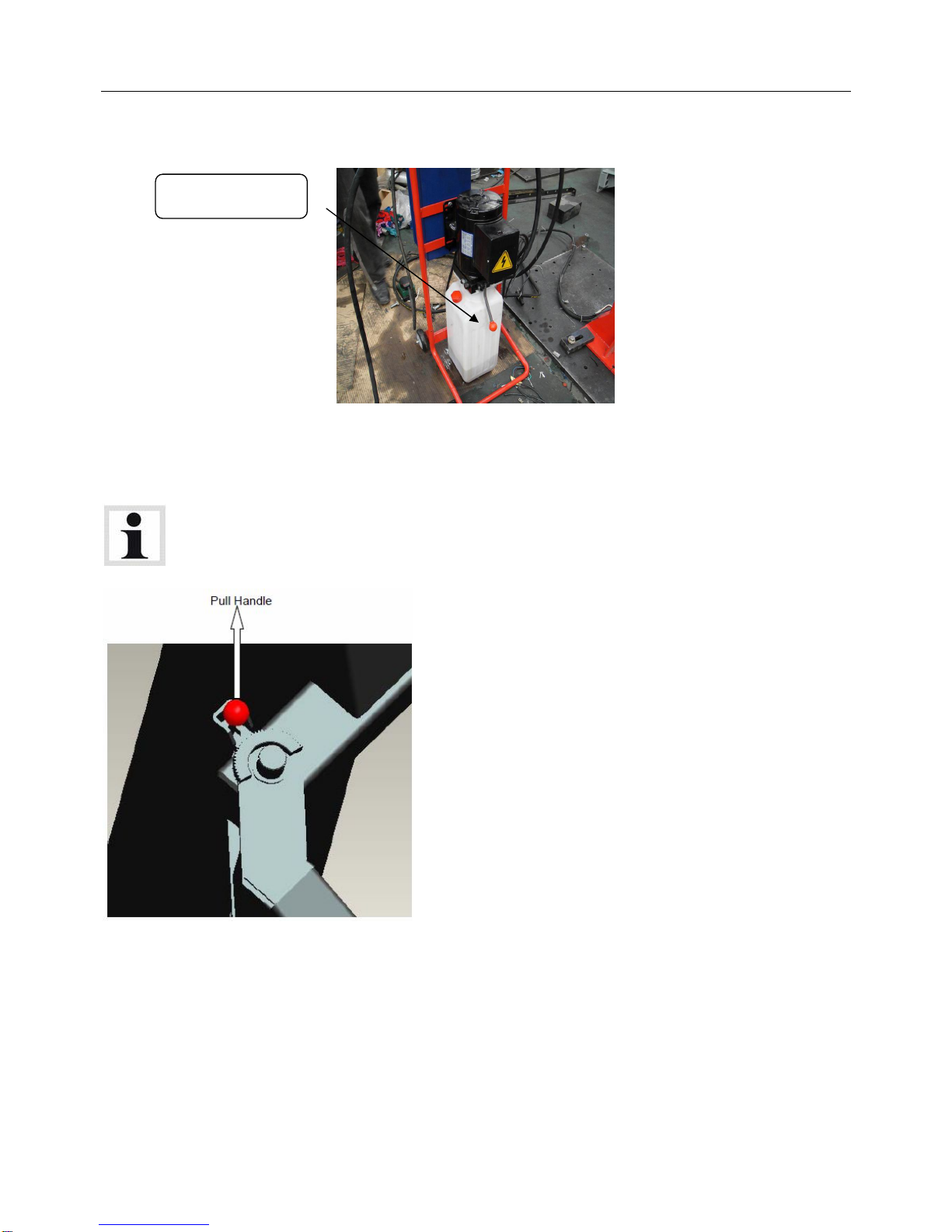

5.1 Controls ............................................................................................................................................10

5.2 Operation..........................................................................................................................................10

6 Maintenance................................................................................................................................................13

6.1 Maintenance schedule......................................................................................................................13

6.2 Annual inspection.............................................................................................................................13

6.3 Maintenance by the operator............................................................................................................13

6.4 Cleaning............................................................................................................................................15

7 Troubleshooting ..........................................................................................................................................16

8 Disposal.......................................................................................................................................................16

9 EC Declaration............................................................................................................................................17

10 Attached drawings...................................................................................................................................18

10.1 Electrical drawing.............................................................................................................................18

10.2 Hydraulic drawings...........................................................................................................................18

10.3 Explosive view..................................................................................................................................19