Fancy Foam Models Rans S-7 Courier User manual

Rev. 1.0, 3-31-2015

Fancy Foam Models, LLC

635 Laramie Cir. Maize, Ks. 67101

.fancyfoam.com

Assembly Instructions for the Rans S-7 Courier.

Recommended Electronics and motors:

Propeller: 10x5 electric

Motor: 2810-1100kv or any equivalent motor

Speed control: 20-30 amp.

Battery: 1300mah, 3 cell, 20C rated Li-Po or

equivalent.

Receiver: 5-8 channel (see radio setup).

Servos: (6) HXT 900.

Servo Extensions: (4) 30cm long

Disclaimer: Fancy Foam Models has done

everything we can to caution and inform the end

user regarding the use of Lithium polymer battery

technology. We are in no way responsible for any

damage that may be caused by these batteries.

Please read, understand and follow all instructions

for the charger and batteries. Failure to use this

battery technology properly can result in the ris of

fire. If you are not comfortable with this

technology, return the batteries pac s and it to us

for a refund. By building the it and using the

batteries, you accept full responsibility for the

safety of these batteries.

Recommended building methods and glues:

Much of the construction of this model is done by

laying the parts on a flat table. It is strongly

recommended that you put ax paper do n on the

surface first so any excess glue doesn’t soak through

the foam and glue the parts to the table. For all

assembly, use “Foam-Tac” contact adhesive. The

hinges are also done ith Foam-Tac, see our video on

the eb site. Hot glue can be used to attach the servos

and control horns.

Painting:

It is easiest to paint the parts before assembly. Card

stock can be used to make templates for stripes,

checkers, ect... Epp does is not affected much by

solvents so Krylon, Testors and airbrush paints can be

used.

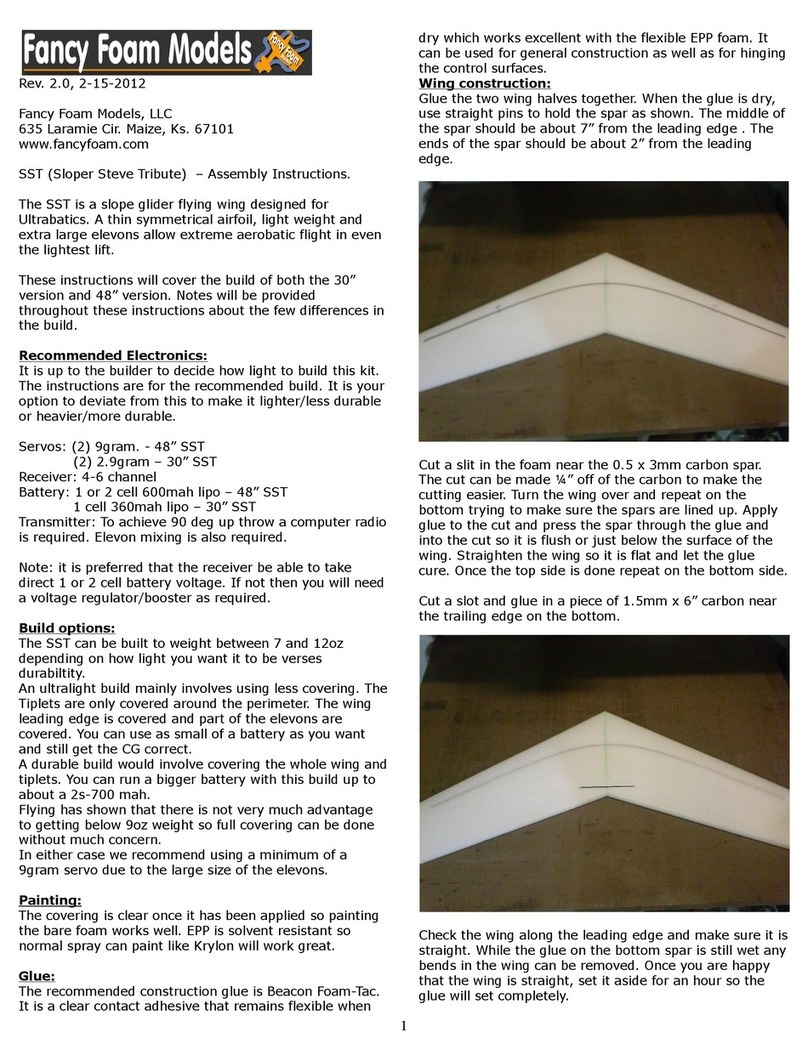

Wing assembly:

Start by gluing the t o ing halves together. The

Foam-Tac glue is a contact adhesive. Apply glue to

both sides of the joint and spread to a thin layer. Allo

to dry a minute or so and press the parts together.

Allo 10 minutes for a full cure.

There are marks on each ing tip 2-3/4” back from the

leading edge. Align a strait edge ith these marks and

using a sharp razor blade cut a 1/8” deep slot 40” long

on the top and bottom of the ing. Put a small bead of

glue on the slot and push one of the carbon rod spars

through the glue and into the slot. Spread any

remaining glue into the foam over the spar. When the

glue is dry, repeat for the other side.

1

Cut a 6” long slot 1/2” for ard of the hinge line on the

bottom of the ing and glue in the 6” long carbon rod.

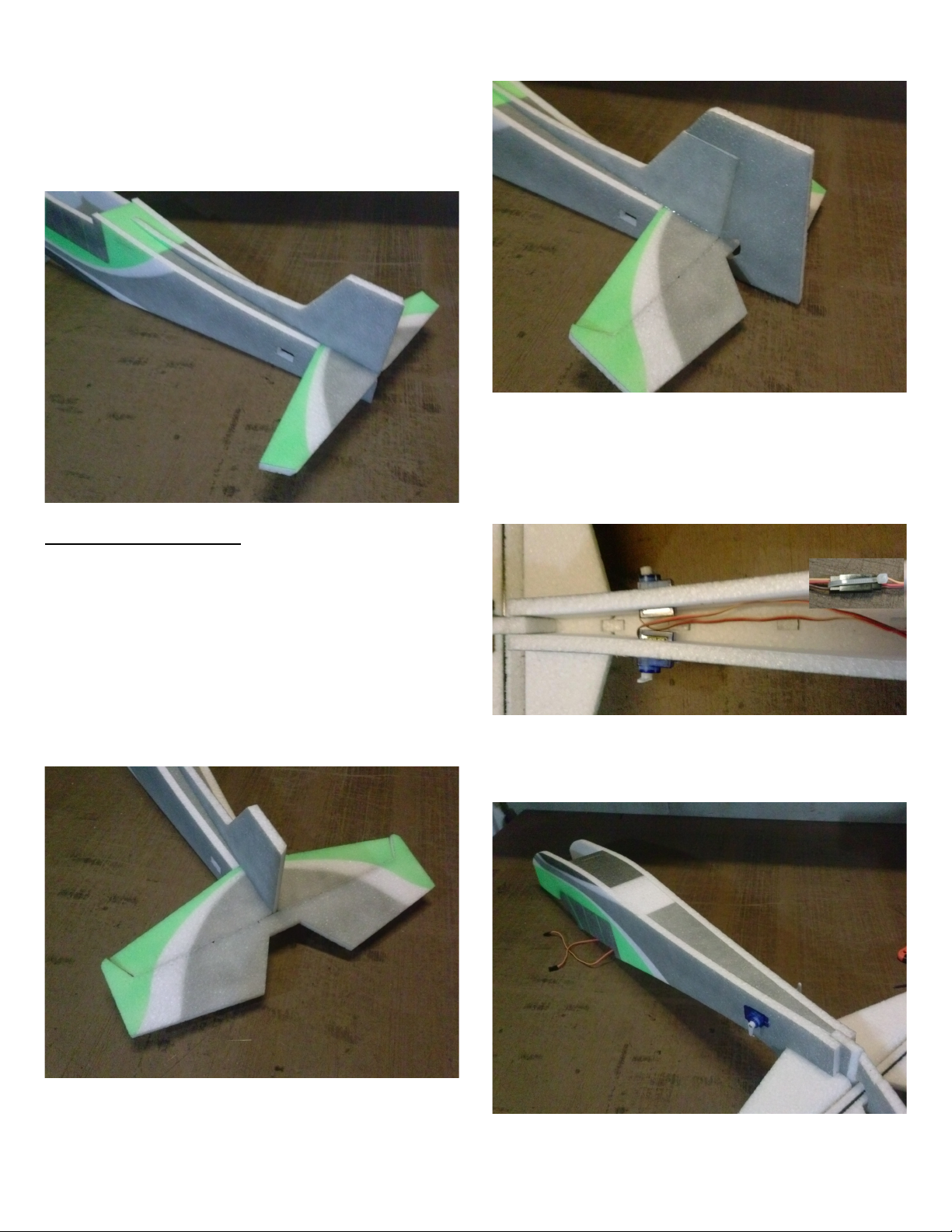

Servo installation:

Cut slits about ¼” deep in the foam from servo cutouts

to the center as sho n for the servo ires. Glue the

servos into the cutouts. Push the servo ires into the

slits so they are buried in the foam. The flap servos ill

need servo extensions or a reversing Y-harness

installed. There is a pre-cut pocket in the ing for the

connectors.

Cut a 1/2” slit in the ailerons and flaps in line ith the

servo arm for the control horn tab. The holes in the

control horns should be directly above the hinge line.

Glue the control horns in place. Cut four pieces of the

included push rod ire and bend a Z-bend on one end.

Set the servo arm centered and the control surface

neutral. *(For a non computer radio see the radio setup

section at the end for suggested servo arm angle.)

Fuslage construction:

Glue the carbon tube into the slot in the bottom of the

elevator and set aside to dry.

Glue the top rear fuselage piece to one of the side

fuselage pieces and then the other. The top piece ill

be bet een the side pieces not on top of them. Take

care that the t o side pieces are aligned ith each

other.

2

Glue the horizontal stabilizer in position on the vertical

stabilizer. Glue the vertical/horizontal stabilizer to the

fuselage. The lo er section goes bet een the fuselage

sides and overlaps them 3/4”. Before the glue has

dried, verify that the horizontal stabilizer is square to

the fuselage looking at it from the top and the back.

Control surface hinging:

The glue hinge is done ith Foam-Tac glue by

applying a small bead of glue to each side of the edge

of the bevel. Spread this glue into the foam on and

around the edge of the bevel. Let the glue tack up for

about a minute and then press the parts together. Let

the glue dry for about 10 minutes and then flex the

joint several times full deflection to loosen the hinge.

Hinge the elevator to the horizontal stabilizer.

Hinge the rudder to the vertical stabilizer.

Glue the tail servos in the cutouts in the tail. Add the

servo extensions. You can use heavy thread or a zip tie

to tie the connectors together so they do not come

apart.

Glue the lo er fuselage in place bet een the fuselage

sides.

3

Glue the tail heel bracket to the rear of the fuselage. I

tack it in place ith Foam-Tac and then go around the

outside edge ith hot glue. The plastic tube glues to

the rudder and allo s the metal rod to move in and out

as the rudder goes side to side.

Mount the motor to the fire all feed the motor ires

through a cooling hole and hook up the speed control

(ESC). This is a good time to test the motor direction.

DO NOT do this ith a prop attached.

If the motor spins the rong direction, s ap any t o of

the three motor ires and this ill reverse the motor.

Glue the fire all into the slots in the fuselage sides.

Glue the foam doubler onto the for ard lo er fuselage

so the slots line up. Glue together the remaining foam

parts that make up the battery tray and glue them to the

doubler. Smear Foam-Tac on the top surface of the

battery tray and allo it to fully dry. Stick a piece of

velcro to the top of the tray. The glue on the surface

ill help the velcro stick better.

Glue the for ard lo er fuselage in place.

4

Route the tail servo ires though the opening in the

fuselage former. Glue the former in place at the rear of

the ing opening.

Mount the ESC and receiver to the side of the fuselage.

The top nose piece glues in place bet een the fuselage

sides. The back edge should line up ith the notch in

the indo area of the fuselage sides.

Glue the latch assembly in place on the battery hatch.

Place the ing on the fuselage and the battery hatch in

place and check the fit. Using Foam-Tac hinge the

battery hatch to the rear edge of the top nose piece.

When the hinge glue is dry, glue the ing to the top of

the fuselage. Make sure that the ing is square to the

fuselage from the top and the front.

5

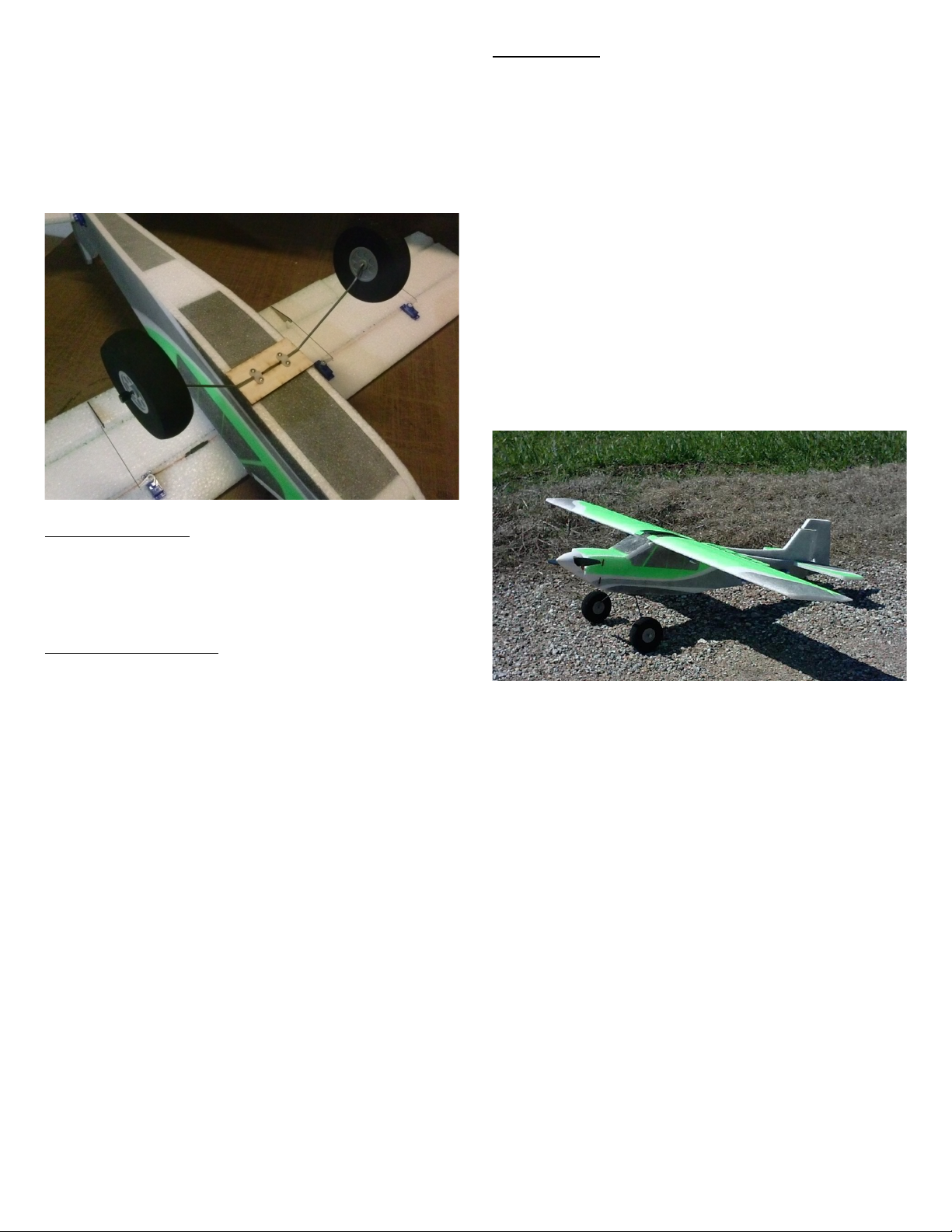

Glue the ply ood plate to the bottom of the fuselage

ith the slot aligned ith the slot in the bottom piece. I

add hot glue around the edges of the ply ood to better

secure it.

Insert the landing gear ire into the slot and secure it

ith the plastic straps and 4 of the scre s that came

ith your servos. Install the heels and the heels

collars.

Center of Gravity:

The battery can be moved on the tray to adjust the CG

to the recommended 2” behind the leading edge of the

ing.

Radio setup for wing:

Computer radio ith correct receiver for a 4 servo

ing can be used or 5 ch receiver ith Y-harness for

ailerons and reversing Y-harness for flaps. See your

radio's instructions for specific information.

For a computer radio, each of the ing servos ill plug

into a separate channel on the receiver. 2 outer servos

assigned to aileron and the 2 inner servos assigned to

flaps. For improved roll rate the ailerons can be mixed

to the flaps so the flaps move ith the ailerons. We do

not advise setting up the ailerons to function as flaps as

this ill increase the chance of ing stall.

For a 5 ch radio setup, both aileron servos ill plug

into a standard Y-harness and then into the aileron

channel. The aileron servo arm should be angled

for ard about 30 degrees. This ill provide

mechanical aileron differential hich ill correct any

adverse ya and help the plane roll ith out ya ing.

The flap servos plug into a reversing Y-harness so they

ill move the same direction and then into the flap

channel.

Flight set-up:

Use your computer radio to set the final sub-trims,

exponential and dual rates. Double check the control

directions before your first flight.

We have found that a 1300 mah 3s battery is perfect for

giving good flight times and plenty of po er as ell as

a proper CG.

The suggested control thro s are +/- 30 degrees for

high rates and +/- 20 degrees for lo rates.

Flaps can be set for any here from 10 deg to 45 deg.

Setting up Aileron differential here the ailerons ill

move about 40% more up than do n ill correct any

adverse ya and help the plane roll ith out ya ing.

We hope you enjoy your airplane.

Thank You,

Mike & Niki Bailey

Fancy Foam Models

6

Other Fancy Foam Models Aircraft manuals