P/N 315-049708FA-44

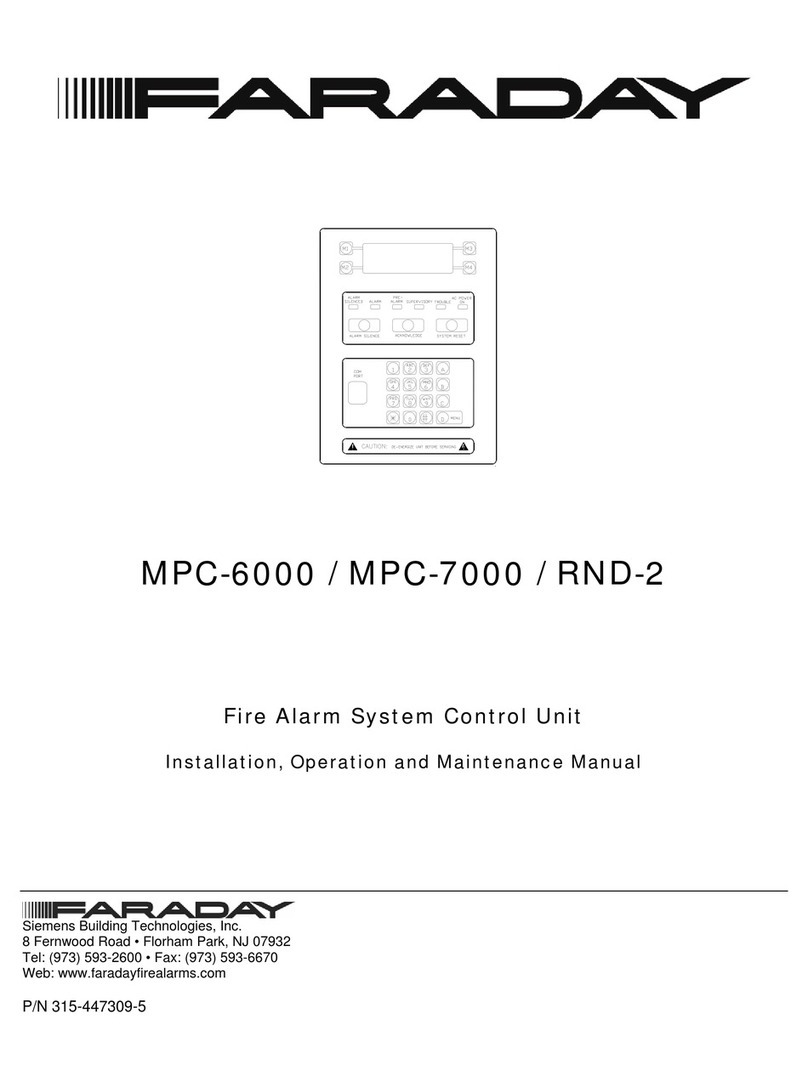

2) To minimize the impact of air turbulence and stratification

on performance, a duct smoke detector should be

located as far as possible downstream from any obstruc-

tion (i.e. deflector plates, elbows, dampers, etc.). In all

situations, confirmation of velocity and pressure differen-

tial within specifications is required.

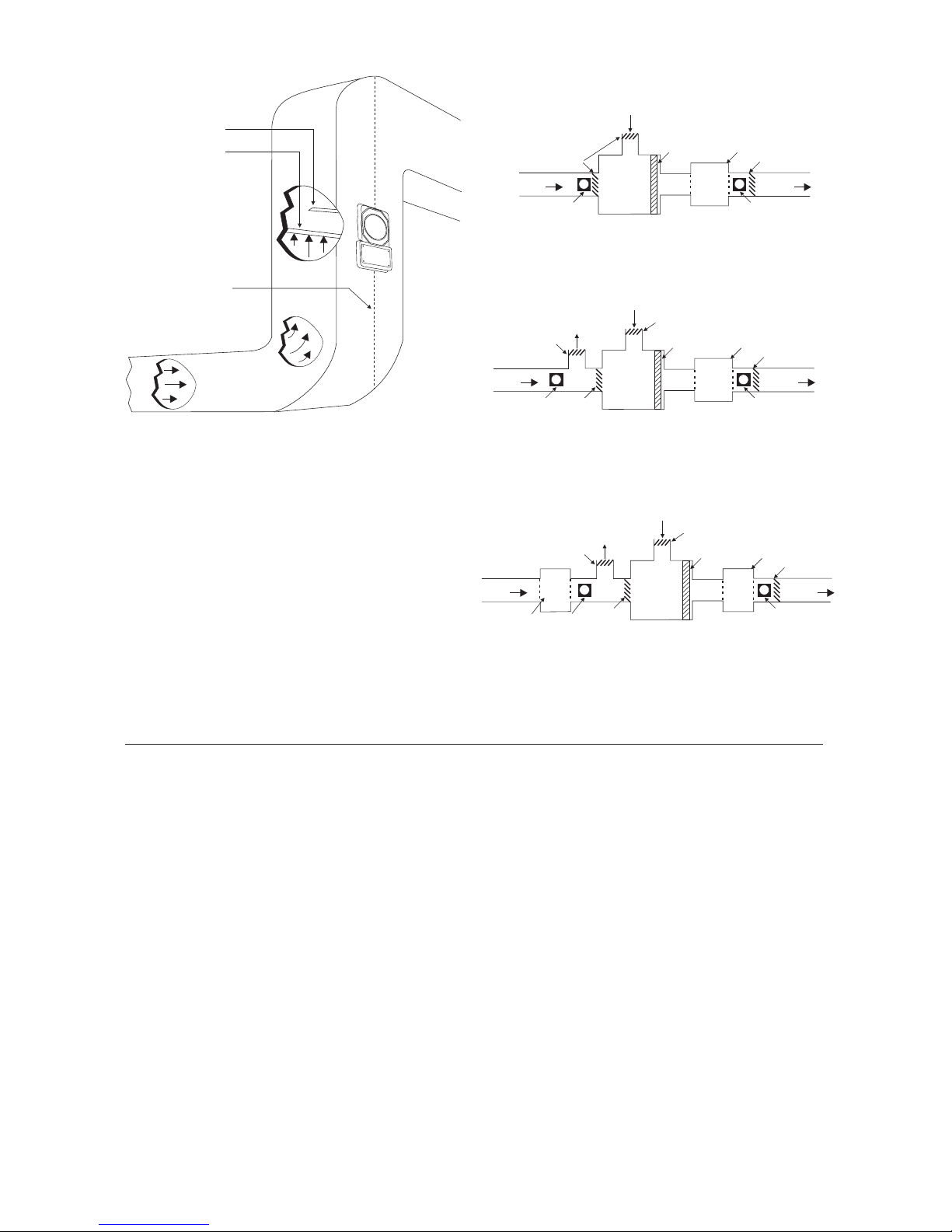

The pressure differential between the input sampling

(high pressure) tube and outlet (low pressure) tube for

the 8741, 8742 or 8743 duct smoke detector should be

greater than 0.01 inches of water and less than 1.2

inches of water.

3) Identify a code compliant location (supply or return side,

or both) for the installation of the duct unit that will

permit easy access for viewing and serviceability.

4) When installing on the return side, install duct units prior

to the air being exhausted from the building or diluted

with outside “fresh” air.

5) When installing duct smoke units downstream of filters,

fires occurring in the filters will be detected, but if the

filters become blocked, insufficient air flow through the

duct unit will prevent the correct operation of the duct

detector. Duct units installed in the supply air side may

monitor upstream equipment and/or filters.

6) Where possible, install duct detectors upstream of air

humidifiers and downstream of dehumidifiers.

7) To prevent false alarms, the duct detector should not be

mounted in areas of extreme high or low temperatures,

in areas where high humidity exists, or in areas where

the duct may contain gases or excessive dust.

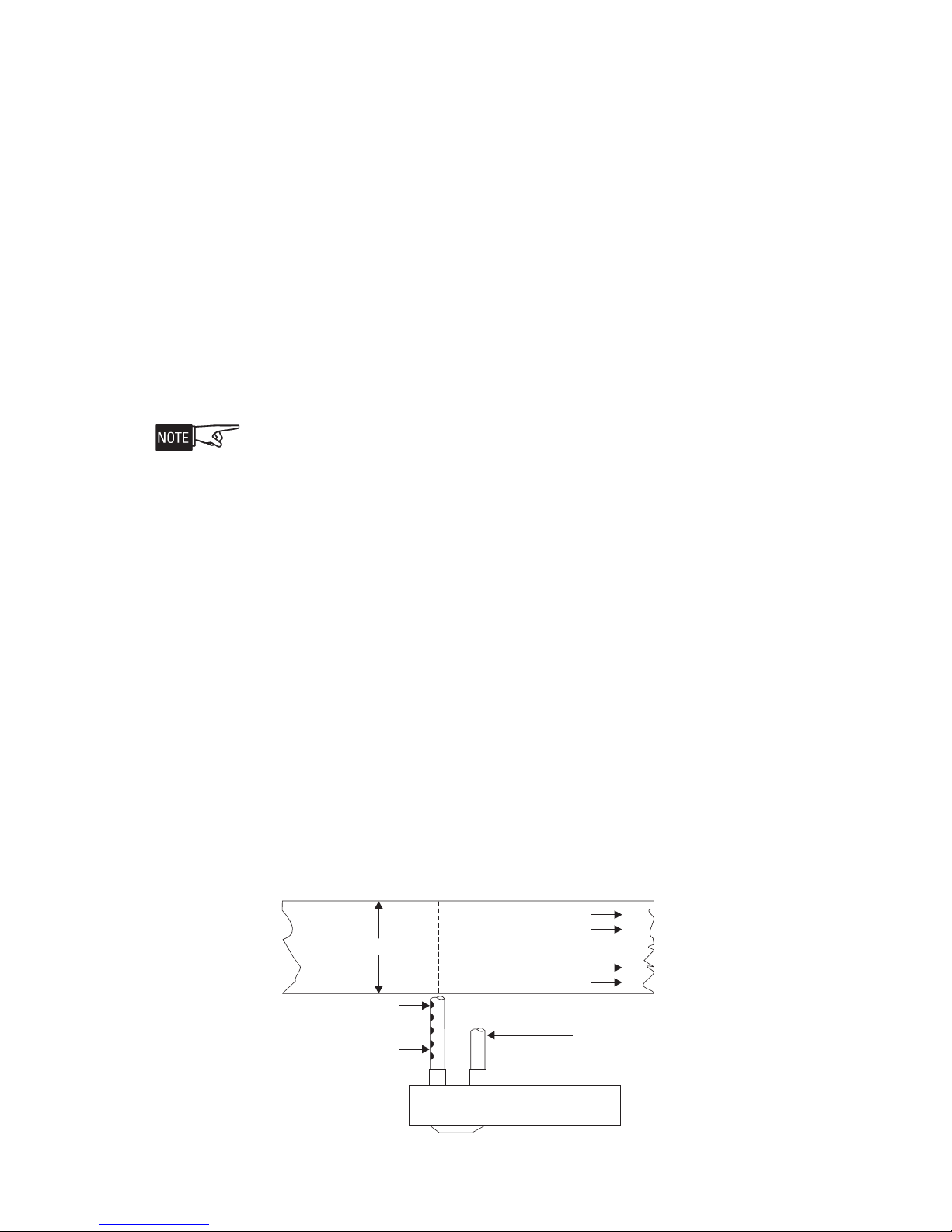

Duct Preparation The 8741, 8742 and 8743 Housings come with an installation

kit that contains the following items:

• Short return (outlet) sampling tube

• Stopper

• Two #12 x 3/4” sheet metal screws

• Mounting template (packaged separately)

Remove mounting template from the installation kit. Remove

paper backing from the mounting template and affix it to the

duct at the desired location. Using the template as a guide,

drill (2) mounting holes, 3/32" (2.5mm) for the #12 X 3/4”

sheet metal screws packaged in the installation kit. Drill or