7

TRANSPORTING DRYER

An optional Transport Kit is available for transporting

the unit by truck or tractor. Make certain to observe the

following safety precautions:

1. Recommended towing hitch height: 16 to 17 inches.

2. Hitch pin to be not less than 3/4 inch in dia. and

securely fastened so it will not come out in travel.

3. Use a safety chain.

4. Dryer must be towed empty and in accordance with

applicable state or provincial regulations.

5. Recommended tire pressure 55-60 psi (cold).

6. Maximum towing speed: 45 mph

7. After first 50 miles and every 200 miles thereafter:

a. Check temperature of transport wheels' hubs and

spindles immediately after stopping. Temperature

should not exceed 150NF. May be hot to touch, but

not melting lubricant.

b. Check wheel lug bolts; they are factory torqued at 115

to 120 ft/lbs. Retighten, if required, to approximately

90 ft/lbs.

INSTALLATION

SYSTEM LAYOUT — Consider the grain handling system

and location of storage bins and existing conveyors in

selecting the dryer site, to facilitate wet grain supply

and dry grain discharge to conveyors.

SITE SELECTION — The dryer is not to be operated

inside a building or in any area not permitted by elec-

trical codes, fuel installation regulations, or insurance

requirements. Do not operate in an area where com-

bustible material can be drawn into the fans. Maintain

the required minimum distance from other structures.

Refer to Fig. 1-1 for installed dryer dimensions.

FILLING POINT — Wet grain must enter the dryer at the

hopper at the rear end of the top auger, since the top

auger moves grain forward, toward the paddle switch

controlling the top auger (except for special build front-

loading units).

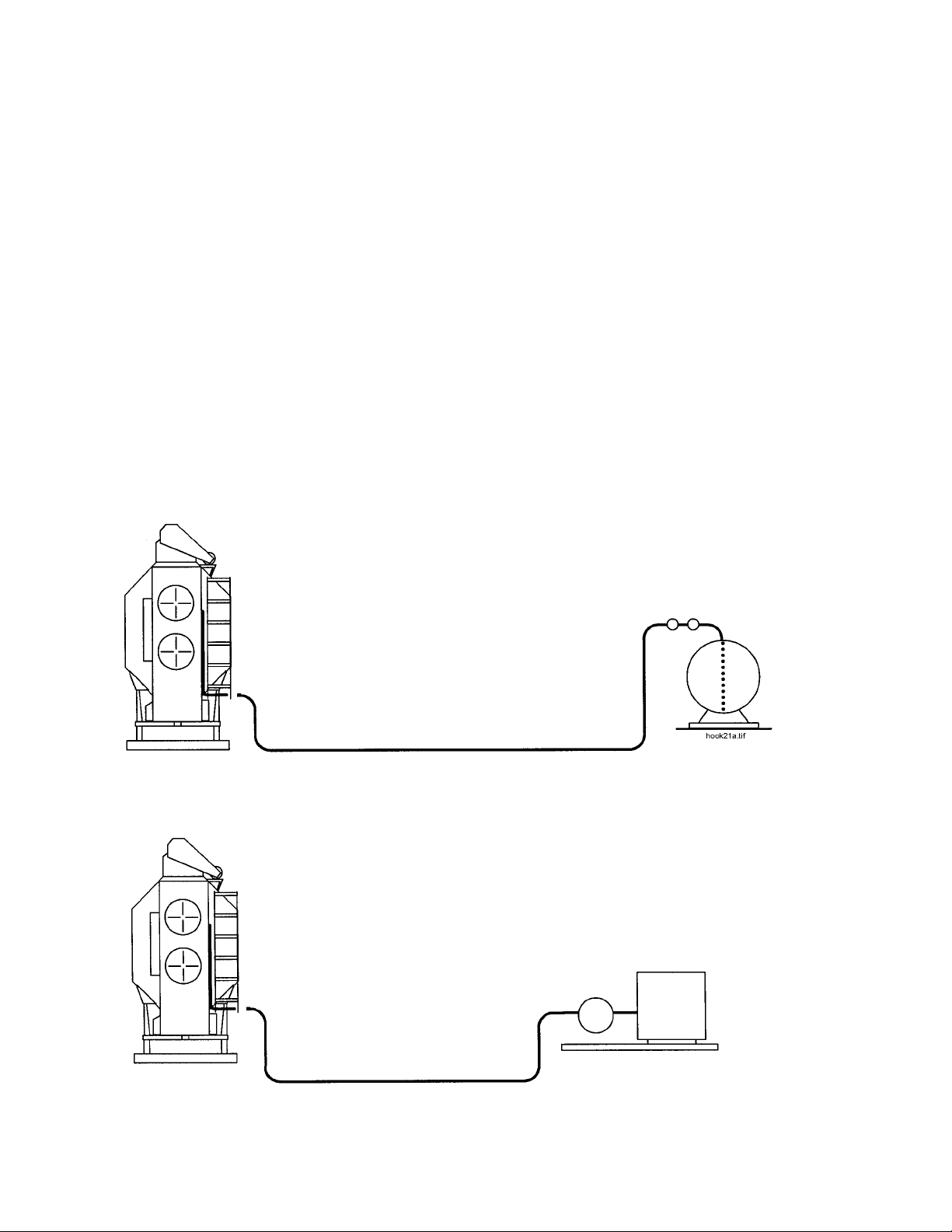

WET GRAIN SUPPLY — A wet holding bin may be utilized

to supply grain to the dryer, with gravity flow into the

dryer loading conveyor. Also, gravity flow from a

wagon or truck into a loading conveyor may be used to

fill the dryer. The top leveling auger will accept grain at

any rate up to its maximum capacity as listed in Table

1-1. In any case, the dryer must have a constant sup-

ply of wet grain. Auxiliary loading conveyors should be

sized to nearly match the capacity of the top auger, to

avoid air loss problems caused by underfilling during

high drying rate operations.

WET GRAIN LOADING — The dryer will automatically

start the top auger and any loading conveyor electri-

cally connected to the power terminal strip on the

power panel (see Section 8 - Wiring Diagrams). At the

beginning, dryer will completely fill, requiring approxi-

mately its full holding capacity. During drying, the top

auger will start and stop as required to maintain the

dryer full of wet grain.

LOAD TIMER — The unit is equipped with a top auger

Load Timer (inside ASC control box), to provide auto-

matic shutdown on wet grain outage, if the top auger

operates for a time exceeding the timer setting (field

adjustable).

DISCHARGE AUGER EXTENSIONS — Special dis-

charge auger extension kits are available, with an addi-

tional length of 1 to 10 feet (one foot increments) to pro-

vide dry grain discharge points at various distances

from the rear of the dryer, for direct discharge into ele-

vator legs or other conveyors. Extensions are avail-

able with either a solid or perforated tube.

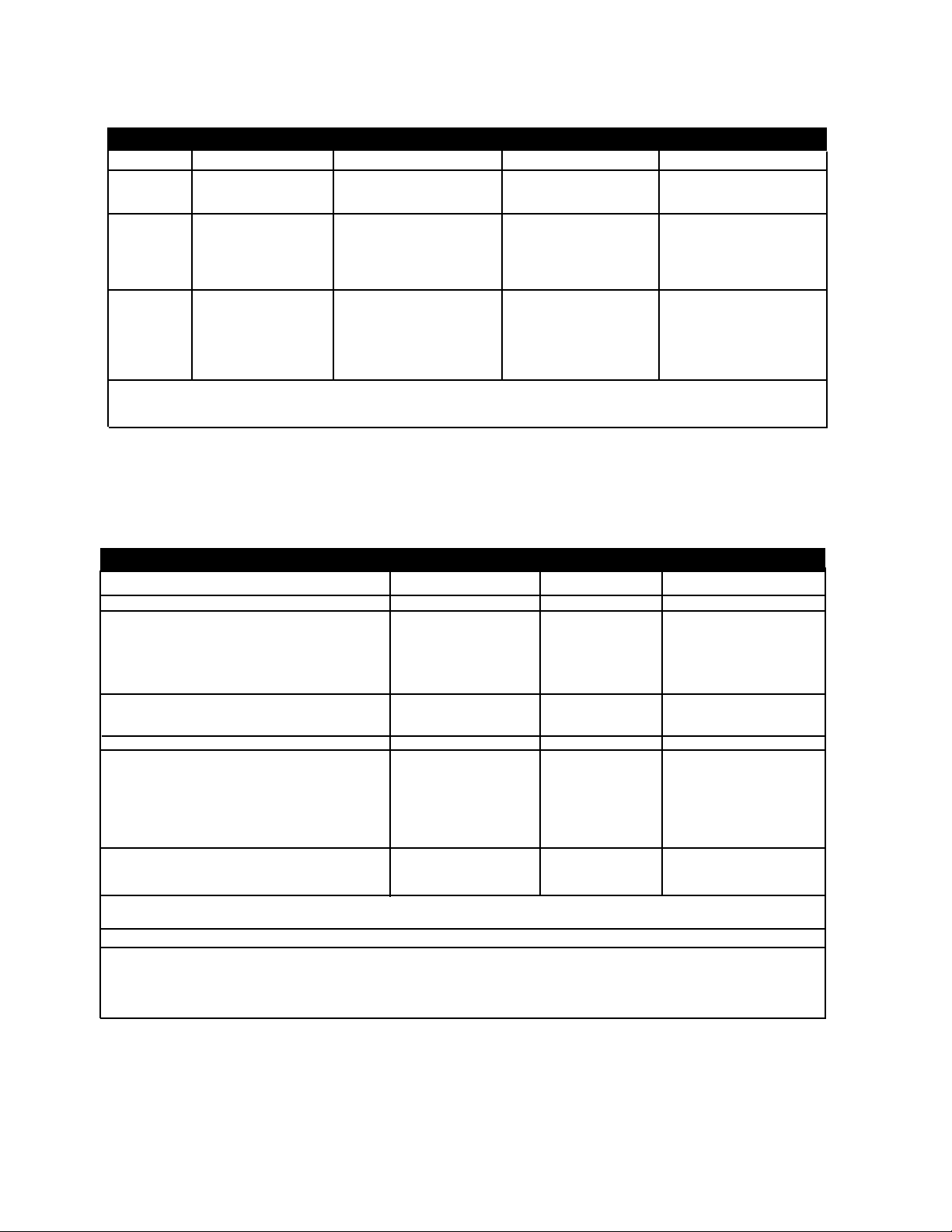

AUXILIARY CONVEYOR OVERLOAD RELAYS —

Overload relays for the loading conveyor and take

away conveyor are factory equipped with heater ele-

ments as listed in Table 2-2 for motors on auxiliary con-

veyors. If other HP ratings are used, it is necessary to

change the heater elements to provide proper running

load protection for the motors.

DRYER FOUNDATION — The wheels are provided only

for transportation of the empty dryers to the site loca-

tion. Before assembling and installing the dryer, pre-

pare a level, secure foundation, with provisions for

dryer tie-down.

NOTE: If the dryer is to be equipped with an optional

Heat Reclaimer Package, also refer to instructions

included with the Heat Reclaimer. Heat Reclaimers for

C-2100A dryers include special dryer support struc-

tures which are intended for a conventional, flat type

concrete foundation.

DRYER PREPARATION

1. Remove Parts — Remove hopper and other parts

shipped inside dryer.

2. Wet Bin — Standard C-2120A models are equipped

with a Compact Wet-Bin. Refer to Bulletin CWB-01-2

for installation instructions. All other standard models

are equipped with a Fold-up Wet-Bin, which is installed

according to Bulletin WBF-01-2. Assemble the top

auger drive according to appropriate wet-bin installa-

tion bulletin.

3. Install Fill Hopper according to the appropriate wet-bin

installation bulletin.

4. Connect Electrical and Fuel.

5. Inspection & Testing — Thoroughly inspect dryer to

make certain all parts have been properly installed and

tightened. See FUEL CONNECTION and ELECTRI-