2113702 Revision date: 10.12.18

REQUIRED TOOLS

The following list identifies the main tools needed

for assembly. Additional tools and supports may be

needed.

• Tape measure, marker, and chalk line

• Variable speed drill (cordless with extra

batteries works best)

• Hammer and gloves

• Long level to set tank

• Utility knife

• Adjustable pliers and assorted hand tools

common to plumbing and electrical work

• 1-3/8", 2-1/2", 3", and 5" hole saws and 7/8"

Forstner bit (required)

• 9/32" drill bit

READ THIS DOCUMENT BEFORE YOU BEGIN

Thank you for purchasing this NFT system. When properly assembled and maintained, this system will provide years of reliable service. These instructions

include helpful hints and important information needed to safely assemble and properly maintain the system. Please read these instructions before you begin. If

you have any questions during the assembly, contact Customer Service at 1.800.245.9881 for assistance.

ASSEMBLY PROCEDURE

Following the instructions as presented will help

ensure the proper assembly of your NFT system.

The steps outlining the assembly process are as

follows:

1. Verify that all parts are included in the

shipment. Notify customer service for

questions or concerns. See below.

2. Read and understand these instructions and

the information included with the shipment

before you begin.

3. Gather the tools and assistants.

4. Assemble the system.

5. Use the system.

Important Information

SAFETY PRECAUTIONS

• Wear eye protection.

• Wear gloves when cutting pvc tubing.

• Use a portable GFCI (Ground Fault Circuit

Interrupter) when working with power tools and

cords.

UNPACK AND IDENTIFY PARTS

The following steps will ensure that you have all

the necessary parts before you begin assembly.

1. Unpack the contents of the shipment and

place where you can easily inventory the

parts. Refer to Bill of Materials/Spec Sheets.

2. Verify that all parts listed on the Bill of

Materials/Spec Sheets are present. If

anything is missing or you have questions,

consult the Pictorial Parts Guide and

all diagrams for clarification, or contact

Customer Service.

NOTE: At this time, you do not need to open

the plastic bags containing smaller parts

such as fasteners or washers (if equipped).

WARNING: Enlist the services of an

experienced electrician when connecting

power to the pump and other electrical

devices—required.

All wiring to be completed according to

established codes and practices.

DROWNING HAZARD: Never leave the

tank cover off when tank is unattended.

Never allow children or others within the

boundary of the pump station at any time.

Always have an assistant present when

completing tank cleaning and system

maintenance to prevent accidents.

Disconnect the pump when performing any

system maintenance.

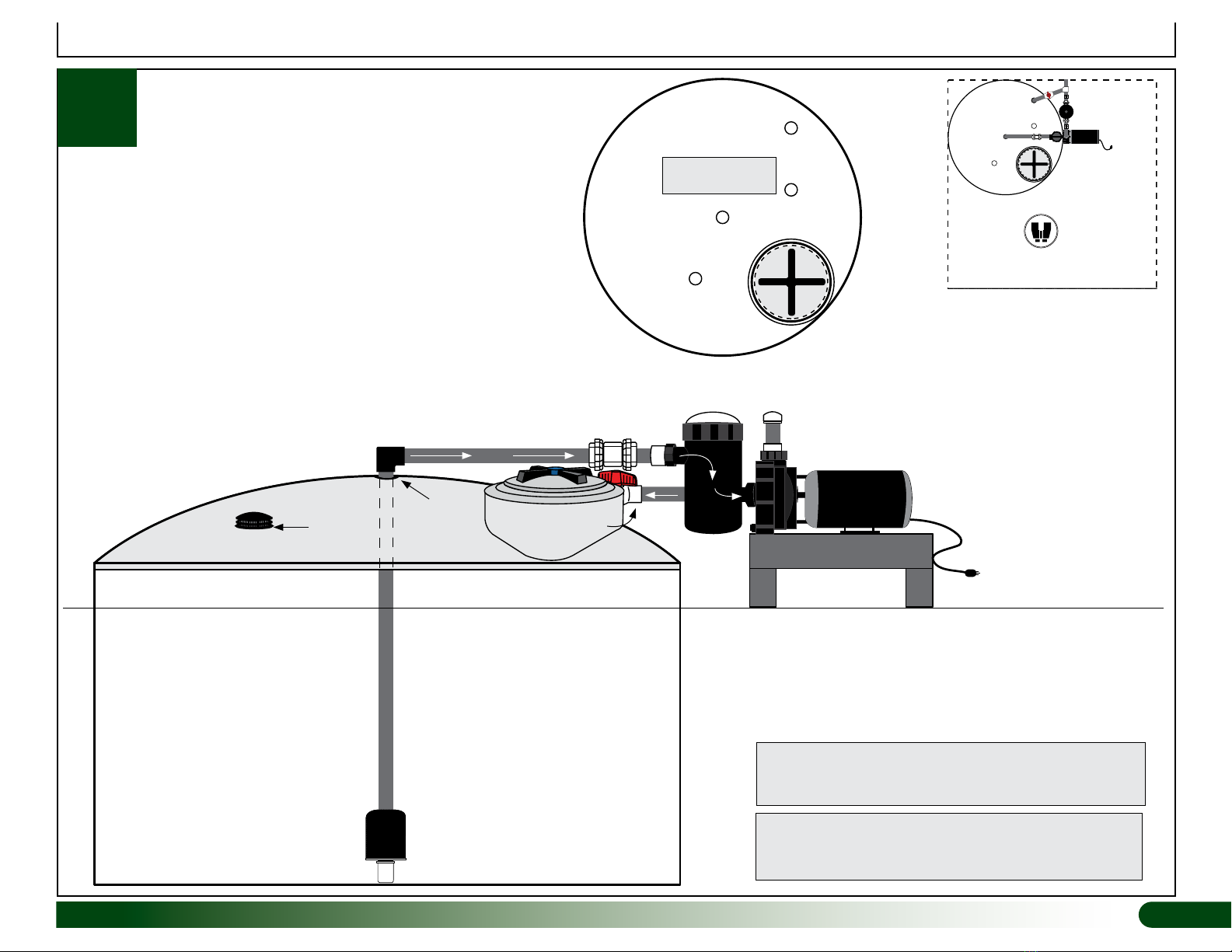

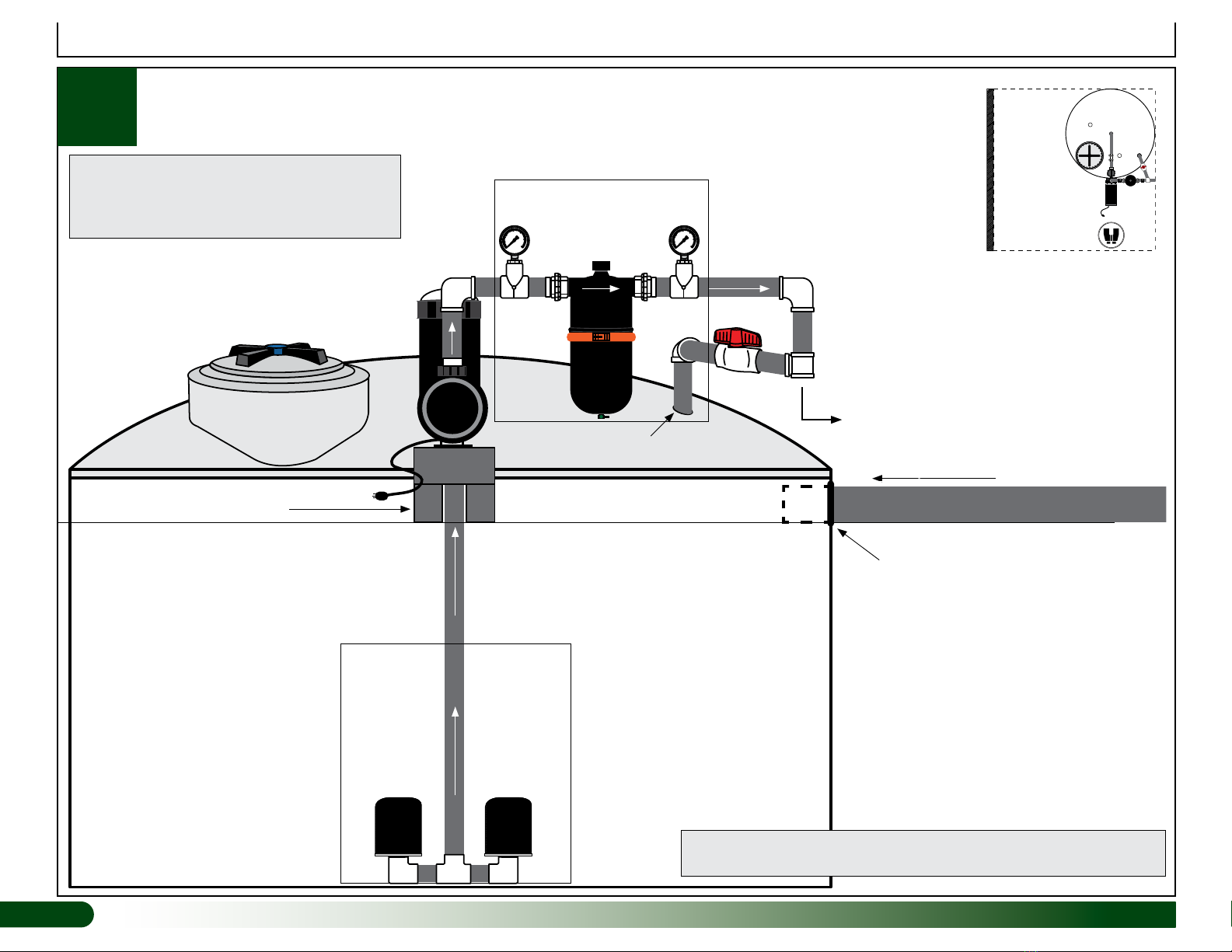

FERTIGATION SYSTEMS

A fertigation system can be connected to your

NFT system to provide constant control of pH

and nutrient levels in the nutrient tank.

Remember to allow space to mount the system

when preparing the pump station site.

To assemble and connect a fertigation system

to this NFT system, consult the information

provided with the fertigation system.

NOTE: Additional pvc tubing and fittings

may be required to connect the fertigation

system. Purchase locally or call your sales

representative for additional information.