2

Contents

page

INTRODUCTION .................................................................................................................................4

1. GENERAL INFORMATION .............................................................................................................6

1.1. Identification data..........................................................................................................................6

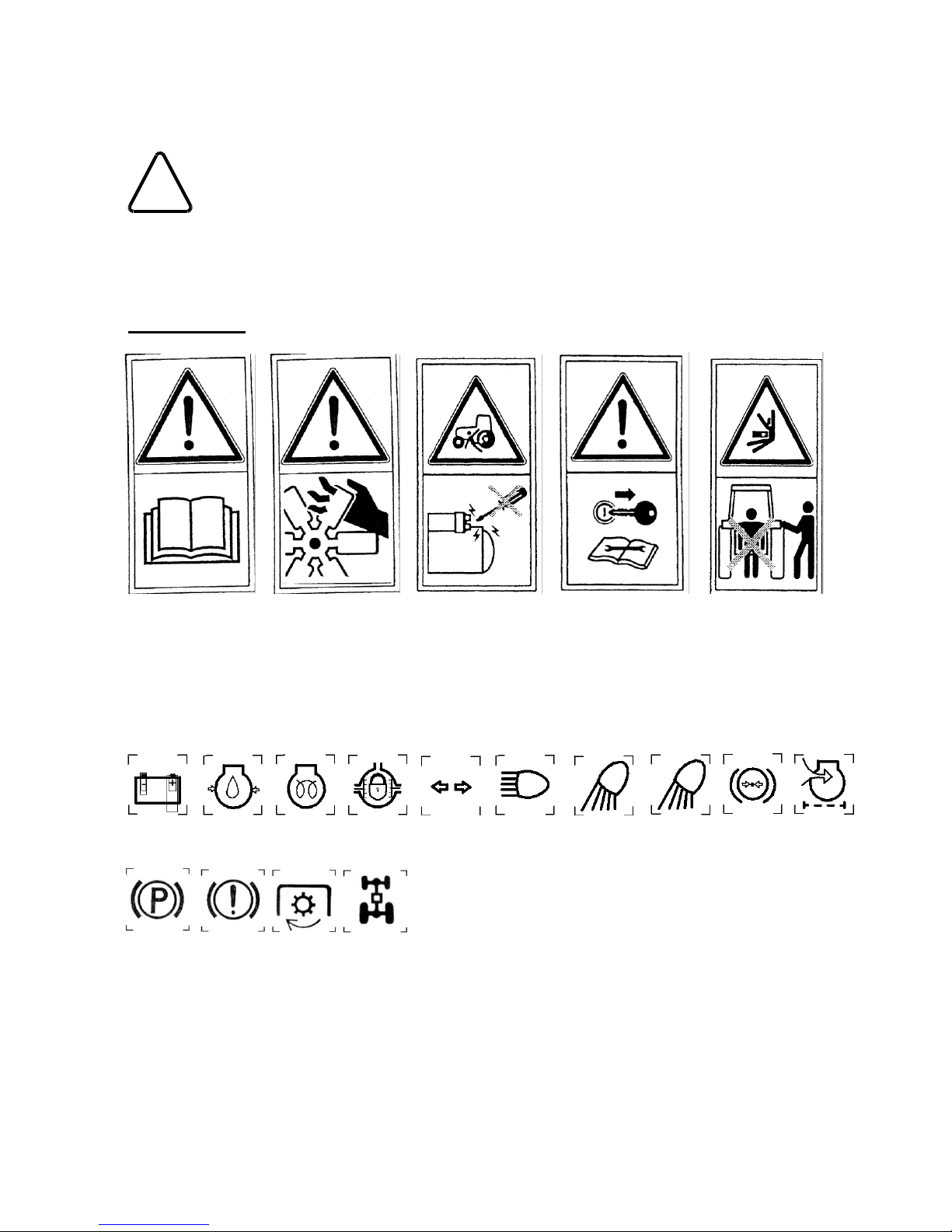

1.2. Safety precautions. .......................................................................................................................6

1.3. Fire precautions. ...........................................................................................................................9

1.4. Warranty.....................................................................................................................................10

1.5. Tractor delivery to purchaser.......................................................................................................10

2. TECHNICAL SPECIFICATION......................................................................................................12

2.1. Engine.........................................................................................................................................12

2.2. Electrical System.........................................................................................................................13

2.3. Transmission...............................................................................................................................13

2.4. Hydraulic lift system....................................................................................................................15

2.5. Three-point linkage. ....................................................................................................................15

2.6. Coupling devices.........................................................................................................................15

2.7. Steering system. .........................................................................................................................15

2.8. Wheels & axles...........................................................................................................................16

2.9. Braking system. ..........................................................................................................................16

2.10. Tractor weight...........................................................................................................................17

2.11. Tractor dimensions....................................................................................................................17

3. INSTRUMENT PANEL & CONTROL DEVICES............................................................................18

3.1. Instrument Panel.........................................................................................................................18

3.2. Control levers and pedal.............................................................................................................20

3.3. Tractor cab..................................................................................................................................23

3.4. Operator’s seat adjustments ......................................................................................................24

4. OPERATION..................................................................................................................................25

4.1. Tractor running in........................................................................................................................25

4.2. Starting and stopping the engine.................................................................................................25

4.3. Driving the tractor........................................................................................................................27

4.4 Power take-off (PTO)...................................................................................................................28

4.5. Tractor hydraulic system.............................................................................................................30

4.5.1. Hydraulic lift system.............................................................................................................30

4.5.2. External hydraulics control...................................................................................................32

4.6. Equipment attaching on three-point linkage.................................................................................33

4.7. Attaching trailed machines and implements. ...............................................................................36

5. MAINTENANCE AND ADJUSTMENT...........................................................................................37

5.1. Periodic maintenance chart.........................................................................................................37

5.2. Lubrication. .................................................................................................................................39

5.2.1. Oils......................................................................................................................................39

5.2.2. Greases...............................................................................................................................39

5.2.3 . Reservoir filling...................................................................................................................39

5.3. Engine.........................................................................................................................................40

5.3.1. Engine lubrication system....................................................................................................40

5.3.2. Fuel system.........................................................................................................................40

5.3.3. Dry air cleaner.....................................................................................................................41

5.3.4. Cooling system....................................................................................................................42

5.3.5. Engine cylinder head...........................................................................................................42

5.4. Electrical system.........................................................................................................................43

5.4.1 Alternator maintenance.........................................................................................................44

5.4.2. Starter motor maintenance. .................................................................................................44

5.4.3. Battery maintenance............................................................................................................44

5.4.4. Spot lights adjustment. ........................................................................................................45

5.4.5. Bulb and fuse - replacement................................................................................................45