Farrar Scientific ULC Series User manual

Model ULC Series

06012021ULC,Rev i Page 1 of 54

ULC Series

ULTRA LOW STORAGE CHAMBER

Model ULC Series

06012021ULC,Rev i Page 2 of 54

Revision Description Approval Date

a Original release JL 24 Apr 2020

b Updated water connection size JL 16 Jul 2020

09022020_a Updated with additional specs per NRTL inspection

requests TS 02 Sep 2020

09032020_b Added a maximum RH value to the spec TS 03 Sep 2020

09032020_c Revised warranty JL 03 Sep 2020

12042020_d Added 32 amp mains breakers for 50Hz models JL 04 Dec 2020

02172021_e Corrected shelving specifications JL 17 Feb 2021

03192021_f Corrected Exterior Dimensions JL 19 Mar 2021

04162021_g Enhanced chamber defrost. Section 11 JL 16 APR 2021

06012021_h Changed pictures to illustrations. Various sections JL 01 JUN 2021

07292021_i Add Maintenance security level to User Accounts JL 29 JUL 2021

Model ULC Series

06012021ULC,Rev i Page 3 of 54

Model ULC Series

06012021ULC,Rev i Page 4 of 54

Read This Instruction Manual

Failure to read, understand and follow the instructions in this manual may result in damage to the unit, injury

to operating personnel, and poor equipment performance.

CAUTION! All internal adjustments and maintenance must be performed by qualified service

personnel.

When plugged in, there is high voltage present on terminals inside the machine space. Proper care

must be taken if the electrical control panels are opened to perform any kind of maintenance.

The material in this manual is for information purposes only. The contents and the product it describes are

subject to change without notice. Farrar Scientific makes no representations or warranties with respect to this

manual. In no event shall Farrar Scientific be held liable for any damages, direct or incidental, arising out of

or related to the use of this manual.

Important operating and/or maintenance instructions. Read the accompanying text carefully.

Equipment being maintained or serviced must be turned off and locked off to prevent possible injury

Always dissipate high or low temperatures, especially inside of the control space

before performing any maintenance on the unit.

Always use the proper protective equipment (clothing, gloves, goggles, etc.)

Always dissipate extreme cold or heat and wear protective clothing.

Always follow good hygiene practices.

Each individual is responsible for his or her own safety.

For any questions or concerns, please contact the manufacturer:

Farrar Scientific, Inc.

30765 State Route 7

Marietta, Ohio, USA 45750

Phone: (740) 374-8300

Model ULC Series

06012021ULC,Rev i Page 5 of 54

-80C ULC Series Instruction Manual

Table of Contents

1. Receiving ..................................................................................................

2. Introduction ...............................................................................................

3. Specifications ...........................................................................................

4. Installation Requirements .........................................................................

5. Control System..........................................................................................

6. Operation ..................................................................................................

a. HomeScreen

b. SetupScreen

c. SystemHealthScreen

d. InformationScreen

e. Technical/ServiceScreen

f. ManagingUserAccounts

g. SettingSystemClock

7. Sensor Validation .....................................................................................

8. Alarms ......................................................................................................

9. External Access Ports ..............................................................................

10. Troubleshooting ........................................................................................

11. General Maintenance ...............................................................................

12. Factory Default Control Settings ...............................................................

13. Warranty - North America .........................................................................

14. Warranty - International ............................................................................

15. Contacting Farrar Scientific ......................................................................

Model ULC Series

06012021ULC,Rev i Page 6 of 54

1.0 Receiving

1.1 Preliminary Inspection

This item was thoroughly inspected and carefully packed prior to shipment and all necessary precautions

were taken to ensure safe arrival. Immediately upon receipt, before the unit is moved from the receiving area,

carefully examine the shipment for loss or damage. Unpack the shipment and inspect both interior and exterior

for any in-transit damage.

1.2 Visible Loss or Damage

If any loss or damage is discovered, note any discrepancies on the delivery receipt and call the delivering

carrier and request that their representative perform an inspection. Do not discard any of the packing material

and do not move the shipment from the receiving area prior to their inspection. Document in writing and with

photos, for your records.

1.3 Responsibility for Shipping Damage

For products shipped FCA. Marietta, Ohio, the responsibility of Farrar Scientific ends when the merchandise

is loaded onto the carrier's vehicle. On FOB Destination shipments, Farrar Scientific’s and the carrier's

responsibility ends when your Receiving Department personnel sign a free and clear delivery receipt.

2.0 Introduction

The Farrar Scientific ULC/ULCi is a forced air low temperature long term storage freezer which can attain

interior chamber temperatures between -20°C to -80°C, depending on the model. The ULC Series chamber

consists of two (2) redundant cascade refrigeration systems. There are two (2) condensers, two (2)

evaporators, and a total of four (4) compressors. Both refrigeration systems are packaged type systems

(compressor, evaporator, condenser & circulating fan), resting on top of the chamber. The refrigeration

systems have separate electrical power supply via two (2) power cords including two (2) redundant LCD

controllers mounted onto each of the exterior doors. The ULC Series is not meant as a walk-in chamber, but

rather a shelved unit for long term storage of samples and/or product at temperature between -20°C to -80°C.

ULC Series offers a true fully redundant solution (refrigeration, displays, and controls). The LCD Display

information center enables users with access control to adjust the temperature control setpoint between -20°C

to -80°C, depending on the model. All functions and set points can be performed by accessing either LCD

display located on each of the exterior doors. Since the displays are synchronized any adjustments or set

point programmed on one of the LCD displays will automatically be synchronized on the other LCD display.

The ULC Series is delivered with factory default, therefore, we recommend proper access control assignment

to each user e.g. (User Name) from the facility Administrator or Operator to Users. If a user does not have

sufficient privilege or granted access control, then no set points or values can be changed within each of the

LCD display controllers; only warning acknowledgment. Without sufficient access privilege to controller

assigned by the Administrator, each LCD display will offer a view only mode to a non-authorized user. A User

Name/Password can be assigned and programmed by facility Administrator and the User Name/Password

should be maintained and controlled according to company protocols.

Model ULC Series

06012021ULC,Rev i Page 7 of 54

The blower motor circulates airflow throughout the chamber and, should the temperature deviate for more

than +3°C from setpoint (adjustable), the controller is designed to automatically start both refrigeration

systems in order to reach and maintain temperature of control setpoint e.g. -70°C.The ULC Series controllers

are designed to properly maintain the temperature setpoint and automatically initiate an automatic defrost of

the evaporator coil for each refrigeration system. During the defrost period, the system blower motor will be

turned off specific to the refrigeration system (system A or system B) in defrost mode. The secondary

refrigeration system will operate and its blower motor will be energized to maintain proper temperature set

point within the chamber. Defrost cycles are factory programmed to be enabled every 12 hours. However, the

defrost cycles can be modified by the end user to occur every 2 to 168 hours, depending on the following:

ambient moisture, frequency of door openings and/or warm product being placed inside the ULC Series.

Farrar Scientific technical support team can assist users with any questions related to controller adjustments

and settings.

The ULC series internal blower motor will automatically turn off when either of the two exterior doors are

opened. Should one of the two exterior doors be opened, the Controller LCD will display a “warning” icon,

along with a “Yellow” light indicator on the light bar located in the top middle of both doors. Should the door

remain open for too long (user adjustable setting from 5 to 300 sec.) the Controller display will change from a

“Warning” to an “Alarm” condition, and the light bar will change from “Yellow” to “Red”, including an audible

alarm to notify local user of an alarm condition. Additional warming and alarm status items can be found in

Section 8 of this manual.

3.0 Specifications

ULC Series

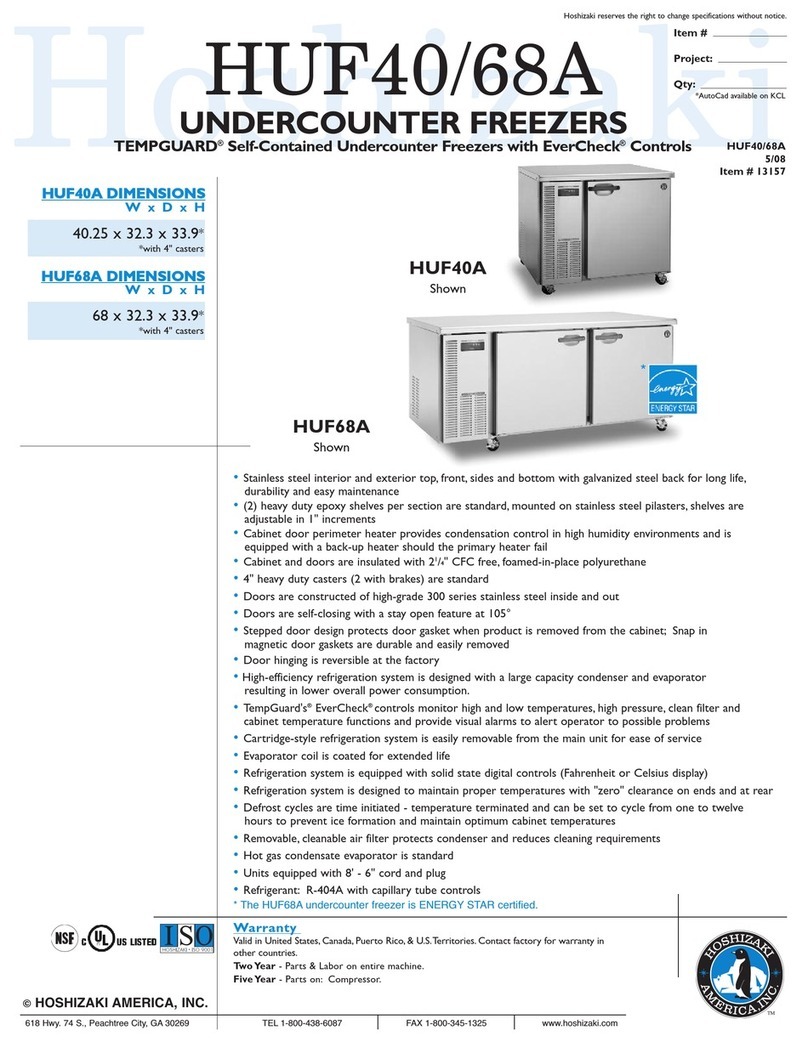

Exterior Dimensions incl. refrigeration systems in / mm 122 x 60 x 150 / 3098 x 1524 x 3810 (W x D x H)

Exterior Dimensions- Chamber/latch only in / mm 122 x 60 x 102 / 3098 x 1524 x 2591 (W x D x H)

Interior Dimensions in / mm 110 x 38 x 90 / 2794 x 927 x 2286 (W x D x H)

Chamber Volume ft³ / l 199 / 5635

Stora

g

e Volume ft³ / l 190 / 5380

Chamber Floor Space ft² / m² 47 / 4.36

Door Opening in / mm -Qt

y

42 / 1067 W x 87/ 2210 H x 2 doo

r

Chamber Wall Thickness in / mm 6 / 152.4

Net Wei

g

h

t

lbs / k

g

3000 / 1360.8

A

mbient Conditions °C/%RH

18°C to 30°C / 70%RH Max

NOTE: FOR INDOOR USE ONLY

Pollution Degree 2

2" Box Capacit

y

Not Included Qt

y

2,880

3" Box Capacit

y

Not Included Qt

y

2,400

Inventor

y

Racks for 2" Boxes- Not Included Qt

y

96

Inventor

y

Racks for 3" Boxes- Not Included Qt

y

80

Vial Space- 2” / 3” Box Qt

y

288,000/ 240,000

Electrical

Electrical ULC/ ULCi V / Hz /Qty

208-230 VAC, 1 Ø, 60 Hz / 2,

230 VAC, 1 Ø, 50 Hz / 2

Mains Supply Fluctuation +/- 10%

Overvoltage Category II

Electrical breakers

A

mp/ Qt

y

30A, 60Hz. (32A, 50HZ)/ 2 Circuits;

Noise level dB

(

A

)

65

Model ULC Series

06012021ULC,Rev i Page 8 of 54

Refrigeration Systems

Refrigeration System Qty 2

Scroll Compressors Qty 4

Blower Motor Cfm/ l/m 500 / 14,158

Blower Motor Qt

y

2

Thermal Room Load

Air Cooled

Water Cooled

BTU/ Kw

BTU/ Kw

14,500 BTU/hr / 4.25 kW/hr Maximum

< 1,550 BTU/Hr / 0.44 kW/h

r

Maximum

Refri

g

erant Hi

g

h Sta

g

e R- 449A (HFO)

Refri

g

eran

t

Low Sta

g

e R-290 & R-508B (HFC)

Construction

Chamber Exterior Material Painted Aluminum- White Embossed Finish

Chamber Interior Material Painted Aluminum- White Embossed Finish

Optional Shelving System information

Shelving Material Stainless Steel

Shelving Adjustment in / mm 1" Adjustment / 25

Shelvin

g

Size in / mm 54 x 36 / 1371.6 x 914.4 (W x D)

Shelf Weight Capacity lbs / kg 300 / 136

Load Capacit

y

per chamber side lbs / k

g

2,000 / 907 (4000/1814 total)

Performance

Temperature Control Range (ULC/ULCi)

Temperature Control Ran

g

e

(

ULC-WR, ULCi-WR

)

-40˚C to -80˚C @ 1˚C Increments

-20˚C to -80˚C @ 1˚C Increments

Temperature Minimum Set Point -80˚C

Temperature Pull Down Time From +20˚C to -80˚C within (4 Hours- 25 minutes)

Temperature Air Stability at -80˚C

at -20°C +/- 3˚C Uniformity

+/- 5C Uniformity

Cooling Assist Mode

If Air Temperature is > 3˚C from set point / Both

System A & System B Operational (User Adjustable)

Energy Consumption per cu. ft 0.33 kWh/ day per cu.ft.

Power failure warm up from -80˚C to -50˚C 6 Hours

Temperature recovery to -80˚C from 30 sec. door opening 25 Minutes (empty chamber)

Temperature recovery to -80˚C from 60 sec. door opening 35 Minutes (empty chamber)

Power Consumption

Average @ -80˚C Set Point

(one refrigeration system controlling chamber temperature)

2.62 kWh

Maximum @ -80˚C Set Point

(one refrigeration system controlling chamber temperature, one

system running a defrost cycle – average defrost cycle time 1.83 hr.)

6.74 kWh / 24hr.

Performance Cont.

24-hour power consumption - No defrost

62.81 kWh / 24hr.

Model ULC Series

06012021ULC,Rev i Page 9 of 54

24-hour power consumption - Defrost every 12 hours

(2 defrost events)

66.66 kWh / 24hr.

Backup Generator to ULC

2 to 5 minutes generator delay start time

from power outage

During Power Off

All ULC operation and display are Off

Dry Alarm Contacts

Screw Terminals- C / NO

1st set of contacts will change state from closed to

open when either chamber door is open. The

contacts will close when both chamber doors are

closed.

2nd set of contacts will change state from closed to

open when a “General Alarm Signal” is generated by

the ULC. (High temperature, door open too long,

failed refrigeration system, etc.)

Power Receptacle Location

At least 3 feet (1 meter) clearance in front of

receptacle, with a 30” (75 cm) wide working space,

and headroom at least the height of the equipment.

Network (LAN) Connection

Network (LAN) Connection is not available on the

standard ULC series.

If the optional Farrar Remote Predictive Monitoring

Analytic Solution or Monitoring Hardware Solution is

purchased, then each refrigeration unit will require a

hardwired RJ45 internet connection.

Water Cooled Condenser

Water Cooled Condenser

4 x ½” FPT connections (2 per refrigeration

system)

Pressure differential = approximately 20 PSI (1.4

bar)

*Tower water:

Water temperature ≤30°C.

Maximum flow rate = 7 gpm (27 lpm)

Average flow rate = 4.5 gpm (17 ipm)

*Chilled water:

Water temperature ≤10°C

Maximum flow rate = 3.5 gpm (14 lpm)

Average flow rate = 2.0 gpm (8 lpm)

*Total for both refrigeration systems

Model ULC Series

06012021ULC,Rev i Page 10 of 54

4.0 Installation requirements

1. For installation of the Construct on Site chamber and for installation of the refrigeration systems,

please refer to the Installation Manual. If lifting unit, place lift forks under center of enclosure.

2. For proper air flow, ensure there is a minimum of the following distances from the unit to the nearest

wall or ceiling:

Back of unit: 14.0 in. / 35.0 cm

Sides of unit: 14 in. / 35 cm

Top of unit: 12 in./ 30 cm. Overall minimum height of location, floor to ceiling is 13 ft 4 in. / 4.05

meters.

3. Ensure there is 3 feet (1 meter) of free space in front of power supply receptacles.

4. For proper performance, ensure that all product loaded into the chamber is kept at least 1” (2.5

cm) from all wall and ceiling surfaces.

5. Two plugged access port are provided 0.875” (2.22 cm) (see Mechanical Layout drawing for

location). These ports may be used for customer temperature mapping of chamber or continuous

sample monitoring. The port is filled with insulation and both ends are plugged to reduce moisture

infiltration. After monitoring sensors are installed replace the insulation and seal or plug both inside

and outside of the cabinet to reduce moisture infiltration. Failure to properly seal the access

port on both the interior and exterior will result in moisture infiltration, and performance

degradation of the unit.

6. Connect each refrigeration system to a separate receptables 30 Amp (32 Amp 50Hz.) 208-230

VAC 2 pole, 2 wires + GND (3 wire receptacle).

Note: The ULC/ULCi must be powered by 2 separate single phase circuits.

NEMA L6-30P, LOCKING PLUG (North America) IEC 60309 Plug (International)

7. Water cooled system (ULC-WC, ULCi-WC).

a. The inlet and outlet water connections are located on the top of each refrigeration

system. The connections are 1/2” FPT.

Model ULC Series

06012021ULC,Rev i Page 11 of 54

b. To allow for movement of the equipment during servicing, we recommend using

½” industrial grade flexible hose; 8’ (2.5m) in length.

c. We strongly recommend installing a 1/2” ball valve at the water inlet along with a

strainer and pressure gauge. These will facilitate any servicing or testing

requirements.

d. Check all connections for leaks.

e. Verify the water differential pressure is adequate along with nominal flow and

temperature requirements (see Specifications).

5.0 Control System

The unit consists of heating, cooling components, fans, and control components. The major cooling

components include a compressor (heat moving component), condenser (heat rejection part),

evaporator (heat absorption part) and PWM valve (refrigerant flow control devices). Controls consists

of a circulation fan, IDEC PLC Series FC6A, RTD temperature sensors, PWM valve hot gas control,

solid state relay and miscellaneous other hardware.

There are various settings that the user can adjust to suit their specific requirements. These are

described in the Operation section of this manual.

6.0 Operation

1. POWER CONTROL:

Electrical power is provided via a power cord. Internally, power passes through a 2-pole

main circuit breaker, which is accessible inside the main control enclosure.

The only user accessible means of power disconnection is by unplugging the power cord

from the wall receptacle.

Torefrigeration

systemwater

connections

Model ULC Series

06012021ULC,Rev i Page 12 of 54

2. UNIT OPERATION:

All unit operation is performed using the door mounted touch screen displays.

3. Basic Operation:

After unit setup, plug the power cord(s) into the properly sized receptacles. The door

mounted displays will turn on with the Home screen being displayed. The present interior

chamber temperature will be displayed.

Starting the cooling:

Note: Operator privileges or higher are required to access AUTO button and

change the temperature set point.

a) To start the unit cooling to operating temperature, press the Health icon on the

Home screen (see Health System Screen 1). Press the “AUTO” button, then enter

the access code and press Enter. After a short delay period, the compressors will

start and the unit will begin to cool down to set point. It is not necessary to remain

on this screen while waiting for the compressors to start.

b) To set the chamber temperature, press the Setup icon (see Setup Screen 1). Touch

the Temp Set Point display, then enter the access code and press Enter. Input the

desire temperature set point and press ENT (enter).

Review the Setup, System Health, Unit Information and Technical Service screens to input

your required values and familiarize yourself with the features of the ULC series.

Model ULC Series

06012021ULC,Rev i Page 13 of 54

a. Home Screen

Home Screen

Previous Screen

Next Screen

System Setup This icon will display the system setup screens for alarms, alarm delays, defrost

cycles, screen settings, service intervals and factory defaults in sequential order.

System Health This icon will display the general system health screens for primary cooling,

defrost status and system critical temperatures in sequential order.

Unit Information This icon will display the general information concerning the unit, such as typical

serial label information, software revisions, and support contact information.

Technical/Service This icon will allow access to the technical and service functions of the unit. Note;

these functions will typically be under log-in security protection and should only

be accessed by trained, service personnel. The operation of these screens is

described in a separate Service Manual.

Model ULC Series

06012021ULC,Rev i Page 14 of 54

Alarm Silence This icon will be displayed during an active alarm. Touching this Alarm Silence

Icon will silence the audible alarm for a period of time set up by the user. Should

the alarm condition remain active, the audible will sound again at the end of the

delay period.

Warning Icon This icon will be displayed during an active warning. The “Warning Icon” is visible

when a warning message is active. Touching this “Warning” icon will display the

active warning message(s). A warning informs users that an Alarm Condition

may occur if the warning conditions is not resolved within the programmed delay

period. Example: door open warning with system in a defrost mode.

Alarm Icon This icon will be displayed during an active alarm. The “Alarm Icon” is visible

when an alarm condition is active. Touching this “Alarm” Icon will display the

active alarm condition(s). Action is required by the end user to resolve the Alarm

condition. Example: door open alarm, system failure alarm.

Service Icon This icon will be displayed to indicate the system is due for maintenance or

calibration.

Note: Operator privileges or higher will be required to make changes

to any of the controller settings. The access will return to view only if

the control is left unattended for more than 5 minutes.

Model ULC Series

06012021ULC,Rev i Page 15 of 54

b. Set-up Screen

RETURN TO HOME SCREEN

RETURN TO PREVIOUS SCREEN

GO TO NEXT SCREEN IN THIS SEQUENCE

ALARM HIGH: Touch the “Alarm High” display. A numerical entry keypad will be displayed. Enter

the high temperature alarm set point. The available range is +30°C to -80°C. The Factory Default

value is 30°C. Press ENT (enter) to save.

TEMP SET POINT: Touch the “Temp Set Point” display to enter the chamber control temperature.

The available ranges are

ULC, ULCi -40°C to -80 °C

ULC-WR, ULCi-WR -20°C to -80°C

The Factory Default setting is -80°C.

Press ENT (enter) to save.

ALARM LOW: Touch the “Alarm Low” display to enter the low temperature alarm set point. The

available range is -40°C to -99°C. The Factory Default is -88°C. Press ENT (enter) to save.

Home Screen

Each screen will display

the current internal

chamber temperature

Previous screen Next Screen

Model ULC Series

06012021ULC,Rev i Page 16 of 54

REFRIG ASSIST: The ULC series is equipped with a refrigeration assist feature. When the

chamber warms up by the programmed Refrig Assist temperature, the Standby system will run to

assist the Primary system to return the chamber to the temperature set point.

Touch the “Refrig Assist” display to enter the temperature warmup above Temp Set Point that will

cause the standby system to turn on. The available range is 0 °C to +40 °C. The Factory Default

is 3°C. Press ENT (enter) to save.

3°C is the recommended setting and should not be changed without consulting the factory.

Press to go to the next screen

SETUP 2:

TEMP ALARM DELAY: Touch “Temp Alarm Delay” display to enter the delay time before a High

or Low Temperature Alarm condition will cause the audible and visual alarm to be activated. The

available range is 0 to 120 minutes. The Factory Default is 5 minutes. press ENT (enter) to save.

DOOR OPEN DELAY: Touch the “Door Open Delay” to enter the time delay before an open

chamber door will cause the Door Open Too Long alarm to be activated. The available range is

5 to 300 seconds. The Factory Default is 30 seconds. Press ENT (enter) to save

RING BACK DELAY: Touch the “Ring Back Delay” display to enter the desired time period before

the audible/visual alarm will be re-enabled after the Alarm Silence is pressed. The available range

is 1 to 3000 minutes. The Factory Default is 1 minutes. Press ENT (enter) to save.

Press to go to the next screen.

Model ULC Series

06012021ULC,Rev i Page 17 of 54

SETUP 3:

DEFROST CYCLE TIME: Touch “Defrost Cycle Time” display to enter the interval time period

between automatic defrosts. The available range is 2 to 168 hours. The Factory Default is 12

hours.

12 hours is the recommended setting and should not be changed without consulting the

factory.

DEFROST MAX TIME: Touch “Defrost Max Time” display to enter the length of the defrost cycle.

Note: the defrost is typically terminated automatically when the coil temperatures warm to the

designed defrost levels. The available range is 5 to 60 minutes. The Factory Default is 30 minutes.

30 minutes is the recommended setting and should not be changed without consulting the

factory.

DEFROST END TEMP: Touch “Defrost End Temp” display to enter the defrost automatic

termination temperature. The available range is 0 °C to +40 °C. The Factory Default is 5°C.

5°C is the recommended setting and should not be changed without consulting the factory.

*Only the cooling coils (evaporators) are defrosted by the automatic defrost system. It

keeps the coils clear in order to maintain air flow through the chamber. The chamber walls,

shelves, doors, etc. will be covered with ice/snow over time. It will have to be removed

manually. See the maintenance section for chamber defrost instruction.

Model ULC Series

06012021ULC,Rev i Page 18 of 54

Press to go to the next screen.

SETUP 4:

SINGLE/DUAL SYSTEM: Touch either “Select Single Operation” or “Select Dual Operation”,

denoting if there are one or two refrigeration systems operational on this chamber. The software

to automatically switch between the two systems.

OTHER SIDE DETECTED: This icon indicates if the controls are detecting one or two

refrigeration systems operational.

The opposite side system is not detected.

The opposite side system is detected.

SCREEN BRIGHTNESS: Touch the “Screen Brightness” Arrow and the adjustment screen will

open. Adjust the display brightness to the desired level. Touch the ‘x’ in the upper right corner of

the screen to return to the System Configuration screen.

IGNORE DOOR SWITCH: Normally, opening either door will cause the refrigeration system to

turn off and remain off as long as the door is open. This icon allows the operator to disable the

door switch input, so that the refrigeration system remains on when the door is open.

Note: this is not the recommended mode of operation. The Ignore Door Switch mode should

only be used if a door switch fails. In this mode, the refrigeration systems will continue to operate

when the door is open or closed. Once the door switch is repaired, the Ignore Door Switch should

be turned off.

Pressing the icon will toggle between the two modes of door switch control.

The door switches will be monitored. Both refrigeration systems will turn off as

long as the door remains open.

Model ULC Series

06012021ULC,Rev i Page 19 of 54

The door switches will be ignored. The refrigeration system will continue to run

under temperature control, regardless whether the doors are open or closed. When this mode

is selected, there will be a message on the Home Screen stating:

WARNING: DOOR SWITCH DISABLED

to remind the operator that the door switch is being ignored. No alarms or lights related to door

openings will be activated.

Press to go to the next screen.

SETUP 5:

CALIBRATION INTERVAL: Touch the “Calibration Interval” display to enter the time interval

between calibration notification messages. The available range is 1 to 24 months. The Factory

Default is 12 months.

The Service Icon will display 30 days prior to the end of the interval to allow for scheduling.

RESET CALIBRATION TIMER: Touch the right arrow icon to reset the calibration notification

timer. A second screen will display to confirm the reset of the calibration notification timer.

MAINTENANCE INTERVAL: Touch the “Maintenance Interval” display to enter the time interval

between preventative maintenance notification messages. The available range is 1 to 24 months.

The Factory Default is 24 months.

The Service Icon will display 30 days prior to the end of the interval to allow for scheduling.

RESET MAINTENANCE TIMER: Touch the right arrow icon to reset the maintenance notification

timer. A second screen will display to confirm the reset of the maintenance notification timer.

Model ULC Series

06012021ULC,Rev i Page 20 of 54

Press to go to the next screen.

SETUP 6:

RESET SETTINGS TO FACTORY DEFAULTS: Touch the right arrow to reset all control settings

to factory default values. A second screen will display to confirm the reset. Touching the green

check mark on the second screen will reset all settings the factory values.

Table of contents

Other Farrar Scientific Freezer manuals

Popular Freezer manuals by other brands

HSS Hire

HSS Hire 56772 Operating & safety guide

Haier

Haier HCM050EC - 5.0 cu. Ft. Capacity Freezer user manual

montpellier

montpellier MCF140WLED Installation and operating instructions

Premium

Premium PFR10680M Service manual

Panasonic

Panasonic MDF-U7586SC operating instructions

Randell

Randell 20048SCF-32 Specifications