Fast UT3P User manual

820037 FAST™ UT3P Sprayer 9-20-2018

FAST™ UT3P

Sprayer

OPERATION AND

MAINTENANCE

MANUAL

820037 FAST™ UT3P Sprayer 9-20-2018

820037 FAST™ UT3P Sprayer 9-20-2018

TABLE OF CONTENTS

SECTION PAGE

UT3P DELIVERY INSPECTION CHECKLIST ............................................................ 1

INTRODUCTION ......................................................................................................... 3

SAFETY....................................................................................................................... 4

MAJOR COMPONENTS ........................................................................................... 13

PREPARING MACHINE............................................................................................ 17

ATTACH SPRAYER TO TRACTOR ......................................................................... 21

DETACH SPRAYER FROM TRACTOR ................................................................... 25

TRANSPORTING ...................................................................................................... 28

OPERATION.............................................................................................................. 29

CONTROLS............................................................................................................... 43

SPRAYER ADJUSTMENT AND CALIBRATION ..................................................... 51

MAINTENANCE AND SERVICE .............................................................................. 59

TROUBLESHOOTING .............................................................................................. 72

STORAGE AND WINTERIZING................................................................................ 75

SPECIFICATIONS..................................................................................................... 77

UT3P DELIVERY INSPECTION CHECKLIST

PAGE 1

UT3P DELIVERY INSPECTION CHECKLIST

Dealers should complete this check sheet upon equipment delivery.

Date: _____________________

Model: ____________________________

Serial Number:______________________

Inspected by: _______________________

Remove this page from the manual and

retain for your records.

Task Initial

Look over unit for any damage that may have occurred during

shipping.

Verify the unit configuration to the sales order to ensure no parts

have been removed or changed.

Verify that all hardware is tight.

Verify that all plumbing connections are tight. Leave any discon-

nected product hoses disconnected until pre-delivery preparations

are completed.

Verify the tail lights are in working order.

UT3P DELIVERY INSPECTION CHECKLIST

PAGE 2

This page intentionally left blank.

INTRODUCTION

PAGE 3

INTRODUCTION

Read this manual carefully

before operating your FAST

equipment. The information pre-

sented will prepare you to safely

operate and service your

machine. Require all operators to read this

manual carefully and be acquainted with all

the operating and adjustment procedures

before attempting to operate. Failure to follow

the information in this manual and on decals

may result in personal injury or equipment

damage.

This manual should be considered a perma-

nent part of this equipment and should remain

with the equipment when you sell it. Replace-

ment manuals can be obtained from your

FAST dealer.

This equipment has been engineered and

manufactured to provide dependable and sat-

isfactory use. Like all mechanical products, it

will require cleaning and upkeep. Inspect your

equipment before putting it into service. Your

authorized FAST dealer has trained mechan-

ics, genuine FAST service parts, and the nec-

essary tools and equipment when service is

needed. Use only genuine FAST parts for ser-

vice or repairs. Substitute parts will void the

warranty and may not meet standards for safe

and satisfactory operation.

Warranty is provided as part of FAST’s support

program for customers who operate and main-

tain their equipment as described in this man-

ual. The warranty is explained on the warranty

certificate you should have received from your

dealer. This warranty provides you with the

assurance that FAST will back its products

where defects appear within the warranty

period. Should the equipment be abused, or

modified to change its performance beyond

the original factory specifications, the warranty

will become void.

These instructions have been compiled from

field experience and engineering data. Some

information may be general in nature, due to

unknown and varying operating conditions.

However, through experience and these

instructions, you should be able to develop

procedures suitable to your particular situa-

tion.

The illustrations and data used in this manual

were current at the time of printing. However,

due to possible in-line production changes,

your machine may vary slightly in detail. We

reserve the right to redesign and change the

machines as may be necessary without notifi-

cation.

Throughout the manual references are made

to right and left direction. These are deter-

mined by standing behind the equipment fac-

ing the direction of forward travel.

Equipment Identification

The equipment serial number is located on the

serial tag or serial plate attached to the main

frame.

Write the equipment serial number below. Use

the serial number when ordering parts and

service.

We recommend that you also file the model

and serial number in a secure place off the

machine.

MODEL___________________________

SERIAL NUMBER___________________

PURCHASE DATE __________________

SAFETY

PAGE 4

SAFETY

The most important safety devise on this equipment is a safe operator. It is the operator’s respon-

sibility to read and understand and follow all safety and operating instructions in this manual.

As the operator, you are responsible for the safe operation and maintenance of this equipment.

You must ensure that you and anyone else who is going to operate, maintain or work around the

machine is familiar with the operating and maintenance procedures and related safety informa-

tion contained in this manual.

You are the key to safety. Good safety practices protect you and people around you. Be certain

that everyone operating this equipment is familiar with the recommended operating and mainte-

nance procedures and follows all safety precautions. Do not risk injury or death by ignoring

good safety practices.

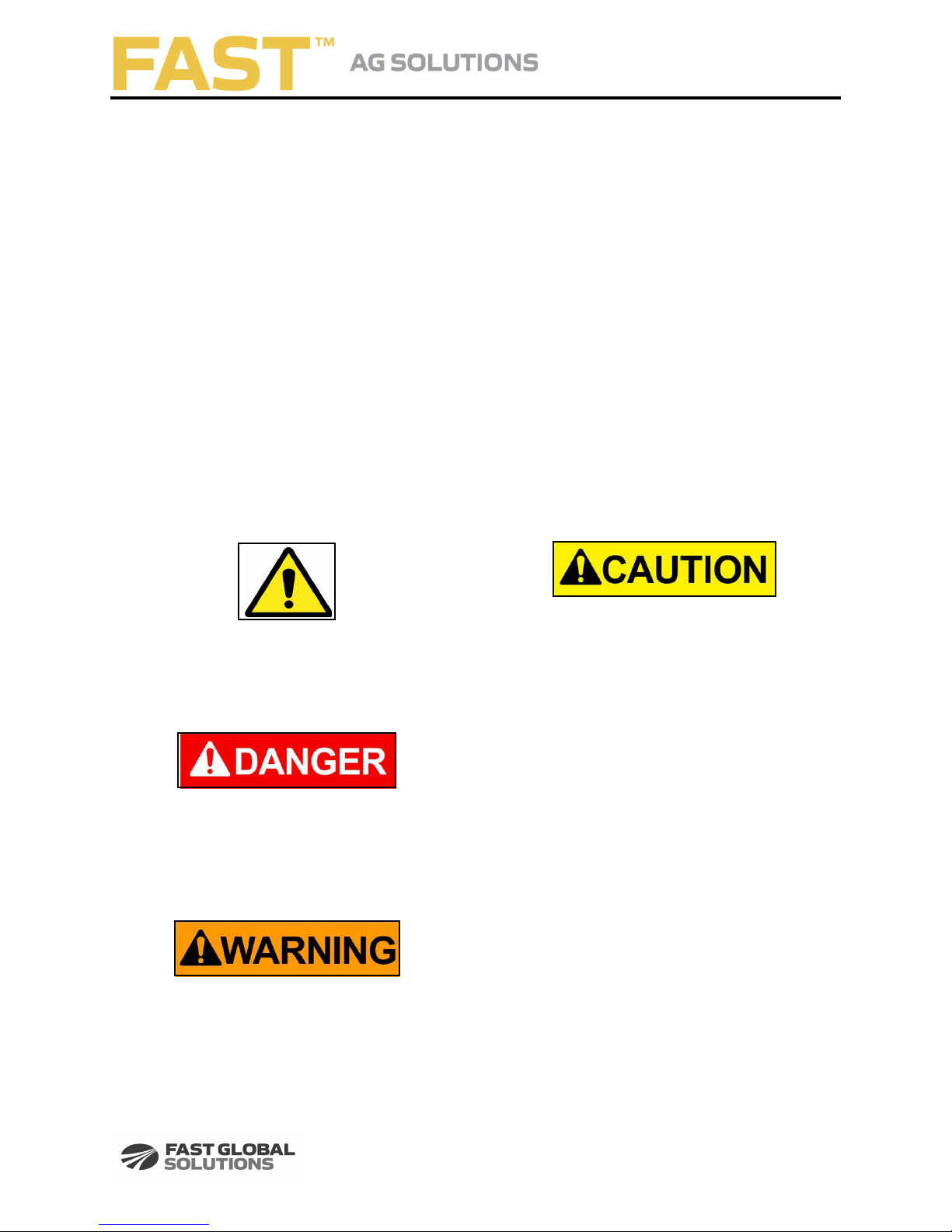

Safety Alert Symbols and Signal Words

Throughout this manual, the terms Caution, Warning, and Danger are used along with the safety

alert symbol to indicate the degree personal safety hazard. The term Important is used to indicate

that failure to observe can cause damage to the equipment.

SAFETY ALERT SYMBOL

A SAFETY ALERT SYMBOL means

there is a hazard. Become Alert! Your

Safety is Involved!

DANGER

The word DANGER indicates an immi-

nently hazardous situation that, if not

avoided, will result in death or serious

injury.

WARNING

The word WARNING indicates a

potentially hazardous situation that, if

not avoided, could result in death or

serious injury.

CAUTION

The word CAUTION indicates a

potentially hazardous situation that if

not avoided may result in minor or

moderate injury.

IMPORTANT

The word IMPORTANT indicates that

failure to observe can cause damage

to equipment.

NOTE

The word NOTE indicates helpful infor-

mation.

SAFETY

PAGE 5

General Safety

Carefully read and follow all safety messages

in this manual and safety signs (decals) on

equipment.

A safety sign may contain more than one haz-

ard message and more than one avoidance

panel.

Learn how to operate the machine and how to

use the controls properly. Do not let anyone

operate the machine without instruction.

Keep the machine in proper working condition.

Unauthorized modifications to the machine

may impair the function and/or safety and

affect machine life.

Do not operate or transport this machine while

under the influence of alcohol or drugs. Con-

sult your doctor about operating this machine

while taking prescription medications.

If you do not understand any part of this man-

ual and need assistance, contact your FAST

dealer.

Prepare for Emergencies

Keep a fire extinguisher and first aid kit handy.

Know how to use them.

Keep emergency numbers for doctors, ambu-

lance service, hospital, and fire department

near your telephone.

Keep the Poison Control emergency tele-

phone number for your area on sprayer before

using chemicals.

Have the chemical container and SDS avail-

able when seeking medical attention.

Personal Protection Equipment (PPE)

Wear close fitting clothing and safety equip-

ment appropriate for the job.

Wear the appropriate protective clothing and

devices as described on the chemical SDS

sheet.

SAFETY

PAGE 6

Handle Chemicals Safely

Direct exposure to hazardous chemicals can

cause serious injury.

A Safety Data Sheet (SDS) (formerly Material

Safety Data Sheet (MSDS)) provides specific

details on chemical products: physical and

health hazards, safety procedures, and emer-

gency response techniques.

Read the chemical

manufacturers warn-

ing, instructions and

procedures before

starting and follow

them exactly.

Potentially hazardous

chemicals are used with FAST equipment

include such items as lubricants, coolants,

paints, and adhesives.

Check the SDS before you start any job using

a hazardous chemical. That way you will know

exactly what the risks are and how to do the

job safely. Then follow procedures and recom-

mended equipment.

Keep Riders Off Machine

Do not allow riders on the

sprayer or the tractor

during operation or trans-

port.

Riders are subject to

injury from being struck

by foreign objects, expo-

sure to chemicals, and being thrown off the

machine.

Riders obstruct the operator’s view resulting in

the machine being operated in an unsafe way.

Riders are subject to exposure to chemicals

as they are being applied which could create a

health hazard.

Maintenance Safety

Understand service procedures before starting

work.

Keep service area clean and dry.

Never lubricate, service or adjust machine

while it is moving. Keep hands, feet and cloth-

ing from power-driven parts.

Lower equipment to the ground.

Disengage all power.

Relieve hydraulic pressure before serving or

disconnecting from the tractor.

Stop the engine. Remove the key. Allow the

machine to cool.

Securely support all machine elements that

must be raised for service work. Use tools,

jacks, and hoists of sufficient capacity for the

job.

Clear area of bystanders when making adjust-

ments, filling, servicing or repairing the equip-

ment.

Use adequate lighting for the job.

Keep all parts in good condition and properly

installed. Fix damaged components immedi-

ately. Replace worn and broken parts.

Remove any build-up of grease, oil, or debris.

On towed implements, disconnect the wiring

harness from the tractor before servicing elec-

trical system components or welding on

machine.

Remove paint and any residue from solvents

before welding or heating.

SAFETY

PAGE 7

Hydraulic Safety

The hydraulic system operates under

extremely high pressure. Escaping fluid under

pressure can penetrate the skin causing seri-

ous injury.

If an accident occurs, seek medical assistance

immediately. DO NOT DELAY. Any fluid

injected into the skin must be surgically

removed. Serious infection or toxic reaction

can develop from hydraulic fluid piercing skin

surface.

Doctors unfamiliar with the is type of injury

should reference a knowledgeable medical

source.

Avoid the hazard by relieving pressure before

disconnecting hydraulic or other lines.

Tighten all connections before applying pres-

sure.

Replace worn, cut, abraded, flattened or

crimped hoses.

Do not attempt makeshift repairs to hydraulic

lines, fittings or hoses by using tape, clamps

or cements.

Check for leaks with a piece of cardboard, Do

Not use your hands to check for leaks. Protect

hands and body from high-pressure fluids.

Avoid Heating

Near Pressurized

Fluid Lines

Flammable spray can be generated by heating

near pressurized fluid lines, resulting in severe

burns to yourself or bystanders.

Do not heat by welding, soldering, or using a

torch near pressurized fluid lines or other flam-

mable materials. Pressurized lines can be

accidentally cut when heat goes beyond the

immediate flame area.

Waste Disposal Safety

Improper disposal of waste can threaten the

environment and ecology. Potentially harmful

waste used with FAST equipment includes oil,

coolant, brake fluid, filters, and batteries.

Use leak-proof containers when draining flu-

ids. Do not use food or beverage containers

that may mislead someone into drinking from

them.

Do not pour waste onto the ground, down a

drain, or into any water source.

Follow instructions on chemical containers or

SDS sheets for disposal of chemicals, contain-

ers, and water used for cleaning the equip-

ment.

Safety Signs (Decals)

Keep safety signs in good condition.

Replace missing or damaged safety signs.

Be sure new equipment components and

repair parts include the current safety signs.

Replacement signs are available from

your FAST dealer.

SAFETY

PAGE 8

Storage Safety

Store equipment away from human activity.

Do not allow children to play on or around the

stored machine.

Empty and clean out the chemical tank before

storing.

Lower the machine and securely block.

Transportation Safety

Obey all applicable laws and regulations for

transporting equipment.

Verify that the chemical tank is empty before

transporting on roadways.

Do not allow riders.

Do not exceed 20 mph (32 km/h) when trans-

porting.

Use caution on inclines, curves, when making

turns and adverse road conditions.

Be sure sprayer is properly connected to the

towing vehicle and a retainer is used.

Always engage the safety locks on the hitch.

Booms must be folded into transport position

when transporting.

Reduce speed on rough terrain and on slopes.

Stopping distance increases with speed,

weight, and on slopes.

When transporting on roadways frequently

check for traffic from the rear, especially in

turns, and use turn signal lights.

Use headlights, flashing warning lights, and

turn signals day and night.

Keep lighting, reflectors, and markings visible,

clean and in good working order.

Repair or replace lighting and markings that

have been damaged or lost.

Do not operate or transport the equipment

while under the influence of alcohol or drugs.

Consult your doctor about operating this

machine while taking prescription medica-

tions.

SAFETY

PAGE 9

Operation Safety

Read and understand this Operator’s Manual

and all safety signs before using.

This sprayer is intended to be used ONLY on

tractors with an enclosed, pressurized opera-

tor station.

Before each use inspect the entire machine.

Check tightness of nuts and bolt and fittings.

Lower machine to the ground, stop the tractor

engine and remove key, set parking brake,

and wait until all moving parts have stopped

before leaving the operator’s compartment to

adjust, lubricate, clean or unplug the machine.

Keep hands, feet, hair, and clothing away from

all moving parts.

Do not allow riders on the sprayer or tractor.

Make sure everyone is clear of the machine

before filling sprayer tank, starting tractor

engine or beginning operation.

Read chemical or fertilizer manufacturers

warnings, instructions, and procedures before

starting and follow them exactly.

Do not breathe, touch or ingest chemicals or

fertilizers. Always wear protective clothing and

follow safe handling procedures.

Keep bystanders away when unfolding or fold-

ing wings.

Stay away from overhead power lines when

folding or unfolding wings.

Keep clear of wings when unfolding or folding.

Avoid pinch points.

Install and secure all guards and shields.

Always operate the machine at rated speed.

Drive slowly over rough ground.

SAFETY

PAGE 10

SAFETY AND INSTRUCTIONAL LABELS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS

INJURY OR DEATH!

REPLACE LABELS IMMEDIATELY IF DAMAGED!

DECALS AND DECAL LOCATION MAY VARY BY MODEL.

A. Serial Number Tag

H. Decal 800112

*Models with Booms Only

C. Decal 800007

E. Decal 800105

*Models with Booms Only

D. Decal 800002

A

B

C

E

H

F. Decal 800004

*Hydraulic Power Only

D

B. Decal 10208

G. Decal 800013

F

G

SAFETY

PAGE 11

LIGHTS AND REFLECTORS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS

INJURY OR DEATH!

REPLACE LIGHTS AND REFLECTORS IMMEDIATELY IF DAMAGED!

1. Red Reflectors

2. Tail Light

3. SMV Sign

4. Yellow Reflectors (boom models only)

ASABE S279 for North America Compliant

4

3

1

2

SAFETY

PAGE 12

CHEMICAL SAFETY

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

FAILURE TO FOLLOW THESE INSTRUCTIONS COULD RESULT IN SERIOUS

INJURY OR DEATH!

REPLACE LABELS IMMEDIATELY IF DAMAGED!

This equipment is designed for the spray application of chemicals.

Read chemical manufacturers’ warnings, instructions and procedures before

starting and follow them exactly.

Wear protective clothing including but not limited to gloves, eye protection, and

breathing mask.

This sprayer is intended to be used ONLY on vehicles with an enclosed, pressur-

ized operator station.

Always carry the SDS sheet of the chemical being used on the sprayer.

Be alert and use caution when folding or unfolding wings, filling tank, setting chemical

pumps and servicing to avoid chemical spills, drips, and vapors.

Spray only when the potential for chemical drift is at a minimum. Even small amounts can

affect neighboring crops, sensitive plants, and people.

Do not eat while using this equipment.

Wash hands and arms thoroughly before eating. Use a detergent to remove chemical

residue. Rinse carefully and dry with disposable towels.

Store this equipment away from children and livestock.

Always follow instructions for the chemical being used.

Post Poison Control Emergency telephone number for your area on sprayer.

Washington DC: (202) 962-4525 Ottawa: (613) 992-5606

Have SDS and chemical container label available when seeking medical attention.

MAJOR COMPONENTS

PAGE 13

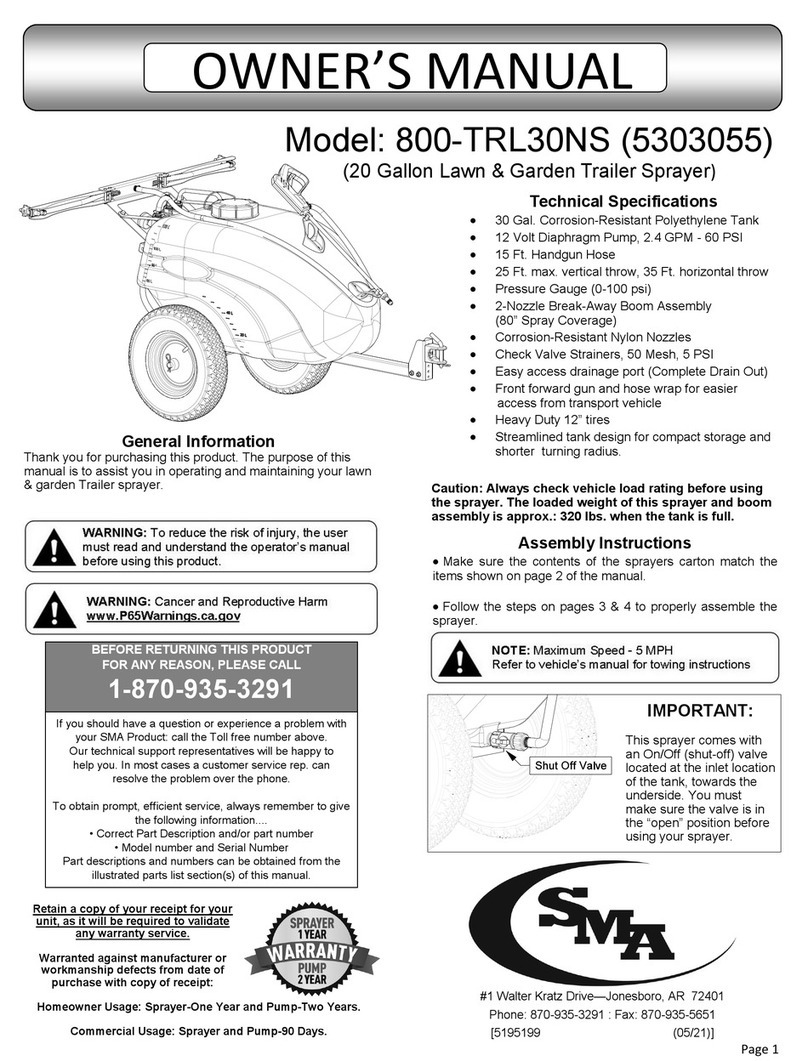

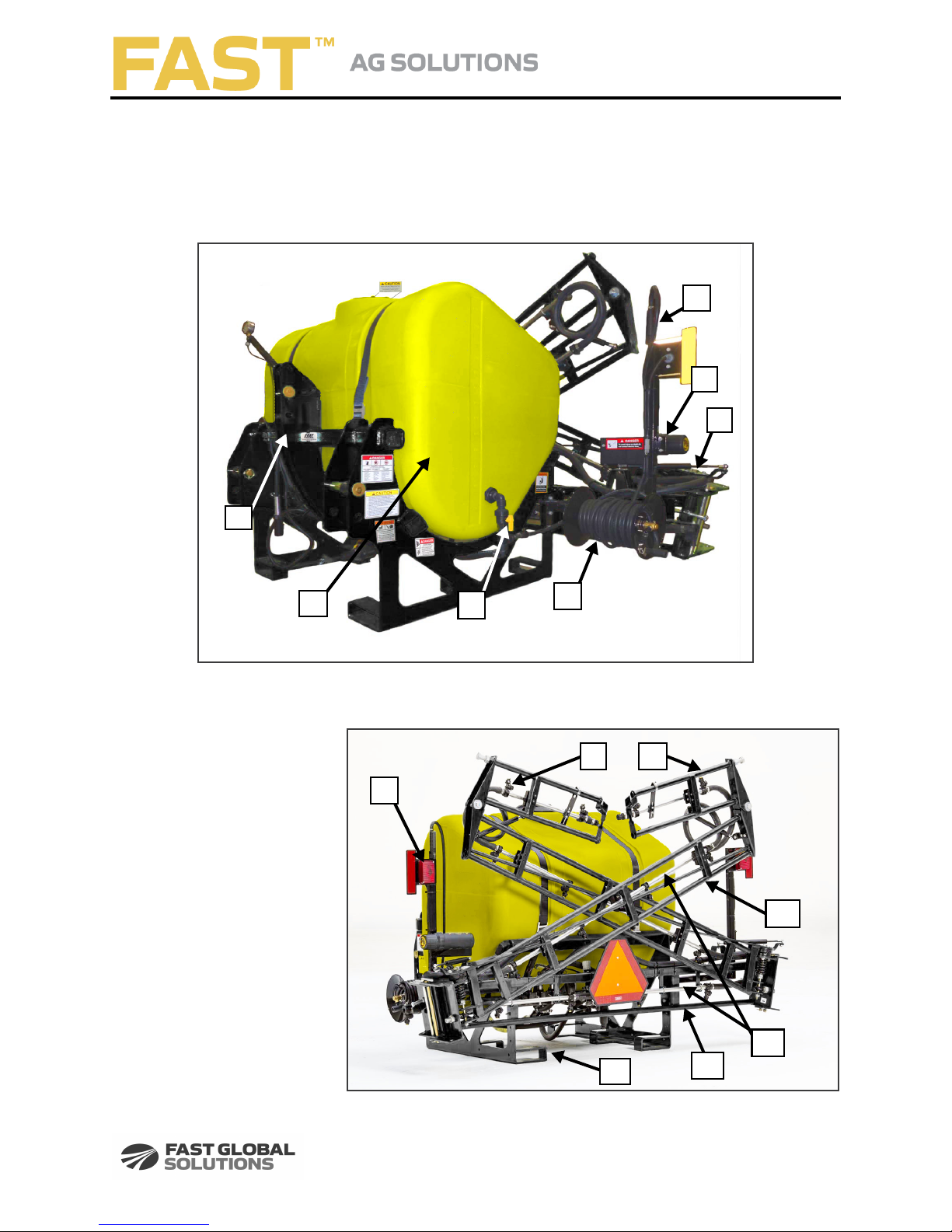

MAJOR COMPONENTS

1. 3 Point Hitch

2. Tank

3. Tank Agitation Valve

4. Hose Reel

5. Spray Wand

6. Manual Holder

7. Breakaway Wing Clutch

8. Tail Lights

9. Nozzle

10.Flip Wing Section

11. Main Wing Section

12.Stainless Steel Wet

Boom

13.Center Boom Section

14.Stand / Forklift Tine-

ways

7

6

5

4

3

2

1

8

12

10

13

11

14

9

MAJOR COMPONENTS

PAGE 14

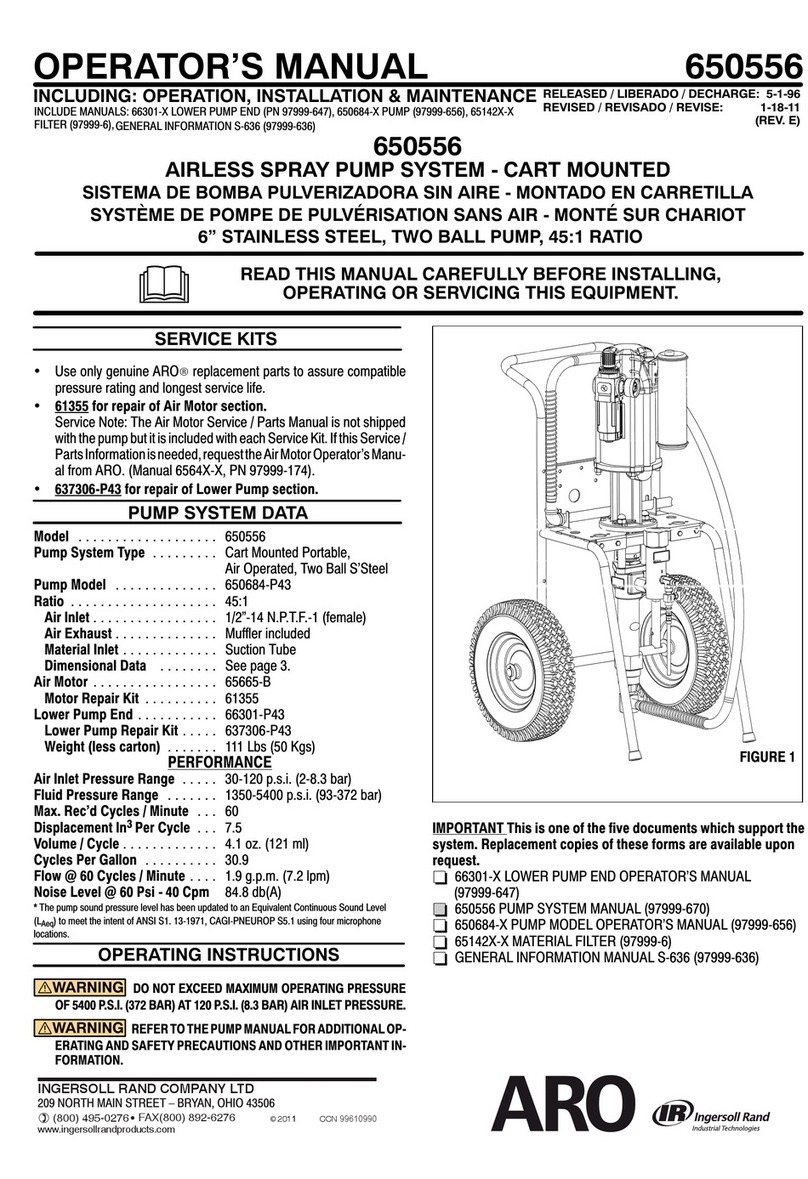

Boomless Models

15.Nozzle

16.Solution Lines

17.Tail Lights

18.Stand / Forklift Tineways

19.Section Control Valves

20.Motorized Control Valve

21.Relief Valve (PTO pump models only)

22.PTO Pump (PTO pump models only)

23.Hydraulic Motor Driven Chemical

Pump (hydraulic models only)

24.Tank Valve

18

15

17

16

19 21

20

23

24

MAJOR COMPONENTS

PAGE 15

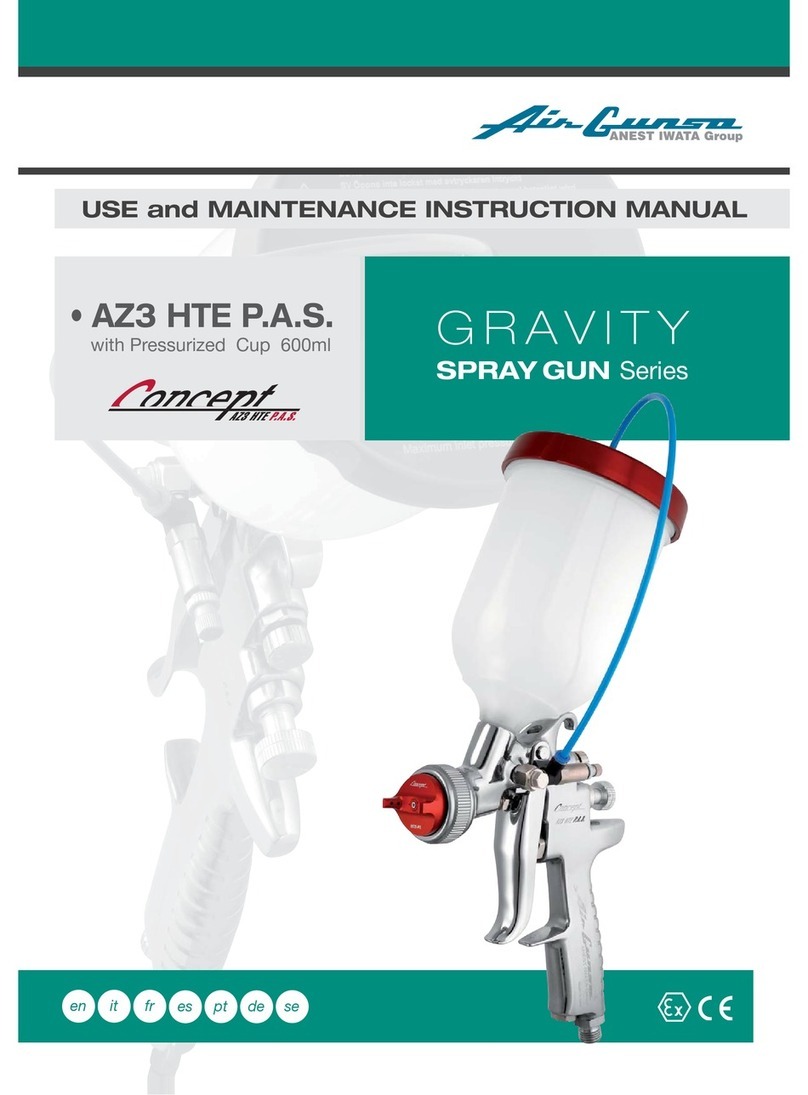

25.Pressure Gauge

26.Cord / PTO Storage

27.Valve Control Box (Installed in tractor

cab)

25

26

27

MAJOR COMPONENTS

PAGE 16

This page intentionally left blank.

PREPARING MACHINE

PAGE 17

PREPARING MACHINE

ASSEMBLY

Upon arrival the sprayer will require initial

assembly. This will typically be completed

by a FAST Dealer.

Drain and Rinse the Tank

The sprayer is shipped with a small

amount of RV antifreeze in the tank. The

tank must be drained and rinsed before

use.

Drain Filters

1. Place a pail under filter.

2. Remove the drain plug from the filter.

3. Allow to drain.

4. Replace plug.

5. Repeat for additional filters.

See “PUMP MAINTENANCE AND SER-

VICE”

Drain Tank

1. Locate the tank drain below the tank.

2. Place a pail or container under drain.

3. Disconnect the fitting from the tank.

4. Allow fluid to drain.

5. Reinstall hose fitting.

6. Add 10 gallons of water to the tank.

7. Disconnect the fitting from the tank.

8. Allow rinse to drain.

9. Reinstall hose fitting and tighten.

Table of contents

Other Fast Paint Sprayer manuals