HARDI-EVRARD ALPHA PLUS 3500 Operating instructions

EVRARD GGRROOUUPPEE

HARDI

Reference : 677833

Edition : 07/05

OPERATING and

MAINTENANCE Man al

HARDI

HARDI NO

NOV

VA

A

AALLPPHHAA PPLLUUSS HHAARRDDII NNOOVVAA

SSUUMMMMAARRYY

SSUUMMMMAARRYY

I

11- DDEECCLLAARRAATTIIOONNOOFF CCOONNFFOORRMMIITTYY FFOORR EEEECC --------------------------------------------------

1-1 USING THE SELF-PROPELLED ALPHA -----------------------------------------------

1-2 DELIVERY REPORT --------------------------------------------------------------------------

1-3 SAFETY PRECAUTIONS -------------------------------------------------------------------

1-4 ROAD DRIVING --------------------------------------------------------------------------------

1-5 PLANT PROTECTION PRODUCTS ------------------------------------------------------

1-6 CLEANING THE SPRAYER -----------------------------------------------------------------

1-7 NITROGEN ACCUMULATOR --------------------------------------------------------------

22- DDEESSCCRRIIPPTTIIOONN OOFF SSPPRRAAYYEERR ---------------------------------------------------------------

2-1 MAIN EQUIPMENT IDENTIFICATION ---------------------------------------------------

2-2 SAFETY PRECAUTIONS -------------------------------------------------------------------- 2-3

IDENTIFICATION ------------------------------------------------------------------------------

2-4 CAB ACCESS ----------------------------------------------------------------------------------

2-5 CONSOLE DESCRIPTION ----------------------------------------------------------------

2-5-1 STEERING COLUMN WITH CONSOLE ----------------------------------------------

2-5-2 CONSOLE ------------------------------------------------------------------------------

2-5-3 CAB ACCESSORIES ------------------------------------------------------------------

2-6 DRIVER S COMFORT -----------------------------------------------------------------------

2-6-1 SEAT ------------------------------------------------------------------------------------

2-6-2 HEATING ------------------------------------------------------------------------------

2-6-3 AIR CONDITIONING -------------------------------------------------------------------

2-7 ENGINE -----------------------------------------------------------------------------------------

2-7-1 ENGINE ACCESS -----------------------------------------------------------------------

2-7-2 STARTING THE ENGINE ---------------------------------------------------------------

2-7-3 ENGINE ACCELERATOR ---------------------------------------------------------------

2-7-4 STOPPING THE ENGINE ---------------------------------------------------------------

2-8 ADVANCE CONTROL ------------------------------------------------------------------------

2-8-1 DRIVER S CONTROL LEVER ----------------------------------------------------------

2-8-2 BRAKE ENGINE -------------------------------------------------------------------------

2-8-3 PARKING BRAKE -----------------------------------------------------------------------

2-8-4 COMBINED EMERGENCY/ PARKING BRAKE ---------------------------------------

2-8-5 SPEED SELECTOR --------------------------------------------------------------------

FAST Speed ---------------------------------------------------------------------------

SLOW Speed ---------------------------------------------------------------------------

‘ INTERMEDIATE Speed ---------------------------------------------------------------

2-9 WHEEL STEERING ---------------------------------------------------------------------------

2-9-1 DESCRIPTION --------------------------------------------------------------------------

2-9-2 TWO WHEEL STEERING ---------------------------------------------------------------

2-9-3 FOUR WHEEL STEERING ------------------------------------------------------------

2-9-4 TWO WHEEL IN ‘ CRAB FORMATION -----------------------------------------------

2-10 SPRAY PUMP --------------------------------------------------------------------------------

2-11 BOOM FUNCTIONS ------------------------------------------------------------------------

2-11-1 SPRAY AND ANGLING OF AIR CONTROL -----------------------------------------

2-11-2 FOAM MARKER CONTROL-----------------------------------------------------------

2-12 BOOM FUNCTIONS ------------------------------------------------------------------------

2-12-1 SAFETY --------------------------------------------------------------------------------

2-12 ‘ HAZ BOOM ‘ ---------------------------------------------------------------------------

2-12-3 ‘ LA/GVA BOOM ----------------------------------------------------------------------

2-12-2 FOAM MARKER -----------------------------------------------------------------------

11-11

1-2

1-3

1-4

1-4

1-4

1-5

1-6

22-11

2-1

2-2

2-3

2-4

2-4

2-4

2-5

2-6

2-6

2-6

2-7

2-7

2-8

2-8

2-8

2-9

2-9

2-10

2-10

2-10

2-11

2-11

2-12

2-12

2-12

2-12

2-13

2-13

2-13

2-14

2-15

2-16

2-17

2-17

2-17

2-17

2-17

2-18

2-19

2-20

AALLPPHHAA PPLLUUSS HHAARRDDII NNOOVVAA

II SSUUMMMMAARRYY

2-12 AIR ASSISTANCE ---------------------------------------------------------------------------

2-13-1 AIR SPEED / AIR VOLUME -----------------------------------------------------------

2-13-2 ANGLING OF AIR AND LIQUID ------------------------------------------------------

2-13-3 WATER SENSITIVE PAPER -----------------------------------------------------------

33- PPRREEPPAARRAATTIIOONN -------------------------------------------------------------------------------------------

3-1 ELECTRIC CIRCUIT -------------------------------------------------------------------------

3-2 DIESEL TANK ---------------------------------------------------------------------------------

3-3 HYDRAULIC OIL RESERVOIR ------------------------------------------------------------

3-4 SCREEN WASH RESERVOIR ------------------------------------------------------------

3-5 ENGINE ------------------------------------------------------------------------------------------

3-6 TYRES -------------------------------------------------------------------------------------------

3-6-1 PRESSURE -----------------------------------------------------------------------------

3-6-2 BOLTS TIGHTING ----------------------------------------------------------------------

3-6-3 STRAW DIVIDERS ---------------------------------------------------------------------

3-7 SPRAY -------------------------------------------------------------------------------------------

3-7-1 FITTING THE NOZZLES ---------------------------------------------------------------

3-7-2 FILTERS ---------------------------------------------------------------------------------

Suction filter ----------------------------------------------------------------------------

delivery filter ---------------------------------------------------------------------------

In-line filters -----------------------------------------------------------------------------

3-7-3 PUMP- DRAIN VALVE - LEVEL INDICATOR ------------------------------------------

Mix/ Admixture unit ---------------------------------------------------------------------

Centrifugal pump ------------------------------------------------------------------------

Diaphrams pump ------------------------------------------------------------------------

3-7-4 ADJUSTMENT OF PRESSURE EQUALISATION -------------------------------------

44 - OOPPEERRAATTIINNGG TTHHEE LLIIQQUUIIDD SSYYSSTTEEMM ---------------------------------------------------------------

4-1 Function diagram -----------------------------------------------------------------------------------

4-2 Use the Manifold valve system --------------------------------------------------------------------

4-3 Top operate the soraying function -----------------------------------------------------------------

Electric operated MANIFOLD valves (if fitted) -----------------------------------------------------

Pictograms GREEN disc (pressure) --------------------------------------------------------------

4-4 Filling hand washing tank and rinsing tank -----------------------------------------------------

4-5 Filling with suction filling device (if fitted) ----------------------------------------------------------

4-6 Filling with fast filling device (if fitted) --------------------------------------------------------------

4-7 Filling device and fast filling device used simultaneously (if fitted) -------------------------------

4-8 Use of Quick coupler for external filling -----------------------------------------------------------

4-9 Filling of chemical ---------------------------------------------------------------------------------

Filling through tank lid ----------------------------------------------------------------------------

4-10 Filling by HARDI Filler chemical inductor --------------------------------------------------------

Filling of liquid chemicals -------------------------------------------------------------------------

Filling of powder chemicals -----------------------------------------------------------------------

4-11 Spraying -------------------------------------------------------------------------------------------

Spraying with agitation ---------------------------------------------------------------------------

Spraying without agitation -------------------------------------------------------------------------

4-12 Use of rinsing tank and rinsing nozzles -----------------------------------------------------------

4-13 Emptying the main tank ---------------------------------------------------------------------------

4-14 Emptying the rinsing tank -------------------------------------------------------------------------

2-20

2-20

2-20

2-23

33-11

3-1

3-1

3-2

3-2

3-3

3-3

3-3

3-3

3-3

3-4

3-4

3-4

3-4

3-5

3-5

3-5

3-5

3-5

3-5

3-6

44-11

4-1

4-2

4-1

4-2

4-2

4-3

4-3

4-4

4-5

4-5

4-6

4-6

4-7

4-7

4-8

4-9

4-9

4-9

4-9

4-10

4-10

AALLPPHHAA PPLLUUSS HHAARRDDII NNOOVVAA

III

SSUUMMMMAARRYY

55- CCAARREEAANNDDMMAAIINNTTEENNAANNCCEE --------------------------------------------------------------------------

5-1 TABLE OF LUBRICANTS -------------------------------------------------------------------

5-2 MAINTENANCE -------------------------------------------------------------------------------

5-2-1 MAINTENANCE DURING THE RUNNING-IN-PERIOD -------------------------------

5-2-2 PERIODIC MAINTENANCE -------------------------------------------------------------

5-2-3 OCCASIONAL MAINTENANCE ---------------------------------------------------------

5-2-4 ALUMINIUM BOOM MAINTENANCE ---------------------------------------------------

5-2-5 ENGINE MAINTENANCE ----------------------------------------------------------------

Coolant level -----------------------------------------------------------------------------

Heat exchanger cleaning -----------------------------------------------------------------

Air filter ----------------------------------------------------------------------------------

Changing Engine oil ---------------------------------------------------------------------

Changing fuel filter and draining fuel prefilter ---------------------------------------------

Fuel circuit venting -----------------------------------------------------------------------

Fuel prefilter -----------------------------------------------------------------------------

Fuel tank --------------------------------------------------------------------------------

Safety cartridge --------------------------------------------------------------------------

Draining cooling system -----------------------------------------------------------------

5-2-5 EVERY HOURS --------------------------------------------------------------------------

Spray filters ------------------------------------------------------------------------------

5-2-6 EVERY 10 HOURS -----------------------------------------------------------------------

Hydraulic oil level ------------------------------------------------------------------------

Air conditioning condenser ---------------------------------------------------------------

5-2-7 EVERY 50 HOURS ----------------------------------------------------------------------

463 Diaphragms pump -------------------------------------------------------------------

Wheels ----------------------------------------------------------------------------------

Chassis and boom ----------------------------------------------------------------------

5-2-8 EVERY 250 HOURS ---------------------------------------------------------------------

Hydraulic oil filters -----------------------------------------------------------------------

Carbon cab filters -----------------------------------------------------------------------

Triplet -----------------------------------------------------------------------------------

5-2-9 EVERY 500 HOURS ---------------------------------------------------------------------

Air conditioning --------------------------------------------------------------------------

GVA Aluminium boom ------------------------------------------------------------------

HAZ Boom adjustment -------------------------------------------------------------------

5-2-10 EVERY 1000 HOURS OR ANNUAL ---------------------------------------------------

Nitrogen accumulator --------------------------------------------------------------------

Valves ans diaphragms ------------------------------------------------------------------

Battery -----------------------------------------------------------------------------------

5-2-11 OCCASIONAL MAINTENANCE ----------------------------------------------------------------

Level indicator adjustment ---------------------------------------------------------------

Nozzle tubes and fittings ------------------------------------------------------------------

Cone check / renewal EVC operating unit -------------------------------------------------

Cone check / renewal, EVC distribution valves --------------------------------------------

Adjustment of 3-way-valve ---------------------------------------------------------------

Seal renewal, drain valve -----------------------------------------------------------------

Adjustment of slanting indicator ----------------------------------------------------------

Cab --------------------------------------------------------------------------------------

Fan trasmission priming ------------------------------------------------------------------

Fan trasmission pressure adjustment -----------------------------------------------------

55-11

5-1

5-1

5-1

5-2

5-2

5-3

5-4

5-4

5-4

5-5

5-5

5-5

5-6

5-6

5-6

5-7

5-7

5-8

5-8

5-8

5-8

5-8

5-9

5-9

5-9

5-9

5-11

5-11

5-12

5-12

5-13

5-13

5-13

5-14

5-15

5-15

5-16

5-16

5-17

5-17

5-17

5-17

5-18

5-18

5-18

5-19

5-19

5-20

5-20

AALLPPHHAA PPLLUUSS HHAARRDDII NNOOVVAA

IV SSUUMMMMAARRYY

66-GGAARRAAGGIINNGG ---------------------------------------------------------------------------------------------------

6-1 OFF-SEASON STORAGE ----------------------------------------------------------------------

6-2 PREPARING THE SPRAYER AFTER STORAGE ---------------------------------------

77 - FFAAUULLTTSS IINN OOPPEERRAATTIIOONN ---------------------------------------------------------------------------------

7-1 ELECTRIC CIRCUIT -----------------------------------------------------------------------------

7-1-1 FUSES AND RELAY ------------------------------------------------------------------------

7-1-2 AIR CONDITIONING WIRING DIAGRAM -------------------------------------------------

7-1-3 ENGINE -------------------------------------------------------------------------------------

7-1-4 FOUR-WHEELS STEERING ---------------------------------------------------------------

7-2 HYDRAULIC CIRCUITS -------------------------------------------------------------------------

7-2-1 OIL RESERVOIR ALARM ------------------------------------------------------------------

7-2-2 TOWING -------------------------------------------------------------------------------------

ACTION ON WHEEL MOTORS (Standard brake version) -----------------------------------

ACTION ON WHEEL MOTORS (With combined brake version) -----------------------------

ACTION ON WHEEL MOTORS (With Dyna+ version) ---------------------------------------

ACTION ON THE ADVANCING HYDROSTATIC PUMP --------------------------------------

7-2-3 BOOM CONTROL DISTRIBUTOR ---------------------------------------------------------

7-2-4 HYDRAULIC CIRCUIT (Combined brake) -------------------------------------------------

7-3 SPRAYING CIRCUIT -----------------------------------------------------------------------------

7-3-1 PUMP DOES NOT PRIME -----------------------------------------------------------------

7-3-2 FOAM FORMS ------------------------------------------------------------------------------

7-3-3 NO ADMIXTURE OF PRODUCTS ---------------------------------------------------------

7-3-4 INCORRECT SPRAYING -------------------------------------------------------------------

7-3-5 NO SPRAYING ------------------------------------------------------------------------------

7-3-6 VOLUME/HA CANNOT BE OBTAINED ----------------------------------------------------

7-3-7 WHEEL SENSOR --------------------------------------------------------------------------

7-3-8 PRESSURE GAUGE -----------------------------------------------------------------------

88 - LLIISSTT OOFF MMAAIINN PPAARRTTSS ------------------------------------------------------------------------------------

66-11

6-1

6-2

77-11

7-1

7-1

7-3

7-4

7-4

7-5

7-5

7-5

7-6

7-6

7-6

7-7

7-8

7-9

7-10

7-10

7-10

7-10

7-10

7-11

7-11

7-11

7-12

88-11

ALPHA PLUS TWIN FORCE

11- 1

FFOORREEWWOORRDD

TTHHEE MMAAKKEERR

HARDI-EVRARD

301, Rue du 21 Mai 1940

F -62990 BEAURAINVI E

Declares that the product

TTyyppee AAPPHHAA PPUUSS 33550000 aannddAAPPHHAA PPUUSS 44110000 SSPPRRAAYYEERR

Which is the subject of the declaration conforms to the basic of health and safety requirements stipulated in

EEC Directive 89/392/CE, 91/368/CE et 93/368/CE.

The following standards have been taken into account in order to implement, according to normal practice,

the health and safety regulation laid down in EEC Directives :

EN 292-1

EN 292-2

In addition, the owner of the machinery is obliged to keep this manual throughout the life of the machine

and, in the event of resale, to pass it on the purchaser.

Beaurainville, 1 February 2004

The Manager

HARDI-EVRARD

11- DDEECCAARRAATTIIOONN OOFF CCOONNFFOORRMMIITTYY FFOORR EEEECC

ALPHA PLUS TWIN FORCE

11- 2FFOORREEWWOORRDD

The agricultural sprayer is designed for applying plant protection products and liquid fertilizers to crops. It

must be used only for this purpose, to the exclusion of all others.

Please follow the Highway Code and any regulations in force with regard to road driving.

We strongly recommend that you obtain training in crop protection and handling plant protection products

to ensure crop treatment with total safety for those accompanying you and for the environment.

All the following specifications and characteristics are subject to improvements without notice and immediate revision of this

manual.

11-11 UUSSIINNGGTTHHEESSEEFF-PPRROOPPEEEEDD AAPPHHAA

11-22 DDEEIIVVEERRYY RREEPPOORRTT

TThhee ddeelliivveerryy rreeppoorrtt,, ggiivveenn wwhheenn tthhee mmoobbiillee uunniitt iiss ddeelliivveerreedd,, mmuusstt bbee rreettuurrnneedd ttoo ::

HHAARRDDIIEEVVRRAARRDD

BBPP 5599

7777554422 SSAAVVIIGGNNYY EETTEEMMPPEE CCEEDDEEXX

FFRRAANNCCEE

dduullyy ccoommpplleetteedd,, ddaatteedd aanndd ssiiggnneedd bbyy tthhee ccoonncceessssiioonnaaiirree aanndd tthhee uusseerr,, tthhee rreettuurrnn ooff tthhiiss ddooccuummeenntt ccaauussiinngg

tthhee gguuaarraanntteeee ttoo ssttaarrtt rruunnnniinngg.. WWee wwoouulldd aasskk yyoouu ttoo rreeaadd ccaarreeffuullllyy tthhee gguuaarraanntteeee ccllaauusseess ssttiippuullaatteedd iinn tthhee

ddeelliivveerryy rreeppoorrtt..

ALPHA PLUS TWIN FORCE

11- 3

FFOORREEWWOORRDD

Read and pay attention to the instruction book before starting and operating the sprayer.

It is equally important that other operators of this equipment read and understand this book.

Do not permit passengers to ride on the machine. There are no safe places for others than the driver.

Pressure test with clean water prior to filling with chemicals.Wear personal protection, always (gloves, overalls,

rubber boots, and face protection shield).

Wash the entire machine inside and outside, as far as possible, to remove all chemicals.

Depressurize equipment after use and before servicing.

Do not service and repair the machine when the machine is running.

Disconnect electrical power before servicing (arc welding, etc.).

Before starting the engine, make sure that nobody is carrying out service or maintenance jobs on the sprayer.

Wash and change cloths after spraying jobs.

Remove all inflammable or explosive material from the area.

Do not eat, drink or smoke whilst spraying or working with contaminated equipment.

Immediately, after spraying job, wash and change the clothes.

In case of poisoning, seek medical advice or call an ambulance. Retain chemical label or container for identifi-

cation of chemical.

Keep childrens away from the sprayer.

Do not enter the sprayer tank.

If any portion of this instruction book remains unclear after reading, contact your HARDI-EVRARD dealer for

futher explanation before using the equipment.

11-33 SSAAFFEETTYY PPRREECCAAUUTTIIOONNSS

Watch for this symbol, it means WARNING, CAUTION, PAY ATTENTION. Your safety is involved, so be

alert !

This symbol indicate the possibilty of frost damage.

11-44 RROOAADD DDRRIIVVIINNGG

On the road, it is essential to follow the directions of the Highway Code or any other regulation with regard

to compulsory equipment on agricultural machinery (lighting, warning beacon, etc.) The sprayer and tractor

must conform to local rules.

It is essential to take note of the overall dimensions of the sprayer prior to any road travel. These dimensions

are the subject of chapter 10.

ALPHA PLUS TWIN FORCE

11- 4FFOORREEWWOORRDD

Chemicals will penetrate gloves, rubber boots etc. after a certain period of contact. This period will vary

from a few hours to several days depending on rubber materials and chemical used. Be familiarised with the

quality of your protection equipment, and renew them according to the instructions.

Wash your gloves before taking them off. Do not touch the contaminated outer side of the gloves with bare

hands when taking them off.

If chemicals are splashed over you, remove soaked clothing at once and wash with soap and water instantly.

Plant protection chemicals will penetrate the skin, and affect your health. Consult chemical label regarding

precautions to be taken against poisoning.

Please obtain current information for decontamination methods (e.g. leaching of pesticides).

If you do not know this legislation, refer to the agricultural authorithies (Department Agriculture)

The sprayer must be cleaned on an uncultivated piece of land. There must be no seepage or running to

watercourses, gutters, wells or springs. The rinsing water must not no discharged into drains.

11-66 CCEEAANNIINNGG TTHHEE SSPPRRAAYYEERR

11-55 PPAANNTT PPRROOTTEECCTTIIOONN PPRROODDUUCCTTSS

Safe use of sprayers is dependent on the user, who must take the usual precautions when he is handling

plant protection products and working with machine. It is, for example, essential to be aware of the non-

compatibility of various different products used and be careful to read the product maker’s instructions. The

sprayer must be carefully cleaned after each use as chemical residues can damage the spray circuit.

Decree n° 92-1261 of 03 Décembre 1992.

Observe local legislation regarding chemical residues and mandatory decontamination methods. If in doubt

contact the authorities e.g. Department of Agriculture.

Do not store chemicals near the water. Store chemicals behind locked doors do not allow unauthorized per-

sons and children to access the chemicals.

11-55-11CCOONNTTAAIINNEERRSS

11-55-22SSTTOORRAAGGEE OOFF TTHHEE PPRROODDUUCCTTSS

11-55-33PPEERRSSOONNNNAA PPRROOTTEECCTTIIOONN

11-55-44PPAANNTT PPRROOTTEECCTTIIOONN CCHHEEMMIICCAA

ALPHA PLUS TWIN FORCE

11- 5

FFOORREEWWOORRDD

11-77 NNIITTRROOGGEENN AACCCCUUMMUUAATTOORR

O AER OPERATING INSTRUCTIONS CE 109294-1

ALPHA PLUS TWIN FORCE

11- 6FFOORREEWWOORRDD

ALPHA PLUS TWIN FORCE

11- 7

FFOORREEWWOORRDD

ALPHA PLUS TWIN FORCE

11- 8FFOORREEWWOORRDD

ALPHA PLUS HARDI NOVA

DDEESSCCRRIIPPTTIIOONN AANNDDOOPPEERRAATTIIOONNCHAPTER 22- 1

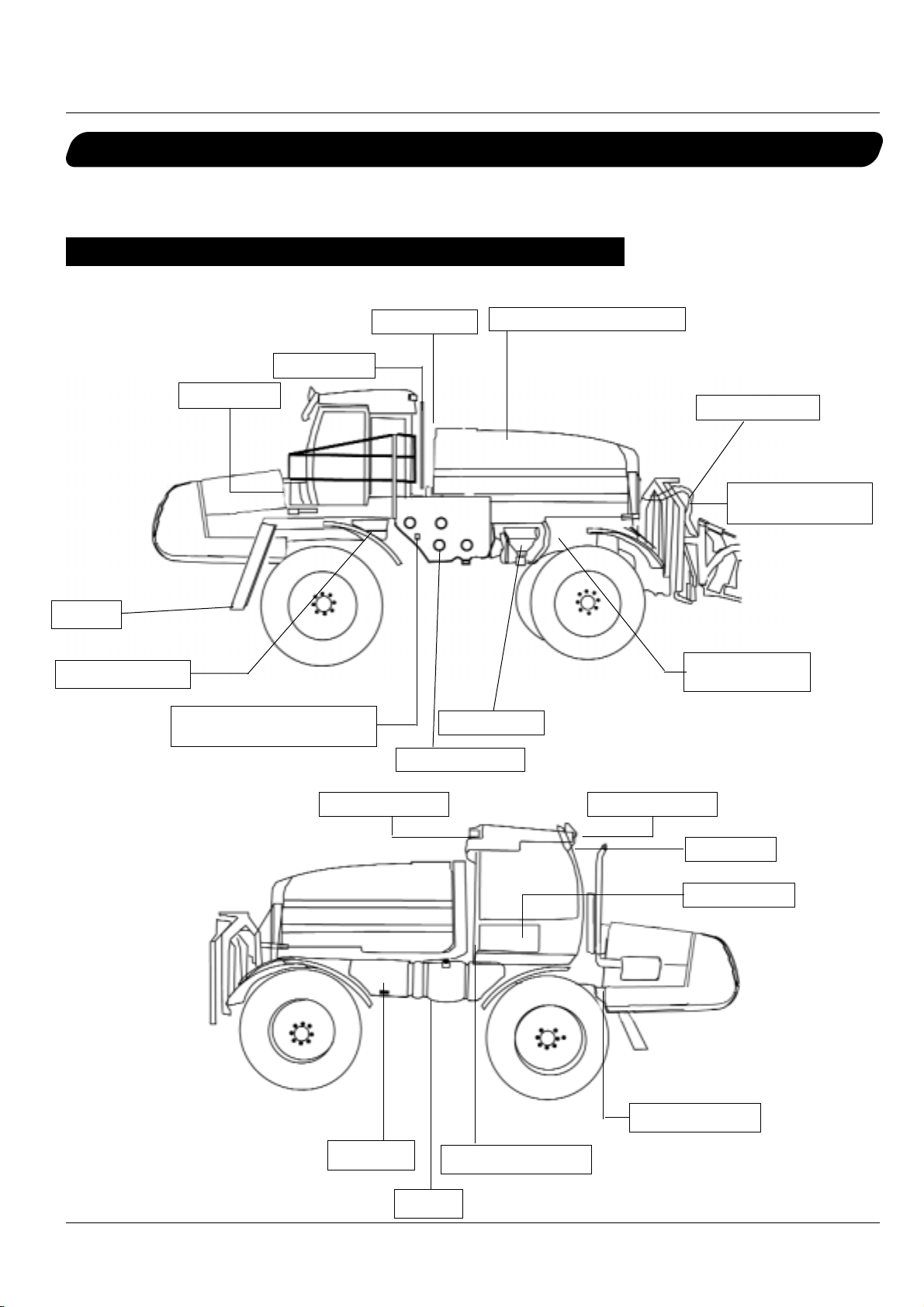

22-11 MMAAIINN EEQQUUIIPPMMEENNTT IIDDEENNTTIIFFIICCAATTIIOONN

22- DDEESSCCRRIIPPTTIIOONN OOFFAALLPPHHAASSPPRRAAYYEERR

Mirrors

Suction

De ivery fi ter

Remote va ves

Hydrau ic distributors

connection box

Front works ights

Externa spraying pump switch

E ectric acce erator

Identification p ate

Fuses box

Leve indicator

Rinsing tank Main tank rinsing nozz e

Chemica fi er

SMART Va ves

Hand wash tank

Ladder

Screen wash reservoir

Fue tank

Transport box

Rear works ights

cut-off batterie

ALPHA PLUS HARDI NOVA

DDEESSCCRRIIPPTTIIOONN AANNDDOOPPEERRAATTIIOONN

CHAPTER 22- 2

22-22 SSAAFFEETTYY PPRREECCAAUUTTIIOONNSS

Danger of fa ing part

use adder

Danger of user error

Hot parts, danger of

burning

Do not use if a protection

guards are missing

see operating and maintenance book

Spraying circuit drained with com-

pressed air (winter period)

SSPPRRAAYYEERR DDRRAAIINNEEDD

AACCIIEERR HHAAUUTTEE LLIIMMIITTEE EELLAASSTTIIQQUUEE

NNEE PPAASS PPEERRCCEERR - NNEE PPAASS SSOOUUDDEERR

HHIIGGHH SSTTRREENNGGTTHH SSTTEEEELL

NNOO DDRRIILLLLIINNGG - NNOO WWEELLDDIINNGG

STAHL MIT HOCH ELASTISCHEM WIDERSTAND

NNIICCHHTT BBOOHHRREENN - NNIICCHHTT SSCCHHWWEEIIBBEENN

Check periodica y the a uminium boom

SSPPRRAAYYEERR DDRRAAIINNEEDD

ALPHA PLUS HARDI NOVA

DDEESSCCRRIIPPTTIIOONN AANNDDOOPPEERRAATTIIOONNCHAPTER 22- 3

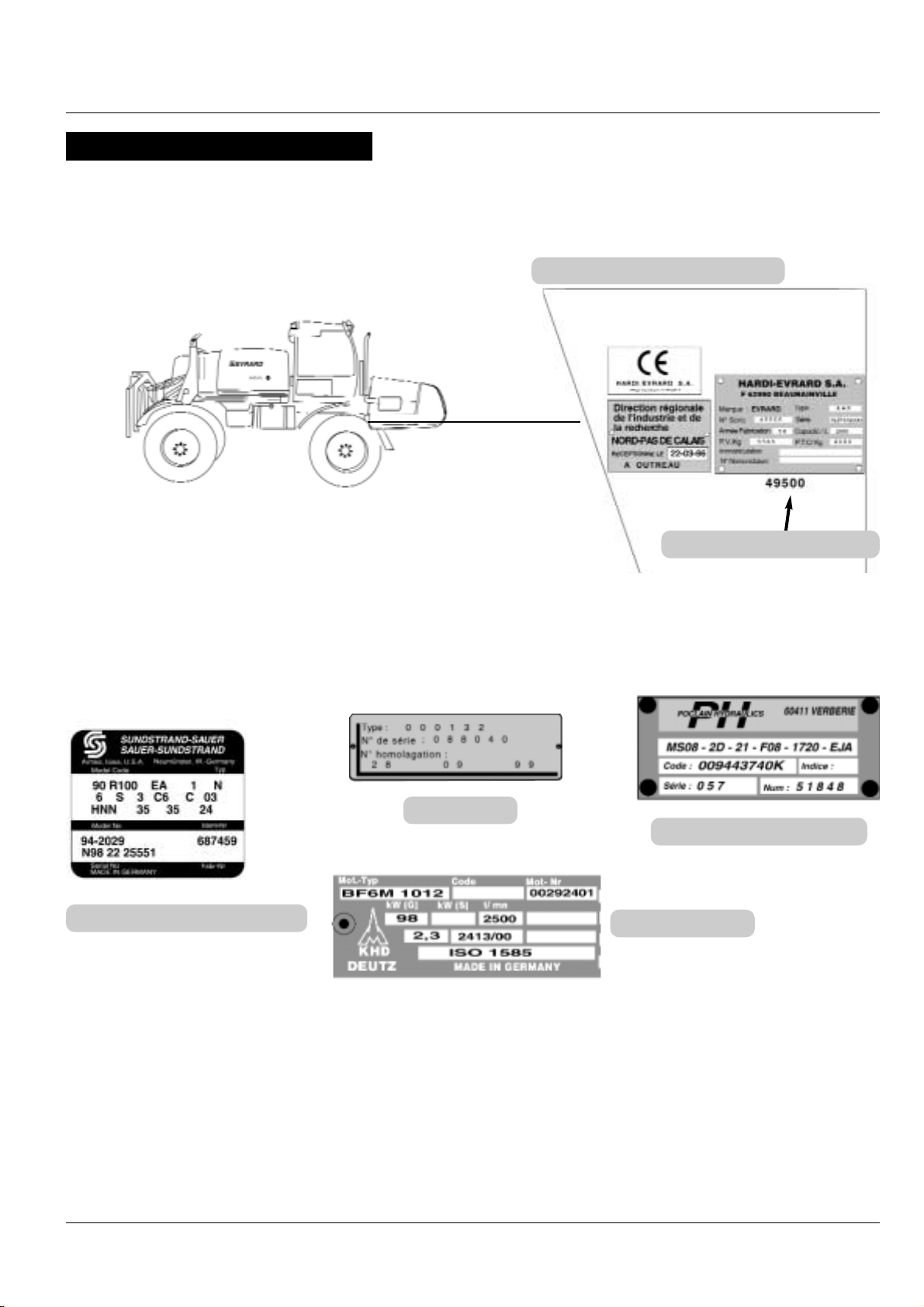

22-33 IIDDEENNTTIIFFIICCAATTIIOONN

‘’co d’’ marking of seria no

HYDROSTATIC PUMP PLATE

CAB PLATE

ENGINE PLATE

HYDRAULIC WHEEL PLATE

The information re ating to the identification of the se f-prope ed ALPHA appears on a p ate p aced on the

right-hand side of the machine. (seria number, type of mode , manufacturing date, capacity of main tank,

empty and fu weights).

IDENTIFICATION PLATES

ALPHA PLUS HARDI NOVA

DDEESSCCRRIIPPTTIIOONN AANNDDOOPPEERRAATTIIOONN

CHAPTER 22- 4

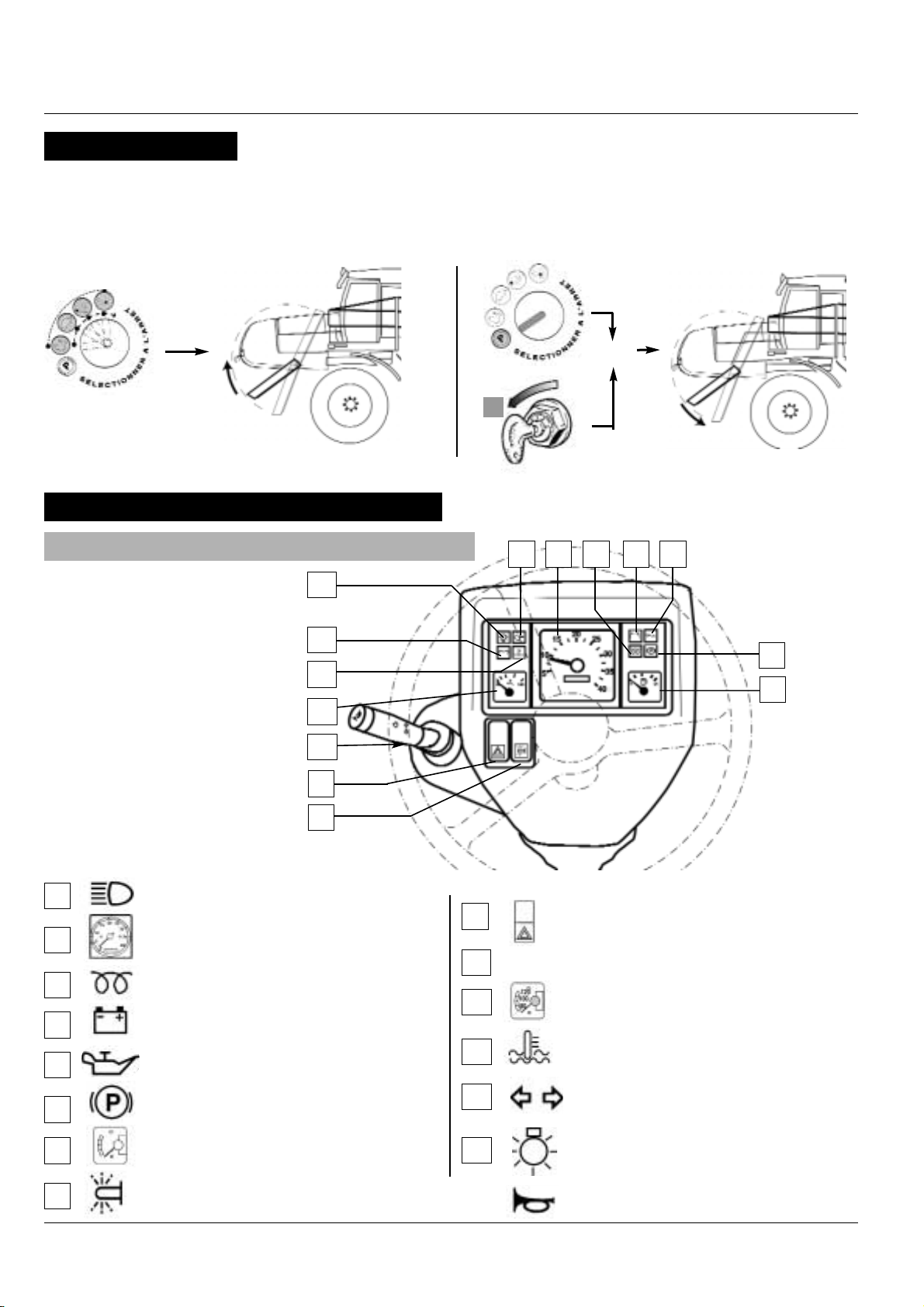

22-55-11SSTTEEEERRIINNGG CCOOLLUUMMNN WWIITTHHCCOONNSSOOLLEE

22-55 CCOONNSSOOLLEE DDEESSCCRRIIPPTTIIOONN

22-44 CCAABB AACCCCEESSSS

Battery charge warning amp

Engine oi pressure warning amp

Parking Brake Light Direction indicator warning amp

Position amp and dipped beam contro

amp

Head amp, main beam

Rev. counter and hour meter

Hazard warning ight switch

Mu ti-function contro switch

Horn

Pre Heating ight

Fue gauge

Rotating amber warning beacon swit-

ch

Engine temperature gauge

Engine temperature and coo ant

gauge ight

When the machine is stopped, the adder is at ow position.

- To raise automatica y the adder, start the engine AANNDDre ease the parking brake .

- To come down the adder, stop the engine OORR operate the parking brake.

OR

0

1 32 4 5

6

7

14

13

12

11

10

9

8

1

2

3

4

5

6

7

8

9

10

11

12

13

14

ALPHA PLUS HARDI NOVA

DDEESSCCRRIIPPTTIIOONN AANNDDOOPPEERRAATTIIOONNCHAPTER 22- 5

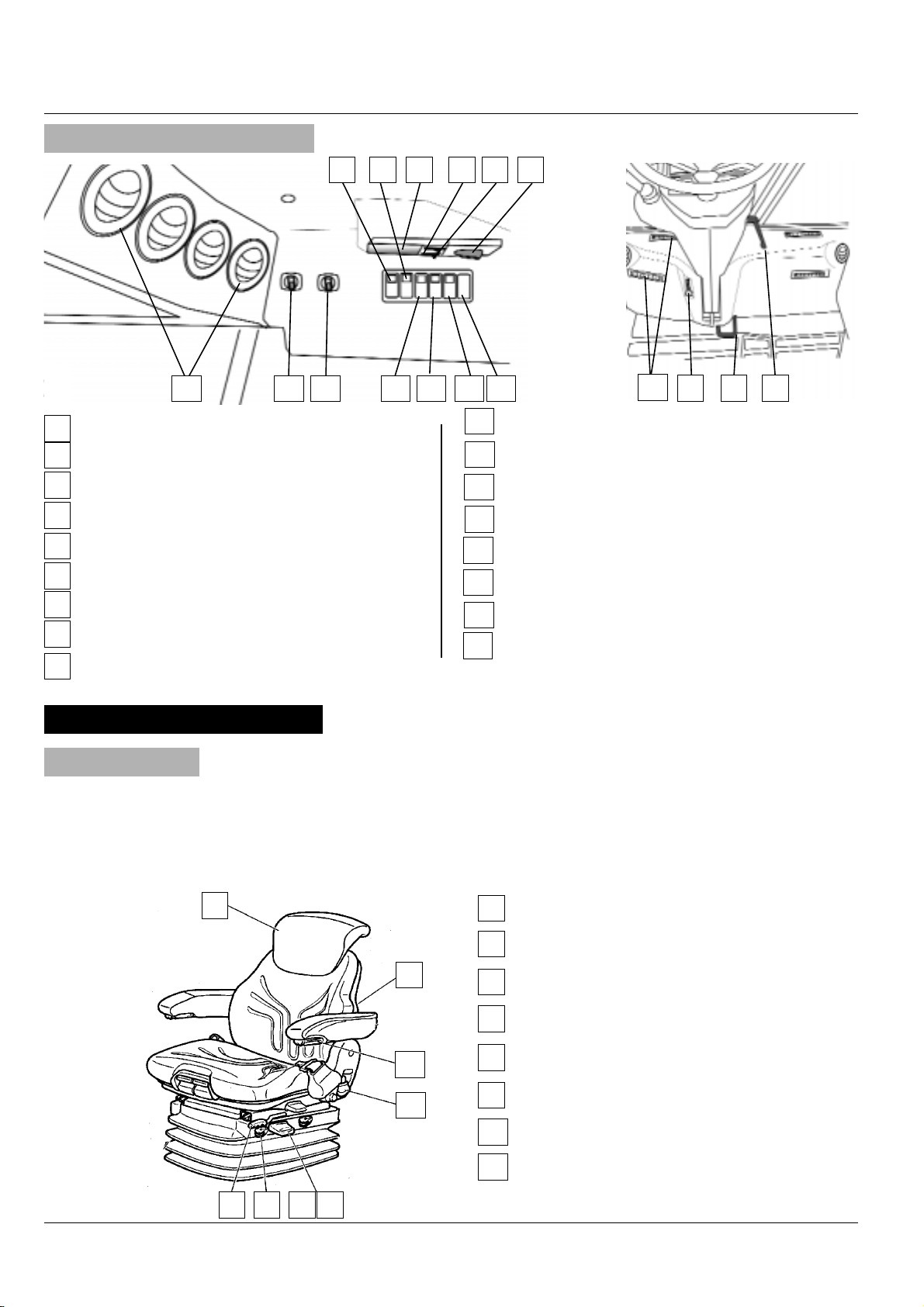

2

23 22

Hardi NOVA

Pump engagement ight

Steering a ignment ight front

Steering a ignment ight rear

4 Whee steering mode ight

4 Whee steering mode switch

Speed se ector switch(rotating)

Thrott e switch

20 Anti-skid switch (optiona )

19 Not used

Road security switch

Ignition switch

21 Not used

22 Not used

23 Not used

Liquid pump engagement switch

Road security amp

14 Oi pressure contro contro amp

(combined brake)

Joystick forward/reverse

Hydrau ic and spraying contro

Iso ator warning amp

2414

24 Not used

21

22-55-22CCOONNSSOOLLEE

OOPPTTIIOONNSS

1

2

3

4

5

6

7

8

10

12

13

15

16

17

18

1

3 4 5 62 7 8 171819

16 15 13 12 10

ALPHA PLUS HARDI NOVA

DDEESSCCRRIIPPTTIIOONN AANNDDOOPPEERRAATTIIOONN

CHAPTER 22- 6

22-55-33CCAABB AACCCCEESSSSOORRIIEESS

Windscreen wiper switch

Windscreen washer switch

Interior ight

Map ight switch

Map reading ight switch

Map reading ight

Steering co umn height adjustment

Steering co umn ang e adjustment

Heater temperature contro

Adjustab e air vents

work ights switch (optiona )

Front work ights switch

2 Speed fan switch

Air conditioning fan contro 3-speed switch

Rear work ights switch

3 Speed fan switch, air conditioning

Air conditioning air vents

22-66 DDRRIIVVEERR’’SS CCOOMMFFOORRTT

22-66-11SSEEAATT

As this is mounted on hydrau ic shock absorbers and integrated ongitugina suspension, it protects the dri-

ver from shaking which inevitab y occurs during driving. The various position adjustments, made by means

of identifiab e evers, improve comfort. The body-contoured seat and back cushions are fitted with aerated

fabric which is p easant to the touch and very strong.

Weight adjustment

Height adjustment

Fore/aft iso ator

Fore/aft adjustment

Backrest extension

Lumbar support

Armrest adjustment

Backrest adjustment

1 2 3 4 5 6

111213141516

17

10

11

12

13

14

15

16

17

2

3

4

5

6

7

8

9

1

10 8

97

23

7

8

1

10

11

4

1

2

3

4

7

8

10

11

ALPHA PLUS HARDI NOVA

DDEESSCCRRIIPPTTIIOONN AANNDDOOPPEERRAATTIIOONNCHAPTER 22- 7

22-66-22HHEEAATTIINNGG

Heating of cab is provided by the DEUTZ engine water system. A venti ation device with adjustab e air out-

ets ((1100))ocated near the windscreen provides heating and de-misting

- Adjust temperature by means of the thermostat ((99))

- PPrreessss sswwiittcchh ((1144)) ttoo sseeeecctt vveennttiiaattiioonn ssppeeeedd ((ppoossiittiioonn 11 oorr 22))

The air conditioning ON/OFF switch ((1155)) must be on OFF position

22-66-33AAIIRRCCOONNDDIITTIIOONNIINNGG

Air conditioning of cab is provided by acompressor driven by the DEUTZ engine. The coo ing unit is fitted

under the cab roof.

- Adjust the temperature by means of the thermostat ((1166))

- Set air conditioning switch ((1155)) on position ON

PPrreessss sswwiittcchh ((1144)) oonn ppoossiittiioonn 11

- Set heating thermostat ((99 ))on owest position

- Open and adjust ang ing of the air out ets ((1177))

9

10

10

15 14

17

14

15

16 9

0

1

2

CCAAUUTTIIOONN

TToo mmaaiinnttaaiinn tthhee bbeesstt aaiirr qquuaaiittyy iinn tthhee ccaabb ::

- ccaabb ddoooorr mmuusstt ssttaayy ccoosseedd

- vveennttiiaattiioonn sswwiittcchh ((1144)) mmuusstt bbee oonn ppoossiittiioonn 11..

This manual suits for next models

1

Table of contents