INTERNATIONAL CARBONIC TUACA Manual

CIINTERNATIONAL CARBONIC INC.

16630 Koala Rd.

Adelanto, California 92301

800 854-1177

Installation and Service Manual

3/22/05

TUACA

PUSH

HERE

IMPORTANT: This manual is a guide for installing,

operating, servicing and maintaining this equipment. Refer

to Table of Contents for page location of detailed

information to answer questions that arise during

installation, operating, service and maintenance, or

installation of this equipment.

TABLE OF CONTENTS

PAGE

PREFACE ........................................................................................... 1

CHAPTER 1

GENERAL DESCRIPTION.................................................................. 2

SYSTEM DESCRIPTION .................................................................... 2

DESIGN DATA.................................................................................... 2

THEORY OF OPERATION.................................................................. 3

EXPLODED VIEW............................................................................... 4

EXPLODED VIEW DESCRIPTION ..................................................... 5

ELECTRIC SCHEMATIC..................................................................... 7

CHAPTER II

UNPACKING AND INSPECTION........................................................ 8

SELECTING LOCATION..................................................................... 8

LOCATION RECOMMENDATIONS.................................................... 8

ELECTRICAL REQUIREMENTS......................................................... 8

TUACA UNIT INSTALLATION INSTRUCTIONS................................. 9

FLOW PLAN BOTTLE MOUNT........................................................... 11

CHAPTER III

OPERATORS INSTRUCTIONS.......................................................... 12

DAILY PRE-OPERATION CHECK...................................................... 12

COOLING UNIT MAINTENANCE........................................................ 12

CLEANING NOZZLE........................................................................... 12

CLEANING CONDENSER COIL......................................................... 13

CLEANING AND SANITIZING............................................................. 13

FREQUENTLY ASKED QUESTION.................................................... 14

CHANGING PERISTALTIC PUMP TUBING ....................................... 14

TROUBLE SHOOTING ....................................................................... 15

NOTES................................................................................................ 17

PREFACE

INTERNATIONAL CARBONIC INC. has enjoyed

over 53 years of manufacturing excellence in the

field of carbonation and in the beverage related

industry. We have been located in the Southern

California area since 1952 and have a long and

proud history with quality as our standard and

innovation as our goal. Originally started just

after World War II in Canfield Ohio as Carbonic

Dispensers we enjoyed patents on the first

Sodajet type carbonator. This method of

carbonation instantaneously carbonated the

water to 100% saturation. We developed the

first patented dispensing valve to dispense bulk

beverage with carbonation equal to or in excess

of bottled beverages. A valve with three flavors

and soda was another first. We were the first to

incorporate the total post-mix package; i.e.,

carbonation, refrigeration & the ability to

dispense from one self contained unit. We have

pioneered many such firsts and will continue to

develop advance systems for the future, such as

electronic interrogatable portion controls to

electronic liquid level controls.

We hope you enjoy this product that has been

produced to give many years of trouble free

service. We thank you for your purchase and

hope we may serve you in the future.

1

TUACA CHAPTER I

GENERAL DESCRIPTION

This chapter gives the description, theory of operation, and design data for the TUACA unit.

SYSTEM DESCRIPTION

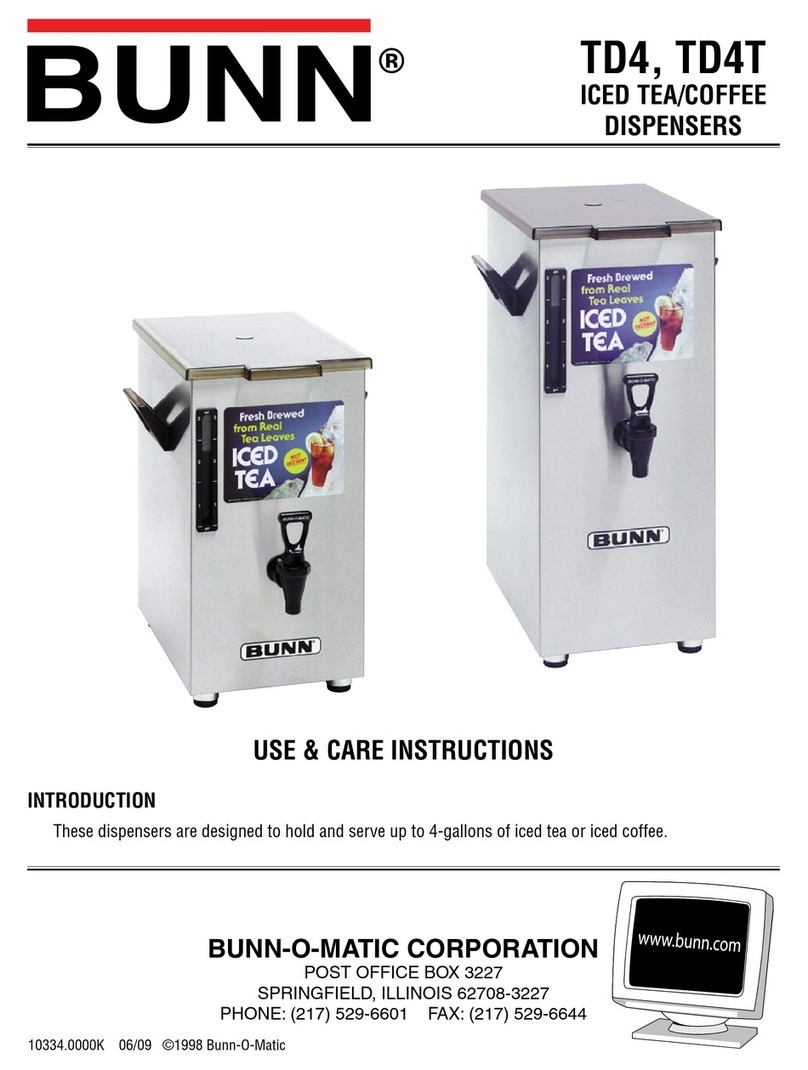

The TUACA unit is a complete self-contained liquor dispenser which when supplied with TUACA will

dispense a delicious chilled TUACA drink. The unit consists of a cabinet, refrigeration system, modular

peristaltic pumps, and lighted merchandising. The cabinet is housed in an attractive black vinyl and then

decaled with vibrant TUACA Decals. The front plate and drain are formed from attractive grained

stainless steel. The TUACA unit has been designed to fit in the smallest possible space while dispensing

a maximum amount of highly chilled 1oz, servings of TUACA and lime.

Essentially the TUACA unit is designed to plug and play. For proper function the TUACA unit must have

120 volt electrical supply and proper space around unit to allow the refrigeration to breath during

operation. The TUACA unit is designed with a unique lift off drain pan that can be emptied at any

convenient drain outlet.

DESIGN DATA

TUACA

Cabinet:

Height .. ............................................................................................................17 ½

Overall Height w/Merchandiser .........................................................................22 ½

Width ..............................................................................................................11 ¾

Depth .............................................................................................................14 7/8

Depth w/Switch Housing....................................................................................17 ¾

Weights:

Shipping.............................................................................................................75 LBS.

Operational weight.............................................................................................69 LBS.

Refrigerant requirement (R-134a)...............................................3.18 ounces

90 grams

Ambient operating temperature.........................................................................40 F to 100 F

Electrical Requirements:

The cooling unit requires a 120 VAC, single phase, 60 Hertz power circuit.

Circuit Ampacity.................................................................................................3.1 Amps

Condensing Unit................................................................................................2.1 Amps

Peristaltic Pump Assembly................................................................................ 1. Amp

REFRIGERATION 1/9 H.P. capillary air-cooled.

2

THEORY OF OPERATION

The TUACA unit was designed to cool and dispense a chilled serving of alcohol

based TUACA. After initial connection to an electrical outlet and installing the

TUACA bottles into the bottle reservoir’s. The unit’s push switch must be

activated until a small portion of TUACA is dispensed. In approximately 15

minutes from the time the unit is electrically activated the unit will dispense a

chilled shot below 32 degrees.

When the Push Switch is pushed the incoming TUACA is routed to a peristaltic

pump, and then through a cooling coil that is positioned next to the refrigeration

evaporator coil. The temperature of the incoming TUACA is at ambient

temperature as it enters the cooling coil. As the incoming TUACA passes

through the cooling coil the heat is removed from the TUACA and chilled to a

temperature acceptable for a quality drink, normally a temperature 7 to 16

degrees is reached. The TUACA is now directed to a dispensing nozzle where

the TUACA is dispensed.

3

INTERNATIONAL CARBONIC INC.

ADELANTO, CALIFORNIA

TITLE

DATE

DRN. BY

CHK. BY

APPR. BY

ICI

CHILL SHOT

TUACA

GLW

58

57 59

60

51

45

44 46 47

41

42

43

14

8

4

7

9

27

10

28 29

30

31

40

36

34 32

56

50

52

53

55

62

63

65

64

66

67

61

35

26

8

8

48

33

37

38

49

5

1

23

6

39

8

11 12

14

19

21 22

24

23

20

16

17 18

15

13

TUACA

25

54

7/20/05

4

TUACA

SYM QTY PART NO. DESCRIPTION

1 2 12074 SUPPORT ASSEMBLY, BOTTLE RESERVE

2 2 12008 BOTTLE CAP ASSEMBLY

3 2 18013 STRAINER

4 4 A0023 SCREW, 10-24 X 3/8 TH SS

5 1 12005C BOTTLE RESERVE

6 1 18020 1/4P X 1/4H PLASTIC FITTING

7 1 S1836 BOTTLE MTG BRKT

8 16 A0020 8-32 X 3/8 T.H., S.S. SCREW

9 1 S1825 LID, BACK

10 1 S1826 LID, FRONT

11 1 S1862 LED LIGHT BAR COVER

12 1 S1851 LED LIGHT BAR

13 2 TM04 SNAP BUSHING

14 8 S1335 TERMINAL SPACER

15 1 S1850 LED BRACKET

16 1 S1851 LOGO BRACKET

17 2 A0060 SCREW, 6-32 X 1/4, FLAT HEAD

18 1 S1229-9 MERCHANDISER/LIGHT BASE BACK

19 1 S0952 BALLAST

20 1 S0958 STARTER HOLDER

21 1 S0956-9 LAMP, 9"

22 1 E0665 STRAIN RELIEF

23 1 S0955 STARTER

24 2 S0973 LAMP HOLDER

25 1 S1832 LOGO FRONT, I.D., TUACA

26 1 S1832-F FRAME, LOGO FRONT, I.D., TUACA

27 1 S1827 SERVICE PANEL, REAR

28 1 S1828 SERVICE PANEL, LEFT

29 1 S1829 SERVICE PANEL, RIGHT

30 1 S1830 FRONT PLATE

31 1 S1833 FRAME

32 1 S1834 EVAPORATOR COIL ASSEMBLY

33 1 Z0009 CAP TUBE, 12' - .042

34 17 S1325 SQUARE GROMMET NUT

5

TUACA Cont.

SYM QTY PART NO. DESCRIPTION

35 17 A0014 SCREW, #10 X 1/2 PH TH COMBO SS

36 1 - - - - - INSULATION, EVAP, 3" IPS X 3/4 WALL, 12"

37 1 S0509 ACCUMULATOR

38 1 E0664 STRAIN RELIEF

39 1 S1722 TUBING, NOR-6F-250, 8"

40 1 S1737-CS PERISTALTIC PUMP MODULE, CS

41 1 S-1738 MOTOR/GEAR ASSY

42 2 - - - - - PPM PLASTIC WASHER, PPM

43 1 S1740 ROLLER ASSY, PPM

44 2 S1739-C HOUSING/COVER, PPM

45 3 - - - - - SCREW, 6-32 X 3/4 PH SS

46 4 A0019 SCREW, 8-32 X 3/8 PH SS

47 1 S1739-H PUMP HOUSING BODY, PPM

48 1 S1741-CS PPM CONTROL

49 4 S1318 CUSHIONED FEET

50 1 S0276-A TRANSFORMER

51 1 S1837 CONTROL BOX

52 1 S1309 TERMINAL BOARD

53 1 S1840 CONTROL BOX COVER, ONLY

54 1 S0766 ROCKER SWITCH

55 3 S0046 BUSHING

56 1 S1838 HOT GAS BY PASS DISCHARGE VALVE ASSY

57 2

AZA0370YXAXA CONDENSING UNIT, 1/9TH

58 1 A0046 5/16-18 X 3/4 FLANGE WHIZ LOCK

59 1 AZA0370YXA COMPRESSOR ONLY, 1/9TH

60 1 E0141-12 POWER CORD

61 1 S1839 HOT GAS BY PASS DISCHARGE VALVE

62 1 S1841 SWITCH HOUSING

63 1 S1313 SWITCH ASSEMBLY

64 1 E0581-B NOZZLE, TWIST LOCK

65 1 S1843 SHOT REST

66 1 S1842 DRAIN PAN

67 1 S0743 DRAIN PAN MTG HARDWARE, SET

6

INTERNATIONAL CARBONIC INC.

ADELANTO, CALIFORNIA

TITLE

DATE

DRN. BY

CHK. BY

APPR. BY

6/13/05

G.L. WHEELER

ICI

31

C

SR

M

S

1

FAN MOTOR

COMPRESSOR

CONDENSING UNIT

GROUND

TERMINAL

SCREW IN

CONTROL

BOX

110/VOLT

LAMP/LED

LIQUOR MOTOR

GREEN

WHITE

BLACK

FO5 - PP

12 3 45 6

6

65

5

54

4

4

3

3

3

2

2

2

1

1

1

6

A

B

C

D

110 Volt

RIBBED

SMOOTH

BLACK

BLACK

WHITE

PUSH HERE SWITCH

WHITE

BLACK

RIBBED

SMOOTH

CU ROCKER SWITCH

7

CHAPTER II

INSTALLATION

TUACA

This chapter covers unpacking and inspection, selecting location, installing TUACA unit and electrical

requirements.

UNPACKING AND INSPECTION

Upon receiving unit, immediately remove TUACA unit from shipping carton and inspect for shipping

damage.

NOTE: Remove the TUACA unit from the shipping carton and inspect for shipping damage. If

shipping damage is found immediately contact Sentry BevCon at (800) 661-3003. Do not

discard the shipping carton or any shipping materials in the event a freight claim must be

filed.

SELECTING LOCATION

IMPORTANT: Ambient temperature for cooling unit should not exceed 100 degrees

“F". Operation of cooling unit in ambient above 100 degrees “F" can

and will contribute to early failure of condensing unit and poor quality

of finished product.

LOCATION RECOMMENDATIONS FOR THE TUACA UNIT

1. Position unit as close as possible to proper electrical source, 120V 6OHz.

2. Position unit with a minimum of 2" space between bulkhead and cabinet for sufficient space for

ventilation. Allow enough space between ceiling and unit for vessel removal.

LOOSE - SHIPPED PARTS

Item Part

No. No. Name Qty

1 - - - - - Installation/Service Manual 1

2 S1842 Drain pan 1

3 12008CS Bottle Cap w/Sleeve 2

4 18013 Strainer 2

ELECTRICAL REQUIREMENTS:

The TUACA unit must be wire in accordance with N.E.C. or local ordinance.

8

12008 BOTTLE

CAP ASSEMBLY

WITH SLEEVE

12074 SUPPORT

ASSEMBLY

18013 RESERVE

STRAINER

TUACA unit

12074 Support Assembly

Bottle Reserve

18013 Strainers

S1842 Drain Tray

and

S1843 Shot Rest

12008 Bottle Cap

Assembly

TUACA Installation Instructions

Remove the TUACA unit from the shipping carton and inspect for shipping damage.

If shipping damage is found immediately contact Sentry BevCon at 800 661-3003.

Do not discard the shipping carton or any shipping materials in the event a freight

claim must be filed.

1. The following parts are included

with this Shippment.

2. Find a convenient location to

place the unit.

3. DO NOT PLUG UNIT INTO

ELECTRICAL OUTLET.

12005C BOTTLE

RESERVE

5. Install both stainless steel strainers

in bottle reserves.

6. Slip bottle caps into the TUACA bottles.

4. Remove protective plastic from drip

Tray. Align mounting holes over the

mounting screws on front of the machine.

#18018 Bottle Cap

Sleeve Large

9

7. Turn TUACA bottle upside down

and insert into bottle reserve. Adjust

support assembly to stablize bottle.

8. Plug unit into a 110 volt outlet. The

refrigeration system will automatically

start. If refrigeration does not come on

go to step #12.

9. Activate the "PUSH HERE" switch

until the TUACA is dispensed. The level

of the TUACA in the bottles will drop as

the cooling coils are filled. Dispense 6-8

ounces in order to flush unit.

DO NOT REUSE!

10. In approximately 15 minutes the unit

will dispense ice-cold TUACA shots.

11. Your unit is equipped with an on/off

switch. This switch is supplied to shut

off the refrigeration during time of flush-

ing. If refrigeration does not initially

come on remove front panel and check

switch to make sure it is in the on

position.

Note: to increase

y

our customers en

j

o

y

ment cool

y

our shot

g

lasses before ser

v

For Service and/or Installation Assistance

Please Call Sentry BevCon

800 661-3003

10

"Cold Shot"

BOTTLE CAP ASSEMBLY

SUPPORT ASSEMBLY

RESERVE STRAINER

"Cold Shot"

10/03

Revised

9/5/04

1.75 Litre750 ml

FLOW PLAN BOTTLE MOUNT

Note: Chill Shot should be positioned

prior to the following being performed:

1. Remove cap from liquor bottle to be

dispensed from Chill Shot.

2. Locate Bottle Cap Assembly and

Sleeve. 750 ml bottle uses small

sleeve, the 1.75 L bottle uses

medium large sleeve.

3. Install Sleeve on to Bottle Cap

Assembly.

4. Install Bottle Cap Assembly with

Sleeve onto the liquor bottle to be

served.

5. Locate Reserve Strainer and place

into the Bottle Reserve Assembly.

6. Carefully turn liquor bottle over and

install into Chill Shot Bottle Reserve

Assembly.

7. Adjust the Support Assembly to

balance the liquor bottle.

8. Repeat steps 1 through 7 for each

bottle to be served.

9. Plug unit into 110-volt outlet to

engage the condensing unit and

lights. Immediately activate PUSH

switch until a small amount of Tuaca

is dispensed.

10. Tuaca will be ready to dispense in

approximately 15 minutes.

11

CHAPTER III

TUACA UNIT

OPERATORS INSTRUCTIONS

This chapter covers operators’ responsibilities for daily pre-operation check, adjustments, cleaning, and

sanitizing.

DAILY PRE-OPERATION CHECK

1. Make sure TUACA reservoir is full and ready to dispense.

2. Make sure nozzle is clean.

3. Make sure electrical power is supplied to unit.

4. Make sure unit is clean.

COOLING UNIT MAINTENANCE

NOTE: Air circulation through the condenser coil required to cool the condenser coil/compressor, is

drawn in through grills on cooling unit, through condenser coil and is exhausted out grills on

the other side of the unit. Restricting air circulation through the cooling unit will decrease its

cooling capacity.

To avoid needless and sometimes costly repairs, it is imperative to keep condenser fins clean. This may

be accomplished by one of three methods. One method is use of a condenser brush (a longhaired, soft

bristle brush) to gently sweep fins of condenser clean. Second method is to use a strong vacuum. The

third method is to use C02 or an air hose to blow out condenser. The latter method should only be

attempted after normal business hours to avoid dust contamination.

CLEAN NOZZLE

Use a bottlebrush and clean nozzle nightly.

PERIODIC INSPECTION AND CLEANING

Daily:

1. Clean TUACA bottles and reservoir

area with warm water.

2. Clean the beverage dispensing area.

3. Clean nozzle and all exposed areas

on valve plate.

4. Wipe exterior of unit with moist towel.

Weekly:

1. Order TUACA to maintain product inventory.

2. Check condenser coil for obstructions or dirt.

Monthly:

1. Clean condenser fins or filter to make sure the refrigeration unit has adequate airflow.

2. Check entire system for leaks or damaged components. Repair as necessary.

DO NOT USE ABRASIVE TYPE CLEANERS.

12

CLEANING CONDENSER COIL

IMPORTANT: Air circulation through the condenser coil required to cool the condenser

coil/compressor, is drawn in through grills on cooling unit, through condenser coil and

exhausted out grills on the other side of unit. Restricting air circulation through the

cooling unit will decrease its cooling capacity.

NOTE: Cleaning condenser coil should be done during non-business hours.

1. Unplug refrigeration unit power cord from electrical socket.

2. Remove 9 screws securing service panels, 3 screws per service panel. Remove panels in

preparation for service.

3. Vacuum or use a soft brush to clean fins of condenser coil.

4. Replace panels.

5. Plug refrigeration unit power cord in electrical socket.

FLUSHING LIQUOR COIL

Unit On/Off

Switch

It is recommended to flush the Liquor Coil

periodically. To accomplish this task shut

off the condensing unit at condensing unit

on off switch located under the control

box on the lower right hand side.

Flush all liquor out of liquor coil and into a

container to be reused.

After condensing unit has been off for at

least one hour fill liquor reservoir with hot

water and flush through coil. Flush coil

until water comes out clear.

Refill reservoir with saved liquor and flush

all water out of liquor coil.

When all water is flushed out of system

turn on condensing unit. In

approximately 15 minutes cold shots can

be dispensed.

CLEANING AND SANITIZING

Your local Health Department rules and general area cleanliness should determine the frequency of

which the unit should be sanitized. SANITIZING PROCEDURES

Your local health department rules and general area cleanliness should determine the frequency at which

the unit should be sanitized. Note: Your Liquor plumbing will not need cleaning as often as the Lime mix

section of your unit if at all.

13

EQUIPMENT REQUIRED:

1. Stainless Steel container (product tank), or large volume container.

2. Cleaning Agent.

3. Sanitizing Solution.

4. Phenolphthalein.

NOTE: One recommended cleaning agent and sanitizing agent is manufactured by:

MT. HOOD CHEMICAL CORP.

4444 N.W. Yeon Avenue

Portland, Oregon 97210

Trade names are: STAR - CHLORINATED CLEANER

CROWN - 12.5% SODIUM HYPOCHLORITE BLEACH

Use STAR at 18 oz. per 1 gallon of water yields 2% Sodium Hydroxide Solution.

Use Crown at 2 ounce per 9 gallons of water (gives 200 PPM of available chlorine) at a minimum contact

time of 10 minutes.

1. Turn off TUACA by unplugging unit. Remove front panel and then remove control access panel.

Disconnect wires at A6 and B6 on control terminal board. Plug TUACA into 110 volt outlet, activate

push switch and empty out product from tubing by flushing with warm water.

2. Visually inspect valve by removing nozzle and inspecting nozzle and valve cavity. Clean nozzle with

cleaning agent, then sanitizing solution, then with potable water. Inspect valve cavity and if dirty

clean with soft bristle brush. Clean exteriors of nozzle tubes with a soft clothe and warm water.

Replace valve nozzle then go to step #3.

3. Fill bottle reserve with a caustic-based (low sudsing, non-perfumed, and rinsed) detergent solution,

(STAR). The solution should be prepared in accordance with the manufacturers recommendations,

but should be at least 2 percent sodium hydroxide. Make sure the syrup lines are completely filled

and allow standing for at least 10 minutes.

4. Flush the detergent solution from the bottle reserve with clean water. Continue rinsing until testing

with phenolphthalein shows that the rinse water is free of residual detergent.

5. Fill the bottle reserve with a low PH (7.0) chloride solution containing maximum 200-PPM chlorine.

Make sure that lines are completely filled and allow standing for 30 minutes.

6. Refill bottle reserve with clean hot water.

7. Draw water until chloride solution is dispensed from unit and liquor reservoir is empty.

8. Fill reservoir with TUACA.

9. Push switch until TUACA is dispensed.

10. Replace wires at control box terminal, i.e., A6 and B6.

11. Replace panel and control box cover.

12. Wait 15 minutes and then taste the beverage to verify that there is no off taste.

14

FREQUENTLY ASKED QUESTION:

Q. Should the machine be left on all the time?

A. Yes, your electrical usage will be minimal and the TUACA unit will have less electrical and

refrigeration problems.

Q. If the machine is left on how much will the electricity bill go up?

A. The amount will vary depending on your area but on average the cost will be approximately $.75 per

day.

Q. How often should I clean the unit.

A. As often as necessary, refer to previous section PERIODIC INSPECTION AND CLEANING.

Q. What happens if the TUACA gets low?

A. When you reservoirs are low the nozzle will have a noticeable drip wasting your product.

Q. Is there any periodic maintenance that must be performed?

A. Yes, again depending on usage your peristaltic pump tubing will have to be changed.

Q. How often must this tubing be changed?

A. Again depending on the usage approximately every 6 months to a year.

CHANGING PERISTALTIC PUMP TUBING

1. Remove #10 X 1/2” Phillips TH. Screw. Then slide out S-1027 Assy.

2. Remove three 6-32 x 3/4 PH screws.

3. Remove S-1739 cover.

4. Remove neoprene tubing by pulling tubing while turn S-1740 roller.

5. Replace old neoprene tubing with new.

6. Squeeze new tubing with pliers two insert tubing in between first roller and housing wall. Force tubing

into position at second roller by spinning roller while inserting tubing.

7. Reverse procedure to reinstall S-1737 assembly.

S-1698

PLASTIC

CLAMP

6-32 X 3/4 PH

SS SCREW

S-1737

ASSY.

.250 X .427

NEOPRENE

TUBING

S-1739

S-1698

PLASTIC

CLAMP

S-1740

ROLLER

15

TROUBLE SHOOTING

IMPORTANT: Only qualified personnel should service TUACA unit and

components.

WARNING: To avoid personal injury and or property damage, always disconnect electrical power,

before starting any repairs. If repairs are to be made to the TUACA unit, drain TUACA unit before

proceeding. COOLING UNIT

Trouble Probable Cause Remedy

Cooling or

condensing unit

non-

operational

1.

2.

3.

4.

5.

6.

7.

No electrical power.

Improper voltage/amperage

Loss of refrigerant.

Bad overload and relay.

Compressor bad.

Restriction (pinched or crimped

line).

Condenser Dirty

1.

2.

3.

4.

5.

6.

7.

Plug power cord into electrical

box.

Check for proper

voltage/amperage.

Repair leak and replenish

refrigerant.

Replace overload and relay

Replace compressor.

Repair, straighten or replace

defective line.

Clean condenser unit w/vacuum

cleaner.

Condenser fan

motor not

operating

1.

2.

3.

Electrical cord loose or

disconnected from condenser fan

motor or compressor terminals.

Fan blade obstructed.

Inoperative condenser fan motor.

1.

2.

3.

Tighten connections or replace

cord.

Remove obstruction.

Replace condenser fan motor.

Compressor

does not

operate

1.

2.

3.

4.

5.

6.

No power source.

Electrical power to cooling unit

turned off.

Low voltage.

Loose, disconnected, or broken

wire.

Inoperative overload protector or

start relay.

Inoperative compressor.

1.

2.

3.

4.

5.

6.

Plug power cord to electrical box.

Check line voltage.

Voltage must be at least 110 V at

compressor terminals at start.

Tighten connection or replace

broken wiring.

Replace defective part.

Replace compressor.

Note: During overload protector shut off condenser fan motor will continue to work. Otherwise,

troubleshooting condenser fan motor problems is the same as “Compressor does not operate”,

paragraph in addition to the following.

Condenser fan

motor not

operating

1.

2.

3.

Electrical cord loose or

disconnected from condenser fan

motor or compressor terminals.

Fan blade obstructed.

Inoperative condenser fan motor.

1.

2.

3.

Tighten connections or replace

cord.

Remove obstruction.

Replace condenser fan motor.

16

TUACA leaking

from nozzle

after actuation

1. Peristaltic pump tubing has lost

its elasticity. 1. a. Replace PPM tubing.

No TUACA

being

dispensed

1.

2.

3.

4.

5.

6.

7.

No electrical power.

Pinched or crimped lines.

Broken liquor switch.

Bad transformer.

Disconnected wire.

Defective PPM assy.

Worn or defective neoprene

tubing in PPM assy.

1.

2.

3.

4.

5.

6.

7.

Plug power cord into electrical

box. Check line voltage.

Repair defective line.

Replace defective switch.

Replace defective transformer.

Attach disconnected wire.

Replace PPM assy.

Replace defective tubing.

No TUACA

being

dispensed

1.

2.

3.

4.

TUACA reservoir empty.

PPM Assy defective.

Defective neoprene tubing.

Defective transformer.

1.

2.

3.

4.

Replenish TUACA supply.

Replace PPM Assy.

Replace neoprene tubing.

Replace transformer.

NOTE SECTION

Frequently Called Numbers:

__________________________________ ____________________________

__________________________________ ____________________________

__________________________________ ____________________________

__________________________________ ____________________________

__________________________________ ____________________________

__________________________________ ____________________________

_____________________________________ __________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________________________________________________________________________________

____________

17

Table of contents

Other INTERNATIONAL CARBONIC Beverage Dispenser manuals

Popular Beverage Dispenser manuals by other brands

Cornelius

Cornelius QLT180/1000-1 Installation & service manual

Cecilware

Cecilware MT-2-UL Maintenance manual

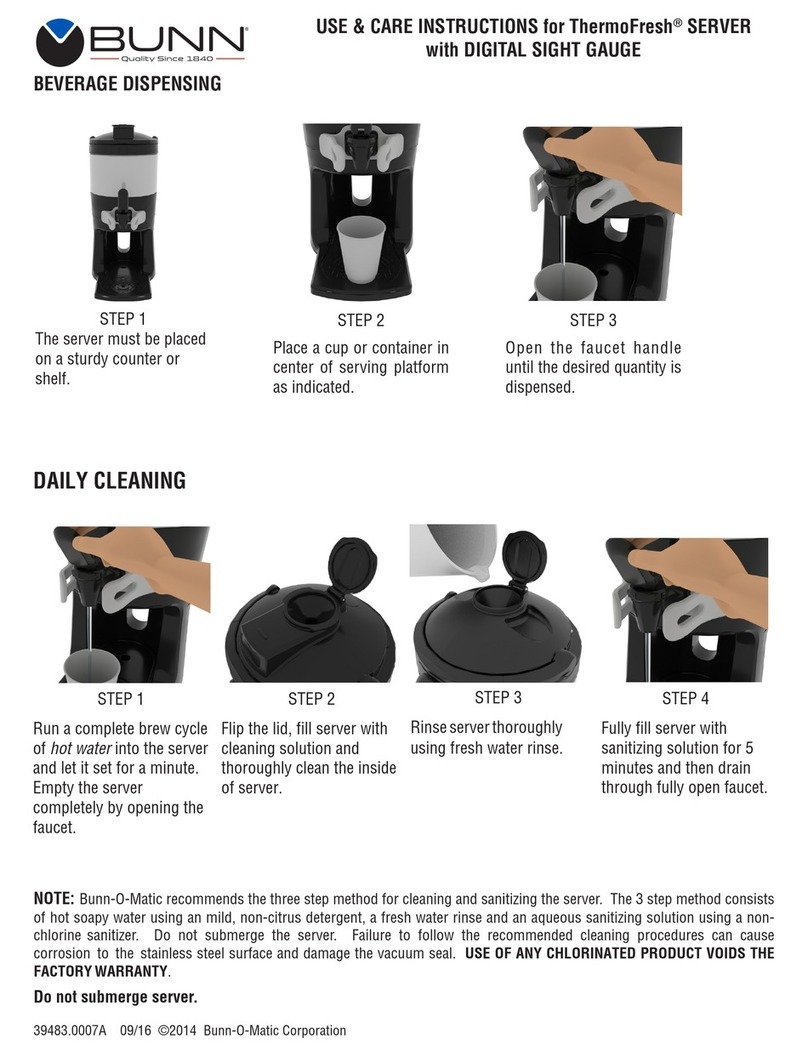

Bunn

Bunn ULTRA-2 PAF Use and care instructions

Bunn

Bunn IMIX-5S+ Installation & operating guide

Marvel

Marvel ML24BNS2 Installation, operation and maintenance instructions

GMCW

GMCW Crathco Classic Bubbler D Series Operation manual