FCI 7100 SERIES Installation instructions

301 2nd Ave. Waltham, MA 02451-1133 USA TEL:(781) 487-0088 FAX: (781) 370-4132

Copyright © 1998 Part Number:9000-0447

All Rights Reserved Version 1.4

Published in U.S.A.

7100 SERIES

FIRE ALARM CONTROL

INSTALLATION/OPERATING MANUAL

Technical Manuals Online! - http://www.tech-man.com

Technical Manuals Online! - http://www.tech-man.com

IMPORTANT INFORMATION

This manual is designed for use by factory trained installers and operators of the Fire Control Instruments, Inc.

(FCI) 7100 Series Fire Alarm Control. All illustrations, functional descriptions, operating and installation proce-

dures, and other relevant information are contained in this manual.

The contents of this manual are important, and the manual must be kept with the fire alarm control panel at all

times.If building ownership is changed, this manual, including any testing and maintenance information, must

be passed along to the new owner(s).

The fire alarm control panel is part of a system.Manuals and instructions for other devices forming part of the

system should be kept together. Purchasers who install this system for use by others must leave the instructions

with the user. A copy of these instructions is included with each product and is available from the manufacturer.

This equipment is Listed by various listing agencies for use in fire alarm systems.Use only components which

are compatible with the FCI system.The installation MUST be in accordance with the instructions in this manual.

THEREFORE:

•DO NOT deviate from the procedures described in this manual.

•DO NOT assume any details not shown in the instructions.

•DO NOT modify any electrical or mechanical features.

•DO comply with all codes and standards set forth by the authority having jurisdiction.

The term “Authority Having Jurisdiction” has become a standard term in the fire alarm industry.An acceptable

definition of “Authority Having Jurisdiction” is:

Fire alarm systems installed in the USA fall under the jurisdiction of some authority.In some areas this may be

a local fire department;in other areas it may be a building inspector, insurance firm, etc. Different authorities

may have their own local requirements for the way the fire alarm system is installed and used.Most local

authorities base their requirements on the NFPA codes, but there may be important differences.You must install

this system in the way in which the authority having jurisdiction requires.If you do not know which authority has

jurisdiction in your area, contact your local fire department or building inspector for guidance.

It is important that you tell users to be aware of any requirements defined by the authority having jurisdiction.

The installation MUST be in accordance with the following standards:

•National Fire Alarm Code (NFPA 72)

•National Electrical Code (NFPA 70)

•Life Safety Code (NFPA 101)

WARNING:Touching components which are improperly installed, applied or operated could be

hazardous and possibly fatal. Short circuits could cause arcing that could result in molten metal injuries.

Therefore, only qualified technicians familiar with electrical hazards should perform checkout procedures. Safety

glasses should be worn, and test equipment used for voltage measurements should be designed for this

purpose and be in good working order.

ENVIRONMENTAL CONSIDERATIONS:

It is important that this equipment be operated within its specifications:

Recommended operating temperature range: 60 to 80oF (15 to 27oC)

Absolute maximum operating temperature range: 32 to 120oF (0 to 49oC)

Operating humidity: not to exceed 85%,

non-condensing at 90oF (32oC)

Operating this equipment within the recommended temperature range will extend the useful life of the system

standby batteries.

!

9000-0447 1 of 43

Technical Manuals Online! - http://www.tech-man.com

INSTALLATION CONSIDERATIONS:

Check that you have all the equipment you need to make the installation.Follow the field wiring diagrams and

installation notes in this manual.

Install the equipment in a clean, dry environment (minimal dust).Avoid installing equipment where vibrations

will occur.

Remove all electronic assemblies prior to drilling, filing, reaming, or punching the enclosure.When possible,

make all cable entries from the sides, being careful to separate the power limited conductors from the non-

power limited conductors.Before making modifications, verify that they will not interfere with battery, transformer

and printed circuit board location.

Do not over-tighten screw terminals.Over-tightening may damage threads, resulting in reduced terminal

contact pressure and difficulty with screw terminal removal.

Disconnect all sources of power before servicing, removing, or inserting any circuit boards. Control unit and

associated equipment may be damaged by removing and/or inserting cards, modules, or interconnecting cables

while the unit is energized.

WIRING CONSIDERATIONS:

This fire alarm control panel contains power-limited circuits.You cannot connect external sources of power

to these circuits without invalidating their approval.

Verify that wire sizes are adequate for all initiating device and notification appliance circuits. Most devices

cannot tolerate more than a 10% drop from the specified device voltage.

The installer must make sure that the wiring and devices installed in the system meet the current National

Electrical Code, NFPA 70, and all applicable state and local building code requirements.

Use the conductor size and type required by local codes.(see NFPA 70, Article 760). Wiring resistance must

not be more than that shown on the field wiring diagrams.

To reduce errors and help in servicing the system, all conductors should be tagged or otherwise coded and

logged at installation to identify circuit assignment and polarity.If the conductors are logged with a code, keep

the log that explains the code with the manual, so that it is available to other people working on the panel.

Like all solid state electronic devices, this system may operate erratically or be damaged when subjected

to lightning induced transients. Although no system is completely immune to lightning transients and interfer-

ence, proper grounding will reduce susceptibility.We do not recommend the use of overhead or outside aerial

wiring due to the increased susceptibility to nearby lightning strikes.Consult with the FCI Technical Support

Department if any problems are anticipated or encountered.

To prevent the spread of fire, use proper patching materials to areas where system wiring passes through

fire-rated walls or floors.

OTHER CONSIDERATIONS:

The equipment was tested according to EC directive 89/336/EEC for Class A equipment and was verified

to the limits and methods of EN 55022.

NOTE: System Reacceptance Test: To ensure proper system operation, this product must be tested in

accordance with NFPA 1996, Chapter 7.Reacceptance testing is required after any modification, repair

or adjustment to system hardware or wiring.

All components, circuits, or system operations known to be affected by a change must be 100% tested.

In addition, to ensure that other operations are not inadvertently affected, at least 10% of initiating devices that

are not directly affected by the change, up to a maximum of 50 devices, must also be tested and proper system

operation verified.

Equipment used in the system may not be technically compatible with the control panel.It is essential to use

only equipment listed for service with this control panel.

CAUTION

To keep your fire alarm system in excellent working order, ongoing

maintenance is required per the manufacturer’s recommendations and UL

and NFPA Standards. At a minimum, the requirements of Chapter 7 of

NFPA 72, The National Fire Alarm Code, shall be followed.A preventive

maintenance agreement should be arranged through the manufacturer’s

local representative. Though smoke detectors are designed for long life,

they may fail at any time.Any smoke detector, fire alarm system or any

component of that system which fails shall be repaired or replaced immedi-

ately.

!

2 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

FCC WARNING:This equipment generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause interference to radio communications.It has

been tested and found to comply with the limits for Class A computing device pursuant to Subpart B of Part 15

of FCC Rules, which is designed to provide reasonable protection against such interference when operated in

a commercial environment. Operation of this equipment in a residential area is likely to cause interference, in

which case the user will be required to correct the interference at his own expense.

If these instructions are not clear, or if additional information or clarification is needed, please consult your

local authorized Fire Control Instruments, Inc. distributor.

Because of design changes and product improvements, the information in this manual is subject to change

without notice.FCI reserves the right to change hardware and/or software design, which may subsequently

affect the contents of this manual.FCI assumes no responsibility for any errors that may appear in this manual.

Neither this manual nor any part of it may be reproduced without the advance written permission of Fire

Control Instruments, Inc.

Limitations of Fire Alarm Systems

Manufacturer recommends that smoke and/or heat detectors be located throughout a protected premise

following the recommendations of the current edition of the National Fire Protection Association Standard 72,

National Fire Alarm Code (NFPA 72), manufacturer’s recommendations, State and local codes, and the

recommendations contained in Guide for the Proper Use of System Smoke Detectors, which is made avail-

able at no charge to all installing dealers.A study by the Federal Emergency Management Agency (an agency

of the United States government) indicated that

smoke detectors may not go into alarm or give early warning in

as many as 35% of all fires.

While fire alarm systems are designed to provide warning against fire, they do not

guarantee warning or protection against fire. Any alarm system is subject to compromise or failure to warn

for a variety of reasons. For example:

•Particles of combustion or “smoke” from a developing fire may not reach the sensing chambers of the smoke

detector because:

–Barriers such as closed or partially closed doors, walls, or chimneys may inhibit flow.

–Smoke particles may become “cold” and stratify, and may not reach the ceiling or upper walls

where detectors are located.

–Smoke particles may be blown away from detectors by air outlets

–Smoke particles may be drawn into air returns before reaching the detector.

In general, smoke detectors on one level of a structure cannot be expected to sense fires developing on

another level.

•The amount of “smoke” present may be insufficient to alarm smoke detectors. Smoke detectors are

designed to alarm at various levels of smoke density.If such density levels are not created by a developing

fire at the location of detectors, the detectors will not go into alarm.

•Smoke detectors, even when working properly, have sensing limitations. Detectors that have photoelectronic

sensing chambers tend to detect smoldering fires earlier than flaming fires, which have little visible smoke.

Detectors that have ionizing-type sensing chambers tend to detect fast flaming fires earlier than smoldering

fires.Because fires develop in different ways and are often unpredictable in their growth, neither type

of detector is necessarily best and a given type of detector may not provide adequate warning of a fire.

•Smoke detectors are subject to unwanted or nuisance alarms.For example, a smoke detector located in or

near a kitchen may go into nuisance alarm during normal operation of kitchen appliances.In addition, dusty

or steamy environments may cause a smoke detector to alarm unnecessarily. If the location of a smoke

detector causes an abundance of unwanted or nuisance alarms, do not disconnect the smoke detector;

call a professional to analyze the situation and recommend a solution.

9000-0447 3 of 43

Technical Manuals Online! - http://www.tech-man.com

•Smoke detectors cannot be expected to provide adequate warning of fires caused by arson, children

playing with matches (especially within bedrooms), smoking in bed, violent explosions (caused by

escaping gas, improper storage of flammable materials, etc.).

•Heat detectors do not sense particles of combustion and are designed to alarm only when heat on their

sensors increase at a predetermined rate or reaches a predetermined level.Heat detectors are designed

to protect property, not life.

•Warning devices (including horns, sirens, and bells) may not alert people or awaken sleepers who are

located on the other side of closed or partially open doors.A warning device that activates on a different

floor or level of a dwelling or structure is less likely to awaken or alert people. Even persons who are awake

may not notice the warning if the alarm is muffled by noise from a stereo, radio, air conditioner or other

appliance, or by passing traffic.Audible warning devices may not alert the hearing-impaired (strobes or

other devices should be provided to warn these people).Any warning device may fail to alert people with

a disability, deep sleepers, people who have recently used alcohol or drugs, or people on medication

or sleeping pills.

Please note that:

I) Strobes can, under certain circumstances, cause seizures in people with conditions such as

epilepsy.

II) Studies have shown that certain people, even when they hear a fire alarm signal, do not respond

or comprehend the meaning of the signal.It is the property owner’s responsibility to conduct fire drills

and other training exercises to make people aware of fire alarm signals and instruct on the proper

reaction to alarm signals.

III) In rare instances, the sounding of a warning device can cause temporary or permanent hearing

loss.

•Telephone lines needed to transmit alarm signals from a premises to a central station may be out of

service or temporarily out of service.For added protection against telephone line failure, backup radio

transmission systems are recommended.

•System components, though designed to last many years, can fail at any time. As a precautionary meas-

ure, it is recommended that smoke detectors be checked, maintained, and replaced per manufacturer’s

recommendations.

•System components will not work without electrical power. If system batteries are not serviced or replaced

regularly, they may not provide battery backup when AC power fails.

•Environments with high air velocity or that are dusty or dirty require more frequent maintenance.

In general, fire alarm systems and devices will not work without power and will not function properly unless

they are maintained and tested regularly.

While installing a fire alarm system may make the owner eligible for a lower insurance rate, an alarm system

is not a substitute for insurance. Property owners should continue to act prudently in protecting the premises

and the people in the premises and should properly insure life and property and buy sufficient amounts of

liability insurance to meet their needs.

4 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

9000-0447 5 of 43

Technical Manuals Online! - http://www.tech-man.com

TABLE OF CONTENTS

Page

IMPORTANT INFORMATION..........................................................................................................1

1.0 System Overview......................................................................................................................9

1.1 Description...............................................................................................................................9

1.2 Features ..................................................................................................................................9

1.2.1 Standard Features .............................................................................................................9

1.2.2 Optional Features ..............................................................................................................9

1.3 Control and Indicators..............................................................................................................10

1.3.1 Switch Controls..................................................................................................................10

1.3.2 LED Indicators....................................................................................................................10

1.3.3 Audible Sounder.................................................................................................................10

1.4 Optional Modules.....................................................................................................................10

1.4.1 Digital Alarm Communicator Transmitter (DACT)...............................................................10

1.4.2 Class A Option Module (CAOM) ........................................................................................10

1.4.3 Municipal Circuit Option Module (MCOM)..........................................................................10

1.4.4 Printer Transient Module (PTRM).......................................................................................11

1.5 Specifications...........................................................................................................................11

2.0 Installation.................................................................................................................................13

2.1 General ..................................................................................................................................13

3.0 Basic System Module (BSM) ....................................................................................................13

3.1 Power ..................................................................................................................................14

3.1.1 AC Input ...........................................................................................................................14

3.1.2 Battery Connections...........................................................................................................14

3.1.3 Auxiliary Power Output.......................................................................................................14

3.1.4 Earth Ground .....................................................................................................................14

3.2 Relay Connections...................................................................................................................14

3.3 Notification Appliance Circuits.................................................................................................16

3.4 Signaling Line Circuits.............................................................................................................16

3.5 Analog Sensors .......................................................................................................................18

3.5.1 Address Switches ..............................................................................................................18

3.5.1 Drift compensation.............................................................................................................18

3.6 Addressable Modules..............................................................................................................18

3.6.1 Address Switches ..............................................................................................................18

3.7 Monitor Modules .....................................................................................................................18

3.8 Control Modules.......................................................................................................................18

3.9 Optional Modules.....................................................................................................................18

3.9.1 Class A Option Module (CAOM) ........................................................................................18

3.9.2 Municipal Circuit Option Module (MCOM)..........................................................................18

3.9.3 Printer Transient Module (PTRM).......................................................................................21

3.10 Digital Communicator Operation (Model 7100-D)..................................................................21

3.11 Central Station Reporting......................................................................................................21

3.12 7100-D DACT Event Reporting Codes..................................................................................22

3.13 Telephone Requirements ......................................................................................................22

3.14 Digital Communicator ............................................................................................................23

3.15 Telephone Company Rights and Warnings............................................................................23

3.16 FCC Required Information.....................................................................................................23

3.17 Repairs ..................................................................................................................................23

3.18 Optional Accessories.............................................................................................................23

3.18.1 LCD-7100 Remote Serial Annunciator.............................................................................23

6 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

TABLE OF CONTENTS

Continued

4.0 Programming/Operating............................................................................................................23

4.1 LED Indicators.........................................................................................................................23

4.2 Panel Switches ........................................................................................................................24

5.0 System Programming ...............................................................................................................25

5.1 Main Menu Selections .............................................................................................................25

5.1.1 Addresses..........................................................................................................................25

5.2 Config. Menu Selections..........................................................................................................27

5.3 WALK/DRILL Menu Selections................................................................................................34

5.4 I/O Menu Selections ................................................................................................................34

5.5 CLOCK Menu Selections.........................................................................................................36

5.6 LOG Menu Selections..............................................................................................................38

5.7 INFO Menu Selections.............................................................................................................38

6.0 Power Up Procedure.................................................................................................................40

6.1 General ..................................................................................................................................40

6.2 To set the system time .............................................................................................................40

6.3 Automatic Configuration ..........................................................................................................40

Appendix

7100 Series Device Types and Functions......................................................................................41

Typical 7100/DRBC-1 Hookup.......................................................................................................42

Power Limited/non-power limited Wiring Connections...................................................................43

9000-0447 7 of 43

Technical Manuals Online! - http://www.tech-man.com

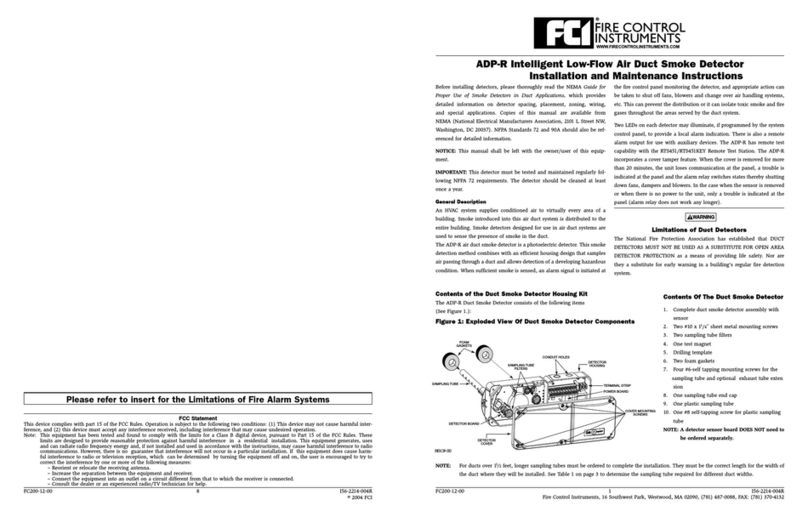

JMP1

BSM

TB2 TB3 TB4

TB6 TB9

TB1

TB7

TB5

8 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

1.0 System Overview

1.1 Description

The FCI 7100 is a multiprocessor-based analog/addressable fire alarm control panel, designed for commer-

cial, industrial and institutional fire alarm applications.It is available with one or two signaling line circuits.

The 7100 Series Fire Alarm Control is Listed by Underwriters Laboratories Standard UL 864. It is suitable for

the following signaling services:

•Automatic Fire Detector alarm

•Manual Fire Alarm

•Waterflow Alarm

•Supervisory

•Automatic smoke alarm, non-coded and master coded operation

•Releasing Device service

The 7100 Series complies with the requirements of the following National Fire Protection Association (NFPA)

Standards:

•NFPA 13 - Installation of Sprinkler Systems

•NFPA 16 - Deluge Foam-Water Sprinkler Systems

•NFPA 16A - Installation of Closed Head Foam-water Sprinkler Systems

•NFPA 72 - National Fire Alarm Code:

–Central Station Fire Alarm Systems

–Local Fire Alarm Systems

–Auxiliary Fire Alarm Systems

–Remote Station Fire Alarm Systems

–Proprietary Fire Alarm Systems

1.2 Features

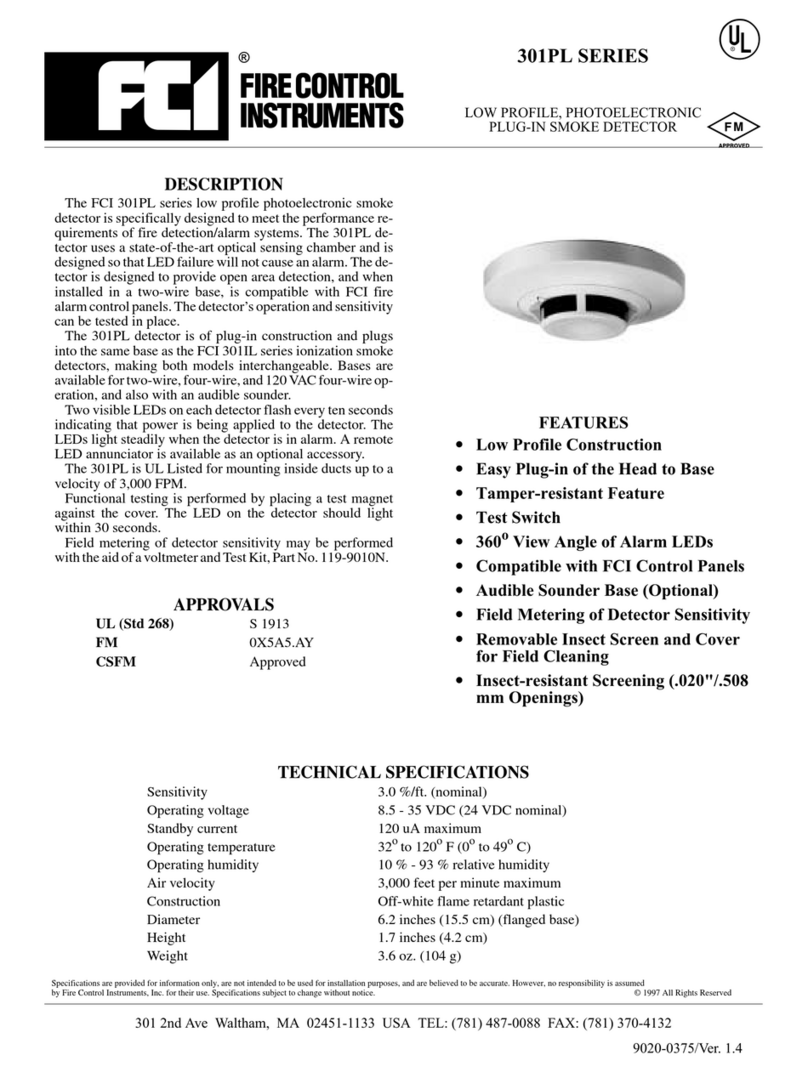

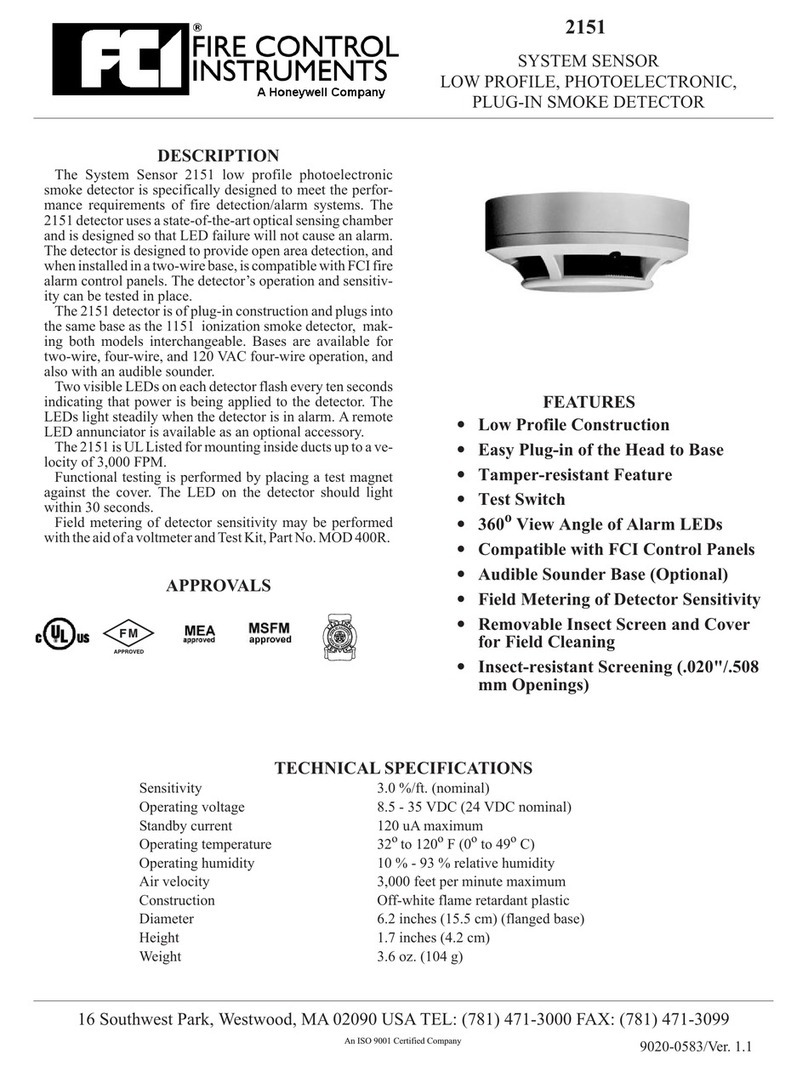

1.2.1 Standard Features

•Two (2) Class B, Style 4 Signaling Line Circuits - Model 7100-2/D (One circuit in Model 7100-1/D)

•Two (2) Class B, Style Y Notification Appliance Circuits

•Alarm and Trouble dry contacts

•Accommodates 99 FCI Approved, UL Listed compatible analog sensors per SLC

•Accommodates 98 FCI Approved, UL Listed compatible addressable monitor/control devices per SLC

•80-character alphanumeric LCD display

•500 event history buffer (non-volatile)

•Power limited

•Resettable/Non-resettable 1.0 amp.@ 24 VDC power output

•Alarm verification

•Walk test

•Multi-level alarm processing

•Positive alarm Sequence (PAS) operation

•NAC coding

•Trouble reminder

•Integral RS-232 port

•Key Switch - keyed alike with the door lock and renders the key pad inoperative until activated.

1.2.2 Optional Features

•Class A Module (CAOM) with Disconnect Switches for NACs and SLCs

•Digital Alarm Communicator (DACT) (Model 7100-D)

•RS-232 Printer Transient Module (PTRM), Supervised

•Municipal Circuit Option Module (MCOM)

9000-0447 9 of 43

Technical Manuals Online! - http://www.tech-man.com

1.3 Control and Indicators

1.3.1 Switch Controls

•Alarm Acknowledge

•Trouble Acknowledge

•Signal Silence

•System Reset/Lamp test

•Programming buttons

–Menu/Back

–Back Space/Edit

–OK

•12 button keypad

1.3.2 LED Indicators

•AC Power On (green)

•Alarm (red)

•Supervisory (yellow)

•System Trouble (yellow)

•Power Fault (yellow)

1.3.3 Audible Sounder

An Alarm/Trouble sounder is located on the Basic System Module (BSM)

1.4 Optional Modules

The following optional modules and

features are available:

1.4.1 Digital Communicator (DACT)

The Model 7100-D provides an integral digital communicator (DACT), fully programmable from the keypad,

which is compatible with Digital Alarm Receivers (DACRs) that can receive the following formats:

SIA DC8

SIA DCS20

Ademco Contact ID

3+1 1400 Hz

3+1 2300 Hz

4+2 1400 Hz

4+2 2300 Hz

1.4.2 Class A Option Module (CAOM)

All 7100 Models are supplied with Class B Notification Appliance Circuits and Class B Signaling Line Circuits.

For Class A operation, the addition of a CAOM Module is required.This module operates with all 7100 Models

and enables the signaling line circuits to operate as Class A, Style 6 or 7 and notification appliance circuits to

operate as Class A, Style Z.It supplies the additional terminals for these circuits.

1.4.3 Municipal Circuit Option Module (MCOM)

The MCOM Module can trip a Local Energy City Master Box, operate in reverse polarity mode for leased line

connection, or energize a solenoid for releasing service.

•Ground Fault (yellow)

•NAC 1Silenced (yellow)

•NAC 2 Silenced (yellow)

•System Silenced (yellow)

10 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

1.4.4 Printer Transient Module (PTRM)

The serial output on the BSM is via an existing RS-232 RJ-11 connector, J3.This can be used to communi-

cate to the control with a laptop computer while at the panel.The PTRM module is intended for systems where

a permanent connection is required.This type of connection requires that the RS-232 port have sufficient

transient protection to comply with the applicable codes for wiring leaving the confines of the control box, as well

as the proper isolation of the signal to prevent damage or interference caused by connection to certain EDP

devices. Connections are limited to the same room.The PTRM supplies supervision and transient protection as

well as the necessary isolation.

1.5 Specifications

Power Supply

Supervisory current 1.0 amp.(max.) (24 VDC nominal)

Alarm current 3.335 amp.(max.) (24 VDC nominal)

Notification Appliance Circuits (TB1)

Two (2) regulated power outputs

Power limited

Supervised

Non-coded

Max. alarm load 1.5 amp. /circuit

For use with any Listed appliance with operating voltage range 17-26 VDC

Use U.L. Listed End of Line Resistor EOL-N (47K), P/N 4700-0512

Trouble Dry Contacts (TB2)

Form “C”

Rated 2 amp.@ 30 VDC

Alarm Dry Contacts (TB2)

Form “C”

Rated 2 amp.@ 30 VDC

Transfer Relay Control (TB2)

To transmit loss of AC power or brown out to FCI Model DRBC-1 charger.

Power limited

Unsupervised

Signaling Line Circuits (TB3)

One (1) or two (2) Class “B”, Style 4 circuits

24 VDC nominal

Power Limited

Supervised

40 ohm max. line resistance

0.5 uf max. capacitance

Capacity of 99 analog sensors and 98 addressable devices per circuit

Earth Ground Connection (TB4)

AC Input (TB6)

120/240 VAC, 50/60 Hz, 2 amp.@ 120 VAC, 1 amp.@ 240 VAC

Non-power limited

NOTICE: Terminal TB4 must be connected to an earth ground connection per Article 760 of the National

Electric Code.Failure to make a proper earth ground connection to a metallic cold water pipe or driven

ground rod to this terminal will result in loss of lightning protection, reduce the tolerance of the system to

transients, and will adversely affect the operation of the system.Panel neutral or conduit ground is not

acceptable;minimum wire size is 14 AWG.

!

9000-0447 11 of 43

Technical Manuals Online! - http://www.tech-man.com

24 VDC power, system (TB4)

Unregulated

Resettable and non-resettable

1.0 amp. max. each circuit, 1.0 amp. max.combined

Unsupervised

Battery Connection (TB7)

Supervised

24 VDC nominal

Max. battery size 31 AH

Non-power limited

0.6 A max. battery charge current

The RS-232 port, consists of an RJ11 connector which provides a standard serial port for connection to a

Listed output device for supplementary type service.Typical examples of such devices include any UL Listed

EDP device (remote printer or video terminal), any UL Listed Signaling Device (such as the Keltron VS4095/5

printer), or any UL Listed Signal System Unit (such as the Model BBM Buffered Data Broadcast unit TL160A-

R2).

Ratings: 15 VDC (max.)

.05 amp. (max.) current

9600 baud

8 bits, 1 stop bit, no parity.

Connections to the RJ11 serial connector are as follows:

Terminal Description

2 RXD

3, 4 GND

5 TXD

6 Supervision

Available cables for RS-232 connection are:

Part No. Model Description

6100-0077 RJ11-DB9PC RJ11 to 9-pin DB9

(Connector only - PC Laptop)

6100-0074 RJ11-DB25 RJ11 to 25-pin (DB25) (connector only-printer)

6100-0075 RJ11C-6 RJ11 to RJ11 cable, 6-inches

6100-0076 RJ11C-20 RJ11 to RJ11 cable, 20 feet

NOTE: The BSM is shipped with jumpers installed on the middle three pairs of pins on J2. These jumpers must

be removed when the PTRM is installed.

These jumpers must be removed prior to installing the PTRM

module.

BSM J2

1

2

3

4

5

6

RJ11 Connector

12 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

2.0 Installation

2.1 General

The 7100 is shipped unassembled.The shipping carton contains an installation drawing, backbox, Basic

System Module (BSM), power transformer and door.

1) Refer to the System Assembly Drawing, P/N 9000-0457.

2) The BSM module consists of a main operating board with pluggable terminal strips, an 80-character LCD

display and programming keypad. Install this module immediately unless any option modules are to be used in

the system. The optional modules are supplied separately, and should be installed on the BSM before it is

mounted in the backbox.Before installing the BSM into the system backbox, refer to the installation instruction

sheets shipped with each module for the proper installation procedures.

3) Install the transformer into the backbox.

4) Install the door after the BSM is in place. Note that the door can only be installed (or removed) when it is

opened at least 90ofrom the backbox.

3.0 Basic System Module (BSM)

Designation Description Comments

TB1-1 NAC Circuit 1 (+) Class B, Style Y

TB1-2 NAC Circuit 1 ( - ) Class B, Style Y

TB1-3 NAC Circuit 2 (+) Class B, Style Y

TB1-4 NAC Circuit 2 ( - ) Class B, Style Y

TB2-1 TRBL Trouble contacts, N/O, 2 amp @ 30 VDC (resistive)

TB2-2 TRBL Trouble contacts, Common

TB2-3 TRBL Trouble contacts N/C

TB2-4 ALM Alarm contacts, N/O, 2 amp.@ 30 VDC (resistive)

TB2-5 ALM Alarm contacts, Common

TB2-6 ALM Alarm contacts, N/C

TB2-7 Transfer control

TB2-8 Not used

TB3-1 Signaling Line Circuit 1 (+) Class B, Style 4

TB3-2 Signaling Line Circuit 1 ( - ) Class B, Style 4

TB3-3 Signaling Line Circuit 2 (+) Class B, Style 4 (7100-2, -2D only)

TB3-4 Signaling Line Circuit 2 ( - ) Class B, Style 4 (7100-2, -2D only)

TB4-1 Resettable Power, 24 VDC 1.0 amp.

TB4-2 Non-resettable Power, 24 VDC 1.0 amp.

TB4-3 System Common

TB4-4 Earth Ground

TB5-1 COM B To LCD-7100 TB1-2

TB5-2 COM A To LCD-7100 TB1-1

TB5-3, -4 Not used

TB6-1 AC “Hot” 120 VAC “Hot”, 50/60 Hz 2 amp., 240 VAC “Hot”, 50/60 Hz 1 amp.

TB6-2 Ground Ground

TB6-3 AC Neutral 120 VAC Neutral, 240 VAC “Hot”

TB7-1 Batt+ Battery terminal (+)

TB7-2 Batt - Battery terminal ( - )

TB9-1 DACT Line 1 Tip In (non-power limited) From street

TB9-2 DACT Line 1 Ring In (non-power limited) From street

TB9-3 DACT Line 1 Tip Out (non-power limited) To phone

TB9-4 DACT Line 1 Ring Out (non-power limited) To phone

TB9-5 DACT Line 2 Tip In (non-power limited) From street

TB9-6 DACT Line 2 Ring In (non-power limited) From street

TB9-7 DACT Line 2 Tip Out (non-power limited) To phone

TB9-8 DACT Line 2 Ring Out (non-power limited) To phone

Table 1 Field Wiring Connections

9000-0447 13 of 43

Technical Manuals Online! - http://www.tech-man.com

3.1 Power

3.1.1 AC Input

Connection of the 120/240 VAC, 50/60 Hz power source must be made per the requirements of the National

Electrical Code, NFPA 70, Article 760, the applicable NFPA requirements, and/or the Authority Having

Jurisdiction.

Guidelines to follow are:

•Connections must be to a dedicated branch circuit

•Connections must be mechanically protected

•All means of disconnecting the circuit must be clearly marked: “FIRE ALARM CIRCUIT CONTROL.

•Accessible only to authorized personnel.

•For 240 VAC operation, no conductor shall have a potential greater than 150 V to ground.

See Table 1 for AC input and battery connections.

3.1.2 Battery Connections

TB7-1 is positive. See Table 1.

TB7-2 is negative.See Table 1.

Observe polarity

See Table 2 for Battery Calculations

3.1.3 Auxiliary Power Output, Resettable/non-resettable

TB4-1 Resettable, 24 VDC, max.1.0 amp.Suitable for use with projected beam smoke detectors SPB-24,

770 Series, or DH Series duct detectors.

TB4-2 Non-resettable, 24 VDC, max. 1.0 amp.Suitable for use with the FM Series door holders.

NOTE: Total output is 1.0 amp max.combined.

TB4-3 Common negative

TB4-4 Not used

3.1.4 Earth Ground Connection

TB4-4 Earth Ground

3.2 Relay Connections

System Trouble Contacts

TB2-1 Normally Open

TB2-2 Common

TB2-3 Normally Closed

Transfers on any trouble condition and/or supervisory alarm.

System Alarm Contacts

TB2-4 Normally Open

TB2-5 Common

TB2-6 Normally Closed

Transfers upon any system alarm except supervisory.

Designation Description Comments

LEDs

LED25 Yellow Line 1 Trouble

LED26 Yellow Line 2 Trouble

Jumpers

W1 Not used

W2 OUT to disable battery

W3 IN - No Local Phone Line 1

W4 IN - No Local Phone Line 2

J6 Connection to keypad

JMP1 Cut for 240 VAC input operation

Table 1a - LEDs, Jumpers

IMPORTANT: Always apply AC power first, then connect the batteries.

14 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

Total Total

Supv. Alarm Supv. Alarm

Qty Module Description Current Current Current Current

BSM-1 Basic System Module, 1 SLC 0.056 A 0.076 A

BSM-2 Basic System Module, 2 SLC 0.065 A 0.085 A

BSM-1D Basic System Module, 1 SLC

w/DACT 0.075 A 0.095 A

BSM-2D Basic System Module, 2 SLC

w/DACT 0.085 A 0.105 A

AMM-2 Addressable Monitor

Module Style B 0.0002 A 0.0003 A

AMM-4 Addressable Monitor

Module 0.0002 A 0.005 A

AMM-4S Addressable Monitor

Module 0.0002 A 0.005 A

AOM/ Addressable Output

AOM-2 Module 0.0002 A 0.005 A

ASD-P, PL,

PTL Analog PE Sensor 0.0002 A 0.005 A

2551T Analog PE Sensor w/therm. 0.0002 A 0.005 A

ASD-I, IL Analog Ion Sensor 0.0002 A 0.005 A

ATD-L/

ATD-RL Analog Thermal Sensor 0.0002 A 0.005 A

M500X Fault Isolator Module 0.00025 A 0.00025 A

SPB-24 Projected beam smoke det. 0.00025 A 0.020 A

PTRM Printer Transient Module 0.020 A 0.020 A

CAOM Class A Option Module 0.001 A 0.001 A

MCOM Municipal Circuit Option Module 0.001 A 0.001 A

LCD-7100 Optional Remote Serial Annunc. 0.050 A 0.075 A

Notification Appliances

Aux.Power Devices

Misc.devices

TOTALS

A Total Supv.Current

B Enter number of standby hours required**

C Multiply Line A times hours in Line B—enter

D Total alarm current from above

E Enter alarm sounding period in hours.(5 minutes = .084 hr.)

F Multiply Line D times Line E —enter

G Total of Lines C & F—enter

H Multiply Line G by 1.2 — enter (Total ampere/hours required*)

NOTE:

* Use next size battery with capacity greater than required. (Use only FCI Model B-1.9R, B-6R, B-7R,

B-17R, or B-31R batteries)

** 24 hrs for NFPA 72 protected premises or Central Station signaling, 60 hrs for Auxiliary or Remote

Supervising Station Fire alarm Systems. 90 hrs Factory Mutual standby requirement for deluge/preaction

systems with 15 minute alarm period.

See Page 43 for additional DRBC-1 connections when battery standby requirement exceeds 31 AH.

Table 2 Battery Standby Chart

9000-0447 15 of 43

Technical Manuals Online! - http://www.tech-man.com

3.3 Notification Appliance Circuits

The 7100 provides two (2) 24 VDC Class B, Style Y

notification appliance circuits. Class A, Style Z operation is

accomplished by adding the Class A Option (CAOM)

Module.

For use with any UL Listed notification appliance having

a nominal operating voltage of 24 VDC.

Wiring Instructions

NAC 1 - TB1-1 (+), TB1-2 ( - )

NAC 2 - TB1-3 (+), TB1-4 ( - )

(Polarity markings indicate the polarity of the circuit in

alarm condition).

Use U.L. Listed End of Line Resistor EOL-N (47K),

P/N 4700-0512

Circuit Ratings

24 VDC regulated

Max. alarm load 1.5 amp./circuit

Supervised

Power limited

NOTE: The CAOM module is furnished with End of Line

resistor installed.

3.4 Signaling Line Circuits

The 7100 provides one (1) or two (2) 24 VDC Class B,

Style 4 signaling line circuits.Class A, Style 6 or 7 opera-

tion is accomplished by adding the Class A Option

(CAOM) Module. See Figure 2 for Style 4 or 6 wiring, and

Figure 3 for Style 7 wiring.

Wiring Instructions

SLC 1 - TB3-1 (+), TB3-2 ( - )

SLC 2 - TB3-3 (+), TB3-4 ( - ) (7100-2 only)

(Polarity markings indicate the polarity that should

be maintained throughout the circuit.Polarity must be

observed on all devices connected to the circuit).

Circuit Ratings

24 VDC (nominal)

Current: 0.090 amp max. (supervisory)

0.097 amp max. (alarm)

0.750 amp max. (short circuit)

40 ohms max. line resistance

0.5 uf max. line capacitance

18 AWG minimum, straight lay or twisted pair

Power Limited

Supervised

1(+)

2 (-) BSM

EOL

1(+)

2(-)

CAOM

DOTTED LINES INDICATE CLASS A,

STYLE Z WIRING. REMOVE EOL

FOR CLASS A, STYLE Z

OPERATION

- +

- +

Figure 1 Notification Appliance Circuit Wiring

1 (+)

ASD

AOM

AMM

2(-)

1 (+)2(-)

CAOM

DOTTED LINES INDICATE CLASS A,

STYLE 6 WIRING

BSM

Figure 2 Signaling Line Circuit Wiring

16 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

SLC NO. 1

2

1

2

1

(+)

45

(-)

(-)

1

(-)

3

(+)

2(+)

(-)

AOM-2 (+)

8

7

9

6

(+)

4

(-)

1

(-)

3

(+)

2

M500X

(+)

4

(-)

1

(-)

3

(+)

2

M500X

(+)

4

(-)

1

(-)

3

(+)

2

M500X

`

NOTE:

WIRING FROM BSM TERMINAL 1 AND CAOM TERMINAL 2

TO FIRST M500X MODULESHALL BE AS SHORT AS

POSSIBLE AND RUN IN RIGID CONDUIT.

(-)

(-)

1(+)

2(+)

(-)

AMM-4 (+)

8

7

9

6(+)

4

(-)

1

(-)

3

(+)

2

M500X

1

211

10

9

3

4

(+)

4

(-)

1

(-)

3

(+)

2

M500X

(+)

4

(-)

1

(-)

3

(+)

2

M500X

(+)

4

(-)

1

(-)

3

(+)

2

M500X

(+)

4

(-)

1

(-)

3

(+)

2

M500X

NOTE:

WIRING FROM BSM TERMINAL 2 AND CAOM TERMINAL 1

TO LAST M500X MODULESHALL BE AS SHORT AS

POSSIBLE AND RUN IN RIGID CONDUIT.

USE TWO (2) CLOSE-NIPPLED ISOLATOR

MODULES PER CONFIGURABLE FIELD DEVICE

BSM -TB1

CAOM-TB1

Figure 3

9000-0447 17 of 43

Technical Manuals Online! - http://www.tech-man.com

3.5 Analog Sensors

The 7100 accommodates only FCI approved, U.L. Listed, Factory Mutual Approved analog sensors and

bases.See FCI Publication, P/N 9000-0427 for a list of approved sensors and bases.Each signaling line circuit

can accommodate 99 sensor address points, using Address numbers 01 to 99.

3.5.1 Address Switches

Addresses are set via the rotary switches on each sensor or module. Setting the address is accomplished

by turning each of the two (2) rotary switches until they point to the numbers indicating the proper address (e.g.,

SW1 @ #2 and SW2 @ #5 would indicate address #25).

3.5.2 Drift Compensation

The 7100 contains a program which performs continuous testing of analog sensors, including sensitivity tests.

This program will compensate all analog sensors for age and environmental conditions.Should a problem occur

in a sensor, a “Failed Test”, “Dirty” or “Very Dirty”indication for the specific device will appear on the system

display and be recorded in the Event Log and the Serial Port.

3.6 Addressable Modules

The 7100 accommodates only FCI approved, U.L. Listed, Factory Mutual Approved addressable modules.

See FCI Publication, P/N 9000-0427 for a list of approved modules. Each SLC can accommodate 98 address-

able module points, using Addresses 101 through 198.

The modules that occupy this address range consist of Monitor (input) modules and Control (output) modules.

3.6.1 Address Switches

These addresses are set via the rotary switches on each module.Setting the address is accomplished by

turning each of the two (2) rotary switches until they point to the numbers indicating the proper address (e.g.,

SW1 @ #5 and SW2 @ #7 would indicate address # 157). Note that the “100" digit is pre-set in all addressable

modules.

3.7 Monitoring Modules

The 7100 accommodates only FCI approved, U.L. Listed, Factory Mutual Approved addressable monitor

modules.Dry contact devices and two wire smoke detectors can be monitored by these modules, which act

as the interface between the manual station, waterflow switch, etc.and the control panel.

See FCI Publication, P/N 9000-0427 for a list of approved modules.

3.8 Control Modules

The 7100 accommodates only FCI approved, U.L. Listed, Factory Mutual Approved addressable output

modules on its SLCs.See FCI Publication, P/N 9000-0427 for a list of approved modules.

Notification appliances, relays and circuits using compatible voltages (through an internal dry contact) can be

controlled by these modules.

3.9 Optional Modules

3.9.1 Class A Option Module (CAOM)

The CAOM provides Class A signaling for the notification appliance circuits and Class A, Style 6 signaling

for the signaling line circuits.It also provides a disconnect switch for each signaling line circuit and a common

disconnect switch for both notification appliance circuits.See Table 3 for wiring connections.

3.9.2 Municipal Circuit Option Module (MCOM)

The MCOM provides output for a Local Energy City Master Box, reverse polarity output for leased line

connection, or releasing solenoid output.See Table 3 for wiring connections and FCI Publication, P/N 9000-

0427 for a list of approved solenoids.

Ratings: Master box (NPL) Polarity Reversal (PL) Releasing Service (NPL)

Nominal voltage 24 VDC 24 VDC 24 VDC

Supervisory current .0018 amp. .012 amp. .0005 amp.

Alarm current .510 amp. (max.) .012 amp. .700 amp.

Line resistance 35 ohms (max.) 2 ohms (max.)

Trip coil resistance 14.5 ohms (max.)

IMPORTANT: In systems incorporating the Positive Alarm Sequence (PAS) in conjunction with addressable

modules, (AMM-2, -4, -4S), only one (1) initiating device may be connected to each module (address).

EXAMPLE: Connect only one manual station per AMM-2 module.

18 of 43 9000-0447

Technical Manuals Online! - http://www.tech-man.com

Table of contents

Other FCI Smoke Alarm manuals

Popular Smoke Alarm manuals by other brands

Air Products & Controls

Air Products & Controls Multi-Flex Series installation guide

Network Technologies

Network Technologies ENVIROMUX-SDS-120V Installation and operation manual

Kidde

Kidde V-PS Installation sheet

Kathrein

Kathrein FRM 100 user manual

The Initiator and Company

The Initiator and Company Chick-a-Dee user guide

Perenio

Perenio PECSS01 quick start guide

AROHA

AROHA SM11W Quick reference guide

LST

LST WMSTR-WR-P01 Specification sheet

Ei Electronics

Ei Electronics Ei3100RF? Ei3500RF Instruction leaflet

Teletek electronics

Teletek electronics SensoIRIS S130 Installation instruction

Firex

Firex FADC manual

Red Smoke Alarms

Red Smoke Alarms R240RC installation instructions