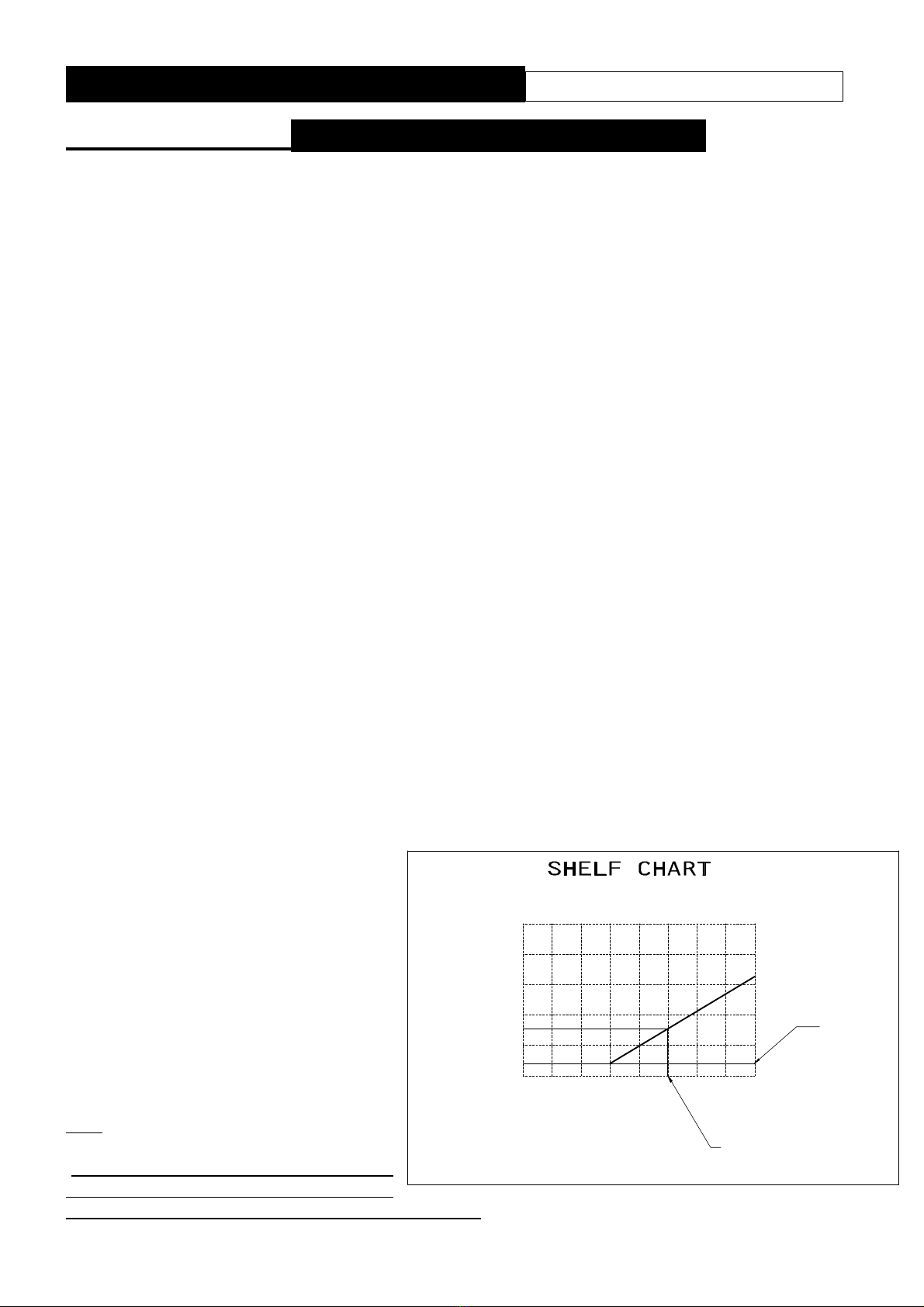

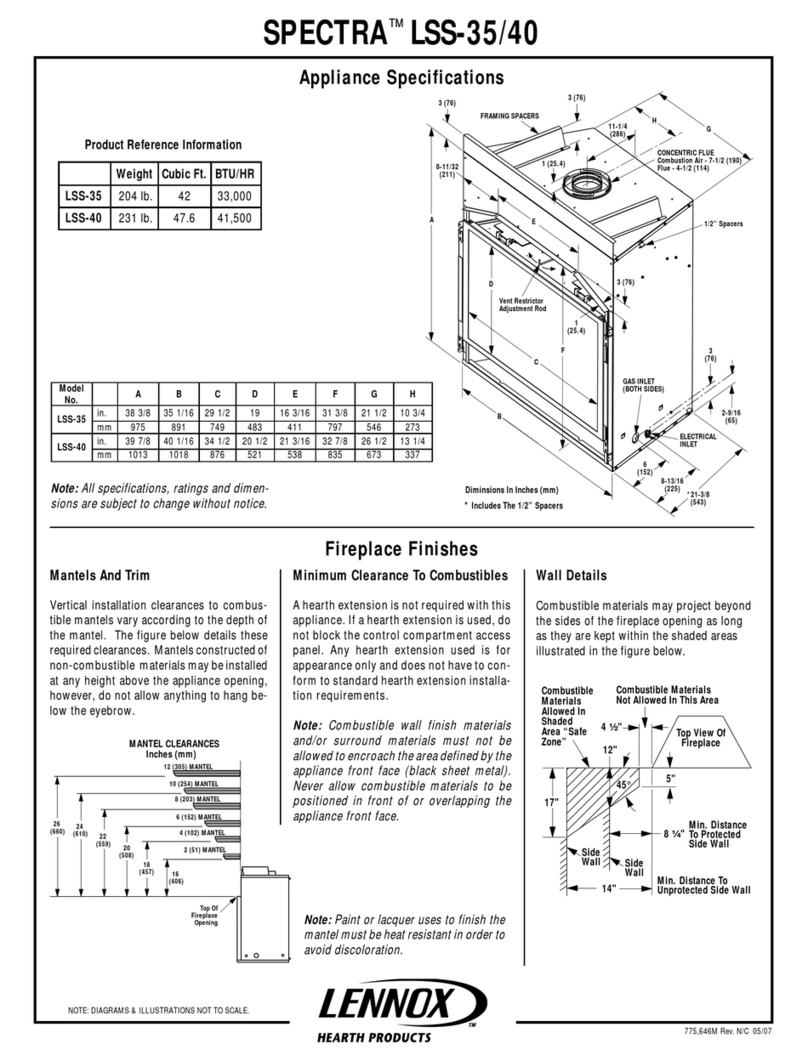

LT4935 (1:01/08) 12

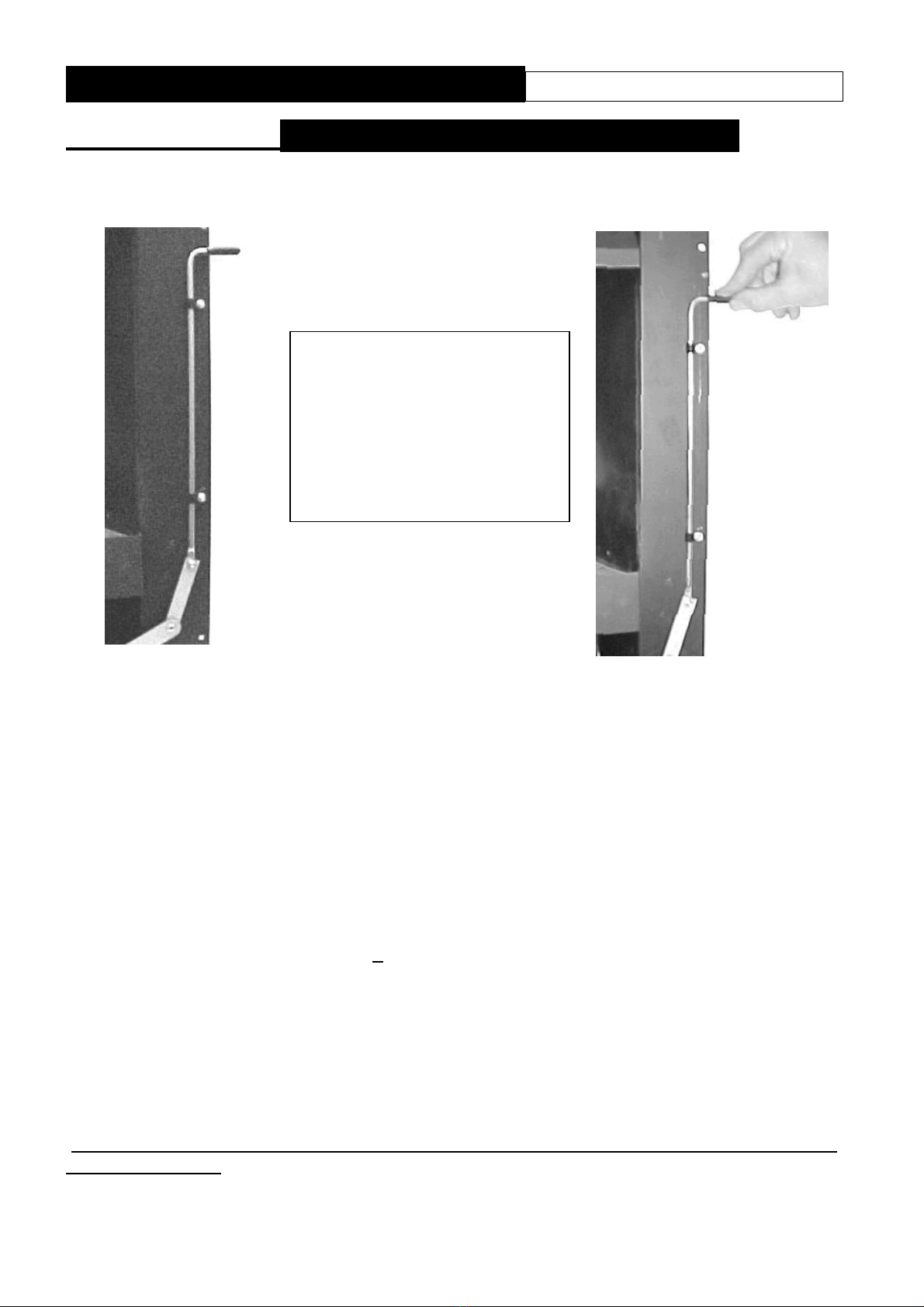

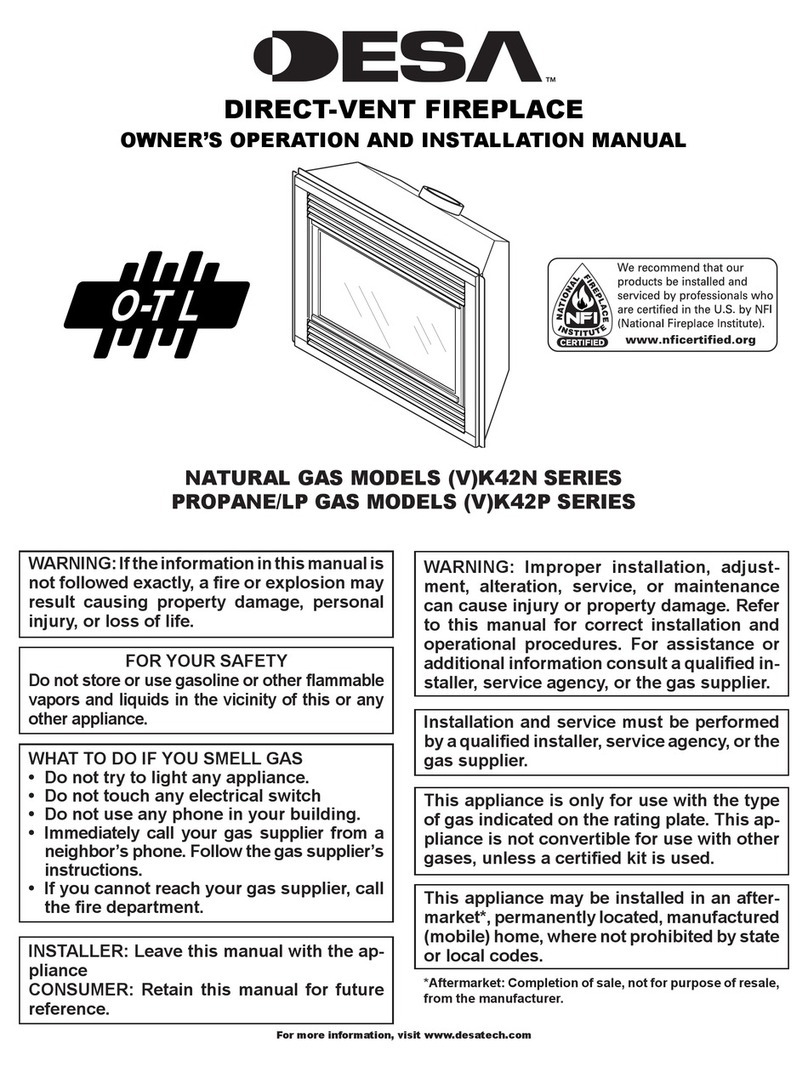

PRE-CAST FLUE BLOCK

ADDITIONAL DEPTH INCLUDING PLASTER AND FIREPLACE

"A"

"X" MINIMUM (INCLUDING PLASTER)

"A"

300

320

NONE

SPACER

20mm 30mm

30

15

10

0

0

0

340 -440

ALL DIMENSIONS IN mm

"A"

740 Min.

W en "A"=150

-

170 OR 140 MIN. IF FLUE HAS NEVER BEEN USED

FOR SOLID FUEL

120 Min.

340Min.-440Max.

640 Min.

550 MIN.- 570 MAX.

OR 500 MIN.-520 MAX.

FOR LOW OPENING

VERSION

300 Min.

50 Min.

ENIGMA II SLIMLINE SLIDE

Installation Instructions

SECTION EIGHT Siting the Appliance

Spacers are available in t e following sizes 42mm, 30mm and 20mm t ese may be used to

reduce t e minimum dept required.

T e fire can be installed in t e following flues and locations:-

• CLASS ONE

A conventional brick or stone c imney, wit t e

builder's opening constructed of non-combustible

material as used for a solid fuel appliance, wit a

minimum effective cross-sectional dimension of

225 x 225 mm (9 x 9 ins) or a lined flue (e.g. clay,

metal etc.) wit a minimum diameter of 125 mm (5

ins), wit a minimum effective overall eig t of 3

metres (10 ft). A builder's opening a minimum of

550 mm ig (or 500mm wit Low lintel version)

and 350 mm wide wit a minimum dept of 170mm

(or 140mm if flue as never been used for solid

fuel) to allow sufficient volume for debris collection.

Any permanent flue restriction or variable dampers

s all be removed or locked fully open. T e

c imney s ould be swept prior to installation if not

new or previously used wit a gas appliance.

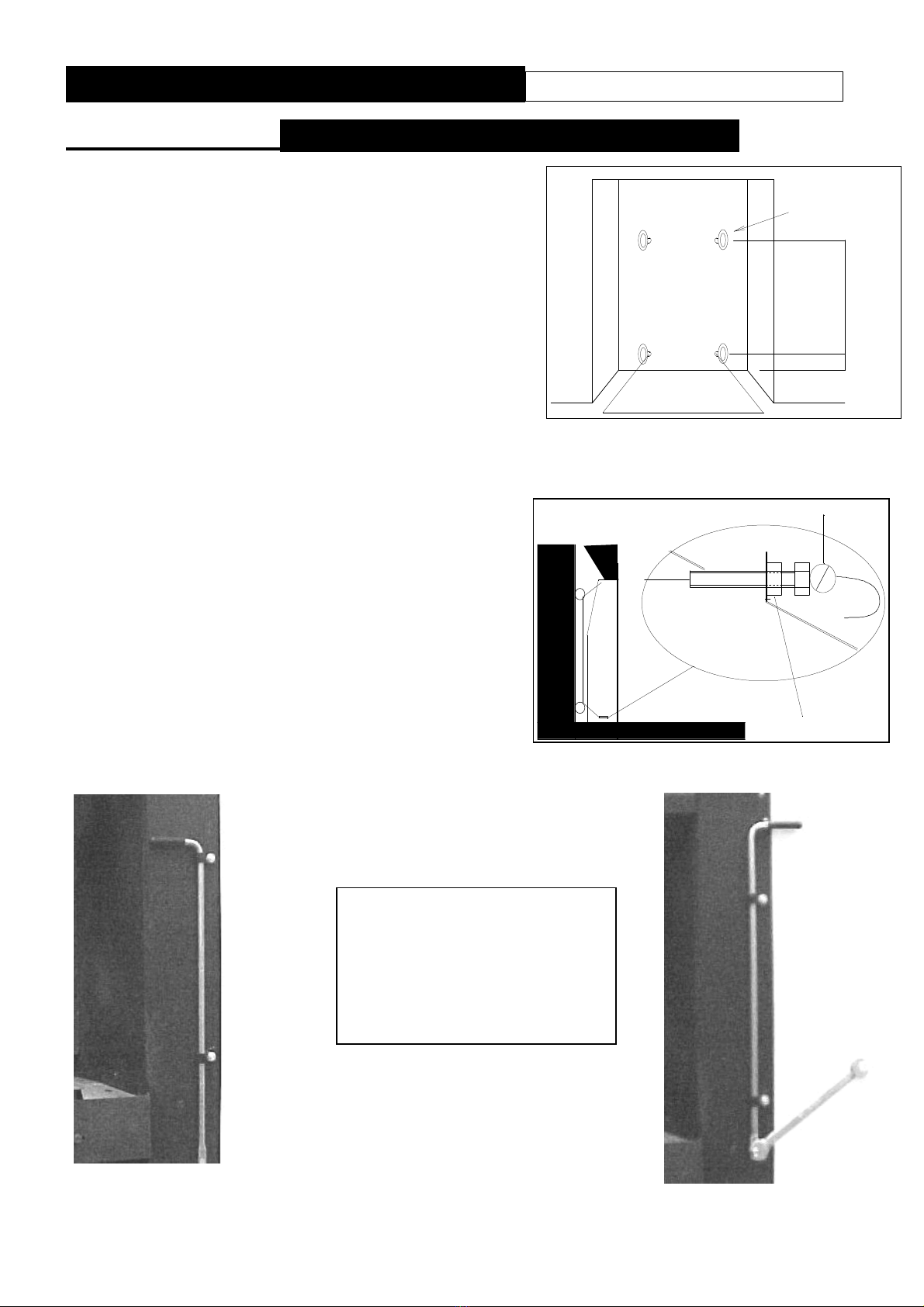

IMPORTANT: - Leave the restrictor plate

upright when installing the appliance into

150mm (6”) diameter flue or larger. Bend down

the restrictor plate if the appliance is installed

into a 125mm (5”) diameter flue or pre-cast

flues.

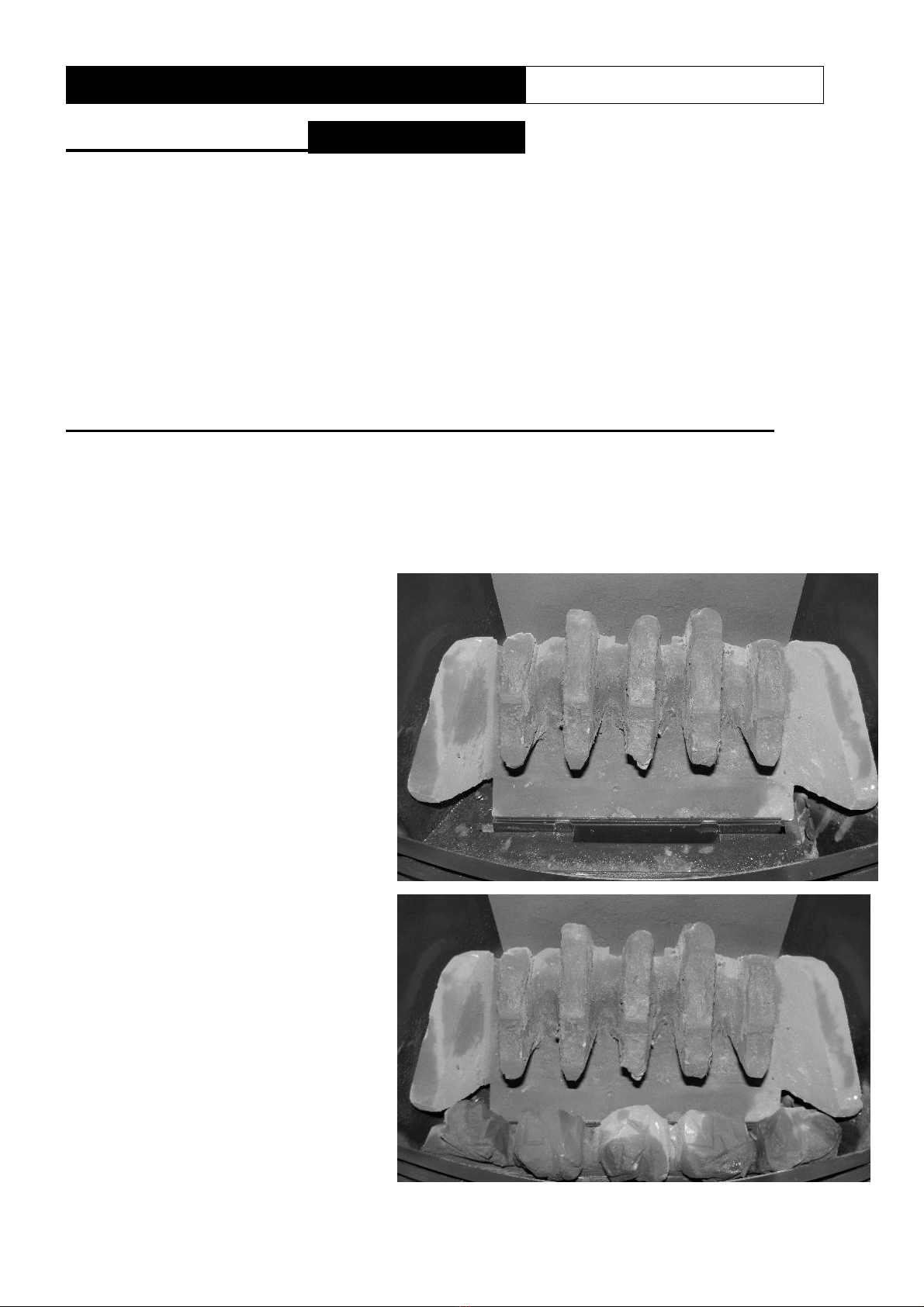

CLASS TWO

Pre-cast

A pre-cast flue correctly constructed conforming to

t e requirements of BS 1289: 1975, 1986 or 1989

wit a minimum effective overall eig t of 3 metres

(10 ft) w ic is correctly terminated (see BS 5440).

It will normally require an additional t ickness of

25mm in t e form of a fireplace back panel or if it is

intended to be fitted back to t e plaster

line t en a spacer may be required to meet wit t e

minimum dept requirement.

IMPORTANT: - Do not fit the restrictor plate if

the appliance is installed into this type of flue.

Note: An inspection s ould be made to ensure t at

t e internal walls of t e flue are clear of mortar fangs. It is recommended t at t e plasterwork

s ould not be directly bonded to t e surface of t e flue blocks, ensuring t at t ere is a small air

gap between t e flue blocks and t e wall surface. T e fire can be installed wit t e plasterwork

being directly bonded to t e flue blocks but t ere is a risk of surface cracking occurring to t e

plaster above t e appliance.