FEDERAL PACIFIC DST 5-75 Guide

Federal

Pacific

Type

DST

-

5

and

DST

-

15

Magnetic

Air

Circuit

Breakers

r

INSTALLATION

INSTRUCTION

MANUAL

TABLE

OF

CONTENTS

Description

3

Shipment

3

Inspection

upon

Receipt

of

Shipment

3

Storage

before

Installation

4

Basic

Accessories

4

Other

Available

Accessories

4

Present

Ratings

of

DST

Breakers

Uncrating

Setting

Up

the

Main

Circuit

Breaker

Assembly

.

.

.

Checking

for

Proper

Contact

Adjustments

Arc

-

Chute

Installation

Installation

of

Inter

-

Phase

Barriers

Electrical

Operation

Check

Safety

Precautions

Installing

Circuit

Breaker

in

Cell

5

5

5

6

6

7

7

7

8

/

General

Information

5

KV

and

15

KV

Magnetic

Air

Circuit

Breakers

DST

Instructions

and

Adjustments

(

with

sketches

)

8

13

18

Method

of

Operation

and

Schematic

Diagram

18

Sources

of

Control

21

Coil

Data

21

Test

Data

21

DST

Air

Circuit

Breaker

Maintenance

23

Replacement

of

Solenoid

and

Shunt

Trip

Coils

(

with

photo

)

Recommended

List

of

Spare

Parts

24

24

Renewal

Parts

List

5

KV

24

Renewal

Parts

List

ISKV

2

Courtesy of NationalSwitchgear.com

Each

circuit

breaker

,

in

its

crate

,

is

enclosed

in

a

poly

-

vinyl

dust

and

moisture

-

proof

envelope

,

which

is

zippered

on

three

(

3

)

sides

.

Within

this

envelope

is

a

proper

amount

of

silica

-

gel

to

absorb

moisture

.

It

is

recommended

that

this

envelope

not

be

opened

prior

to

putting

circuit

breaker

into

service

.

DESCRIPTION

The

DST

magnetic

air

circuit

breaker

is

electrically

operated

,

horizontal

drawout

,

three

pole

,

for

indoor

and

outdoor

metal

-

clad

switchgear

.

The

component

parts

are

mounted

on

a

welded

steel

frame

equipped

with

wheels

so

that

it

can

be

easily

moved

into

its

cell

.

It

has

insulated

interphase

bar

-

riers

,

and

a

steel

grounded

front

barrier

to

assure

safety

to

operating

personnel

.

If

breakers

are

to

be

stored

for

three

(

3

)

months

or

longer

,

silica

-

gel

should

be

removed

and

placed

in

a

dry

oven

to

remove

moisture

,

and

then

replaced

in

breaker

envelope

.

Primary

disconnecting

contacts

carry

the

load

current

,

and

secondary

disconnect

contacts

carry

the

control

circuits

for

operating

the

circuit

breaker

.

The

truck

-

mounted

breaker

is

so

interlocked

with

the

racking

-

in

mechanism

that

it

is

not

possible

to

rack

in

the

circuit

breaker

to

its

operating

position

when

the

circuit

breaker

is

closed

.

It

is

also

not

possible

to

rack

-

out

the

circuit

breaker

from

its

operating

position

when

the

circuit

breaker

is

closed

.

This

protection

is

accomplished

by

a

trip

-

lever

that

must

be

lifted

before

the

racking

-

in

crank

can

be

inserted

in

the

breaker

frame

.

These

magnetic

air

circuit

breakers

are

precision

jig

built

devices

and

are

factory

adjusted

and

tested

in

compliance

with

NEMA

standard

factory

operational

tests

.

Each

breaker

is

assigned

a

serial

number

and

a

careful

record

of

each

test

is

logged

.

This

serial

number

should

be

referred

to

if

it

becomes

necessary

to

contact

the

factory

concerning

a

breaker

.

As

each

breaker

is

carefully

factory

adjusted

before

it

is

shipped

,

no

field

adjustment

should

be

necessary

.

The

following

information

has

been

prepared

for

use

only

by

Federal

Pacific

Electric

field

service

per

-

sonnel

.

Should

it

become

necessary

,

consult

the

nearest

sales

office

for

field

service

assistance

.

SHIPMENT

All

circuit

breakers

are

assembled

in

the

factory

before

shipment

,

and

tested

for

operational

per

-

formance

.

Shipment

is

made

in

a

total

of

five

boxes

and

crates

.

The

basic

circuit

breaker

on

its

truck

is

in

one

crate

.

The

three

arc

-

chutes

are

packed

in

three

separate

boxes

.

The

interphase

barriers

are

packed

in

one

crate

.

For

15

KV

circuit

breakers

,

interphase

barriers

are

inside

the

crate

identified

as

right

hand

and

left

hand

.

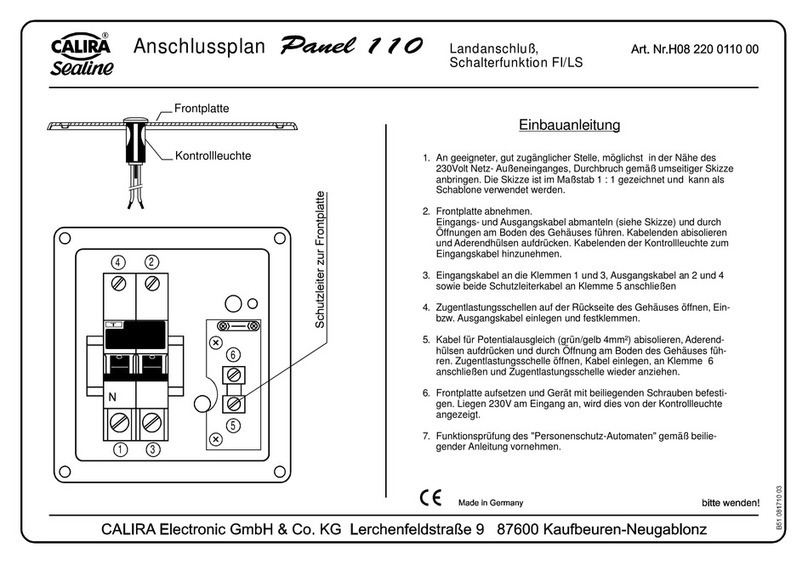

FIGURE

1

INSPECTION

UPON

RECEIPT

OF

SHIPMENT

When

a

shipment

of

circuit

breakers

is

received

,

each

circuit

breaker

should

be

examined

before

it

is

removed

from

the

railroad

car

or

truck

.

If

any

damage

or

indi

-

cation

of

rough

handling

is

evident

,

a

description

of

the

condition

should

be

written

on

the

freight

bill

,

a

claim

should

be

filed

against

the

carrier

immediately

,

and

notice

of

the

extent

of

the

damage

sent

immediately

to

the

company

at

the

address

of

the

breaker

from

which

shipment

was

made

,

giving

serial

number

of

the

breaker

,

the

carrier

'

s

name

,

and

car

number

if

shipped

by

rail

.

This

information

enables

the

company

to

supply

needed

information

to

assist

the

purchaser

in

support

of

the

claim

.

The

serial

number

of

each

circuit

breaker

is

on

its

nameplate

and

also

marked

on

the

circuit

breaker

crate

.

The

two

crates

and

the

three

boxes

are

marked

with

the

factory

FED

number

.

A

copy

of

the

packing

list

,

enclosed

in

a

water

-

proof

envelope

,

is

nailed

on

the

outside

of

the

circuit

breaker

crate

.

One

envelope

only

is

furnished

with

orders

for

more

than

one

circuit

breaker

shipped

to

a

single

destination

.

3

Courtesy of NationalSwitchgear.com

GROUND

AND

TEST

DEVICES

STORAGE

BEFORE

INSTALLATION

r

5

KV

Circuit

breakers

arriving

at

the

job

in

advance

of

installation

should

be

stored

indoors

in

a

dry

place

.

In

cases

where

anytime

is

to

elapse

before

the

circuit

breaker

is

to

be

installed

,

the

insulating

parts

should

be

tested

for

proper

insulation

level

.

If

standard

insulation

level

is

not

found

,

the

insulating

parts

should

be

dried

and

retested

.

If

stored

near

new

con

-

struction

work

,

care

should

be

taken

to

protect

from

dust

or

other

materials

by

covering

with

a

tarpaulin

.

Current

Rating

Symbol

1551

-

0314

1552

-

0314

1200

-

Manual

2000

-

Manual

15

KV

1200

-

Manual

2000

*

Manual

Also

available

electrical

(

solenoid

operated

)

for

Specific

Applications

.

1551

-

0455

1552

-

0455

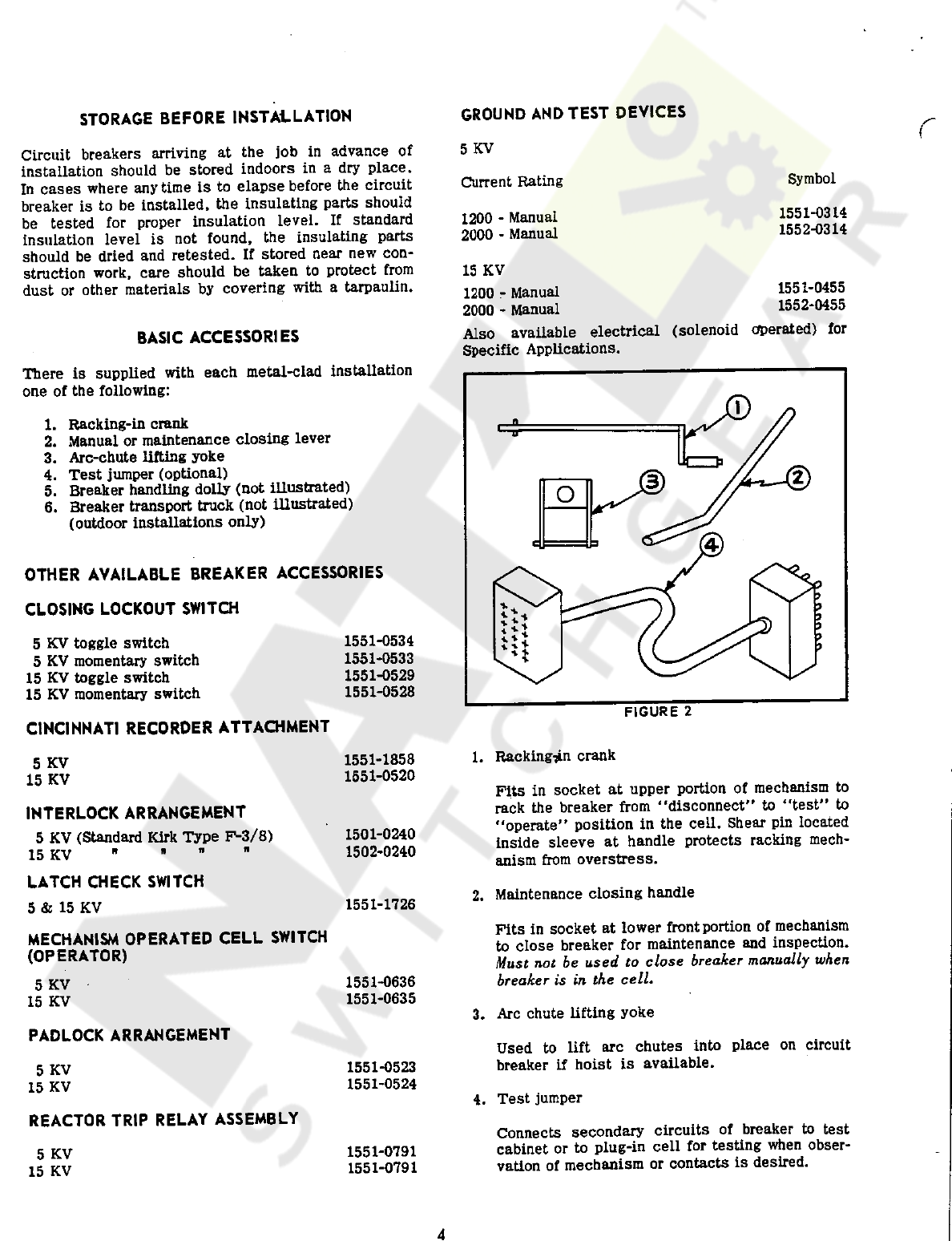

BASIC

ACCESSORIES

There

is

supplied

with

each

metal

-

clad

installation

one

of

the

following

:

1

.

Racking

-

in

crank

2

.

Manual

or

maintenance

closing

lever

3

.

Arc

-

chute

lifting

yoke

4

.

Test

jumper

(

optional

)

5

.

Breaker

handling

doily

(

not

illustrated

)

6

.

Breaker

transport

truck

(

not

illustrated

)

(

outdoor

installations

only

)

OTHER

AVAILABLE

BREAKER

ACCESSORIES

CLOSING

LOCKOUT

SWITCH

5

KV

toggle

switch

5

KV

momentary

switch

15

KV

toggle

switch

15

KV

momentary

switch

1551

-

0534

1551

-

0533

1551

-

0529

1551

-

0528

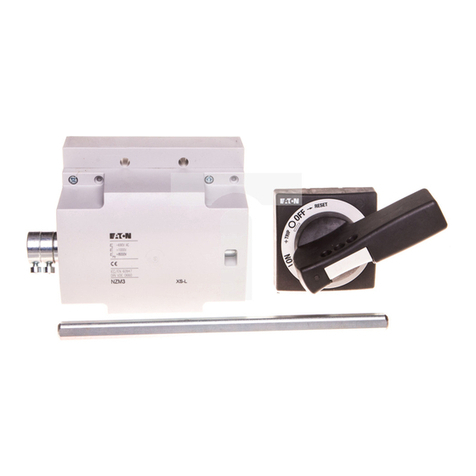

FIGURE

2

CINCINNATI

RECORDER

ATTACHMENT

1

.

Racking

*

n

crank

1551

-

1858

1551

-

0520

5

KV

15

KV

Pits

in

socket

at

upper

portion

of

mechanism

to

rack

the

breaker

from

"

disconnect

"

to

"

test

"

to

"

operate

"

position

in

the

cell

.

Shear

pin

located

inside

sleeve

at

handle

protects

racking

mech

-

anism

from

overstress

.

INTERLOCK

ARRANGEMENT

5

KV

(

Standard

Kirk

Type

P

-

3

/

8

)

15

KV

"

LATCH

CHECK

SWITCH

5

&

15

KV

1501

-

0240

1502

-

0240

2

.

Maintenance

closing

handle

1551

-

1726

Fits

in

socket

at

lower

front

portion

of

mechanism

to

close

breaker

for

maintenance

and

inspection

.

Must

not

be

used

to

close

breaker

manually

when

breaker

is

in

the

cell

.

MECHANISM

OPERATED

CELL

SWITCH

(

OPERATOR

)

5

KV

15

KV

1551

-

0636

1551

-

0635

3

.

Arc

chute

lifting

yoke

PADLOCK

ARRANGEMENT

Used

to

lift

arc

chutes

into

place

on

circuit

breaker

if

hoist

is

available

.

5

KV

15

KV

1551

-

0523

1551

-

0524

4

.

Test

jumper

REACTOR

TRIP

RELAY

ASSEMBLY

Connects

secondary

circuits

of

breaker

to

test

cabinet

or

to

plug

-

in

cell

for

testing

when

obser

-

vation

of

mechanism

or

contacts

is

desired

.

5

KV

15

KV

1551

-

0791

1551

-

0791

4

Courtesy of NationalSwitchgear.com

UNCRATING

RATINGS

OF

DST

BREAKERS

If

the

breaker

has

to

be

moved

to

its

proper

location

,

lift

the

breaker

in

its

crate

if

possible

.

If

not

,

then

lift

the

breaker

without

its

arc

-

chutes

and

barrier

.

Always

remove

these

components

before

lifting

a

breaker

.

Fig

.

3

shows

proper

method

of

attaching

lifting

cable

.

Current

Rating

Type

Symbol

DST

5

-

75

DST

5

-

150

DST

5

-

150

DST

5

-

250

DST

5

-

250

1200

1553

-

1653

1555

-

1653

1554

-

1653

1551

-

1653

1552

-

1653

1200

Uncrate

the

breaker

.

Use

nail

-

puller

for

this

purpose

.

Note

that

the

breaker

was

shipped

with

contacts

open

,

and

blocked

open

with

a

shipping

strut

.

2000

1200

2000

SETTING

UP

THE

MAIN

CIRCUIT

BREAKER

ASSEMBLY

1200

Dummy

Dummy

1551

-

0838

1552

-

0838

2000

1

.

After

the

breaker

is

uncrated

,

inspect

for

damage

.

DST

15

-

150

DST

15

-

250

DST

15

-

250

DST

15

-

500

DST

15

-

500

1200

1552

-

1655

1551

-

1655

1551

-

0606

1551

-

1655

1551

-

0606

2

.

Clean

off

any

accumulated

dust

with

a

dry

cloth

.

1200

3

.

The

contacts

were

not

oiled

or

greased

at

the

factory

,

nevertheless

see

that

they

are

free

from

any

oil

or

grease

.

2000

1200

2000

4

.

Check

for

any

obvious

loose

hardware

.

1200

Dummy

Dummy

1551

-

1680

1552

-

1680

5

.

Do

not

install

arc

-

chutes

and

barriers

until

ready

to

push

the

breaker

into

its

cell

.

2000

6

.

First

,

operate

the

breaker

by

means

of

its

maintenance

operating

handle

.

This

is

to

be

inserted

into

its

socket

at

lower

center

of

mechanism

.

See

figure

8

.

Push

the

handle

downward

to

close

the

breaker

until

an

audible

click

is

heard

,

indicating

that

the

breaker

has

latched

into

the

closed

position

.

Check

for

any

binding

or

friction

.

7

.

Remove

the

manual

closing

handle

.

/

8

.

Trip

the

breaker

by

raising

the

lift

-

to

-

trip

lever

.

9

.

Repeat

6

and

8

several

times

to

insure

proper

operation

.

Raise

the

lift

-

to

-

trip

lever

and

insert

the

racking

-

in

handle

in

socket

that

is

uncovered

by

the

pro

-

jection

on

the

trip

bar

.

Note

that

in

order

to

insert

handle

,

the

circuit

breaker

must

be

tripped

open

.

10

.

11

.

Turn

handle

to

rotate

racking

-

in

lever

against

roller

-

lever

against

the

step

in

the

extended

position

(

protruding

outside

the

frame

)

.

12

.

With

handle

still

in

the

socket

,

place

the

manual

closing

lever

in

manual

closing

socket

and

attempt

to

close

the

breaker

.

It

should

trip

-

free

.

Note

how

trip

-

bar

operates

the

cam

to

depress

the

trip

armature

.

13

.

If

circuit

breaker

does

not

operate

properly

,

check

the

contact

adjustments

as

follows

:

FIGURE

3

5

Courtesy of NationalSwitchgear.com

Arcing

Cortact

Position

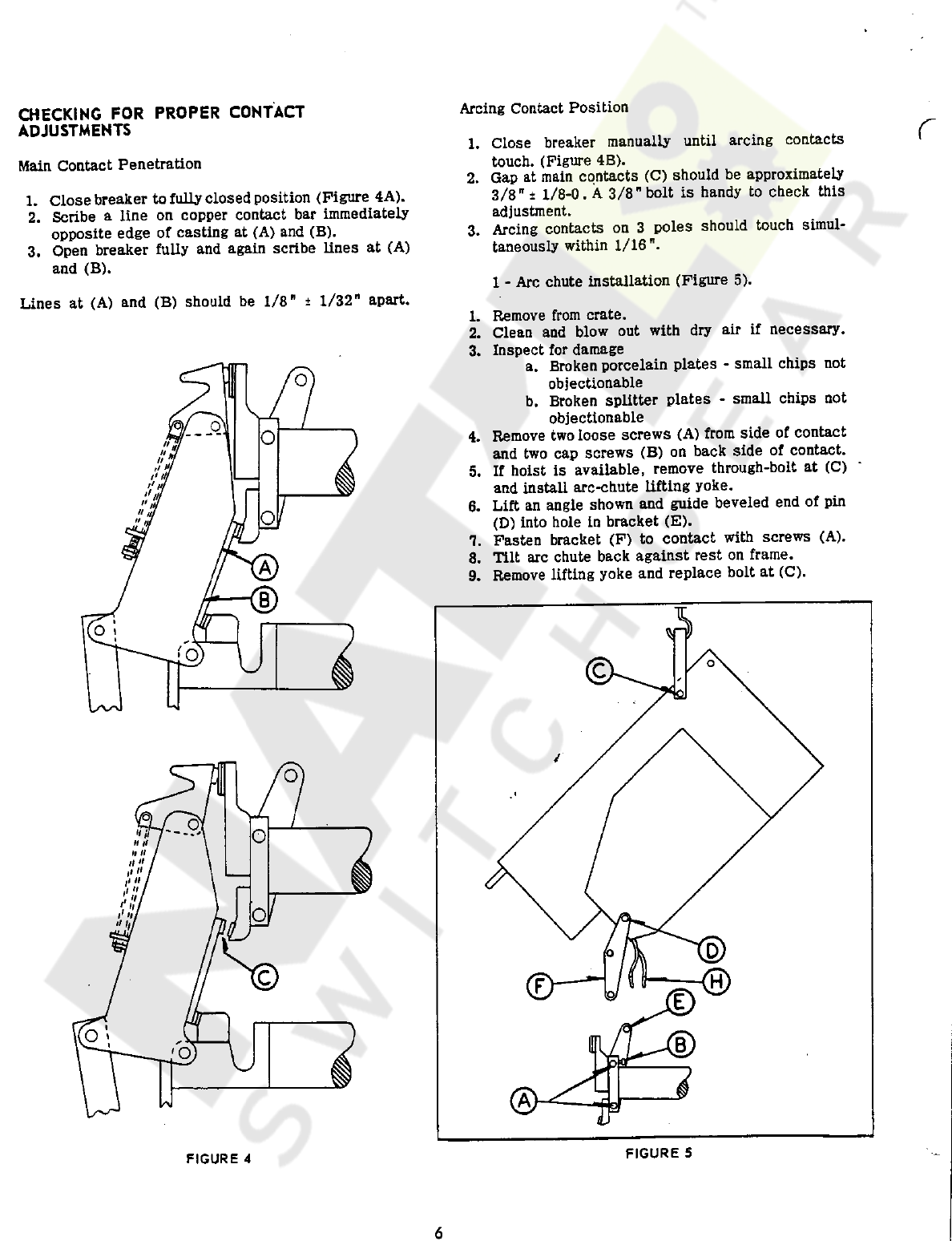

CHECKING

FOR

PROPER

CONTACT

ADJUSTMENTS

r

Close

breaker

manually

until

arcing

contacts

touch

.

(

Figure

4

B

)

.

Gap

at

main

contacts

(

C

)

should

be

approximately

3

/

8

"

±

1

/

8

-

0

.

A

3

/

8

"

bolt

is

handy

to

check

this

adjustment

.

Arcing

contacts

on

3

poles

should

touch

simul

-

taneously

within

1

/

16

1

.

Main

Contact

Penetration

2

.

1

.

Close

breaker

to

fully

closed

position

(

Figure

4

A

)

.

2

.

Scribe

a

line

on

copper

contact

bar

immediately

opposite

edge

of

casting

at

(

A

)

and

(

B

)

.

3

.

Open

breaker

fully

and

again

scribe

lines

at

(

A

)

and

(

B

)

.

3

.

1

-

Arc

chute

installation

(

Figure

5

)

.

Lines

at

(

A

)

and

(

B

)

should

be

1

/

8

"

±

1

/

32

"

apart

.

Remove

from

crate

.

Clean

and

blow

out

with

dry

air

if

necessary

.

Inspect

for

damage

a

.

Broken

porcelain

plates

-

small

chips

not

objectionable

b

.

Broken

splitter

plates

-

small

chips

not

objectionable

Remove

two

loose

screws

(

A

)

from

side

of

contact

and

two

cap

screws

(

B

)

on

back

side

of

contact

.

If

hoist

is

available

,

remove

through

-

bolt

at

(

C

)

and

install

arc

-

chute

lifting

yoke

.

Lift

an

angle

shown

and

guide

beveled

end

of

pin

(

D

)

into

hole

in

bracket

(

E

)

.

Fasten

bracket

(

F

)

to

contact

with

screws

(

A

)

.

Tilt

arc

chute

back

against

rest

on

frame

.

Remove

lifting

yoke

and

replace

bolt

at

(

C

)

.

1

.

2

.

3

.

n

O

o

O

4

.

"

*

/

/

-

7

o

,

/

H

5

.

/

'

/

4

/

'

i f

6

.

"

/

/

>

o

7

.

8

.

A

9

.

B

O

i

;

'

o

o

oi

»

ii

o

;

n

it

a

it

it

"

*

t

'

«

/

a

,

ft

i

r

ii

1

o

o

FIGURE

5

FIGURE

4

6

Courtesy of NationalSwitchgear.com

6

*

Tighten

two

lower

bolts

*

7

.

Check

closing

and

tripping

manually

*

Electrical

operation

check

(

May

be

done

before

installing

arc

chutes

and

barriers

if

power

is

available

)

1

.

Check

the

closing

and

tripping

voltages

on

the

nameplate

of

the

breaker

.

Breakers

used

with

capacitor

trip

devices

will

indicate

125

volts

d

.

c

.

for

tripping

.

Breakers

used

with

closing

rectifiers

will

indicate

125

volts

d

.

c

.

for

closing

.

2

.

Connect

breaker

to

suitable

supply

.

a

.

Connect

test

jumper

(

if

available

)

to

cell

or

test

cabinet

.

b

.

If

suitable

supply

not

available

,

the

breaker

must

be

electrically

operated

several

times

after

it

has

been

installed

in

the

cell

in

the

test

position

.

Before

doing

this

,

follow

procedure

in

the

following

section

entitled

"

Installing

circuit

breaker

in

cell

"

.

Be

sure

arc

chutes

and

interphase

barriers

are

installed

before

entering

breaker

in

cell

.

3

.

Close

and

trip

the

breaker

electrically

several

times

to

insure

proper

operation

.

SAFETY

PRECAUTIONS

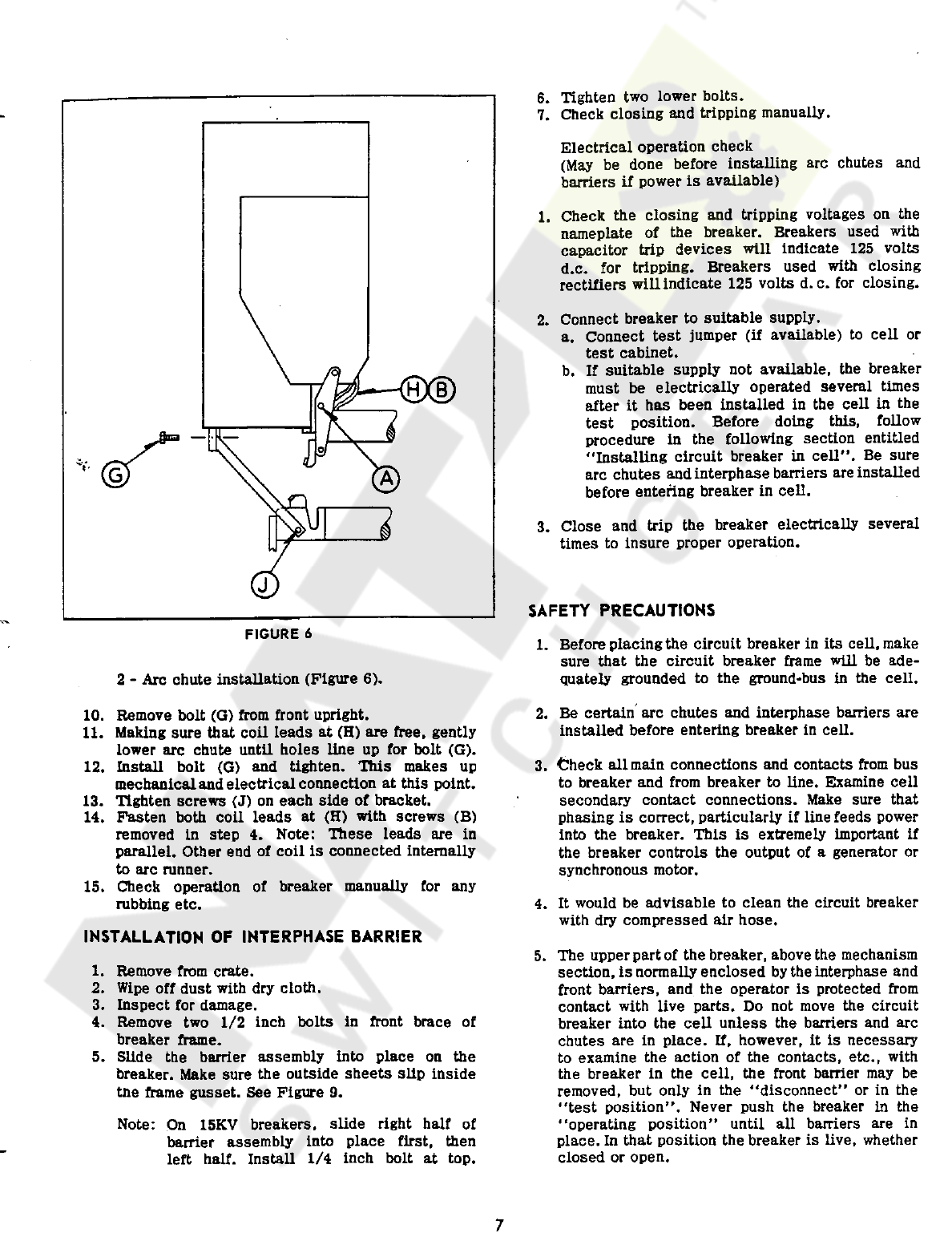

FIGURE

6

1

.

Before

placing

the

circuit

breaker

in

its

cell

,

make

sure

that

the

circuit

breaker

frame

will

be

ade

-

quately

grounded

to

the

ground

-

bus

in

the

cell

.

2

-

Arc

chute

installation

(

Figure

6

)

.

2

.

Be

certain

arc

chutes

and

interphase

barriers

are

installed

before

entering

breaker

in

cell

.

10

.

Remove

bolt

(

G

)

from

front

upright

.

11

.

Making

sure

that

coil

leads

at

(

H

)

are

free

,

gently

lower

arc

chute

until

holes

line

up

for

bolt

(

G

)

.

12

.

Install

bolt

(

G

)

and

tighten

.

This

makes

up

mechanical

and

electrical

connection

at

this

point

.

13

.

Tighten

screws

(

J

)

on

each

side

of

bracket

.

14

.

Fasten

both

coil

leads

at

(

H

)

with

screws

(

B

)

removed

in

step

4

.

Note

:

These

leads

are

in

parallel

.

Other

end

of

coil

is

connected

internally

to

arc

runner

.

15

.

Check

operation

of

breaker

manually

for

any

rubbing

etc

.

3

.

Check

all

main

connections

and

contacts

from

bus

to

breaker

and

from

breaker

to

line

.

Examine

cell

secondary

contact

connections

.

Make

sure

that

phasing

is

correct

,

particularly

if

line

feeds

power

into

the

breaker

.

This

is

extremely

important

if

the

breaker

controls

the

output

of

a

generator

or

synchronous

motor

.

4

.

It

would

be

advisable

to

clean

the

circuit

breaker

with

dry

compressed

air

hose

.

INSTALLATION

OF

INTERPHASE

BARRIER

5

.

The

upper

part

of

the

breaker

,

above

the

mechanism

section

,

is

normally

enclosed

by

the

interphase

and

front

barriers

,

and

the

operator

is

protected

from

contact

with

live

parts

.

Do

not

move

the

circuit

breaker

into

the

cell

unless

the

barriers

and

arc

chutes

are

in

place

.

If

,

however

,

it

is

necessary

to

examine

the

action

of

the

contacts

,

etc

.

,

with

the

breaker

in

the

cell

,

the

front

barrier

may

be

removed

,

but

only

in

the

"

disconnect

"

or

in

the

"

test

position

"

.

Never

push

the

breaker

in

the

operating

position

"

until

all

barriers

are

in

place

.

In

that

position

the

breaker

is

live

,

whether

closed

or

open

.

1

.

Remove

from

crate

.

2

.

Wipe

off

dust

with

dry

cloth

.

3

.

Inspect

for

damage

.

4

.

Remove

two

1

/

2

inch

bolts

in

front

brace

of

breaker

frame

.

5

.

Slide

the

barrier

assembly

Into

place

on

the

breaker

.

Make

sure

the

outside

sheets

slip

inside

tne

frame

gusset

.

See

Figure

9

.

Note

:

On

15

KV

breakers

,

slide

right

half

of

barrier

assembly

into

place

first

,

then

left

half

.

Install

1

/

4

inch

bolt

at

top

.

i

*

7

Courtesy of NationalSwitchgear.com

matically

pushed

toward

the

operator

and

locked

in

its

operate

position

.

The

breaker

is

now

in

the

operating

position

.

4

.

Remove

the

racking

-

in

handle

.

6

*

Do

not

attempt

to

close

the

circuit

breaker

by

hand

against

an

energized

circuit

.

The

maintenance

operating

handle

should

only

be

used

in

testing

the

mechanical

operation

of

the

circuit

breaker

when

not

in

the

cell

.

r

The

circuit

breaker

is

ready

for

service

,

and

should

be

closed

and

tripped

electrically

several

times

to

assure

that

all

control

circuit

connections

and

contacts

are

satisfactory

.

This

should

be

done

on

a

dead

bus

if

possible

.

If

the

test

must

be

made

on

a

live

bus

,

first

read

carefully

the

preceding

section

entitled

"

Safety

Precautions

"

.

7

.

In

order

that

sufficient

closing

force

and

acceleration

are

attained

,

the

circuit

breakers

should

be

closed

electrically

from

an

adequate

power

source

.

See

NEMA

Standard

SG

-

6

-

213

.

8

.

Remove

the

circuit

breaker

from

the

cell

when

it

is

to

be

examined

for

maintenance

or

repair

.

Close

and

fasten

the

cell

door

if

breaker

is

to

be

tested

on

live

bus

.

9

.

When

testing

the

circuit

breaker

,

make

sure

the

circuit

breaker

control

switch

has

a

"

do

not

operate

"

tag

on

it

.

5

.

When

it

is

desired

to

rack

the

breaker

into

the

Test

position

,

first

trip

the

breaker

electrically

by

operating

control

switch

,

then

insert

racking

-

in

handle

.

INSTALLING

CIRCUIT

BREAKER

IN

CELL

Before

placing

the

circuit

breaker

in

the

ceil

,

proceed

as

follows

:

a

.

Before

shipment

,

the

circuit

breaker

closing

relays

in

the

top

of

the

cells

are

"

blocked

"

.

Remove

these

blocks

,

thus

allowing

the

relays

to

operate

.

Rotate

the

racking

-

in

handle

counter

clock

-

wise

eleven

(

11

)

times

.

Shutter

will

close

,

and

secondary

contacts

will

be

disconnected

.

6

.

Remove

the

racking

-

in

handle

.

b

.

See

that

the

secondary

sliding

panel

,

with

its

.

plug

-

in

block

,

is

held

at

the

front

of

the

mechanism

housing

by

its

lock

-

pin

.

To

operate

in

Test

position

,

release

secondary

contact

lock

-

in

pin

and

push

sliding

panel

forward

until

its

contacts

engage

contacts

in

the

cell

.

The

breaker

can

now

be

operated

electrically

in

the

Test

position

.

c

.

Insert

racking

-

in

handle

.

Rotate

handle

counter

-

clockwise

until

lever

-

and

-

roller

assembly

is

against

its

stop

.

This

assembly

is

in

the

rear

of

the

breaker

on

top

of

the

mechanism

housing

.

Racking

-

in

lever

should

protrude

outside

the

frame

before

placing

breaker

in

frame

.

7

.

Insert

the

racking

-

in

handle

.

The

circuit

breaker

can

be

racked

to

the

disconnect

position

by

rotating

the

racking

-

in

handle

counter

clock

-

wi

^

e

six

(

6

)

times

.

The

secondary

contact

sliding

panel

should

be

pulled

forward

to

its

operating

position

and

locked

there

by

its

lockpin

,

otherwise

there

will

be

voltage

on

the

control

wiring

of

the

circuit

breaker

.

Place

breaker

in

its

cell

,

and

push

until

lever

-

and

-

roller

assembly

hits

against

horizontal

racking

-

in

hook

which

is

mounting

on

rear

of

cell

.

1

.

Rotate

racking

-

in

handle

clockwise

six

(

6

)

turns

.

Circuit

breaker

will

at

first

back

out

a

little

and

then

go

forward

to

Test

position

as

shown

by

the

indicators

on

the

right

-

hand

side

-

sheet

.

Note

:

As

stated

previously

,

under

"

Description

"

,

the

circuit

breaker

has

to

be

open

before

the

operator

can

insert

the

racking

-

in

handle

into

its

socket

.

Therefore

,

it

is

impossible

to

rack

a

closed

circuit

breaker

from

Test

to

operating

position

,

or

from

operating

to

test

position

.

2

.

Remove

racking

-

in

handle

.

To

operate

breaker

in

Test

position

,

release

secondary

contact

lock

-

pin

and

push

sliding

panel

forward

until

its

contacts

engage

similar

contacts

in

the

cell

plug

in

block

.

The

breaker

can

now

be

closed

and

tripped

electrically

several

times

to

test

the

control

circuits

.

GENERAL

INFORMATION

5

KY

AND

15

KV

MAGNETIC

AIR

CIRCUIT

BREAKERS

3

.

Insert

the

racking

-

in

handle

.

BREAKER

-

Deod

Front

-

Figure

7

The

breaker

is

now

open

.

Rotate

racking

-

in

handle

eleven

(

11

)

more

times

clockwise

.

The

shutter

will

be

driven

open

as

shown

by

its

indicator

.

The

secondary

contact

sliding

panel

will

be

auto

-

Note

breaker

has

front

steel

plate

that

closes

against

angle

irons

in

switchgear

cell

making

a

completely

"

dead

front

"

arrangement

!

8

Courtesy of NationalSwitchgear.com

FIGURE

7

BREAKER

FRAME

-

Figures

8

&

9

Breaker

frame

is

a

welded

fabricated

assembly

of

1

/

8

n

and

1

/

4

”

thick

steel

very

amply

braced

.

Four

inch

diameter

wheels

provide

ease

of

withdrawal

.

Breaker

14

position

-

indicator

'

'

mechanically

locked

with

“

breaker

operating

mechanism

”

provides

positive

visual

indication

of

contact

position

.

Veeder

counter

is

supplied

to

record

number

of

oper

-

ations

.

GROUNDING

-

Figure

10

(

Ml

)

Breaker

frame

substantially

grounded

in

both

“

operating

”

and

“

test

”

positions

.

1

/

4

"

x

2

"

copper

bar

solidly

bolted

to

breaker

frame

provides

wiping

action

against

stationary

coil

-

spring

loaded

contact

located

in

cell

and

formed

of

1

/

8

”

x

2

"

copper

.

FIGURE

9

9

Courtesy of NationalSwitchgear.com

1

'

I

J

mm

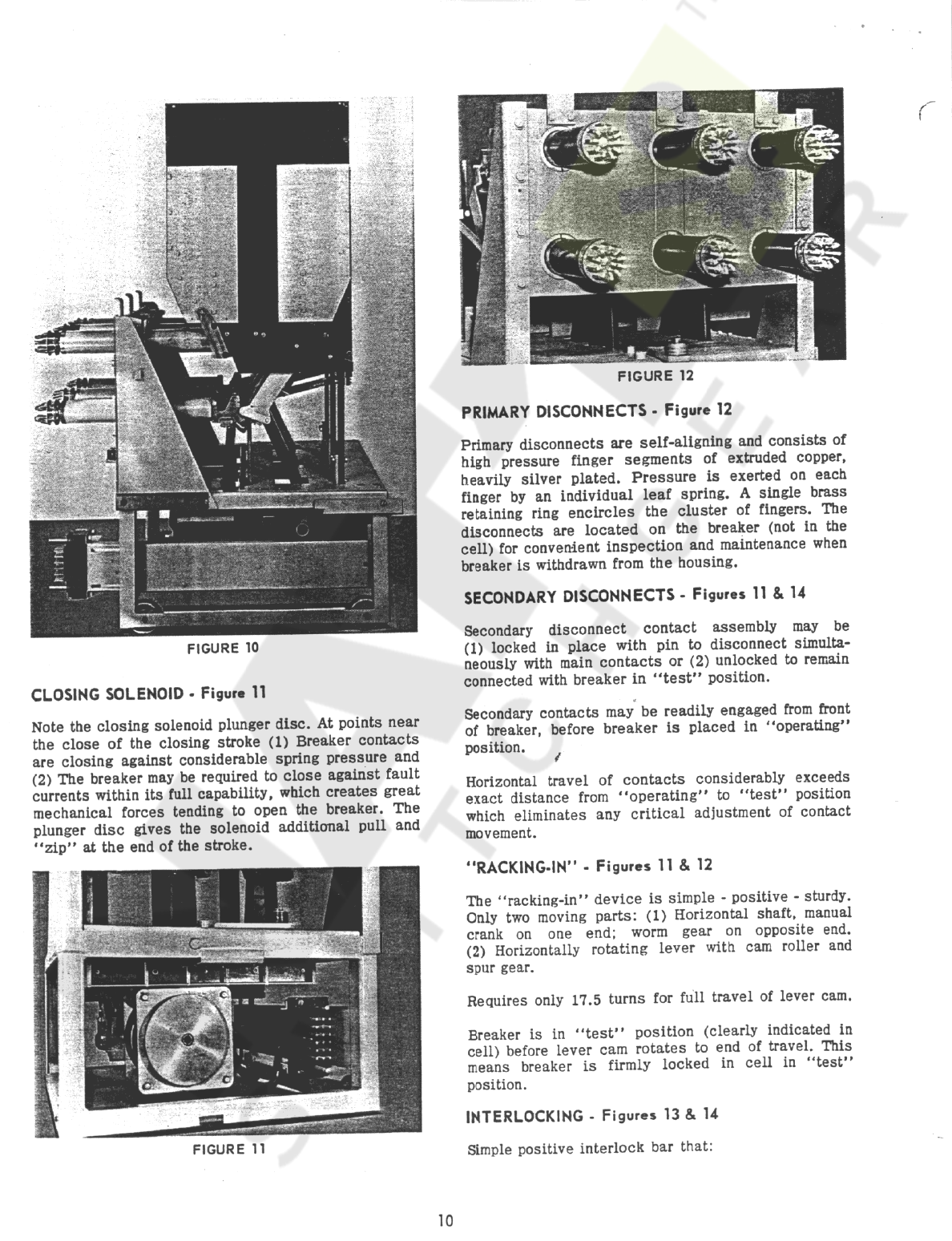

FIGURE

12

PRIMARY

DISCONNECTS

-

Figure

12

Primary

disconnects

are

self

-

aligning

and

consists

of

high

pressure

finger

segments

of

extruded

copper

,

heavily

silver

plated

.

Pressure

is

exerted

on

each

finger

by

an

individual

leaf

spring

.

A

single

brass

retaining

ring

encircles

the

cluster

of

fingers

.

The

disconnects

are

located

on

the

breaker

(

not

in

the

cell

)

for

convenient

inspection

and

maintenance

when

breaker

is

withdrawn

from

the

housing

.

SECONDARY

DISCONNECTS

-

Figures

11

&

14

Secondary

disconnect

contact

assembly

may

be

(

1

)

locked

in

place

with

pin

to

disconnect

simulta

-

neously

with

main

contacts

or

(

2

)

unlocked

to

remain

connected

with

breaker

in

“

test

"

position

.

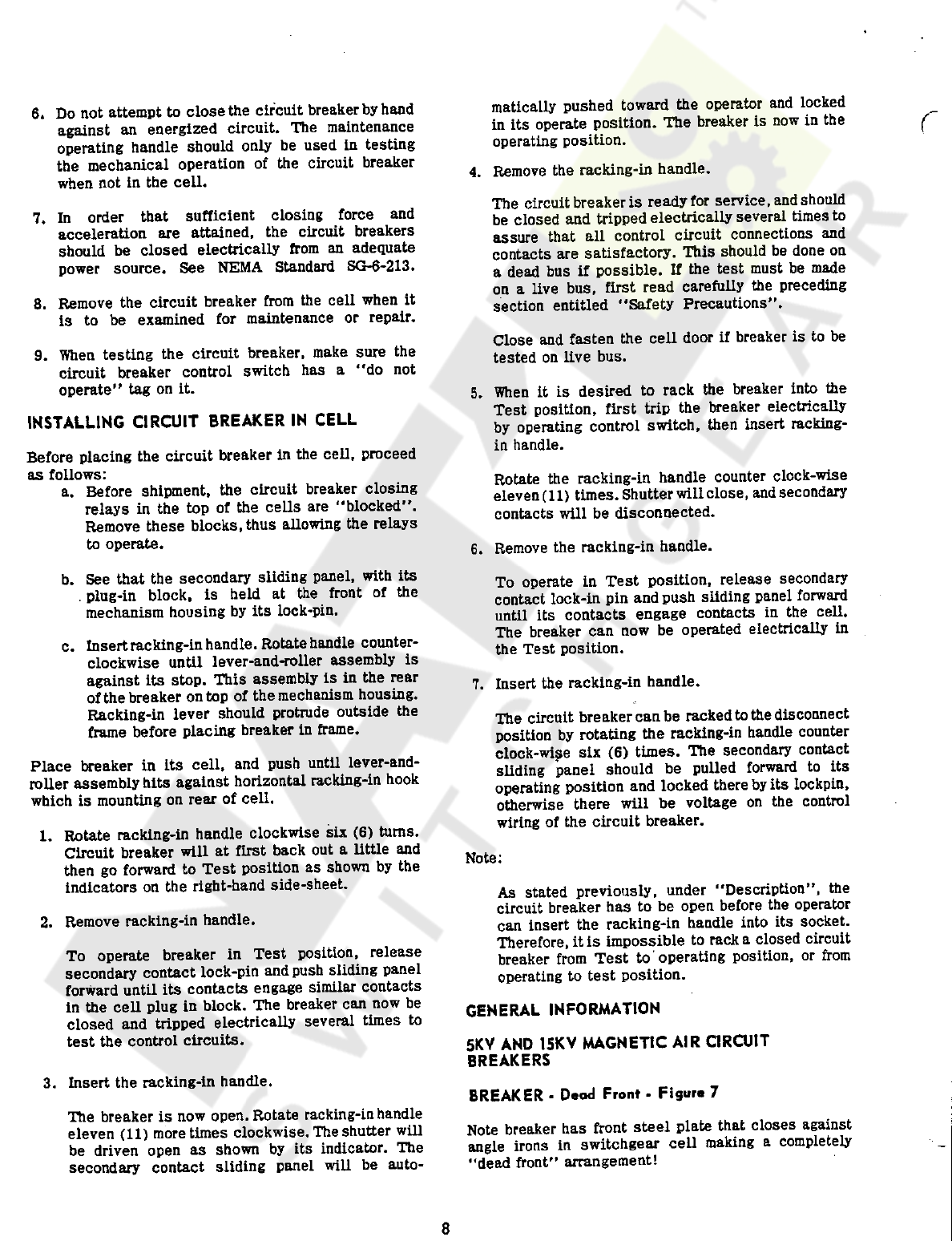

FIGURE

10

CLOSING

SOLENOID

-

Figure

11

Secondary

contacts

may

be

readily

engaged

from

front

of

breaker

,

before

breaker

is

placed

in

“

operating

"

position

.

Note

the

closing

solenoid

plunger

disc

.

At

points

near

the

close

of

the

closing

stroke

(

1

)

Breaker

contacts

are

closing

against

considerable

spring

pressure

and

(

2

)

The

breaker

may

be

required

to

close

against

fault

currents

within

its

full

capability

,

which

creates

great

mechanical

forces

tending

to

open

the

breaker

.

The

plunger

disc

gives

the

solenoid

additional

pull

and

“

zip

"

at

the

end

of

the

stroke

.

/

Horizontal

travel

of

contacts

considerably

exceeds

exact

distance

from

“

operating

"

to

“

test

"

position

which

eliminates

any

critical

adjustment

of

contact

movement

.

“

RACKING

-

IN

”

-

Figures

11

&

12

The

“

racking

-

in

"

device

is

simple

-

positive

-

sturdy

.

Only

two

moving

parts

:

(

1

)

Horizontal

shaft

,

manual

crank

on

one

end

;

worm

gear

on

opposite

end

.

(

2

)

Horizontally

rotating

lever

with

cam

roller

and

spur

gear

.

Requires

only

17.5

turns

for

full

travel

of

lever

cam

.

Breaker

is

in

“

test

"

position

(

clearly

indicated

in

cell

)

before

lever

cam

rotates

to

end

of

travel

.

This

means

breaker

is

firmly

locked

in

cell

in

“

test

"

position

.

INTERLOCKING

-

Figures

13

&

14

FIGURE

11

Simple

positive

interlock

bar

that

:

10

Courtesy of NationalSwitchgear.com

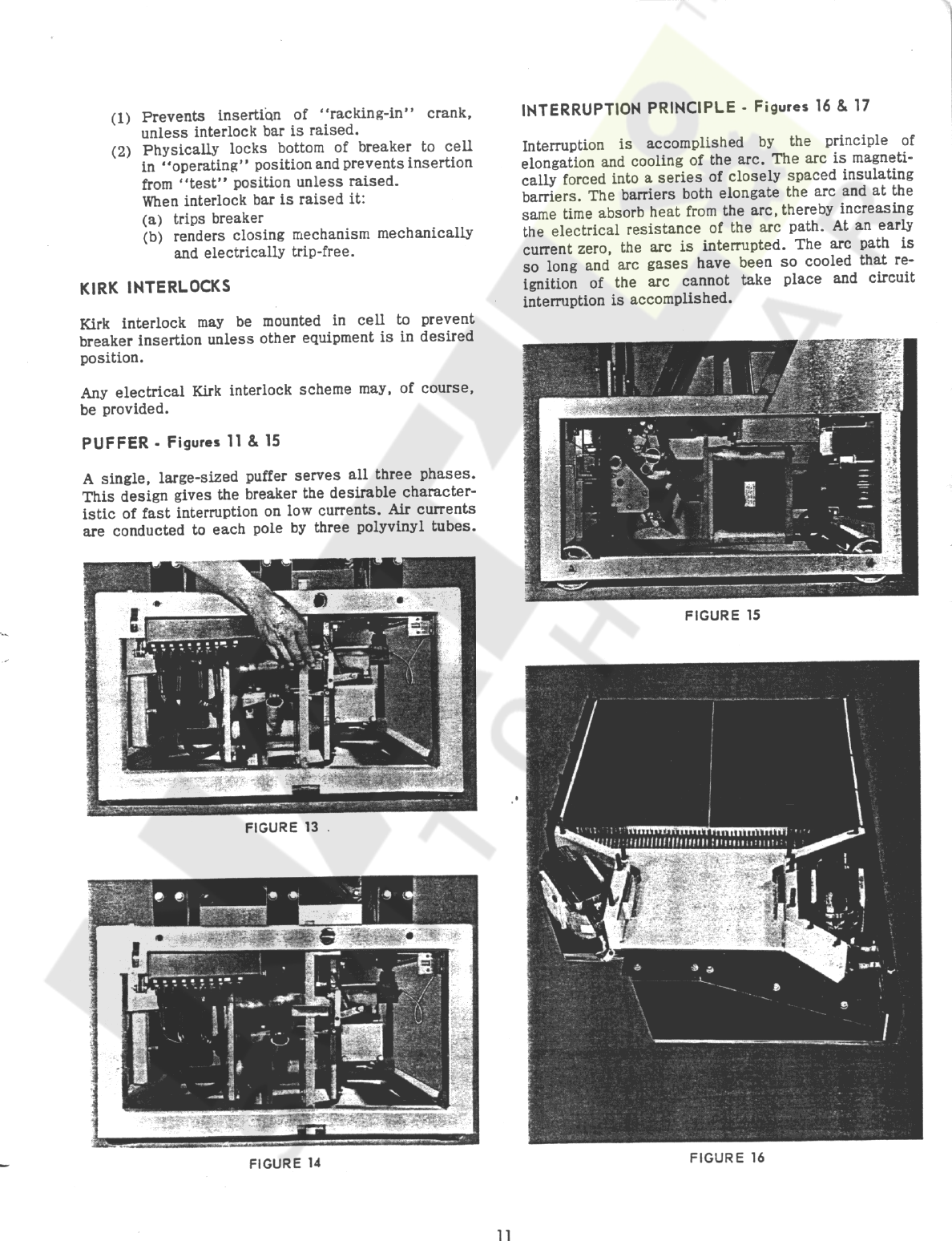

INTERRUPTION

PRINCIPLE

-

Figures

16

&

17

(

1

)

Prevents

insertion

of

1

‘

racking

-

in

*

*

crank

,

unless

interlock

bar

is

raised

.

(

2

)

Physically

locks

bottom

of

breaker

to

cell

in

“

operating

"

position

and

prevents

insertion

from

“

test

"

position

unless

raised

.

When

interlock

bar

is

raised

it

:

(

a

)

trips

breaker

(

b

)

renders

closing

mechanism

mechanically

and

electrically

trip

-

free

.

Interruption

is

accomplished

by

the

principle

of

elongation

and

cooling

of

the

arc

.

The

arc

is

magneti

-

cally

forced

into

a

series

of

closely

spaced

insulating

barriers

.

The

barriers

both

elongate

the

arc

and

at

the

same

time

absorb

heat

from

the

arc

,

thereby

increasing

the

electrical

resistance

of

the

arc

path

.

At

an

early

current

zero

,

the

arc

is

interrupted

.

The

arc

path

is

so

long

and

arc

gases

have

been

so

cooled

that

re

-

ignition

of

the

arc

cannot

take

place

and

circuit

interruption

is

accomplished

.

KIRK

INTERLOCKS

Kirk

interlock

may

be

mounted

in

cell

to

prevent

breaker

insertion

unless

other

equipment

is

in

desired

position

.

Any

electrical

Kirk

interlock

scheme

may

,

of

course

,

be

provided

.

PUFFER

-

Figures

11

&

15

A

single

,

large

-

sized

puffer

serves

all

three

phases

.

This

design

gives

the

breaker

the

desirable

character

-

istic

of

fast

interruption

on

low

currents

.

Air

currents

are

conducted

to

each

pole

by

three

polyvinyl

tubes

.

FIGURE

15

FIGURE

13

.

if

FIGURE

14

FIGURE

16

1 1

Courtesy of NationalSwitchgear.com

BAFFLE

MATERIAL

OF

15

KV

MAGNETIC

CIRCUIT

BREAKER

-

Figures

16

&

17

ARC

CHUTE

-

Figure

9

By

removing

one

bolt

,

the

arc

chute

may

be

easily

pushed

back

on

a

hinge

,

so

contacts

can

be

inspected

.

This

is

a

very

desirable

maintenance

feature

.

During

fault

interruptions

,

the

arc

which

has

a

temperature

of

several

thousand

degrees

F

comes

into

intimate

contact

with

the

splitter

plates

or

baffles

.

The

material

of

the

baffles

must

be

able

to

withstand

this

drastic

heat

-

shock

without

cracking

or

otherwise

disintegrating

.

CONTACTS

-

Figure

18

Main

contacts

of

heavy

copper

and

inlaid

silver

carry

the

normal

operating

current

when

breaker

is

in

opera

-

tion

.

Arcing

takes

place

between

contacts

of

special

alloys

which

are

extremely

resistant

to

arc

damage

.

The

arc

core

is

surrounded

by

hot

gases

which

need

to

be

cooled

at

a

high

rate

.

Fast

propagation

of

the

arc

helps

to

expose

large

areas

of

the

cool

baffle

plates

to

these

hot

gases

.

Porosity

of

the

baffle

material

is

of

particular

benefit

for

this

action

because

it

multiplies

the

surface

area

in

contact

with

the

gases

.

The

three

principle

attributes

which

we

are

looking

for

are

:

1

.

High

heat

-

shock

properties

.

2

.

Porosity

without

mechanical

weakening

.

3

.

Stability

under

high

humidity

.

These

three

qualities

are

not

independent

of

each

other

and

the

problem

for

the

engineer

consists

in

combining

them

into

the

best

possible

compromise

.

Federal

Pacific

engineers

have

succeeded

in

pro

-

ducing

a

material

which

we

believe

has

the

best

properties

available

today

.

FIGURE

17

Heat

shock

resistance

is

generally

a

property

of

high

zirconium

-

content

materials

and

our

baffle

material

is

a

high

zirconium

-

content

refractory

for

which

we

have

developed

special

treatments

to

assure

the

highest

heat

-

shock

resistant

properties

.

Some

materials

when

subjected

to

high

local

temperatures

^

expand

and

contract

at

different

rates

during

a

heating

and

cooling

cycle

.

This

results

in

permanent

distortion

with

high

"

locked

-

in

”

stresses

.

At

each

short

circuit

the

condition

becomes

worse

and

eventually

leads

to

cracking

of

the

plates

.

Our

material

is

stable

in

that

respect

and

no

internal

stresses

develop

.

Porosity

has

been

increased

progressively

during

the

development

of

the

DST

breaker

and

our

present

material

due

to

its

porosity

has

large

effective

area

.

Moisture

absorption

consists

essentially

of

two

types

:

A

.

Mechanical

absorption

of

moisture

.

B

.

Chemical

binding

of

moisture

.

A

.

Mechanical

absorption

of

moisture

is

determined

by

dipping

the

material

in

water

and

then

measuring

the

amount

of

water

absorbed

.

If

the

absorption

is

of

mechanical

nature

only

,

then

the

water

can

be

driven

out

quickly

by

heating

to

about

220

°

F

.

It

is

most

desirable

to

be

able

to

drive

out

all

of

the

water

in

this

manner

and

not

have

any

chemical

binding

.

Any

porous

material

has

the

ability

to

FIGURE

18

12

Courtesy of NationalSwitchgear.com

Solenoid

cut

-

off

switch

adjustment

absorb

varying

quantities

of

water

by

this

dipping

process

but

so

long

’

as

the

water

can

readily

evaporate

there

is

no

detrimental

side

reaction

to

this

type

of

water

absorption

.

Puffer

Shock

absorber

B

.

When

water

is

chemically

bound

,

it

can

usually

not

be

driven

off

by

a

220

°

F

heating

cycle

but

must

undergo

a

much

longer

heating

at

higher

tempera

-

ture

,

say

400

°

F

.

This

type

of

water

absorption

is

very

undesirable

and

usually

leads

to

excessive

warpage

of

the

plates

while

in

service

.

Auxiliary

switch

contact

Contact

adjustments

1

.

Main

2

.

Arcing

The

Federal

Pacific

baffle

material

has

shown

no

tendency

to

warp

because

it

does

not

chemically

bind

moisture

.

3

,

Cluster

Interlock

and

racking

-

in

mechanism

adjustment

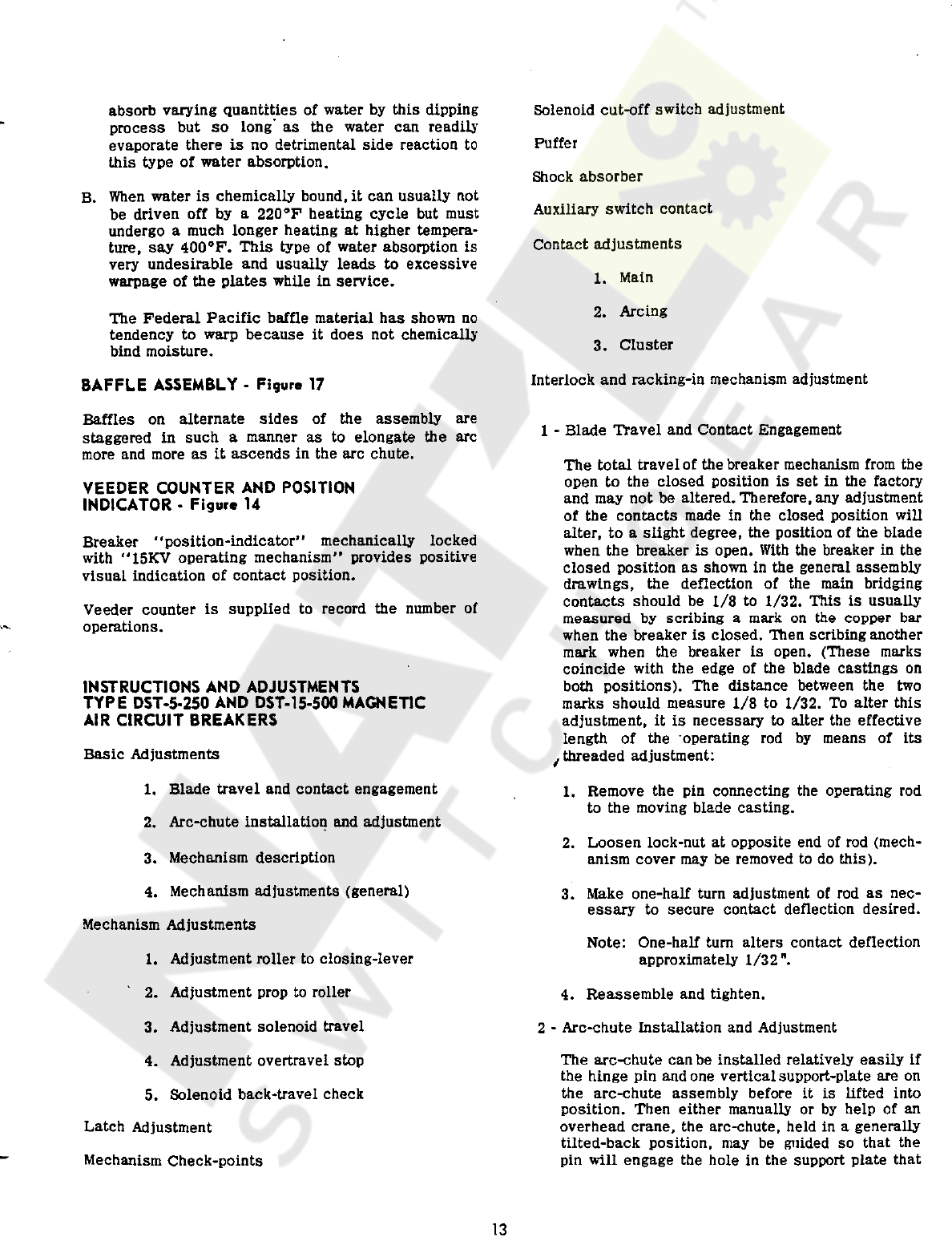

BAFFLE

ASSEMBLY

-

Figure

17

Baffles

on

alternate

sides

of

the

assembly

are

staggered

in

such

a

manner

as

to

elongate

the

arc

more

and

more

as

it

ascends

in

the

arc

chute

.

1

-

Blade

Travel

and

Contact

Engagement

The

total

travel

of

the

breaker

mechanism

from

the

open

to

the

closed

position

is

set

in

the

factory

and

may

not

be

altered

.

Therefore

,

any

adjustment

of

the

contacts

made

in

the

closed

position

will

alter

,

to

a

slight

degree

,

the

position

of

the

blade

when

the

breaker

is

open

.

With

the

breaker

in

the

closed

position

as

shown

in

the

general

assembly

drawings

,

the

deflection

of

the

main

bridging

contacts

should

be

1

/

8

to

1

/

32

,

This

is

usually

measured

by

scribing

a

mark

on

the

copper

bar

when

the

breaker

is

closed

.

Then

scribing

another

mark

when

the

breaker

is

open

.

(

These

marks

coincide

with

the

edge

of

the

blade

castings

on

both

positions

)

.

The

distance

between

the

two

marks

should

measure

1

/

8

to

1

/

32

.

To

alter

this

adjustment

,

it

is

necessary

to

alter

the

effective

length

of

the

operating

rod

by

means

of

its

/

threaded

adjustment

:

1

.

Remove

the

pin

connecting

the

operating

rod

to

the

moving

blade

casting

.

VEEDER

COUNTER

AND

POSITION

INDICATOR

-

Figur

*

14

Breaker

“

position

-

indicator

"

mechanically

locked

with

"

15

KV

operating

mechanism

"

provides

positive

visual

indication

of

contact

position

.

Veeder

counter

is

supplied

to

record

the

number

of

operations

.

INSTRUCTIONS

AND

ADJUSTMENTS

TYPE

DST

-

5

-

250

AND

DST

-

15

-

500

MAGNETIC

AIR

CIRCUIT

BREAKERS

Basic

Adjustments

1

.

Blade

travel

and

contact

engagement

2

.

Arc

-

chute

installation

and

adjustment

Loosen

lock

-

nut

at

opposite

end

of

rod

(

mech

-

anism

cover

may

be

removed

to

do

this

)

.

2

.

3

.

Mechanism

description

4

.

Mechanism

adjustments

(

general

)

Make

one

-

half

turn

adjustment

of

rod

as

nec

-

essary

to

secure

contact

deflection

desired

.

3

.

Mechanism

Adjustments

Note

:

One

-

half

turn

alters

contact

deflection

approximately

1

/

32

"

.

1

.

Adjustment

roller

to

closing

-

lever

2

.

Adjustment

prop

to

roller

4

.

Reassemble

and

tighten

.

3

.

Adjustment

solenoid

travel

2

-

Arc

-

chute

Installation

and

Adjustment

The

arc

-

chute

can

be

installed

relatively

easily

if

the

hinge

pin

and

one

vertical

support

-

plate

are

on

the

arc

-

chute

assembly

before

it

is

lifted

into

position

.

Then

either

manually

or

by

help

of

an

overhead

crane

,

the

arc

-

chute

,

held

in

a

generally

tilted

-

back

position

,

may

be

guided

so

that

the

pin

will

engage

the

hole

in

the

support

plate

that

4

.

Adjustment

overtravei

stop

5

.

Solenoid

back

-

travel

check

Latch

Adjustment

Mechanism

Check

-

points

13

Courtesy of NationalSwitchgear.com

surfaces

involved

;

one

on

the

nose

of

the

closing

lever

-

the

other

on

the

end

of

the

prop

.

is

left

fixed

to

the

upper

bushing

.

With

this

con

-

dition

achieved

,

it

is

relatively

easy

to

engage

the

flathead

screws

to

hold

the

other

upper

plate

to

the

bushing

.

r

The

first

step

in

this

procedure

is

to

adjust

the

position

of

the

roller

with

respect

to

the

closing

lever

.

This

is

done

by

altering

the

position

of

the

main

latch

assembly

by

the

insertion

or

re

-

moval

of

spacing

washers

that

bolt

this

assembly

to

the

mechanism

frame

.

With

the

roller

thus

adjusted

to

the

closing

lever

,

the

breaker

may

be

closed

,

and

the

position

of

the

prop

may

then

be

adjusted

to

the

roller

by

means

of

the

adjusting

castle

-

nut

on

the

prop

return

spring

rod

.

Note

for

5

KV

breaker

:

Cautionl

Install

copper

spacer

when

mounting

arc

-

chute

.

The

arc

-

chute

may

now

be

tilted

forward

and

the

front

support

bolt

or

bolts

tightened

.

It

is

then

possible

to

make

the

terminal

connections

between

the

coil

and

the

upper

bushing

.

If

the

arc

-

chute

is

not

vertical

when

mounted

,

it

is

usually

possible

to

tip

it

the

necessary

amount

after

front

support

bolts

are

loosened

With

this

accomplished

,

the

face

of

the

prop

and

the

face

of

the

closing

lever

will

coincide

when

the

breaker

is

in

the

closed

position

or

when

the

closing

lever

is

brought

up

lightly

against

the

roller

(

by

means

of

the

maintenance

manual

closing

lever

)

.

(

15

KV

only

)

.

3

-

Mechanism

Description

The

closing

mechanism

is

a

solenoid

operated

mechanical

trip

-

free

mechanism

which

closes

and

latches

the

breaker

against

the

operating

forces

exerted

by

the

contacts

,

operating

spring

,

and

electro

-

magnetic

forces

due

to

short

circuits

.

At

any

position

during

the

closing

operation

the

breaker

may

be

tripped

open

,

free

of

the

closing

energy

.

The

solenoid

pushes

on

the

closing

lever

which

is

shaped

somewhat

like

a

crescent

.

This

force

is

then

transmitted

to

the

main

operating

shaft

of

the

breaker

through

a

roller

which

is

held

in

a

fixed

relation

to

these

two

parts

.

If

the

position

of

the

roller

is

altered

,

it

breaks

the

connection

between

these

parts

,

and

the

main

shaft

is

then

free

to

move

to

the

open

position

.

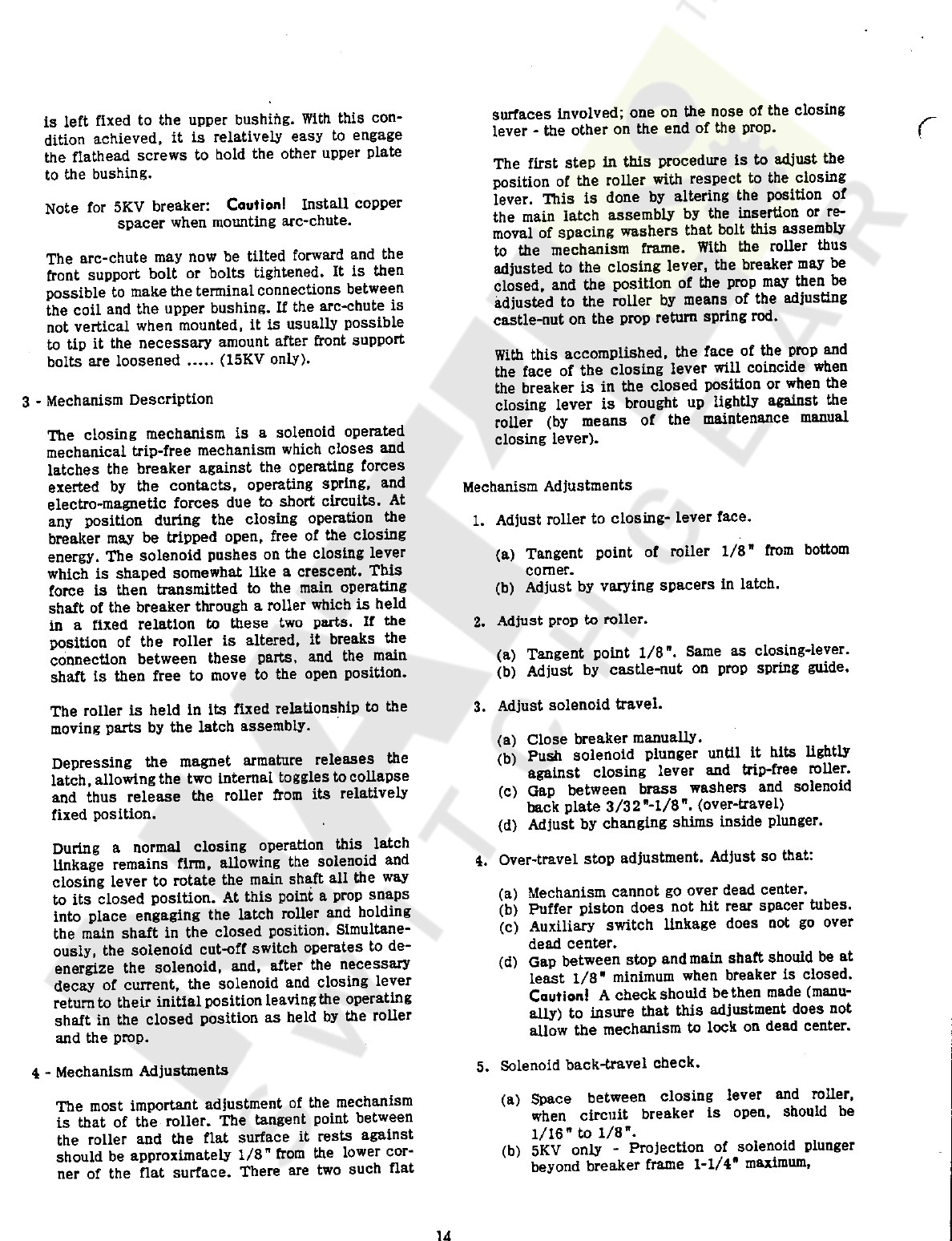

Mechanism

Adjustments

1

.

Adjust

roller

to

closing

-

lever

face

.

(

a

)

Tangent

point

of

roller

1

/

8

"

from

bottom

comer

.

(

b

)

Adjust

by

varying

spacers

in

latch

.

2

.

Adjust

prop

to

roller

.

(

a

)

Tangent

point

1

/

8

"

.

Same

as

closing

-

lever

.

(

b

)

Adjust

by

castle

-

nut

on

prop

spring

guide

.

The

roller

is

held

in

its

fixed

relationship

to

the

moving

parts

by

the

latch

assembly

.

3

.

Adjust

solenoid

travel

.

(

a

)

Close

breaker

manually

.

(

b

)

Push

solenoid

plunger

until

it

hits

lightly

against

closing

lever

and

trip

-

free

roller

.

(

c

)

Gap

between

brass

washers

and

solenoid

back

plate

3

/

32

"

-

1

/

8

"

.

(

over

-

travel

)

(

d

)

Adjust

by

changing

shims

inside

plunger

.

Depressing

the

magnet

armature

releases

the

latch

,

allowing

the

two

internal

toggles

to

collapse

and

thus

release

the

roller

from

its

relatively

fixed

position

.

During

a

normal

closing

operation

this

latch

linkage

remains

firm

,

allowing

the

solenoid

and

closing

lever

to

rotate

the

main

shaft

all

the

way

to

its

closed

position

.

At

this

point

a

prop

snaps

into

place

engaging

the

latch

roller

and

holding

the

main

shaft

in

the

closed

position

.

Simultane

-

ously

,

the

solenoid

cut

-

off

switch

operates

to

de

-

energize

the

solenoid

,

and

,

after

the

necessary

decay

of

current

,

the

solenoid

and

closing

lever

return

to

their

initial

position

leaving

the

operating

shaft

in

the

closed

position

as

held

by

the

roller

and

the

prop

.

4

.

Over

-

travel

stop

adjustment

.

Adjust

so

that

:

(

a

)

Mechanism

cannot

go

over

dead

center

.

(

b

)

Puffer

piston

does

not

hit

rear

spacer

tubes

.

(

c

)

Auxiliary

switch

linkage

does

not

go

over

dead

center

.

(

d

)

Gap

between

stop

and

main

shaft

should

be

at

least

1

/

8

"

minimum

when

breaker

is

closed

.

Caution

!

A

check

should

be

then

made

(

manu

-

ally

)

to

insure

that

this

adjustment

does

not

allow

the

mechanism

to

lock

on

dead

center

.

5

.

Solenoid

back

-

travel

check

.

4

-

Mechanism

Adjustments

(

a

)

Space

between

closing

lever

and

roller

,

when

circuit

breaker

is

open

,

should

be

1

/

16

n

to

1

/

8

n

.

(

b

)

5

KV

only

-

Projection

of

solenoid

plunger

beyond

breaker

frame

1

-

1

/

4

"

maximum

,

The

most

important

adjustment

of

the

mechanism

is

that

of

the

roller

.

The

tangent

point

between

the

roller

and

the

flat

surface

it

rests

against

should

be

approximately

1

/

8

"

from

the

lower

cor

-

ner

of

the

flat

surface

.

There

are

two

such

flat

U

Courtesy of NationalSwitchgear.com

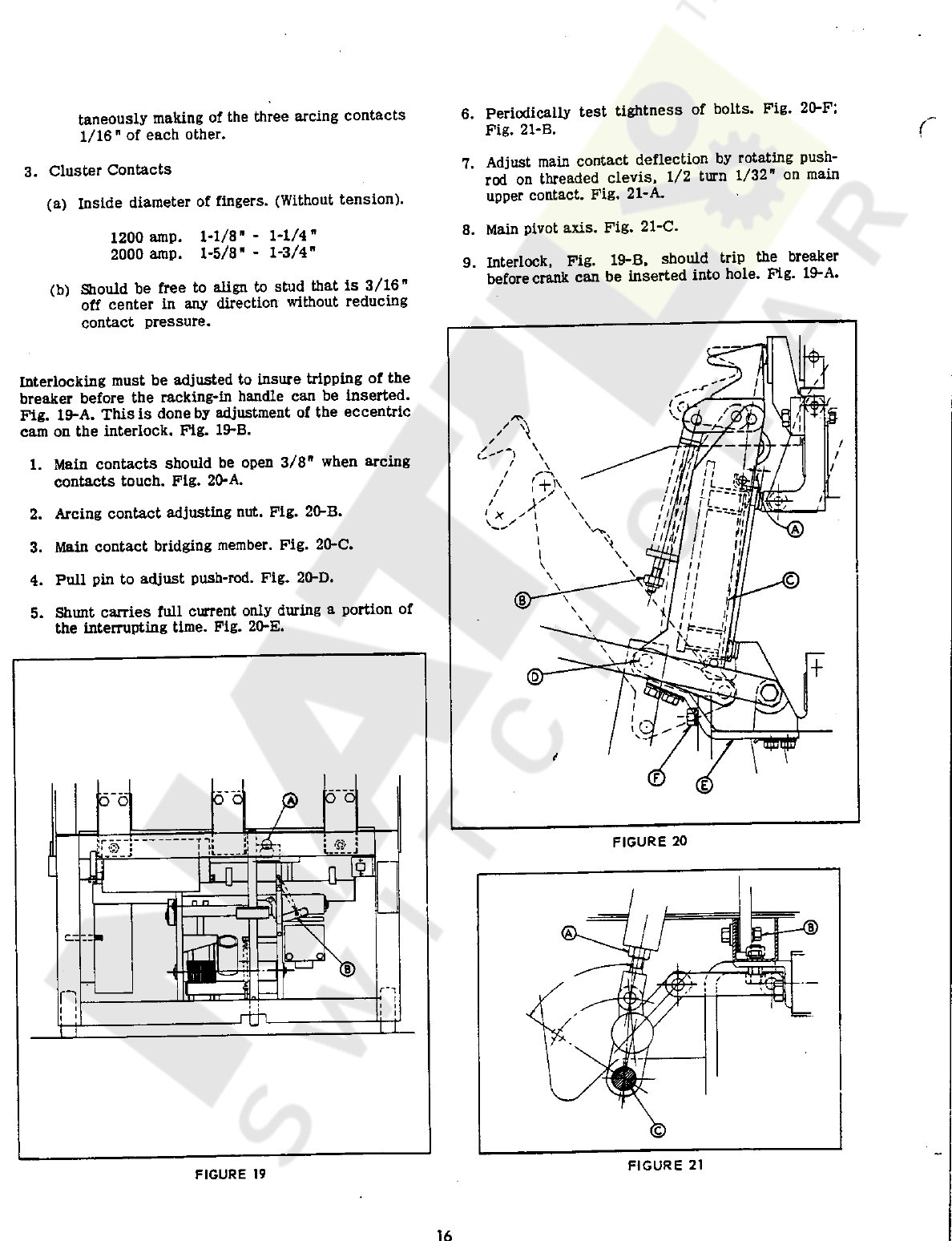

4

.

Piston

should

not

hit

tubular

spaces

in

back

.

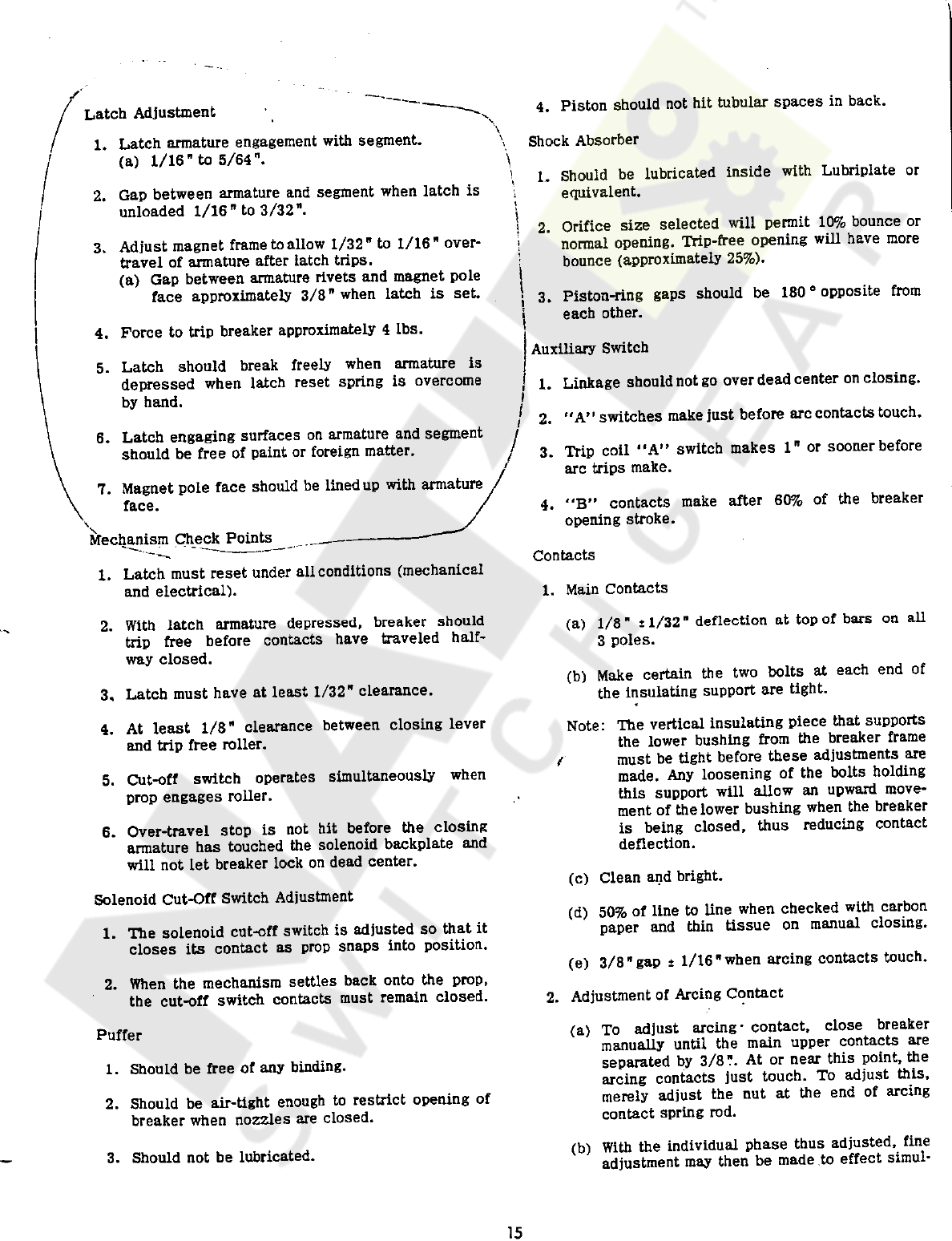

Latch

Adjustment

X

\

v

1

.

Latch

armature

engagement

with

segment

,

(

a