Siemens-Allis LA-600A User manual

WARRANTY

Allis-Chalmers

"LA"

air

circuit

breakers

are

warranted

to

be

free

of

defects

in

material

and

workmanship for a

period

of

one

year

from

date

of

initial

operation

but

not more

than

eighteen

months from

date

of

shipment

by

company.

This

warranty

is limited to

the

furnishing

of

any

part

which

to

our

satisfaction

has

been

proven

defective.

Allis-Chalmers

will

not

in

any

case

assume

responsibility for

allied

equipment

of

any

kind.

(See

Allis-Chalmers

W

arranty

Form

5992-23.

)

Typical Shipping Methods Used With

"LA"

Breakers

,I .

Courtesy of NationalSwitchgear.com

r··

-TABLE OF

CONTENTS

WARH.ANTY

. . . . . . . . . . . . . . . . . . . . . . • . . . • . 1

REC1£VJNG

A~

.Ll

i

l\SPE

C'l'ION . . . . . . . . . . . . . . . 3

Introdu

ct

io

n . . . . . . . . . . . . . . . • • • . . 3

P..eceiving and lnspt>c

tion

for DamagP . . . • . • . . . . 3

St.crag~

. . . . . . . . . . . . . . . . . . . . . . • . . . . . . .

;;

INS'

fALLATlON

..

. . . . . . . . . . . . . . . . . . . . • . . . 3

Installation

Sequen

ce

. . . . . . . . . . . . . . . . . . . . . 3

Cautions

to

be

Observed in Installa.t

jon

and

Op<

!

ration

............

, . . . . • 4

OPERATION

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

De

sc

riptio

n

..

...

.

..........

.

..

.

..

.

..

. . .

{A) Manually

Opera

t

~d

Circuit. B

reak

ers . .

..

.•.

..

(B) Electrically

Operat

ed

Circuit Break

er

s .

..

.

..

.

(C)

Comb

ina

lion E.O. & M.O.

Opera

t

ed

4

6

6

Ci

rcuit

Break

~ rs.

. . . . . . . . . . . . . . . . . . . . 9

Ora

woul

Int

erl

ock

. . . . . . . . . . • . . . . . . . . . . . . 9

Rllcklng Mechanism . . . . . . . . . . . • . . . . . . . . . . 9

Spring

Discharge

In

te

rlo

ck ...

..

. . . .

..

.

......

JO

Li!ting

Bar . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11

Handling

In

struct

i

ons

. . . . . . . . . . . . . . . . . . . 11

MAINTENAN

CE

AND

ADJUSTMENT

S .

......

.

..

12

Maintenan

ce . .

.....

.

..

....

...

....

. .

..

. .

L

ubrication

........

. .

....

.

..

. . .

......

.

Maintenan

ce Closing

....

.

..

..

.

..

. .

..

.

....

.

Adjustme

nts

.

.......

.

..

. . . •

.....

.

....

..

Trip-Latch

Engageme

nt

.....

• .

..

..

...

..

. .

Main

Contact

Make

.....

....

..

.

..

......

Arcing

Co

nt

act

Make

.......

.

..

.

...

.....

12

13

14

16

16

17

17

Contact

Repla

ce

m

ent

. . . . . . . . . . . . . • . . . . . .

18

Ms

in

Contact

Fing

er.

. . . . . . . • . . . . . . . . . . . 18

Stationary

Arcing

Contact

. . . . . . . . . . • . . . . .

111

Hinge Cont.act Fingers

....

. .

..

..

....

· · · · · 18

Movable Arching

and

Main

Contact

. . . . . . . . .

lB

Ttlpping

Actual.or . . . . . . . . . . . . . . . . . . . . . . . 18

Motor

Cutoff

g,.;tch

. . . . . . . . . . . . . . . . . . . . . 19

Se

condary

Disconnect

Assembly

Option

. . . . . . 25

Auxiliary

Switch

Option

. . . . . . . . . . . . . . . . .

26

Shunt

Trip

Option

. . . . . . . . . . . . . . . . . . . . . 27

FUSE

FUNCTIONS

.....

.

.•

.

..

. .

....

....

...

20

Current

Limiting

Fuses . .

.....•....

.

.......

20

Open

Fuse

Trip

Device . . . . . . . . . . . . . . . . . . . . 23

ACCESSORIES . . .

...

.

.........

.

......

.

..

. 2

4.

Current

Sensors

-

Li

mi

Tri

p

........

. . .

... ...

24

Tripping

Transformers

-St.atic

Trip

Il.

. . . . . . . . . 24

OPTIONAL

DEVICES . .

..

.

........

...

......

25

Secondary

Dis

conne

ct

Assembly

Option

. .

.......

25

Auxiliary Switch

Option

. . . . . . . . . . . . . . . . . . .

26

Undervolt.age

Trip

Device

Option

...........

. . 21

\Shunt

Trip

Option

..

.......

. .

...

.........

27

Stati

c

Trip

Option

.......................

27

Bell

Alarm

Switch

Option

. . . . . . . . . . . . . . . . . .

28

LUBRICATION

INSTRUCTIONS

...............

28

INSTRUCTION

BOOK

REFERENCES

. . . . . Back

rover

ILLUSTRATIONS

Figure 1.

Flgur

e 2.

Flgut10

3.

_,Figure

3A

.

Fl&Urf

4.

Figure 5.

Flgurt>

6.

F1gure

7.

Figure 8.

Figure 9.

Figure

10.

F1gure 11.

Figure 12.

Figure

13.

Figure

14.

F1gure

15

.

Figure

16

.

F1gure

17

.

Figure

18

.

Typical

Shipping

Method

used

with

"LA"

Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Fused

&

Unfused

Breakers with

Static

Trip

II

and

LimiTrip

Overcurrent

Trip

Devices . . . . . . . . . . . . . . . . 2

LA-6

00

A,

LA·800A

and

LA-16

00

A O

perator

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . • . . . . 7

Typical

Wiring Diagram - El

eclricaliy

Operated

Brea.

kers

. . . . . . . . . . . . . . . . . . . . . . . . . • . . . . . . .

..

. 8

Detail of Typical

Rac

king

Me

chan

ism

an

d

Drawout

Interlock

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Typical Racking Mechanism

and

Dr.twout

Interlock

..

....

.

...

.

.....

.

.....

.

...

• .

....

..

..

. . .

10

Typical LA·

1600A

Br

eaker

Ouliine .

..

.

..

.

....

.

.....

. . .

.........

..

•

............

.

..

.

..

12

Typical

LA·600A

and

LA·80

0A

Breaker Out(ine

...................

•

....

• . •

...

•.•..

......

13

Maintenan

ce Closing .......

.....

. .

..

.............

.

....

. .

..

...

.....

.......

. .

....

15

Typical

Ope

rator

Assembly. . .

....

..............................

. .

...........

.

.....

.

16

Contact

ASM!m

bly

....

..

....

.....

..

. .

..

.

..

.....

.

..................

. .

..........

.

17

Fuse

Atta

ch

me

nt

Group

LAF-600A,

LAF-800A

Breakers

...........

.

.......

......

.

..

....

.

..

21

Fuse

Attad1ment

G

rou

p

LAF

-1

600A

Breaker

.

.......

..

..........

.

...................

.

..

22

LAF-600

A, LA

F-800A

and

LAF·1600A

Open

Fiise

Trip

Device,Trigger

Fuse

Assembly

...............

23

LA·600A

,

LA-800A

and

LA

-

1600A

Sccon

.

dary

Disconnect

Group

..

. .

.........................

25

LA-600A

,

LA-800A

and

LA-

1600A

Auxiliary

Switc

h

Group

.................................

26

Undenolla

.ge

Trip

with

or

wit

hout

Time

Delay

. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

LA·

600A

,

LA-800A

and

LA·l600A

Shunt

Trip

Group

.

.....

. .

.....•.

..

.

..

.

..

. . .

..

.

..

.

..

.

..

27

LA-

60

0A,

LA·

OO

OA

and

LA

·1600A

Alarm

Switch

Group,

Bell

Alann

.........•..............

.

..

28

Lubricati

on

Cha

rt

..

..

....

.

.....

.

.........

.

.......

.

....................

. . .

..

.

..

29

Lubrication

Points

on

.Breaker .

.........

.

..

...

....

.

........

.

..

.......

.

.......

.

.....

30

TABLES

'Tlble

1.

Ci

rcuit

Breaker

Rating

8

at

60

Hertz

. . . . . . . 5

Table

2.

Fused

Circuit

Breaker

Ratings

at

60

Hertz

. . . 5

'fible

3. Opera.ting

Procedure

-Manually

'fible

5.

Main

tenance

Closing . . . . . . . . . . . . . . . . .

14

'fible

6.

Static

'nip

II

Rating

'fible

-

Amperes

. . . . . 24

'fible

7.

limiTrip

Rating

Table

-

Amperes

. .

....•.

24

Operat

ed Breakers . . . . . . . . . . . . . . . . . 6

Table

4.

Operatin

g

Procedurt

-Electrically

Operated

Breakers . . ,. . . . .

..

...

..

, . . 6

\

The

info

rm

ation

cont

si

nod

within

is

int

ended

to

assist

operating

pe

r

.onnel

by

providing

information

on

th

e

general

c

haracteris

tics

of

l

equipment

of

this

ty

pe.

It

does

not

reliev

e

the

us

er

of

responsibility

to

use

sound

engineering

practices

In

the

installation,

epplicetion

,

operation

and m

eintenanc

e

of

the

particular

<>quipment

purch

a

sed.

I\

drawings

or

other

sup

p

lemt>ntar

y

in

struc

tion

s

for

specific

applications

ere

forwarded

with

thi

s

manual

or

s

ep

o

rata

ly,

they

take

preceden

cej

o

vor

any

confli

cting

or

incom

p

lete

Information

in

t

his

manual

.

-.

' I

i

Courtesy of NationalSwitchgear.com

I

INSTALLATION

AND

INSPECTION

Introduction

....

. .

..

.

...

·

..

Receiving

and

Inspection

for

Damage

Installation

. .

Storage

....

Maintenance.

OPERATION

.

Description

.

Manually-Operated

Breaker

Electrically

-Operated Breaker .

Racking

Mechanism,

Drawout

Interlock,

and

Lifting

Bar

......

. . . .

Spring

Discharge

Interlock

.

MAINTENANCE

AND

ADJUSTMENTS

Maintenance . . . . .

Lubrication

. . . . .

Maintenance Closing

Adjustm

ents . . . . .

Trip-Latch

Engagement

Main

Contact

Make

..

Arcing

Contact

Make.

Fig. 1

Typical

LA-1600A

Breaker

Outline.

Fig. 2

Typical

LA-600A

Breaker

Outline

.

Fig. 3

LA-600A/LA-1600A

Operator

. . .

Fig.

4

Typical

Wiring

Diagram -

Electrically

Operated Breakers

......

.

..

Fig. 5

Typica

l'

Racking

Mechanism and

Drawout

Interlock

.

..

Fig. 6 Maintenance Closing . .

Fig. 7

Typ

ical Panel Assembly

..

..

..

Fig. 8 Fuse

Attachment

Group

LAF-600A

Breaker

Fig. 9 Fuse

Attachment

Group

LAF

-

1600A

Breaker.

Table

1

Operating

Procedure -

Manually-

.1

.1

.1

.1

.2

.2

.3

.3

.3

.4

.5

.6

.8

.8

.9

.9

.

10

.

10

.

10

. 11

.

18

.

18

.

19

.

20

.

21

.

22

.

23

.

24

.

25

Operated Breakers . . . . . . . . . . . . . . . . . . . .

..

4

Table

2

Operat

ing Procedure -

Electrically-

Operated Breakers . . . . . . . . . . . . . . . . . . . . . . . 5

Contact

Replacement

..

. . .

Main

Contact

Fingers

...

.

Stationary

Arcing

Contact.

Hinge

Contact

Fingers .

..

Moving

Arcing

and

Main

Contact

.

Tripping

Ac

t

uator.

FUSE

FUNCTIONS

Current

Limit

Fuse .

Trigger

Fuse .

....

TRIPPING

TRANSFORMERS

OPTIONAL

DEVICES

. .

...

Secondary

Disconnect

Assem.

Option

Auxiliary

Switch

Option

......

Shunt

Trip

Option

...

. .

..

. .

Undervoltage

Trip

Device

Option

.

Bell

Alarm

Switch

Option

Static

Trip

Optio

n . . . .

..

.

..

Fig.

10

LAF-600A/1600A

Anti-Single

Phase

Device,

Trigger Fuse Assembly

.....

.

.......

Fig.

11

LA-600A/1600A

Secondary Disconnect

Group

.

Fig.

12

LA-600A/1600A

Auxiliary

Switch

Group

...

.

Fig

.

13

LA-600A/1600A

Shunt

Trip

Group

.......

Fig.

14

LA-600A/1600A

Under

Voltage

Trip

Attachment

.

Fig.

15

LA-600A/1600A

Alarm

Switch

Group,

Bell

Alarm.

Fig.

16

Motor

Cutoff

Switch

Action

..

Fig.

17

Lubrication

Points

on

Breaker.

Fig.

18

Lubr

i

cation

Chart.

. . . . . . .

Table

3 Maintenance Closing

..

.

..

.

Table

4

Trip

Rating

Table

-

Amperes

.

.

11

.

11

.

11

.

11

.

12

.

12

.

14

.

14

.

14

.

15

.

15

.

15

.

15

.

15

.

15

.

17

.

17

.

26

.

27

.

28

.

29

.

30

. 31

.

32

.

33

.

34

.

10

.

16

The

information

contained

within

is

intended

to

assist

operating

personnel

by

providing

information

on

the

general characteristics

of

equipment

of

this

type.

It

does

not

relieve

the

user

of

responsibility

to

use

sound

engineering

practices

in

the

installation,

application,

operation

and

maintenance

of

the

particular

equipment

purchased.

If

drawings

or

other

supplementary

instructions

for

specific

applications

are

forwarded

with

this

manual

or

separately,

they

ta

ke precedence

over

any

conflicting

or

incomplete

information

in

th

is manual.

Courtesy of NationalSwitchgear.com

/

INSTALLATION

AND

INSPECTION

INTRODUCTION

The

type

"LA"

air

circuit

breakers

may

be

furnished for mounting in

any

one

of

three

ways.

They

may

be

used in

metal-enclosed

switchgear

of

the

drawout

type,

in

individual

enclosures

(drawout

type),

or

for

stationary

mounting in a

customer's

own

enclosing

case

or

switchboard.

All "LA

...

breakers

are

completely

assembled,

tested,

and

calibrated

at

the

factory

in a

vertical

position

and

must

be

so

installed

to

operate

properly.

Customer's

primary

connections

should

be

ad-

equately

braced

against

the

effects

of

short

circuit

currents

to

prevent

overstressing

the

breaker

terminals.

RECEIVING

AND

INSPECTION FOR DAMAGE

Immediately

upon.

receipt

of

this

equipment,

carefully

remove

all

packing

traces

and

examine

parts,

checking

them

against

the

packing

list

and

noting

any

damages

incurred

in

transit.

If

such is

disclosed,

a

damage

claim

should

be

filed

at

once

by

the

customer

with

the

transportation

company

and

Al

I

is-Chalmers

notified.

Two shipping methods

are

used

with

11

LA

11

breakers:

l.

Individually

with

protective

covering.

2.

Within

a

cubicle

when

part

of

a

switchgear

lineup.

Breakers shipped.in

their

cubicles

are

,·

'·;:.

")

-

--

blocked

to

prevent

accidental

tripping

during

shipment.

Note

al

I

caution

tags,

remove 1 .. :

1.

blocking

bolts,

and

open

breaker

contacts

before

installation.

\

"11

INSTALLATION .

The

11

LA

11

air

circuit

breaker

is

completely

adjusted,

tested,

and

inspected

before

shipment,

but

a

careful

check

should

be

made

to

be

certain

that

shipment

or

storage

has

not

resulted

in

damage

or

change

of

adjustment.

Circuit

breakers

should

be

installed

in a

clean,

dry,

well-ventilated

area

in

which

the

atmosphere

is

free

from

destructive

acid

or

alkali

fumes.

Stationary-type

breakers

should

be

mounted high

enough

to

prevent

injury

to

personnel

either

from

circuit

in-

terruption

or

from moving

parts

during

automatic

opening

of

the

breaker.

Al low

sufficient

space

to

permit

access

for

cleaning

and

inspection

and

adequate

clearance

to

insulating

barrier

above

the

breaker

to

prevent

damage

from

arcing

during

interruption.

Before

installing,

make

certain

that

the

breaker

contacts

are

in

the

open

position.

1.

After

the

breaker

is

installed

in

position,

close

.

it

manually

by

the

maintenance

closing

method

(see

MAINTENANCE

AND

ADJUSTMENTS,

page

8 )

to

check

proper

functioning

of

the

mechanism

and

contacts.

CAUTION!!

MAKE

SURE

CIRCUIT

IS

NOT

ENERGIZED.

During

the

closing

operation,

observe

that

the

contacts

move

freely

without

interference

or

rubbing

between

·

movable

arcing

contacts

and

parts

of

the

arc

chutes.

Then

refer

to

OPERATION,

page

3 for a

detailed

description

of

the

circuit

breaker

operating

char-

acteristics

before

putting

the

breaker

in

service.

Courtesy of NationalSwitchgear.com

2.

Trip

units

and

accessory

devices

should

receive

a

thorough

check

prior

to

pl

acing

the

r ' -

breaker

in

service

to

be

certain

that

adjustments

are

proper

and

parts

are

not

damaged.

4IJ

Refer

to

Static

Trip

Device

Instruction

Book 18X4827.

~

w

3.

Cubicle

-mounted

breakers

of

the

drawout

type

are

equipped

with

a

drawout

interlock

to

prevent

movement

of

a

closed

breaker

into

or

out

of

the

connected

position.

See

DRAW-

OUT

INTERLOCK,

page

5 for a

description

of

the

interlock.

Its

operation

should

be

checked

before

the

breaker

is

energized.

4.

Upon

completion

of

the

installation

inspection,

the

breaker

is

ready

to

be

energized

after

the

control

wiring,

if

any,

is

checked

and

the

insulation

tested.

STORAGE

When

breakers

are

not

to

be

put

into

immediate

use,

they

should

be

wrapped

or

covered

with

a

non-absorbent

material

to

provide

protection

from

plaster,

concrete

dust,

or

other

foreign

matter.

Breakers should

not

be

exposed

to

the

action

of

corrosive

gases

or

moisture.

In

areas

of

high

humidity

or

temperature

fluctuations,

space

heaters

or

the

equivalent

should

be

provided.

MAINTENANCE

Occasional

checking

and

cleaning

of

the

breaker

will

promote

long

and

trouble

-

free

service.

A

periodic

inspection

and

servicing

at

least

every

six

months should

be

included

in

the

breaker

maintenance

routine.

If

the

circuit

breaker

is

not

operated

during

extended

periods,

the

breaker

should

not

remain

in

either

the

closed

or

open

position

any

longer

than

six

months.

Maintenance

opening

and

closing

operations

should

be

made

to

ensure

freedom

of

movement

of

all

parts.

CAUTIONS

TO

BE

OBSERVED

IN

THE

INSTALLATION

AND

OPERATION

OF

11

LA

11

CIRCUIT

BREAKERS

1.

Read

Instruction

Book

before

installing

or

making

any

changes

or

adjustments

on

the

breaker.

2.

As

the

closing

springs

on

stored-energy

breakers

may

be

charged

in

either

the

breaker

open

or

closed

position,

extreme

care

should

be

taken

to

discharge

the

springs

before

working

on

the

breaker.

3.

4.

5.

6.

7.

When closing manually-operated breakers

out

of

this

unit,

the

racking mechani

sm

mu

st

be

re-

turned

to

the test position before closing springs can be charged.

When

closing

manually

-

operated

breakers,

always

grasp

closing

handle

firmly

until

it

is

returned

to

the

normal

vertical

position.

.

Check

current

ratings

against

single

line

diagram

to

assure

that

breakers

are

properly

located

in

switchgear

at

installation.

Check

the

alignment

of

the

secondary

disconnect

fingers

to

ensure

against

misalignment

due

to

possible

distortion

of

fingers

during

shipment

and

handling.

Once

the

breaker

is

energized,

it

should

not

be

touched,

except

for

operating,

since

most

of

the

component

parts

are

also

energized

.

2

Courtesy of NationalSwitchgear.com

I

OPERATION

D

ESCRI

PTI

ON

The

LA-600A

air

circuit

breaker

has

a

maximum

continuous

current

rating

of

600

amperes, and

an

inter-

ruption

rating

of

25,000

amperes

at

254,

508

volts

60

Hz,

or

22,000

amperes at

635

volts

60

Hz. when

.

used

with

the

short

time

delay

trip

deivce.

With

instantaneous

trip

device, the

interruption

rat

ing

is

42,000

amperes

at

254

volts,

30,000

amperes

at

508

volts and

22,000

amperes

at

635

volts.

The

LA-1600A

circuit

breaker

has

a continuous current rating

of

1600 amperes and an

interruption

rating

of

50,000

amperes

at

254

and

508

volts,

or

42,000

amperes at

635

volts when

used

with

the short

time

delay

trip

device. The

interruption

with

intantaneous

trip

device

is

65,000

amperes

at

254

volts,

50,000

amperes

at

508

volts and

42,000

amperes at

635

vo

lt

s.

All

currents are symmetrical amperes and voltages

are maximum.

The

breakers

are

also

available

with

integrally

mounted

current

limit fuses. The basic

breakers

are

the

same

with

or

without

the

fuses. The fuses mount on a

bracket

arrangement

that

is

bolted

to

the

side

rails

and upper studs on

the

back

of

the

breaker.

The

current

limit fuses

increase

the

interruption

rating to

that

of

the

fuses. Fused

breakers

are

identified

as LAF-600A,

and

LAF-1600A. Fused

breakers

are

also

equipped

with

an

anti-single

phase

device

to

open

the

breaker

if

one

or

more

current

limit fuses

open.

The

breakers

can

aiso

be

supplied for

stationary

mounting in which

the

racking

components

are

omitted,

and

brackets

are

provided for mounting

to

a

stationary

frame. ·

Both

the

LA-600A

and

LA-l600A

circuit

breakers

use

the

same closing mechanism

or

operator.

·

'-

~

:·

l..

The

closing

springs

are

larger

for

the

1600

ampere

breaker.

Three configurations

of

the

operator

W

are

available

for charging

the

closing springs.

These

are

manual

charging,

electrical

charging

and

combination

manual-electrical

charging.

Al

I

operators

are

identical

except

for

the

means

of

supplying

energy

to

the

closing springs.

A

double-toggle,

trip-free

mechanism is used;

that

is,

the

breaker

contacts

are

free

to

open

at

any

time,

if

required,

regardless

of

the

position

of

the

mechanism.

Manua

11

y-Operated

Breakers ·

The

breaker

has a

center-mounted

frame so many

of

the

latches

and links

are

arranged

in

pairs,

for

descriptive

purposes

they

wi

11

be

referred

to

as

single

items.

Refer to Figure 3

and

Table

l.

Detail

"A

11

shows

the

position

of

the

trip

latch

and

toggle

linkage

when

the

breaker

is

open

and

the

closing springs

are

discharged.

Movement

of

the

charging

handle

downward

rotates

closing

cam (65)

against

roller

(28) thus

pivoting

closing

cam (19)

clockwise

about

pin

(76)

and

extending

the

closing springs thru link (23)

and

spring

hanger

(17).

Rotation

of

cam (19)

allows

roller

(41)

in

toggle

linkage

to

be

moved

into

position shown in Detail

"B".

Kickoff spring (59) moves

rollers

away

from stop

block

(31),

then

the

toggle

linkage

is moved

by

torsion spring until

latch

(35)

clears

trip

latch

(13).

Spring (15)

causes

trip

latch

(13)

to

reset

under

latch

(35).

Trip

flat

(14) should normally stop

against

the

front

surface

of

latch

(35).

When

the

closing springs

are

fully

charged,

roller

(28)

engages

latch

(7).

Charging

cam

(65)

:._

~

engages

a pawl in such a manner

that

the

charging

cam must

complete

the

charging

stroke

before

it

can

return to its normal

position.

3

Courtesy of NationalSwitchgear.com

With

the

ch

argin

g

handle

in

its

normal upright

position,

the

breaker

ca

n

be

closed.

By

pressing

firmly

on

ho

od

(8)

latch

(7)

will

disengage

roller

(28)

and

closing springs

cause

closing cam (19)

to

rotate

against

the

tog

gle

rollers

(

41

) moving

the

toggle

into

its

upr

ight

pcsition,

shown in

de

tail

"C".

The closing

cycle

can

be

interrupted

at

any

point

by

operation

of

one

of

the

tripping

means,

which

cause

rotatio

n

of

trip

latch (13) to a

position

that

release

latch

(35)

allowing

togg

le

I

inkage

to

collapse to

the

position shown in

detai

I

"A".

Manual

opening

of

the

breaker

is

accom

plis

hed

by pressing

on

trip

bar

(48),

this

bar

engages

the

top

of

trip

fl

ap (14)

which

is

in

turn

arranged

to

disenga

ge

the

t

rip

latch.

TABLE

1 - OPERATING PROCEDURE -MANUALLY-OPERATED

BREAKE

RS

Oeeration

Procedure

Charging Springs Pull

charging

handle

down

all

the

way

(approximately

120°)

and

return

to

normal

vertical

position.

(

En

gagem

ent

of

pawl w

it

h

the

ratchet

teeth

pre-

vents

hand

le

reversal

until

the

downward

stroke

is comple

ted.

)

Closing

Push

down

spring-release

latch

hood (8)

after

handle

is returned to normal

ver

tical

position.

Tripping Push in manual

trip

rod

(48).

or

If shunt

trip

is

provided,

operate

remote

trip

control

switch (

CST

) (See

Figure 4).

Electrical

Iy

Operated

Breaker

The mechanism

of

the electrically operated breaker

is

the

same

as

the manually charged breaker except the

manual charging handle

is

replaced

by

a

motor

and

gea

r system. Refer

to

Figures 3 and 4 and Table 2.

With power available

to

the

control

circuit,

closing the

motor

control

switch

(Ml)

will

st

art

the

automatic charging cycle. The

motor

gear

box

pinion

rotates gear

(86)

counterclockwise,

cam

follower

(95)

engages

an

arm

of

wind

and close

ca

m

(85)

which rotates

the

cams

in

the

same

manner

as

for

the

manually charged breaker. When

the

wind and close

cam

(85)

reaches its charged position,

the

back

of

the

cam

engages

switch lever (91)

rotating

the

lever away

from

the

switch operator. Gear switch lever (

93)

will

still be holding the switch in

the

operate position, and

the

motor

will

continue

to

run

until

the

roll

pins on

the side

of

gear

(86)

lifts

lever

(93)

clear, releasing the

motor

cutoff

switch (MCO). When the MCO switch

opens the

motor

stops, and the closing coil

circuit

is

set up

throu

gh one side

of

the MCO switch.

The

breaker

can

now

be

closed

by

manually

releasing

hood (8)

or

by

energizing

the

closing

coil

(CC) through

the

external

close

control

switch

(CSC).

When

the

close

circuit

is

energized

the

"Y"

relay

is

energized

and

opens

the

"Y"

contact

in

the

motor

circuit,

thus

preventing

"p

umping"

or

repeated

attempts

to

charge

the

closing

sp

rings.

If

the

close

circuit

CSC

switch

is

opene

d,

the

m

otor

will

automatically

recharge

the

closing

springs,

if

pcwer

is

ava

ilabl

e for

the

motor

circuit.

The

close

coil

'

circuit

is

always

interrupted

by

the

motor

cut-off

switch

MCO.

Trip

free

operation

of

the

mechanism,

discharging

the

springs

on

a closed

breaker

is

prevented

by

completing

the

close

coil

circuit

thru

auxiliary

contacts

of

the

breaker.

4

Courtesy of NationalSwitchgear.com

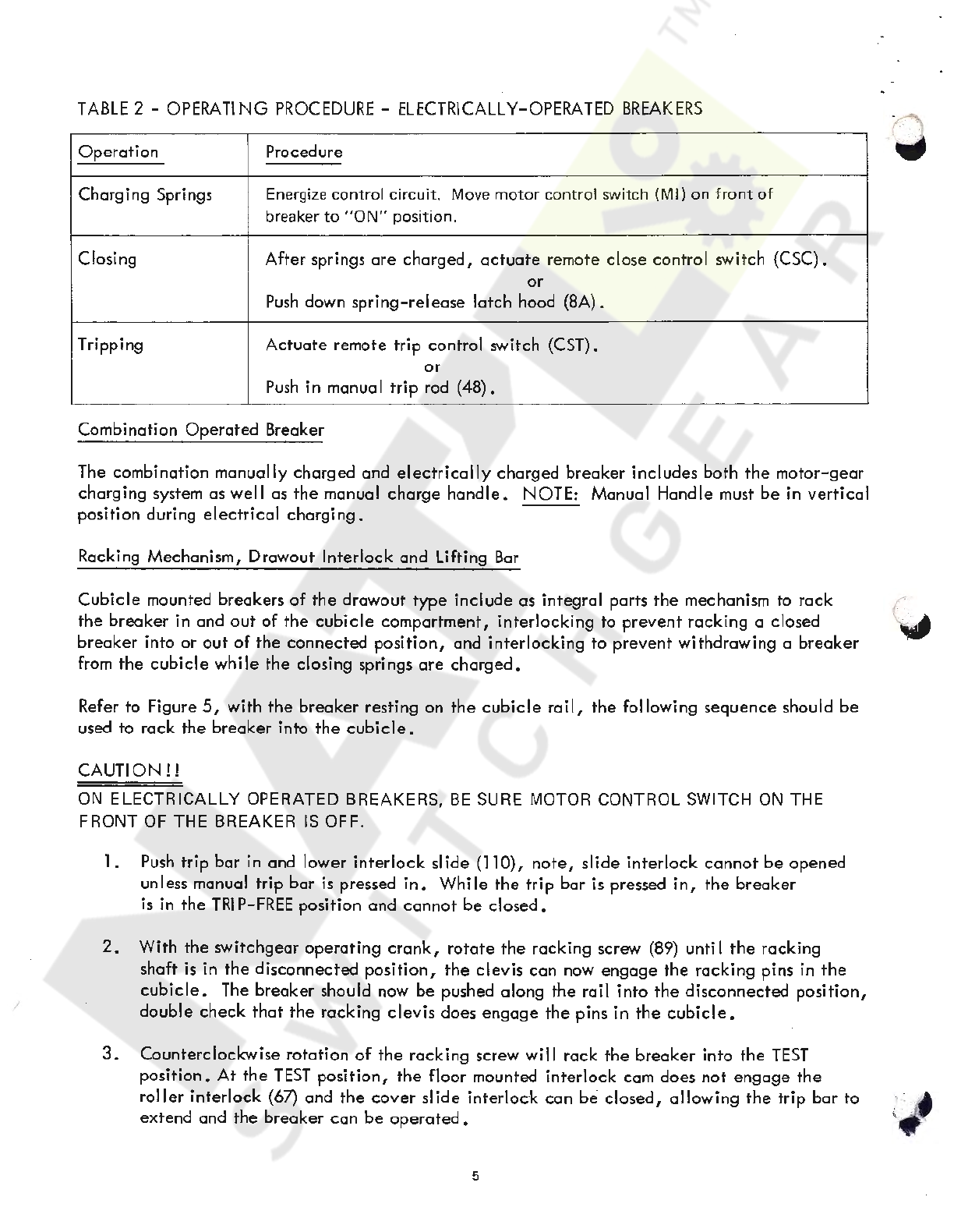

TAB

LE 2 - OPERATING PROCEDURE -ELECTRICALLY-OPERATED

BREAKERS

Operation

Procedure

Charging

Springs Energize con

tro

l circuit. Mo

ve

motor con

tro

l switch

(M

l} on front

of

breaker

to

"ON"

position.

Closing

After

springs

are

charged,

actuate

remote

close

control

switch

(

CSC).

or

Push down

spring-release

l

atch

hood

(8A).

Tripping

Actuate

remote

trip

control

switch

(CST).

or

Push

in

manual

trip

rod

(48).

Combination

Operated

Breaker

The

combination

manually

charged

and

electrically

charged

breaker

i

ncludes

both

the

motor-gear

charging

system

as

welI

as

the

manual

charge

handle.

NOTE:

Manual

Handle

must

be

in

vertical

position

during

electrical

charging.

Racking

Mechanism,

Drawout

Interlock

and

Lifting Bar

Cubicle

mounted

breakers

of

the

drawout

type

include

as

integral

parts

the

mechanism

to

rack

1·

· .

the

breaker

in

and

out

of

the

cubicle

compartment,

interlocking

to

prevent

racking

a

closed

~

breaker

into

or

out

of

the

connected

position,

and

interlocking

to

prevent

withdrawing

a

breaker

from

the

cubicle

while

the

closing

springs

are

charged.

Refer

to

Figure

5,

with

the

breaker

resting

on

the

cubicle

rail,

the

fol lowing

sequence

should

be

used

to

rack

the

breaker

into

the

cubicle.

CAUTION!!

ON

ELECTRICALLY

OPERATED

BREAKERS,

BE

SURE MOTOR

CONTROL

SWITCH ON

THE

FRONT

OF THE

BREAKER

IS OFF.

1.

Push

trip

bar

in and

lower

interlock

slide

(110),

note,

slide

interlock

cannot

be

opened

unless manual

trip

bar

is pressed in .

While

the

trip

bar

is pressed

in,

the

breaker

is in

the

TRIP-FREE

position

and

cannot

be

closed.

2.

With

the

switchgear

operating

crank,

rotate

the

racking

screw (89) untiI

the

racking

shaft

is

in

the

disconnected

position,

the

clevis

can

now

engage

the

racking

pins in

the

cubicle.

The

breaker

should now

be

pushed

along

the

rail

into

the

disconnected

position,

double

check

that

the

racking

clevis

does

engage

the

pins

in

the

cubicle.

3.

Counterclockwise

rotation

of

the

racking

screw

will

rack

the

breaker

into

the

TEST

position.

At

the

TEST

position,

the

floor

mounted

interlock

cam

does

not

engage

the

·

roller

i

nterlock

(67)

and

the

cover

slide

interlock

can

be

closed,

allowing

the

trip

bar

to

\:.:

.·

£1

·)

extend

and

the

breaker

can

be

operated

•

~

.•

-..;

5

Courtesy of NationalSwitchgear.com

Betwe~

(6he

TEST

position and

engag@che floor cam and the

even

i·

ie

cover slide is close

In

the am)NNECTED position,

cubicl:D

~This

prevents moving

4.

To

wit' saaw the breaker

from

1

the

ra<

·

1g

screw rotation is c

5.

Before' ch-empting to

operate

ti

with nleC;ence to the marking

stop

mse

(are provided

on

the

r

adjust'3urby setting the

angle

c

tightepn g

the

nuts against the

agains

-:ich

other.

CAUT

I

'\J

!!

TO

A\HE!D

DAMAGE

TO

THE

ING

01'\NK

IN

THE

COUNT

POSIT

N.

Spring

Discha1

Interlock

When racking:.Jtoe breaker out to t

he

c

discharge,

at

;prlbefore reachi

ng

the

c

interlock

(s

ee

rel,ures 3 and 4), this

ir

closing spring:

CAUTION!!

ON

MANUA!HE

1

CHARGED

BREAKEF

CHARGE

CAf.)C<AND

MUST

BE

CLEA

POSITION.

NOTE:

Manual

charg1isr:>0ndle

must

be

in vert

returned to themest position before cli

cubicle.

Note

also thah cie spring discharge

in

stored energy1e rthe springs is dissipat

trol switch

off

rar the

TEST

position, c

the

normaI

me

er.

CAUTION!!

W

ITH

COVER

BR;MOVED

AND

Cl

RCL

WI

LL

CLOSE

I

CAEN

THE

STORED

EN

SINCE

THE

SI

;EI

NTERLOCK

IS

N<

~

CONNECTED positm

t,

the roller

interlod

th17}

does

~aker

will be

tripped~

trough the interlock m•breanism,

t F

th

x:I

•

.e

roller interlock wil

CGain

clear

the floor c th;

of

the

:losed breaker into ore.

it

of the CONNECTEa <)Osition.

CONNECTED positihdr.

the

procedure is

th~heme

only

:kwise. :kir loc

b

reaker,

the position

at

·the

device

should

be1e

iecked

the

cubicle,

to

be

c~feiin

that it is fully conrin

ted.

Two

dng

screw to set the Jts lnected position, the:

acbre

he racking

clevis,

a~d

bwn in

detail

"A"

FiM

te

5,

and

JP washer

(84)

the

tw1in1uts

(95)

should

be

th'

stdocked

t e:

I

Ot

\CK

ING

MECHANIS/O DO NOT

ROTAT

E

T:

RJ

RACK-

CLOCKWISE DIRECT:RtN,

WH

EN

IN

THE

0ER4NECTED

10

;onnected position,

thhdosing

springs

wi

II

aHscmatically

.onne

ct

position. Theor rrel nut engages

the

Hsdng

:

rn

connects to the

m<

figal close hood which

~

ti.eases the

s.

THE

CLOSE HOOD

_L

)l

NTERLOCKED

TO

ns, MANUAL

~EFORE

RACKING

HA,

BREAKER

TO

THE

Dl~R

p)NNECT

11

position during racle

hg

and racking mechaficc.n must

be

:-ig

springs can be chae t:d, while breaker is rosipved

from

lock produces a

TRI

Pt

tKEE

operation in whic1terl I

of

the

in the mechanism. lof> preferable to turn tl--ednotor

con-

:e

the breaker

normal=

ilin that position,

then:lo~k

out in

inn

=

BREAKER

CONTACT RDPEN,

THE

CIRCUITJITEAKER

GY

SPR!

NGS

ARE

DIWf.HARGED

AUTOMATIER\LL

Y

IN

PLACE.

LID

)T

6

Courtesy of NationalSwitchgear.com

Lift Bar

See

Figure

5.

The Iifting

bar

connects

as

shown in Figure 5 for

the

standard b

rea

k

er

and

the

fused

breaker.

The

additional

lifting lugs

ore

provided

as

part

of

the

breaker

because

the

additional

overhang

of

the

fuses shifts

the

center

of

gravity,

and

lifting from

the

usual position

causes

tipping

of

the

device.

7

:

Courtesy of NationalSwitchgear.com

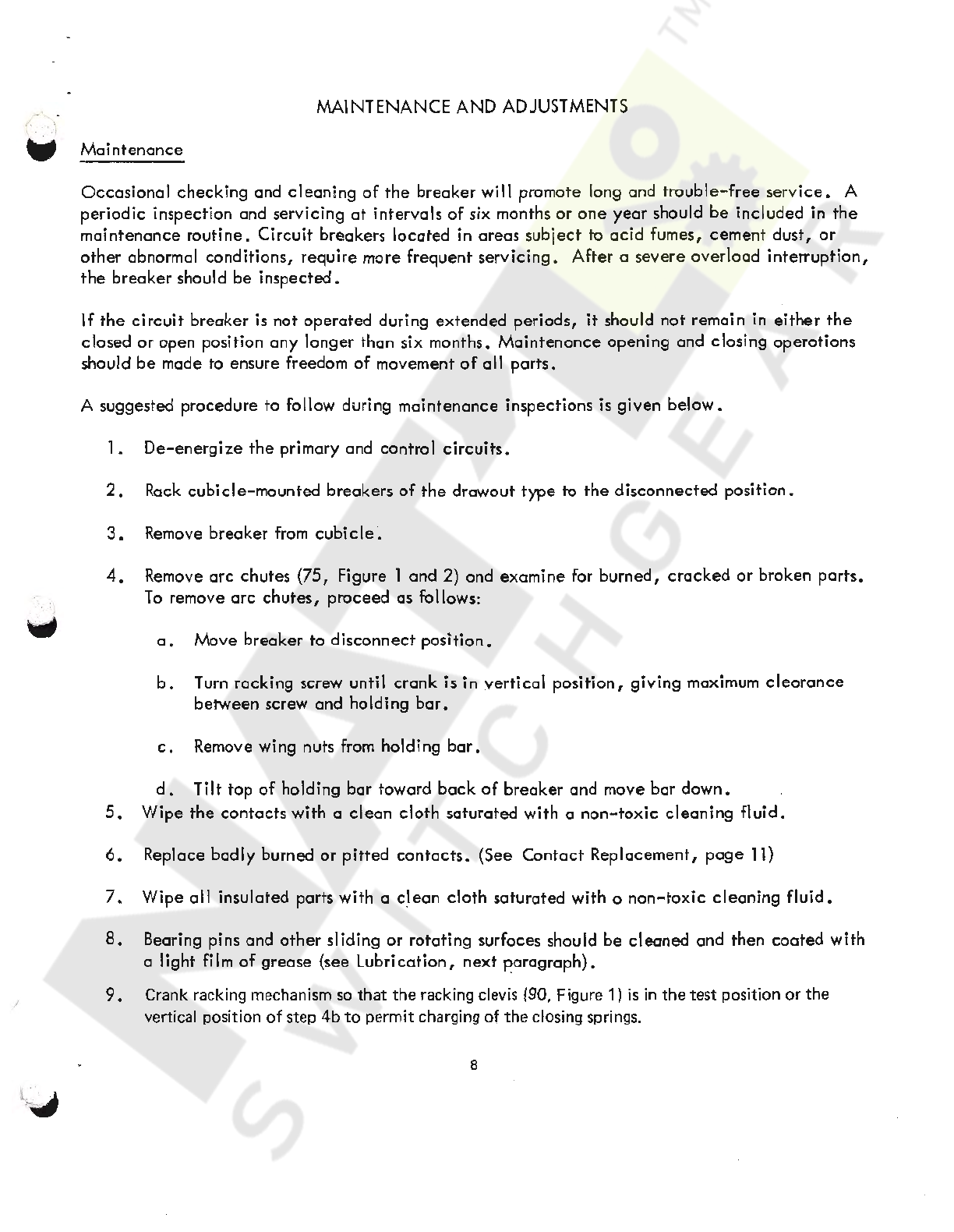

MAINTENANCE

AND

ADJUSTMENTS

W

Maintenance

Occasional

checking

and

cleaning

of

the

breaker

wil I promote long

and

trouble-free

service.

A

periodic

inspection

and

servicing

at

intervals

of

six months

or

one

year

should

be

included

in

the

maintenance

routine.

Circuit

breakers

located

in

areas

subject

to

acid

fumes,

cement

dust,

or

other

abnormal

conditions,

require

more

frequent

servicing.

After

a

severe

overload

interruption,

the

breaker

should

be

inspected.

If

the

circuit

breaker

is

not

operated

during

extended

periods,

it

should

not

remain in

either

the

closed

or

open

position

any

longer

than

six months.

Maintenance

opening

and

closing

operations

should

be

made to ensure freedom

of

movement

of

all

parts.

A suggested

procedure

to follow during

maintenance

inspections is

given

below.

1.

De-energize

the

primary

and

control

circuits.

2.

Rack

cubicle-mounted

breakers

of

the

drawout

type

to

the

disconnected

position.

3.

Remove

breaker

from

cubicle~

4.

Remove

arc

chutes

(7

5,

Figure 1

and

2)

and

examine

for

burned,

cracked

or

broken

parts.

To

remove

arc

chutes,

proceed

as follows:

a.

Move

breaker

to

disconnect

position.

b.

Turn

racking

screw

until

crank

is

in

yertical

position,

giving

maximum

clearance

between

screw and

holding

bar.

c.

Remove wing nuts from

holding

bar.

d.

Ti

It

top

of

holding

bar

toward

back

of

breaker

and

move

bar

down.

5.

Wipe

the

contacts

with

a

clean

cloth

saturated

with

a

non-toxic

cleaning

fluid.

6.

Replace

badly

burned

or

pitted

contacts.

(See

Contact

Replacement,

page

11)

7.

Wipe

al

I

insulated

parts

with

a

cJean

cloth

saturated

with

a

non-toxic

cleaning

fluid.

8.

Bearing pins

and

other

sliding

or

rotating

surfaces should

be

cleaned

and

then

coa

ted

with

a

Ii

ght

fi

Im

of

grease

(

see

Lubrication,

next

paragraph).

9.

Crank racking mechanism

so

that

the

racking clevis (90, Figure

1)

is

in

the

test

position

or

the

vertical position

of

step 4b

to

permit charging

of

the

closing springs.

8

Courtesy of NationalSwitchgear.com

I

'

10. Operate the breaker manually in maintenance closing position

(see

Maintenance Closing, below)

to

check latch and linkage movement.

11.

Check

breaker

adjustments (see Adjustments,

page

10).

NOTE:

After

inspection and before inserting breaker

in

the

cubicle

or

moving

the

breaker

to

test posi-

tion,

turn

racking screw (89)

until

racking clevis (90) reaches its normal disengaged position.

Lubrication

Lubrication should

be

a

part

of

the

servicing

procedure.

Needle

bearings

are

packed

with

grease

anp

should

require

no further

attention.

Old

grease

should

be

removed from

bearing

pins

and

other

non-current

·carrying

rotating

or

sliding

surfaces,

and

they

should

be

wiped

with

a

thin

film

of

petroleum-oil-base

precision-equipment

grease

such

as

BEACON

P-290.

Greasing

should

be

done

with

care

because

excess

grease

tends

to

collect

foreign

matter

which

in

time

may

make

operation

sluggish

an9

may

affect

the

dielectric

strength

of

insulating

members.

Faces

of

main

and

arcing

contacts

should

not

be

lubricated.

The rubbing surfaces

of

the

main

contact

fingers and

hinge

contact

fingers

are

lubricated

with

a

coating

of

A-C

contact

lubricant

15-171-370-002.

If

dust

has

accumulated

disassembly is

necessary

to

relubricate

these

points.

(See

Contact

Replacement,

page

11

.)

Maintenance

Closing

During

inspection

prior to installotion

and

for

routine

maintenance

inspections,

the

breaker

con-

·

-w

tacts

may

be

closed

slowly

to

check

clearances,

contact

adjustments,

and

movement

of

links

and

latches.

The manual closing

handle

is used for

maintenance

closing

the

breaker.

Electrically-operated

breakers

do

not

have

a manual closing

handle,

but

a manual

closing

handle-cam

assembly

is

available

as

a

maintenance

item.

Figure 6 shows

the

maintenance

closing

handle

being

inserted

in

an

electrically-operated

breaker

after

removal

of

the

front

cover

from

the

breaker.

When

the

hole

in

the

maintenance

closing

handle

assembly

is

aligned

with

the

holes

in

the

operating

mechanism

frame,

the

pin

which

is

attached

to

the

chain

is

in-

serted.

This

pin

holds

the

assembly

in

place

and

acts

as

a

pivot

point

for

the

cam.

After

insertion

of

the

maintenance

closing

handle

assembly

on

the

electrically-operated

breaker,

the

actual

maintenance

closing

operation

is

the

same for both

the

electrically-operated

breaker

and

the

manually-operated

breaker.

Refer

to

Table

3

and

Figure

6.

CAUTION!!

THE

PROCEDURE

IN

TABLE

3 SHOULD

BE

USED

FOR MAINTENANCE

CLOSING

ONLY.

MAINTAIN A

FIRM

GRIP

ON

THE

MANUAL

CHARGING

HANDLE DURING

THE

CLOSING

STROKE -

THE

BREAKER

MAY SUDDENLY

LATCH

FULLY

CLOSED AND APPLY UNEXPECTED

FORCE

TO

THE

CLOSING

HANDLE,

9

Courtesy of NationalSwitchgear.com

TABLE

3.

MAINTENANCE CLOSING

Operation

Procedure

Closing Contacts

1.

Pull charging

handle

DO

WN

ALL

THE

WAY (approximately 120°

).

2.

Place

blade

of

screwdriver

between

hood and spring

release

latch

and

hold

it

in this

position.

3.

Slowly return

handle

to

vertical

position.

Observe

contact

touch,

mechanical

operation,

etc.

4.

Remove screwdriver and pull charging handle to

the

fully charged

position.

Allow spring

release

latch

to hold closing springs. Move

charging

handle

to

the

vertical

position.

5 . Close

breaker

norma

lly

by

pressing

close

hood.

Opening

Contacts

Push

in manual

trip

rod.

NOTE:

Holding

the

spring

release

latch

down

prevents

the

stored-energy

springs from propping in

the

charged

position.

Thus, when

the

handle

is slowly returned to

the

normal

vertic

al

position,

the

energy

in

the

springs is slowly released

against

the

closing handle assembly cam

face.

Adjustments

During

maintenance

inspections,

the

following items should

be

checked

to

ensure

that

the

original

settings

are

maintained:

Trip·Latch Engagement

(R

efer

to

Figure

3.)

Toggle

latch

(35) should

engage

the

full width

of

trip

latch

(13) when

the

breaker

is closed

in

the

normal

manner.

To

adjust,

the

tension on spring (15)

can

be

increased

by bending spring

tab

on trip flap towards

the

front

of

the

breaker.

Too

much tension will

interfer

with

the

capability

of

the tripping

actuator

to

move

the

trip

flap,

so

over

bending should be

avoided.

Main

Contact

Make J!Jl- -

IYg

(Refer to Figure 7.) Compression

of

contact

fingers (9) should be between

.093"

an

.125".

This

is

the

difference

in

the

measurement from

the

breaker

base to

the

tip

of

the

finger

contact

surface

when

the

breaker

is open and

the

measurement in

the

same

place

when

the

breaker

is

closed.

This

is

checked

with a normal closing

operation

-

not

maintenance

closing.

Adjustment is provided

by

positioning screws (35)

after

loosening nuts (36). Counterclockwise rotation

of

screws (35)

in-

creases compression.

Care

should

be

taken

to

retighten

nuts (

36

)

after

adjustment.

If

it

is desired

to

check

contact

pressure, a

push-type

spring

scale

can

be

used to compress

contact

fingers

(9),

with

breaker

open.

Contact

pressure should

be

between

20-30

lbs.

10

Courtesy of NationalSwitchgear.com

Arcing

Contact

Make

(Refer to Figure 7

.)

With movable

arcing

contact

(27) in

any

one

phase touching

the

mating

stationary

contact

when

the

breaker is closed

by

the

maintenance

closing method (see Table

3),

the

phase

to phase variation should not

exceed

.062

11

• Adjustment may

be

made

by

positioning

screws

(3

5) as in

the

previous

paragraph,

but

it

is essential

that

the

main

contact

compression

be

maintained

within

the

tolerance

Iisted in the previous

paragraph.

Arcing

contact

pressure should

be

between

30 and 40 pounds when

checked

with a

pull-type

spring

scale

at

the

base

of

the

arc-

ing

contact

tip

insert with

the

breaker

contacts

closed.

Contact

Replacement

(Refer to Figure 7

.)

The

contact

structure consists

of

main

current

carrying

contacts

and

arcing

contacts

arranged so

that

initial

contact

make and final

contact

break

is

by

means

of

the

arcing

contacts.

The

actual

contact

surfaces

are

clad

with

an

alloy

facing which

greatly

reduces

mechanical

wear

and

arc

erosion.

When inspection

of

the

alloy

facing

indicates

that

the

contacts

should be

replaced,

it

should

be

noted

that

hinge

contact

fingers

(20,

21) main

contact

fingers

(9)

and

arcing

:

contacts

(27)

ore

spring

loaded.

Therefore,

care

must

be

exercised in removal and installation

of

any

of

the

con-

tacts.

Main

Contact

Fingers

_<),

·

~

..

t

With

the

breaker

contacts

open

and

the

stored-energy

springs

discharged,

main

contact

fingers

\J

(9) may

be

removed by loosening screws (18) enough to

relieve

the compression on springs

(10).

There

ore

two springs behind

each

finger and

it

is important

that

they

be

positioned properly upon

reinstal

lotion.

If

difficulty

is

experienced

in

correctly

positioning

these

springs,

the

upper and

lower primary disconnects (123, Figure

1)

may

be

removed from

each

phase and

the

breaker

in-

verted to rest on

the

ends

of

connectors (4) and (11).

After

the

contact

fingers

are

replaced,

connector

(4)

should

be

positioned in

the

center

of

the

slot in

the

molded base to assure

correct

alignment

of

the

primary

disconnect

fingers.

Stationary

Arcing

Contact

The

stationary

arcing

contact

is a

part

of

connector

(4) and may

be

replaced

by

proceeding

as

above.

In

this

case,

screws (18) must

be

removed • However, to provi

de

clearance

for removaI

of

connector

(4)

first insert a

3/16"

diameter

rod

at

least 2

11

long through

the

opening in support

(13).

It

~ay

be

necessary to compress

contact

(21) opposite

arcing

contact

(27) in

order

to insert

the

rod.

This will

--

hofd hinge

contact

fingers (21) in position

to

permit removal

of

pin (38) .

After

removaI

of

pin (38), main

contact

(28) and

arcing

contact

(27)

can

be

positioned

so

that

con-

nector

(5)

can

be

removed.

Hinge

Contact

Fingers

Hinge

contact

fingers

(20,21)

may

be

removed

as

follows: Remove top screw (17) from support

(13)

and

replace

it

with

a

1/4-20

screw

at

least

1-1/2"

long.

Remove lower screws and then

gradually

back

off

the

1-1/2"

screw to

relieve

the

loading from springs (16). The

hinge

contact

fingers

can

now

be

removed.

To

provide

easier

access

to

the

hinge

contact

fingers, pin (38)

may

be

removed

after

the

loading is

relieved

from springs

(16).

11

Courtesy of NationalSwitchgear.com

Moving Arcing and Main

Contact

~

Either moving arcing

contact

(27)

or

main

contact

(28) or both may

be

removed and

replaced

as

follows: Follow

the

steps outlined

in

the

above

paragraph including removal

of

pin (38)

or

if

hinge

contact

fingers

are

not to

be

replaced,

omit these steps and begin by

placing

a

3/16

11

diameter

rod

at

least

2

11

long through

the

opening in support (13). Remove pin (38)

if

not removed

previously.

The complete movable

contact

assembly may now

be

brought

to

a

bench.

It is suggested

that

a

1/ 2

11

thick

piece

of

wood

or

phenolic

be

placed

upright in a vise and

the

open slot in

clevis

(26)

placed

against

it

as

a

rest.

The location

of

spacers should

be

noted.

CAUTION!!

EXTREME

CARE

SHOULD

BE

TAKEN

TO HOLD

THE

ASSEMBLY

FIRMLY

TO

RETAIN

SPRING

GUDE

(32) AND SPRING (33,34) UPON

REMOVAL

OF

THE

SCREWS.

The moving

arcing

contact

or

the

main

contact

may now

be

easily

replaced.

The reverse

proce-

dure

is

fol

lowed for

re-instal

lotion.

Core should

be

taken

to

replace

spacers

correctly.

Check

alignment and adjustment

of

contacts

upon reassembly.

Tripping Actuator

When

the

static

trip

device

senses a

circuit

condition

that

requires

the

circuit

breaker

to

open,

it

produces

an

output

that

is fed to

the

tripping

actuator.

This

device

then causes

the

circuit

breaker

contacts

to open

and

isolate

the

circuit

.

Mounted on

the

circuit

breaker,

the

tripping

actuator

is held in a charged position

by

a

perma-

nent

magnet.

It contains a coil

that

is

energized

by

the

output

of

the

static

trip

device.

When

energized,

the

coil causes

the

magnetic flux to shift

to

a new

path,

releasing

the

stored

energy

of

a spring located inside

the

tripping

actuator.

The spring provides

the

energy to trip

the

breaker

moving

the

trip flap

clear

of

the

toggle

latch.

If

the

spring loaded armature does not

reset

during trip

operation

as

explained

above,

spacer

washers may

be

added

to

obtain

positive

reset

of

the

armature.

If adding spacers does

not

al

low

the

armature to

be

reset,

the

tripping

actuator

should

be

re-

placed

(if

br~ker

mechanism is not

at

fault

) .

NOTE:

Do

not

attempt

to disassemble

the

tripping

actuator

as this may d'estroy

the

magnetic field

set-up

by

the

permanent magnet and wi

11

render

the

actuator

latch

inoperative

untiI remagneti

zed.

When

replacing

a tripping

actuator,

the

coiI leads must

be

connected

to

the

terminal

block

of

the

static

trip

in

the

correct

polarity

relationship.

The

black

lead

of

coil must

be

connected

to

terminal 7 (negative) and

the

red lead

of

coil

connected

to terminaI 8 (positive)

of

the

static

trip

device.

12

Courtesy of NationalSwitchgear.com

When

the

tripping

actuator

has

been

replaced

the

circuit

breaker

should

be

given

a

FUNCTION

TEST

to

ensure

proper

operation

of

all

components. Refer to

Allis-Chalmers

Instruction

Book

<J

18X4827 for

the

procedures

of

the

FUNCTION TEST.

Motor

Cutoff

Switches

The

function

and adjustment

of

the

motor

cutoff

switches on electrically operated breakers

is

described

in

Figure 16.

13

Courtesy of NationalSwitchgear.com

I

FUSE

FUNCTIONS

Current

Limiting Fuse

(See

Figure 8-9.) The C.L.

Fuses

are special purpose fuses having NE

MA

Class

"J"

or

Class

"L"

character-

ist

ics

and have an interrupting r·ating

of

200,0

00

Amps

RMS Symmetrical.

When replacement

is

required due

to

the

C.

L. fuse

interrupting,

replace

only

with

a fuse

of

the same manu-

facturer and rating

as

supplied

with

the

circuit

breaker.

Fuses

of

different

manufacture

will

not

mount

on

the breaker terminals.

Open Fuse

Tripping

Device

(See

Figure 10.) The open fuse

trip

mechanism has three functions. The

first

function

is

to

trip

the

circuit

breaker mechanically when a

C.

L. fuse

has

interrupted.

The second

function

is to

indicate

which

phase

C.

L. fuse has

interrupted.

The

plunger

on

top

of

the

trigger

fuse (12)

indicates

visu

ally

whi

ch

phase