FEDERAL PACIFIC FUSEMATIC FP25-600 User manual

IN-810.9

TYPE FP LOW VOLTAGE

POWER: CIRCUIT BREAKERS

and

FM BREAKERS

JUNE,

1971

CIRCUIT BREAKER FM-25400

PACIFIC ELECTRIC COMPANY

POWER EQUIPMENT SYSTEMS DIVISION

INSTRUCTION

MANUAL

for

(

FUSEMATIC

FP

25

-

600

FP

501600

FM

25

-

600

FM

50

-

1600

N

FP

-

25

-

600

FUSEMATIC

®

EDERAL

1

RH

AV

/

FNI

IF

I

NFWARK

NFW

.

IFRSFY

07101

Courtesy of NationalSwitchgear.com

INSTRUCTION MANUAL

for

TYPE FP LOW VOLTAGE POWER CIRCUIT BREAKERS

and

FM

Manually and Electrically Operated

Part 1

Part 2

3

Part 4

Part 5

Part 6

Part 7

Part

BREAKER FUSEMATIC”

Type FP-25-600 FM-25-600

Type FP-50-1600 FM-50-1600

INDEX

PAGE

General 3

Shipment, Receiving, Handling Storage _______________ 3

Inspection Installation 3

Maintenance 6

Accessories 7

Overcurrent Trip Devices 9

Wiring Diagram

11

Recommended Spare Parts 12

FEDERAL PACIFIC ELECTRIC COMPANY

POWER DIVISION

150AVENUE L, NEWARK, NEWJERSEY 07101

rr

—

FUSEMATIC

®

BREAKERS

*

i

Description

&

&

Part

*

8

EQUIPMENT

SYSTEMS

Courtesy of NationalSwitchgear.com

?

PART 1

GENERAL DESCRIPTION

This Instruction Manual the

and Fusematic breakers only. For

instructions on the FP ‘75 series breakers refer in Instruc-

tion Booklet

The FP line of Low Voltage Power Circuit Breakers and

Fusematic Breakers, which ranges from through

1600A continuous current at 600 Volt ratings, are designed

for simplicity of operation, reliability and easy mainten-

ance. FP Breaker and FM Fusematic are equipped

with a stored energy mechanism mechanically trip free in

any position of the closing cycle, three unit pole assemblies,

fully field adjustable timing devices, multi-range series trip

coils, and telescoping roll-out rails. three position

mechanism is operable with the door closed.

STANDARD ACCESSORIES

Maintenance closing handle 115

Cell racking in handle

PART 2

SHIPMENT, RECEIVING, HANDLING

AND STORAGE

Each FP Breaker and FM Fusematic is thoroughly inspect-

ed and tested before leaving the factory. Breakers are

shipped in individual crates or in the cell compartment.

If breakers are crated, no hooks should be used in handling.

Examine equipment carefully for indication of damage

sustained in transit. If damage in transit is indicated, call

for an immediate inspection by the delivering carrier. Upon

assessment of the damage a claim should he filed with the

carrier or, depending on the nature of the damage, an in-

tent to file for concealed damage should be registered. For

assistance in filing the claim, advise the area sales office of

Federal Pacific Electric Company, giving a full description

of the damage, serial number of the breaker, delivering

carrier’s name, and, if shipped by rail, the car number,

waybill reference, and any other information that might he

of help to the Company in aiding the filing of the

damage claim.

When unpacking, make all items are removed

from the box including

packing

list, instruction book, main-

tenance parts and hardware. Report any shortage immed-

iately. See that identification tags are left on the breaker.

Lifting eyelets are furnished for handling. Do not lift or

handle breaker by the front box or the operating handle.

Clean breaker thoroughly. To remove dust industrial

vacuum cleaner is recommended. If the breaker can be

installed in its permanent location, it is advisable to do so,

even if it is not expected to be for some time.

When breakers must he stored in buildings under

tion, be sure they kept in a space free of dust, moisture,

dirt and in an upright position. It is recommended that

the breaker not be operated prior to final inspection.

PART 3

INSPECTION AND INSTALLATION

SECTION I

Inspection Manually Operated

Breakers

The FP and FM breakers consist of a coordinated set of

assemblies mounted on a steel frame, all carefully adjusted

and locked in place for long and trouble-free operation.

To in properly checking and inspecting breakers

to placing into service, the following steps should be

in the order listed:

1. Remove chutes and interphase

2. Charge stored energy by operating

handle positive stop. Return handle to normal

vertical position by rotation.

NOTE: Charging Operation:

FP Rotate handle counterclock-

wise to engage mechanism and then 1 clockwise to

positive stop. (Figure 1)

FP collapsible handle from

vertical down position to vertical up position. Rotate

clockwise to positive stop. Release handle slowly.

Figure 2

FP

25

-

600

,

FP

50

-

1600

,

covers

FM

25

-

600

FM

50

-

1600

#

IN

810

.

!

0

.

15

A

assist

prior

followed

The

barriers

.

mechanism

rotating

counter

-

clockwise

arc

toa

The

drawout

&

FM

25

-

600

—

90

°

1

-

9252

80

°

1101

-

9251

4

all

Figure

X

&

FM

50

-

1600

—

Unfold

180

°

(

Figure

2

)

.

*

in

sure

that

an

energized

construc

-

are

Courtesy of NationalSwitchgear.com

3. Block the trip device, when supplied, to

prevent tripping.

4. Remove’ right and left hand accelerating springs (Fig.

4).

10.

11

12.

5. Insert closing handle as in

Figure 5 and slowly operate until arcing contacts

touch. All arcing contacts should make simultaneously

with permissible variation of Movable

arcing contact fingers should align with stationary

arcing contacts.

Refer to Part 4 for adjusting instructions if

ment or observed. arcing

contacts designed with side clearances for better

guidance inside the chutes. A side to side move-

ment of is allowable. Close breaker and check

on main contacts:

6. With maintenance closing handle in position and trip

bar in tripped position, proceed to close breaker. Oper-

ating mechanism will now be trip free and contacts

should not make.

7. Remove maintenance handle and breaker

by moving bar.

Replace one pull-off spring right side only.

Inspect each arc chute to be plates are dam-

aged. Replace chutes and interphase barriers on break-

ers. Move contacts in by hand to insure contacts

move in and freely.

To avoid possible injury

NEVER

handle or touch any

of the breaker when the stored energy

mechanism is charged. close button on front

Breaker will close. Depress red trip button

(located in charging handle). Breaker will open.

Recharge stored energy mechanism and close breaker.

Slowly move series trip coil magnet (armature) to

fully closed position. Breaker should trip before arma-

ture touches pole face assembly. Repeat this procedure

on poles.

On draw-out breaker, stored energy mech-

anism, close breaker and move draw-out interlock

plate to the left. Breaker will trip. D/O interlock plate

must be fully to the right before operating

breaker to prevent trip-free operations. (Figure 6).

Figure 6

Charge stored energy mechanism and close breaker.

Pull padlock lever out. Breaker should trip before pad-

lock slot is fully exposed.

14. Check retaining rings and hardware for tightness.

15. Basket and finger should be secured with

Nylok retaining screws. Contact must be free

of dirt and foreign particles. The secondary contacts

should operate freely.

undervoltage

ure

closing

trip

trip

8

9

sure

no

out

moveable

part

Press

cover

.

all

charge

a

i

Figure

4

reset

f

m

Figure

5

4

I

maintenance

#

1151

-

9252

1

/

32

max

.

a

13

.

misalign

-

misadjustments

are

Moveable

assembly

are

Fingers

arc

1

/

8

.

overtravel

l

/

8

"

±

1

/

32

"

.

4

Courtesy of NationalSwitchgear.com

SECTION II

Inspection Electrically Operated

Breakers

The stored mechanism is charged by

fractional AC/DC universal motor. Identifi-

cation, voltage ranges and requirements

below. The stored mechanism charges in

approximately one second.

CHARGING MOTORS FOR FP BREAKERS

STORED ENERGY MECHANISM

Rating

Part Fuse’

D.C.

162.007

15056 20 50

12.0

14976

6.5 25

5.0

14978

6.1 12

3.5

Maximum use control power transformer

forhighervoltage

‘Class 1330

element fuses

From wiring diagram supplied with equipment, or standard

diagram Part 7 of this book, locate motor on

secondary contacts and connect required power source.

Motor will charge when power is applied and shutoff auto-

matically when is

Breaker cannot be closed with the maintenance closing

handle unless stored energy mechanism is charged. 0” all

electrically operated FP breakers the stored energy mech-

anism will recharge immediately following a closing opera-

tion ready for instant if needed.

Follow inspection procedure as outlined

Manually Operated Breakers.”in “Inspection

In addition the following steps are recommended:

16. From wiring diagram locate on secondary

contacts and connect proper control power supply and

controls for shunt close and shunt trip attachments.

Close and open breaker five times electrically and

check for proper operation.

17. Disconnect control power supply. and

breaker manually. Do not leave breaker in the charged

and/or closed position while in storage.

18. Move shunt close solenoid

release closing springs without control power.

SECTION Ill Installation

Before installing breaker in cell, check following points

inside cell:

1. contact support when supplied make

sure all connections are tight and adjusted to proper

dimensions.

2. Ground connections should he tight.

3. Extension rails should be free to in and

check rail stops for tightness.

4. Rail rollers should be free and well lubricated.

5. Main stabs should be tight free of dust

and dirt. Lubricate with contact grease.

6. Check condition of insulating plate in roof of

case. Screws should be tight.

7. Remove control fuses.

8. Place breaker fully extended rails. Make

four rollers inside grooves (Outside

grooves fit into stationary rails inside cell). (Figure 7).

Figure 7

9. Draw-out mechanism on breaker should be in

position.

10. Push breaker inside the cell until racking-i” cranks

engage a positive stop. This is the OUT position.

11. Close and fasten the door. The metal mask provided

on outside of front box freely back it

in contact with the door. The door should

all the way with the breaker in the OUT position.

12. Push interlock to left, insert lever

1101-9251, (Figure 8) into the bottom hole of the

mechanism and, with up-stroke, rack

breaker into the

TEST

position.

Remove lever,

interlock plate should snap into position com-

pletely covering holes.

13. Install control power fuses, energizing the circuit. The

motor will the stored energy mechanism. The

closing and tripping control become energized

in the TEST position.

14. Open and make sure that grounding contact in

cell is in with the breaker. Close door and

check breaker for proper closing and

opening operation.

If breaker operates properly, rack breaker back to OUT

position and leave there until ready to be put into service.

ratchet

-

driven

horsepower

energy

a

are

speci

-

current

energy

fied

FLA

.

LRA

.

Voltage

48

V

A

.

C

.

/

48

V

115

V

A

.

C

.

/

125

V

D

.

C

.

230

V

A

.

C

.

/

250

V

D

.

C

.

240

V

,

Econ

Dual

FPE

#

Motor

162

-

004

162

-

006

terminals

OUT

charging

cycle

completed

.

will

move

as

close

reclosure

comes

drawout

drawout

drawout

an

terminals

drawout

drawout

the

charge

Close

trip

trip

-

circuits

armature

manually

to

door

contact

electrically

Secondary

out

;

move

and

contact

transite

power

moveable

on

sure

all

engage

on

Figure

8

Courtesy of NationalSwitchgear.com

15. To put circuit breaker into service push

interlock to left, insert lever in bottom 3. Make sure all retaining rings are in place.

bole of the mechanism (Figure 8) and

4. Surfaces marked “F” should be lubricated by thin

upward stroke rack breaker into operating position. of “Conducto-Lube before assembly.

Remove

lever. interlock should in

Contacts must be inspected after every known short circuit

and should also he at regular in-

spect& periods. If contacts are found to be worn or

cessively pitted they should be dressed or replaced.

When

reinstalling the arc chutes, adjust the

retaining screws on the arc chute retaining bar so that

the contact insulating block clears the arc chute base when

the breaker is closed.

CONTACT ASSEMBLY

repair or replace arcing contacts,

follows (Figure 11)

1. stored energy

2. Remove arc chutes and barrier.

3. Remove insulating block and fork assembly.

4. Tighten arcing adjusting screw

Figure 9 Figure

PART 4

MAINTENANCE

The breakers with all component have been

tested for performance as per Standards SG

3 and ANSI and proved to be satisfactory

wide margin of safety.

solid and retaining pins.

6. Remove arcing

contact pivot pin and replace

arcing contacts. contacts should be replaced at

one time.

6. Make nylon bushings on arcing pivot pin

are in place and in good condition, when replacing

arcing contact.

A periodic maintenance should be established. An

annual inspection should made for clean,

applications. More frequent inspections should be made

for dirty, corrosive or high-use applications.

Reassemble following the reverse of operations

and adjust per Figs. 10 and 11. In most it is not

to replace contacts, but occasional

and readjustments are

recommended.

The following instructions and should be fol-

lowed carefully:

CONTACT ADJUSTMENT

Figure 10 and 11

MAIN AND ARCING CONTACTS ADJUSTMENT

FOR AND BREAKERS

To replace stationary arcing contacts (Figure remove

unit pole assembly, replace main stud and arcing contact

assembly, part 1151-9939, for 600A breaker and

9937 for breaker.

Adjust as per 10, 11 12.

“A” Main Contact Pressure

Over Travel Mains

Arcing Contact Press

Gap (distance) between

mains when arcing

contacts touch

42-50 lbs., measured at

point of contact

lbs., measured at

of contact

& (Fig. 10)

CHECK POINTS

-Figure 11 and 12

1. Stationary arcing contacts make sure that retaining

screws and contacts are tight.

2. Main contacts should be clean and free

drawout

the

drawout

a

with

drawout

>

drawout

,

i

plate

i

i

position

and

red

IN

appears

.

(

Figure

9

and

9

A

)

.

i

vn

.

n

:

#

240

-

200

”

film

an

(

Fieure

121

.

snap

interruption

inspected

r

ex

-

CAUTION

:

I

ij

If

!

)

proceed

as

moveable

i

mmM

J

&

J

*

mechanism

.

interphase

push

contact

’

s

remove

Charge

i

,

'

tri

4

I

moveable

until

springs

are

5

&

9

A

moveable

i

Both

exten

-

parts

NEMA

sively

contact

sure

with

a

C

37

-

13

a

moveable

schedule

sequence

be

low

-

use

cases

redressing

necessary

adjustments

10

)

,

1151

-

1600

A

&

Figures

contacts

FP

1600

A

FP

600

A

\

600

A

j

—

r

25

-

35

point

1600

A

L

i

±

%

2

“

B

”

-

“

C

”

-

SHOWN

FULLY

CLOSED

'

.

2

-

25

lbs

.

,

measured

at

a

>

oint

Mi

below

tip

of

ontact

6

±

%

2

(

Fig

.

11

)

J

“

D

”

-

B

10

,

\

r

\

r

\

cc

:

:

:

l

:

r

*

-

H

T

’

T

*

Figure

10

Courtesy of NationalSwitchgear.com

PART 5

ACCESSORIES

SHOWN AS ARC

CONTACTS MAKE

11

SHOWN FULLY OPEN

Figure 13

The shunt

trip attachment is mounted directly above the

trip shaft. It is a non-adjustable intended

for intermittent duty only, and its circuit should inter-

rupted only by an auxiliary contact.

SHUNT CLOSE

12

STORED ENERGY MECHANISM

Check latch engagement and adjust if necessary

min. of latch surface contact. Make springs

in place and in good condition. On

breakers, remove motor to make is

free and well lubricated. Reinstall motor. Make that

retaining in place.

Check

mechanism to insure

that all moving parts ate free and well

MECHANISM

Make that all retaining and springs in place

and that the mechanism is free. Replace nylon bumper

rollers if excessive is evident. Make sure that the

operating mechanism when stored energy mech-

anism is slowly and that the trip shaft is free. It

should take no more than 22 inches of torque to

trip the breaker.

GENERAL

Make that current carrying parts secured and The shunt close attachment is mounted on top of the stored

associated hardware is tight. Basket and finger assembly energy mechanism and is used to electrically discharge the

should be secured but free enough to compensate for stored energy mechanism and thus close the breaker. It

alignment in cell. The free up and down movement should is a non-adjustable intermittent duty device and its circuit

be approximately should be interrupted by an auxiliary contact.

J

—

r

c

_

»

•

S

I

:

:

:

:

=

:

v

4

)

SHUNT

TRIP

D

R

Wf

'

=

6

^

4

\

7

v

\

ta

P

IT

Figure

r

i

-

i

s

I

I

J

I

3

-

-

-

a

,

1

-

lr

-

i

L I

m

electro

-

magnet

be

¥

<

c

:

»

T

"

[

:

i

Figure

to

provide

.

062

"

a

sure

electrically

are

operated

sure

roller

sure

all

rings

are

lubricated

.

OPERATING

!

rings

sure

L

wear

resets

charged

ounce

all

sure

%

6

.

Courtesy of NationalSwitchgear.com

UNDERVOLTAGE ATTACHMENT (Figure 15)

SCREW

The attachment is a continuous duty device,

which can be provided with or without a time delay, and

which mechanically trips the breaker if the voltage drops

30% to 60% of normal voltage. It is mechanically

set and has no auxiliary contact in its circuit. The

voltage time delay mechanism is of the pneumatic delay

type. The time is controlled by the adjusting

screw.

To the attachment, hold the move-

able by hand, close breaker and slowly release

the is fully opened, the spring

loaded plunger will be released, strike the lever and

trip the breaker. Check for missing retaining rings and

loose missing and bolts. Check condition of coil.

If attachment is noisy while being energized,

clean faces of and

AUXILIARY SWITCH (Figure 16)

max. 6 stage,

12 contact is available. It

mounted on top of the energy mechanism on the

right hand of the breaker and is by the main

contacts. All contacts are operated by

and factory adjusted provide “a” (normally

open) and

“b" (normally

closed) contacts.

The position and the condition of all contacts can be see”

and inspected through the transparent dust The

contacts may be changed from a b b to by

removing the and inverting the contact bridge.

INTERRUPTING CAPACITY

IN

SINGLE CONTACT

24 20

15

10

7.5

230

250

CONTACT

230

250

BELL

ALARM SWITCH (Figure

Figure 17

A

bell switch attachment is mounted on the

hand side of the breaker and will function only when

breaker is tripped by the trip units. It be

manually and/or electrically reset. Closing of breaker also

resets the switch.

To check the alarm switch attachment, hip breaker with

trip button, the” with shunt trip. In both cases the switch

should not be actuated. Trip breaker by moving the series

trip coil magnet the switch should operate.

is

switch

A

stored

operated

side

phenolic

moveable

cams

are

to

covers

.

to

or

a

cover

TYPE

R

-

4

AUXILIARY

SWITCH

INTERRUPTING

RATING

AMPS

D

.

C

.

•

ir

.

A

.

C

.

D

.

C

.

Inductive

Volts

Non

-

Inductive

Inductive

Non

-

Inductive

48

30

115

50

2.0

125

2.5

15

25

DELAY

.

45

0.5

ADJUSTING

m

BLE

24

40

50

20

48

25

115

60

80

undervoltage

7

125

12

50

30

2

.

25

to

re

-

under

-

17

)

10

-

32

delay

inspect

undervoltage

armature

armature

.

Before

armature

screws

or

undervoltage

armature

core

.

right

alarm

overcurrent

can

alarm

and

Figure

16

Courtesy of NationalSwitchgear.com

PART 6

OVERCURRENT TRIP DEVICES

GENERAL DESCRIPTION

The

direct acting series coils and magnet assemblies pro-

vide the energy to operate the over-current time delay

device and to trip the circuit breaker, interrupting sustain-

ed and faults. There (7) different

coils covering the range from 15 to 1600 amperes.

Each is and calibrated in the factory at the

desired continuous current rating. Any one of the seven

series coils be used in any of the circuit breakers

and FM Fusematic circuit breakers the

rating dues not exceed the maximum continuous current

rating of the circuit breaker frame. [IE.,

Dual Magnetic

Overcurrent Trip Device

(Figure 18)

The dual magnetic device, in combination

with the series coil and magnet, provides inverse long de-

layed tripping for below the instantaneous

pickup setting, and adjustable instantaneous tripping.

devices are factory calibrated and be field adjusted.

Selective Overcurrent Trip Device (Fig. 18)

The selective

trip device, in combination with

the series coil and dual magnet, provides inverse

long delayed tripping for all below the short

delay pickup setting, and short delayed tripping for all

and faults above the short delay pickup set-

ting. devices factory calibrated and can be field

adjusted.

Phasing Protection (Fig.

19)

When fuses are used to protect circuits feeding three phase

motors similar reactive apparatus there is always the

possibility, upon the blowing of fuse only, that the

apparatus, single phased, will bum out. To eliminate this

danger, Fusematic Air Circuit Breakers incorporate three

single phase trip coils, one in parallel with each of the three

main fuses.

The voltage drop a blown fuse energizes the single

phase trip coil in parallel with it.

The trip coils will operate from 630 volts down to 24 volts.

Each coil, when energized, releases a spring loaded plunger

which trips and locks the circuit breaker in the “TRIP

FREE,” (Open) position. The plunger(s) which has been

released indicates which fuse(s) have blown. They are

reset manually, after replacing the blown fuses, by pulling

the plunger(s) out as far as they will go and releasing

them. The reset plunger will remain latched in the “OUT”

position. The circuit breaker should be thoroughly in-

spected after every “Blown Fuse” operation and returned

to service only after the conditions in part 3 Section 1

II “Inspection and Installation” have been satisfied.

OF OPERATION

A.

Series Coil and Magnet

The current through the series coil provides the

motive force to energize the magnet assembly. The clapper

type exerts force on the push rod which

operates the trip unit and trips the circuit breaker. The

current rating of the and magnet may he changed by

moving the pole assembly up down. The trip

system must recalibrated after adjusting the magnet

face.

B. Dual Magnetic Overcurrent Trip Device

(TD-1)

(Long Time Delay and Instantaneous Trip)

The delay trip device of

dash

which by the positive displacement of liquid

and adjustable tension coupling

spring which permits the push md to rapidly when

the force the magnet exceeds predetermined value.

The lever ratio between the push and the dash pot is

adjustable permitting the time delay to be varied. There

three adjustment bands, identified minimum, inter.

mediate and maximum. In addition to the long delay band

adjustment there is a” adjustable tension spring which

prevents motion of the push rod for currents below the

maximum desired continuous current. This is the long

delay pickup. It is adjustable from 80 percent to 160

percent with calibrated points at

and 160%.

I

overcurrents

are

seven

magnet

set

FP

may

&

provided

current

600

A

,

1600

A

.

]

tm

„

'

I

*

w

ca

Pun

K

.

Figure

19

>

METHOD

Rgure

18

magneto

-

(

TD

-

l

)

armature

a

overcurrent

trip

coil

all

overcurrents

face

or

All

be

pole

can

(

TD

-

2

)

overcurrent

armature

overcurrents

long

overcurrent

pot

operates

through

a

fixed

orifice

an

consists

a

overcurrents

a

All

are

move

from

Single

a

(

Fusematic

)

rod

or

are

as

one

»

80

%

,

100

%

,

120

%

,

140

%

across

Courtesy of NationalSwitchgear.com

The tension in the coupling spring determines the current

at which the dash pot will be mechanically by-passed. This

is the instantaneous pickup adjustment. The high range

instantaneous element has calibrated settings at 7.5, 10 and

15 times the coil and magnet setting.

C.

Selective Service Trip Device (TD-2)

(Long Delay and Short Delay)

The selective trip device is similar to the

magnetic trip device except that it has a rigid coupling link

in of instantaneous pickup coupling spring and it

has mechanical escapement timing device which provides

short delay for hiih values of and for faults.

The long delay dash pot is identical to that on the

dual magnetic trip device. The short delay device is

operated by separate in the series coil and

magnet assembly. It has pickup adjustment range of 5 to

10 times the coil and magnet setting. In addition, the short

delay has adjustable band with minimum, intermediate

and maximum settings.

MAINTENANCE ADJUSTMENTS

Remove breaker completely from cells before servicing.

A.

Series Coil and Magnet Assembly

The

series coil and magnet requires no maintenance other

than cleaning periodically to dust and dirt which

may accumulate on bearings and pivots of the magnet

All pivots and bearings are made of nylon and no

lubrication is required.

The entire series coil and magnet assembly may be remov-

ed and replaced in the field by removing the coil retain-

ing screws and magnet retaining screws at the

of the pole insulator. replacing coils, always tighten

the coil retaining screws securely. This is important to pre-

vent overheating and possible failure. Care should be taken

not to damage the coil insulation

B.

Dual Magnetic Overcurrent Trip Device (TD-1)

(Long Delay and Instantaneous Trip)

The circuit breakers are shipped the trip devices in-

stalled and properly adjusted. It is only necessary to keep

the devices reasonably clean. They are lubricated for the

life of the circuit breaker and be lubricated again.

It is possible to remove and replace a trip device in the

field.

To Remove a Trip Device

The trip units which contained in transparent plastic

cases should be removed as units. Remove the two screws

which hold the trip unit to the breaker frame. These

screws located in the back of the trip unit and can be

removed by reaching in from behind. The connecting rod

which connects the magnet assembly must be Slipped

off the pin connection at the magnet. The plastic con-

nector and trip finger are then removed fmm the push-rod.

To Install a Trip Device

Insert the rod in the hole in the front channel

and the trip unit to the channel using the two

hex. nuts provided. Run special nut

down the push rod. Follow it with trip finger on top of

the push rod with spacer between the wings and another

10.32 nut. (Do not tighten it yet.) Install the nylon

turn-buckle and adjust its length that it is longer

than is just to permit the trip device to reset the

magnetic armature against its stop. Install the buckle

on the armature pin and retain it with E-ring provided.

Adjust the position of the trip so that the breaker

does not trip when the magnet is closed with thick

shim in the air gap, and does trip with thick shim

in the air gap. Tighten the finger and check thii adjustment

again. The trip unit must reset the magnet the

way until the armature is against the stop.

C. Selective Service Trip Device (TD-2)

(Long Delay and Short Delay)

The maintenance and adjustment of the selective service

trip device is the same as the dual magnetic trip device,

except that the trip finger on the short delay push rod is

installed under the push rod. Care should be taken to en-

sure that the long delay trip finger on top of its push rod

does not interfere with the short delay trip linger which

is installed under its push rod.

with

must

not

dual

service

are

place

an

a

are

overcurrents

a

used

to

armature

a

a

an

push

proper

5

/

16

”

screw

“

Dyna

-

lock

”

10

-

32

a

a

a

&

1

/

32

”

so

necessary

turn

finger

a

1

/

32

”

a

1

/

64

”

remove

arm

-

armature

all

atures

.

Vs

"

the

Vi

"

rear

When

Courtesy of NationalSwitchgear.com

PART 7

WIRING DIAGRAMS

DEFINITION OF SYMBOLS

TC2 B phase fuse trip coil

TC3 C phase fuse trip coil

Closing release coil

Y Anti pump relay

01

Control switch

BA Bell alarm switch

PF Power fuse

uv Undervoltage device

A Main power circuit A phase

B Main power circuit B phase

M Spring charging motor c Main power circuit C phase

Motor cut off switch (Shown with

closing mechanism spring discharged)

a

Auxiliary switch contact (open when breaker is open)

b Auxiliary switch contact (closed when breaker is open)

FP BREAKER OPERATING SEQUENCE

1. Control switch 01-C closed (local close) or remote close via Terminal

2. “X” coil is energized “b” contact of the “Y” relay, contact of the breaker auxiliary switch,

and contact of the motor cut-off switch.

3. Stored energy closing spring released via coil, closing breaker.

4. Closing breaker operates auxiliary switch opening “b” contacts and closing “a” contact thus energizing

anti pump relay and “X” coil.

5. “Y” relay remains energized via seal-in contact thus providing anti-pumping lockout of “X” coil if

held closed

Cl

6. “Y” relay is de-energized when #contact is opened.

7. Closing breaker, closes auxiliary switch “a” contacts permitting the breaker to be tripped electrically

when control

power

is switched to auxiliary stabs and 6B.

Motor cut-off switch contact “bb” closes when spring discharges and when spring is fully

charged.

9. Auxiliary switch contact closes when the breaker is tripped.

10. Motor cut-off switch contact when the closing mechanism spring is fully charged.

11. The breaker will close when control switch

01

local

Cl

close

TC

Trip

coil

A

phase

fuse

trip

coil

TCI

X

MC

/

aa

MC

/

bb

}

NO

NC

A

A

iO

4

A A

586

7

B

?

9

C

<

!

A

AAA

150

$

I

7

E

>

19

EJ

2

lFn

rm

i

k

11

<

.

i

AUXILIARY

SWITCH

3

Ay

IIC

6

130

23

F

6

ff

)

(

0

to

CO

<

M

N

04 04

(

Jl

01

Cl

01

O

)

01

01 01

aiii

0

O

O

i

i i

6

0

»

CO

N

(

D

II

)

ID

If

)

•

H

f H

%

CONTACTS

FUNCTIONS

*

2

C

7

Vo

1

-

!

JS

1

-

2

a

CONTACT

3

—

4

a

CONTACT

5

-

6

b

CONTACT

7

-

8

b

CONTACT

r

-

4

»

r

-

i

r

-

i

9

—

10

a

CONTACT

i

11

—

12

b

CONTACT

55

B

AI

3

AI

3

AI

7

119

T

°

T

°

T

914

VIS

VIS

920

9

=

A

2

I

A

23

"

^

o

:

ib

%

13

—

14

a

CONTACT

BA

I

6

$

15

—

16

b

CONTACT

92

B

94

S

22

924

ft

17

—

18

a

CONTACT

b

13

—

20

b

CONTACT

5

,

7

4

21

—

22

a

CONTACT

b

:

23

—

24

b

CONTACT

ivo

©

8

6

IY

IT

'

IX

©

X

M

TYPE

FP

5

FM

ELECTRICALLY

OPERATEO

A

.

C

.

B

.

SCHEMATIC

DIAGRAM

FP

25

FP

50

FM

25

FM

50

:

b

ix

2

Yv

-

2

T

<

2

UO

IM

2

A

$

IOCQ

I

2

C

4

A

.

«

;

v

140

160

IBE

620

E

<

<

V

|

V V

V

V

22

F

6

24

f

6

'

1

i

V

I

I

BASIC

ELECTRICAL

CONTROL

I

ISSERVOUASE

'

EXTR

*

AUXILIARY

CONTACTS

j

i

I

i

i

1

A

.

thru

"

b

"

aa

“

X

"

4

/

yn

deenergizing

01

is

5

B

8

.

re

-

opens

"

b

"

“

aa

"

closes

i

01

is

closed

.

Cl

Courtesy of NationalSwitchgear.com

PART

RECOMMENDED SPAREPARTS

No. FP.25.600 No. Reg.

1151.9939

61151-9088

SHUNT CLOSE

Voltage Assembly No.

AC 48V DC

AC

230V AC 230V DC

SHUNT TRIP

Assembly No

AC 48V DC

1151.6039

AC 125V DC

1152.6039

230V AC. 250V

MOTORS TO CHARGE ENERGY MECHANISM

Voltage Assembly No.

AC DC1102-6013

AC DC

1103-6013

230V AC 250V OC

12

UNOER VOLTAGE TRIP DEVICE

Assembly No.

1151.9986

1151.9937

1151.9354

1152.9354

1151-0632

Mounting

Ref.

1100~6034

Mounting Ref.

Drawing

1100.6035

Mounting Ref.

Drawing

Mounting Ref.

Description

Moving arcing contacts

Upper stud assembly

Main Stationary contact assembly

Leading contacts

Cluster assembly

Arc Chutes

r

>

'

a

8

FP

-

50

-

160

D

Reg

.

66

3

3

12

3

6

6

1151

-

9566

3

1151

-

9566

3

•

•

*

]

Drawing

1151

-

6038

1152

-

6038

1153

-

6038

48

V

125

V

DC

,

115

V

Voltage

48

V

115

V

DC

1153

-

6039

STORED

48

V

48

V

115

V

125

V

1100

-

6014

1104

-

6013

:

Voltage

115

V

AC

230

V

AC

'

480

V

AC

Drawing

1151

C

6138

1152

C

6138

1153

C

6138

1100

C

6032

Printed

in

U

.

S

.

A

.

Courtesy of NationalSwitchgear.com

This manual suits for next models

3

Table of contents

Other FEDERAL PACIFIC Circuit Breaker manuals

Popular Circuit Breaker manuals by other brands

CHINT

CHINT NM1 Series User instruction

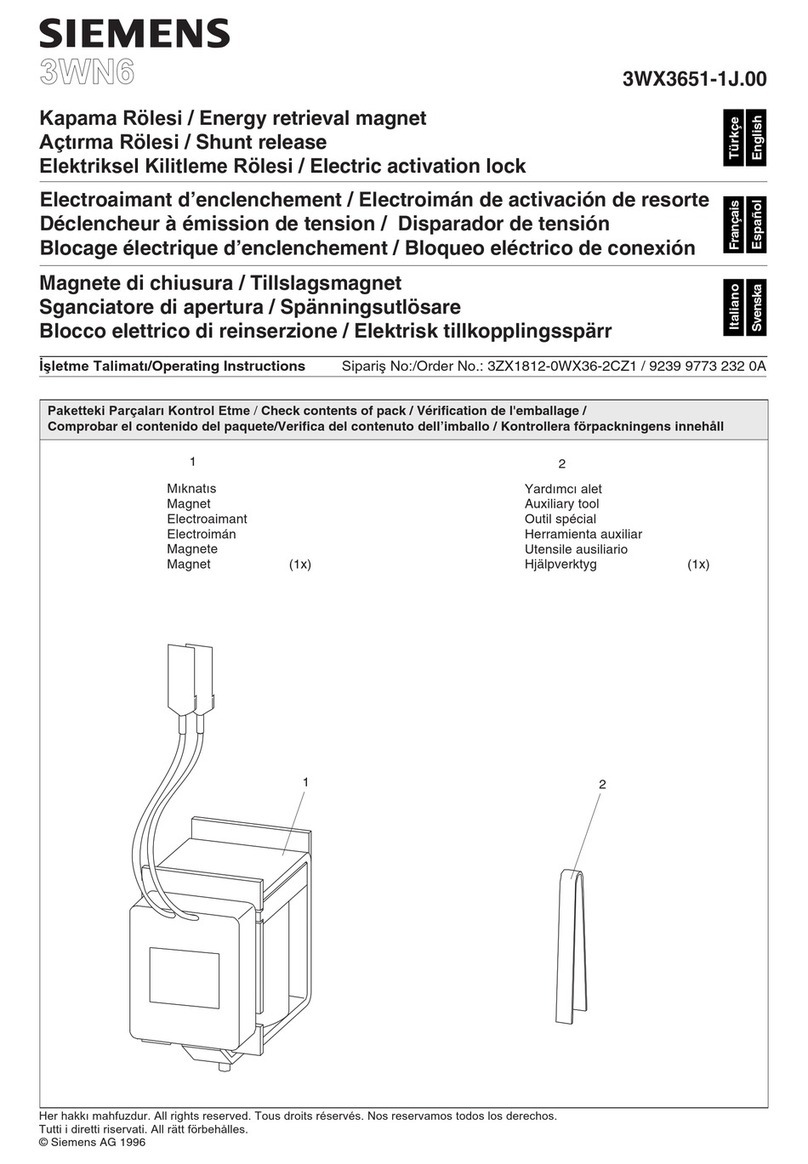

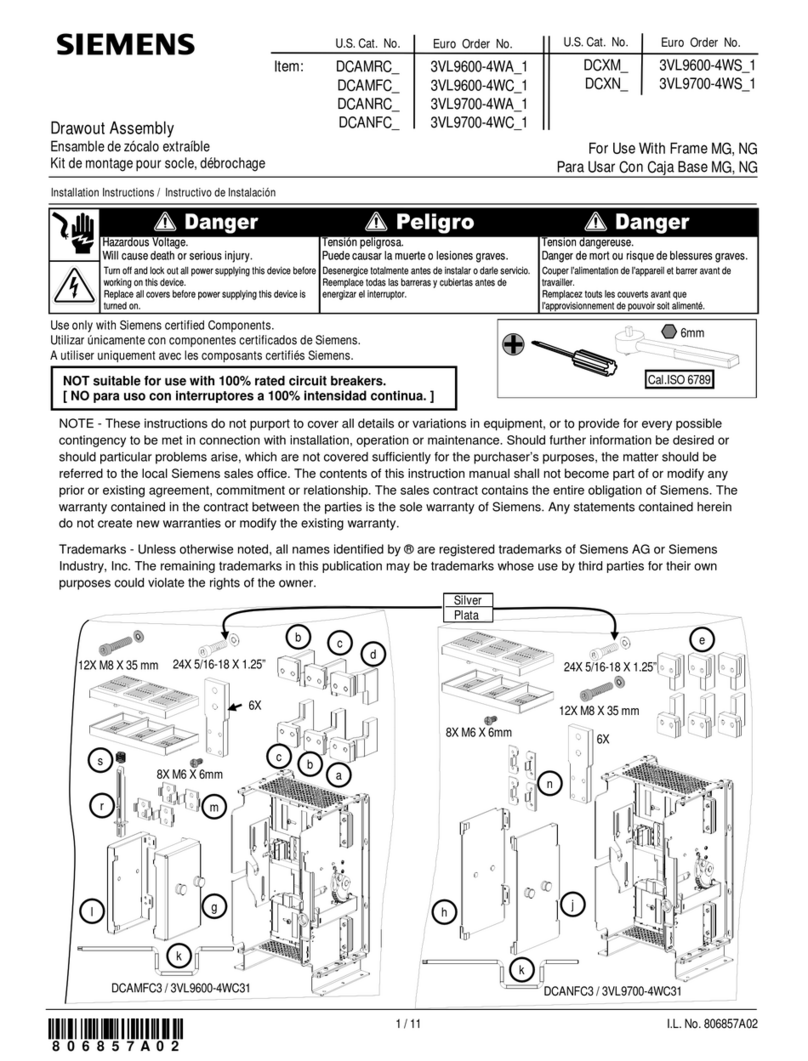

Siemens

Siemens SIRIUS 3RV2 3 Series Original operating instructions

Siemens

Siemens 3VT9300-4TC30 operating instructions

Siemens

Siemens 3VT9300-8CB30 operating instructions

Westinghouse

Westinghouse DB-75 instructions

Rockwell Automation

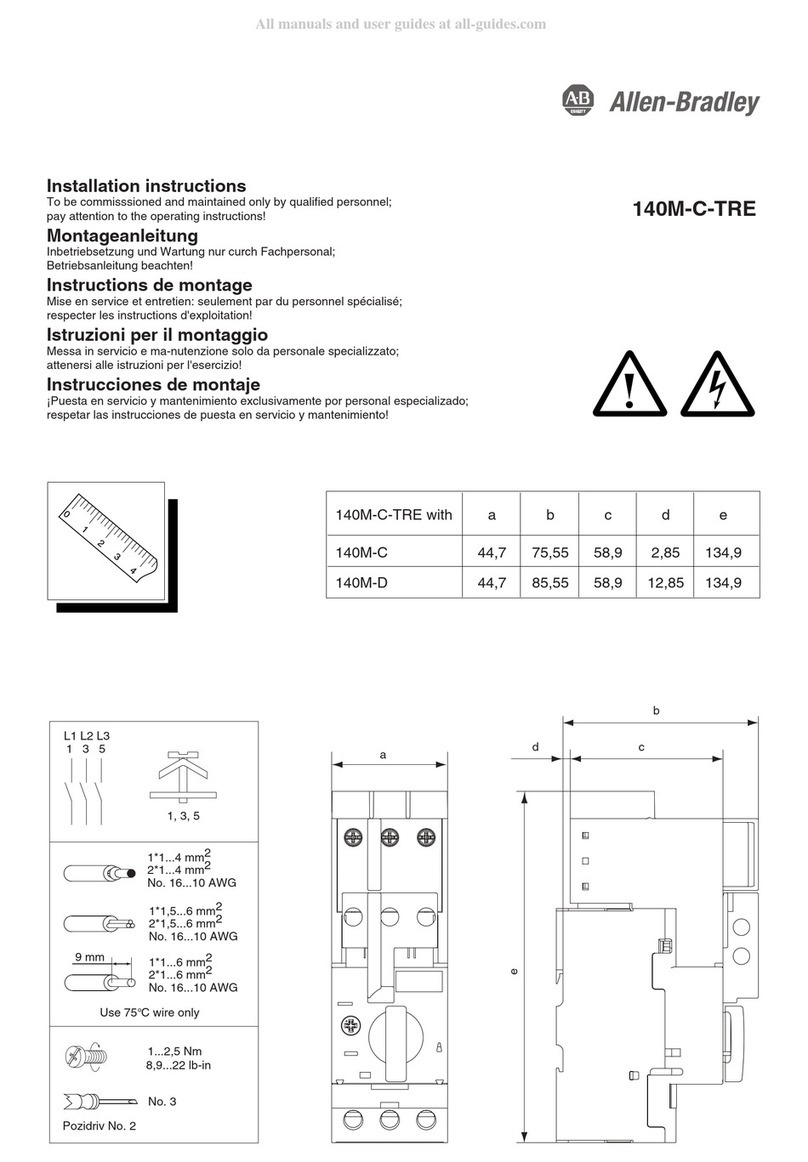

Rockwell Automation Allen-Bradley 140M-C-TRE installation instructions