FEDERAL PACIFIC PSI Series Operating and maintenance instructions

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 1

TYPE PSI

PAD-MOUNT SWITCHGEAR

15kV • 25kV • 35kV

INSTRUCTIONS

For Installation and Operation

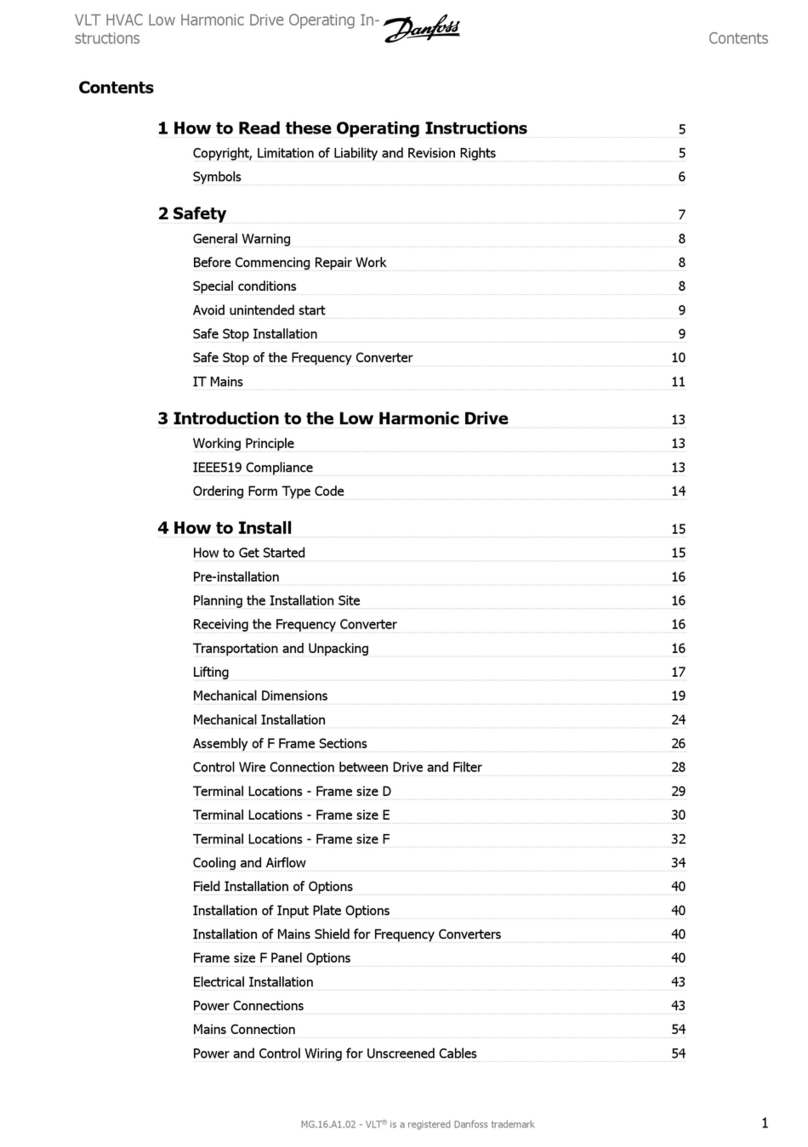

INTRODUCTION..................................................................................1

Receiving...........................................................................................1

Handling............................................................................................1

Storage..............................................................................................1

GENERAL DESCRIPTION .................................................................. 1

SAFETY FEATURES ............................................................................1

INSTALLATION ...................................................................................2

Placement of Unit .............................................................................2

Barrier System Removal ................................................................2,3

Customer Cable Connections............................................................3

SWITCH DESCRIPTION..................................................................4,5

Ratings ..............................................................................................4

Operating the Auto-jet® Switch.................................................................................................6

FUSE DESCRIPTIONS........................................................................7

Load-break Fuse Operation...............................................................7

Non-load-break Fuse Operation........................................................8

Fuse Ratings......................................................................................9

Recommended Clearances ............................................................. 11

OPTIONAL FEATURES .......................................................................8

AUTO-LATCH DOOR FEATURES.......................................................8

Operation ........................................................................................10

MAINTENANCE................................................................................10

© 2014 Electro-Mechanical Corporation

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 2

Introduction

Type PSI pad-mounted switchgear is designed to make instal-

lation, operation and maintenance as simple as possible and to

provide dependable on-the-line service.

High quality materials and careful workmanship have been

combined to provide the best switchgear available. The switch-

gear has been thoroughly inspected and adjusted at the factory.

However, successful operation depends on proper installation

and care.

This manual has been written to assist you in obtaining long and

economical service from your switchgear.

Read this manual before installing and operating your switch-

gear.

Receiving

Upon receipt of the switchgear, check each item received for

shipping damage. Each item should be checked against the

shipping manifest to assure that the proper number of items

were received. Should any shortage or damage exist, a claim

must be filed at once with the carrier, and the Federal Pacific

agent or sales office must be notified.

Handling

The switchgear is securely mounted to a sturdy shipping pallet

with provisions for forklift use in removing the unit from truck.

The use of a forklift truck is not recommended, but if this method

is used the forks must extend through the skid to avoid damag-

ing the equipment.

Removable lifting plates are provided to allow the use of hooks

to lift the complete enclosure. The lifting device should be ar-

ranged to evenly distribute the lifting force between the lifting

plates. Do not lift at an angle less than 60 ° from the horizontal.

(See Figure 1)

Storage

The switchgear as received will be wrapped in a protective

plastic film. If the switchgear is not to be installed immediately,

the protective film must be removed for outdoor storage of unit.

Export or special packing is available as an option based on

customer's requirements and special conditions. Separate

instructions are available for these situations.

Figure 1. Lifting Method

General Description

Type PSI pad-mounted switchgear consists of one or more

three-pole, single-throw, gang-operated, quick-make, quick-

break, load interrupter switches. When used in conjunction

with power fuses, expulsion or current-limiting type, and other

protective devices, the PSI switchgear provides a safe and

efficient means of 3-pole switching and circuit protection.

Safety Features

Type PSI pad-mounted switchgear incorporates a number of

security features to minimize hazards to operating personnel.

1. Rugged 11-gauge steel, all welded construction of the enclo-

sure, roof, and doors assures a tamper-resistant design.

2. Padlockable switch operating pocket handles and doors with

security bolts provide user-controlled access.

3. Switch position indicators positively verify switch position.

4. Provisions to padlock switch in open or closed position permit

user controlled switch operation. (Optional)

5. Key interlocktoensureapredetermined sequenceof mechani-

cal operations. (Optional)

6. Warning signs and labels, both external and internal, which

indicate potential hazards to personnel.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 3

Installation

Each unit is shipped with this instruction bulletin which will be

located inside the switch compartment door. These instruc-

tions should be reviewed prior to placing unit on pad.

Figure 2. Typical Pad Layout

Placement of Unit

Remove unit from shipping pallet per handling procedures of

Page 2 (Figure 1). When unit has been correctly oriented and

placed on pad (Figure 2), verify that unit is level and shim if nec-

essary between unit base and pad. Secure unit to pad using

four (4) tie-down clips as furnished (see Figures 3 and 4). Check

compartment door operation for any binding due to enclosure

distortion and re-shim if necessary. A recessed grouting

should then be applied between unit base and pad to prevent

entry of foreign objects.

Corner Detail

Base of Cabinet

Anchor Bolt

Customers Pad

Figure 3. Typical Anchor Bolt Location

Barrier System Removal

The use of interphase, phase-to-ground, and dual purpose

front barriers enhances the operation of pad-mounted switch-

gear by field personnel. The standard barrier system for Type

PSI pad-mounted switchgear is the patented drawout barrier

system which maintains all the features of a barrier system and

permits the removal of all barriers from a compartment during

initial installation and cable

termination when the switchgear

is completely de-energized

and grounded.

Removal of the barriers is readily accomplished as follows:

1. The unit must be completely disconnected from all power

sources, tested for voltage and grounded before barrier

removal is attempted.

2. Open main door and secure with door keeper.

3. Remove the dual purpose barriers from their normal hang-

ing position. If the optional B4/B5 barrier is provided, it must

be removed before dual purpose barriers may be accessed

(see page 4).

4. Rotate barrier retaining latches to vertical position. (Figure 5)

5. Grasp nylon pull loops located at upper corners of viewing

window and withdraw barrier assembly approximately 12

inches. (Figure 6)

6. Grasp side-support angles located at upper sides and

remove barrier assembly from unit. (Figure 7)

7. Place barrier assembly and components in convenient

location. (Figure 8)

8. Barrier system may be re-installed by reversing the steps

above.

Figure 4. Bolting Units to Pad

PSI-X

Recommended Pad Layout

Cabinet

Recommended

Pad Section

5/8-11 Anchor

Bolts (by others) 4 Tie Down

Plates Provided w/Unit

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 4

The optional B4/B5 lift-off barrier is provided to meet the

requirements of Section 381-G of the National Electrical Safety

Code. The B4/B5 barrier (if provided) may be removed as fol-

lows:

1. Disengage security bolts at the top of the B4/B5 barrier.

See Figure 6.

2. Grasp nylon lifting loops, remove barrier from support

hooks and remove barrier from unit. See Figure 7.

3.

B4/B5 barrier may be reinstalled by reversing the steps above.

Customer Cable Connections

With draw-out barrier assembly removed, customer cables

may be easily terminated per the following procedure:

1. The hanging weight of the primary cables must not be al-

lowed to place undue strain on the switch/fuse termination

bus. Should this situation exist, cable supports must be

used. The mounting holes in the switch/fuse termination bus

and the cable connector must align to prevent undue strain.

2. Make up the primary cable connections per user URD

operating procedures, cable manufacturer instructions, and

cable terminator manufacturer instructions.

3. Remove surface oxides and coat both surfaces with suitable

joint compound.

4. Attach cable connector to the switch/fuse termination bus

using 1/2-inch hardware as shown in Figure 8.

5. Connect the concentric neutral wires and enclosure

grounding pads inside enclosure to establish a ground sys-

tem conforming to user's standard grounding procedures.

NOTE: The maximum momentary rating of the switchgear

must be considered when selecting cable size for connecting

switchgear to system ground. Refer to unit rating plate.

6. Install and connect surge arresters or fault indicators, if ap-

plicable.

7. Install draw-out barrier system. (See section on barrier

system removal).

Figure 6

Figure 5

Figure 7

Figure 8

Figure 10

Figure 9

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 5

Switch Description

The Auto-jet®switch provides a unique method of load inter-

ruption, producing a laminated jet of air which extinguishes the

arc.

Auto-jet®switches have a heavy gauge steel, all welded base

frame that assures proper alignment and eliminates any prob-

lem of switch-to-enclosure alignment. A quick-make, quick-

break stored energy mechanism with heavy duty, long life die

springs provides high speed opening and closing independent

of the operating handle speed. This durable mechanism as-

sures safe load make, 3-time fault closing capability, and load

interruption with the Auto-jet®interrupter.

Figure 11. Connector/Termination Detail

15 kV and 25 kV Switches

34.5 kV Switches

RATINGS

kV Amperes RMS Fault-

Close

Duty

Cycle*

Nom. Max.

Des. BIL Cont.

Interrupting Mom. &

Fault-Close

(ASYM KA)

Load Cap. Mag.

15 17 95 600 600 100 21 40 3

15 17 95 1200 1200 100 21 40 3

25 27 125 600 600 100 21 40 3

34.5 38 150 600 600 27 21 40 3

*The three-time duty-cycle fault-closing rating means that the

switch can be closed three times into rated fault amperes and re-

main operable and able to carry and interrupt its rated load current.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 6

probe. At the end of its travel, the piston released from the arc-

ing probe and, under the action of the heavy spring, is rapidly

pushed backward into the cavity. This travel produces a jet of

laminated compressed air up through the hollow center of the

piston, which extinguishes the arc. The spring encircling the

movable arcing probe rapidly retracts the probe and increases

the speed of separation, which prevents restrike.

Interrupter Operation

The Auto-jet®switch has a highly efficient system for load cur-

rent interruption. This device consists of a piston (A) mounted

in the cavity of the upper insulator. The movable arcing probe

(B) engages a tulip contact (C) inside the piston. As the switch

blade (D) is pulled open by the stored energy mechanism, the

main contacts open. The piston is pulled forward by means of

the movable arcing probe, which compresses a heavy gauge

spring encircling the piston and a spring encircling the arcing

Switch closed with opening

spring relaxed.

Switch closed with opening

spring charged by manual

operating handle.

Main contacts parted, puffer

and arcing springs charged.

(Simulated condition for

illustrative purposes,

actual duration of event is

approximately 1/2 cycle.)

Switch open with latch

engaged to hold switch in

position.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 7

Operating the Auto-Jet®Switch

1. Remove padlock and open switch lockbox access cover. (Fig-

ure 12)

2. Remove switch operating handle from storage tube and

place on hex switch-operating shaft (Fig. 13). If provision to

padlock switch in open or closed position is provided (K2 op-

tion), padlock must be removed before access to hex switch-

operating shaft can be accomplished.

If key interlock(s) are provided (Optional), switch may be

locked in the open position.

3. Rotate handle in the direction as indicated to open or close

switch. Verify switch position by observing the switch posi-

tion indicator. (Figure14)

4. Remove handle and return to handle storage tube.

5. Close switch lockbox access cover and padlock.

Caution: Access cover should be padlocked whenever switch-

gear is left unattended.

NOTE: The standard barrier system provides dual purpose

barriers for insertion into the open gap when switch is in the

open position (Figure 14). Should an attempt be made to close

the switch with the DP barriers in the inserted position, the DP

barriers will prevent the switch blades from closing (Figure 15).

Should this occur, turn the switch handle briskly in the direction

required to open the switch. The switch mechanism will latch

and after the DP barriers are removed and returned to the hang-

ing position, the switch may be closed in the normal manner.

Figure 16. DP Barrier in slide-in position.

Figure 12. Remove Padlock and Open Door.

Figure 13. Remove Handle. (chained)

Figure 14. Rotate Handle in direction as indicated.

Figure 15. DP Barrier lifted to slide into place.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 8

Auto-Jet®Load-break Fuse

The Auto-jet®fuse mounting has a stored energy load-break

device that permits single-pole live switching in single phase or

three phase circuits by the use of an ordinary hotstick. The de-

vice has a 3-time fault close duty-cycle when the fuse is closed

briskly without hesitation. The overall unit rating may be limited

by the fuse rating.

The same unique laminated air jet interrupter system used in the

3-pole group operated switches is applied in the Auto-jet®load-

break fuse mountings.

Load-break Fuse Operation

1.

Open appropriate fuse compartment door and secure.

2. Remove optional B4/B5 inner door barrier, if applicable.

Remove optional B2 fuse dual purpose barrier, if applicable,

permitting access to desired fuse. The dual purpose barrier

may be removed using hotstick and grappler tool arrange-

ments. See Figure 16.

3. Install grappler tool as shown.

4. Pull the fuse open with one brisk continuous motion to fully

open position (45°). Maintain downward force on fuse until

fuse opening motion has ceased to prevent tendency for

fuse to bounce toward the closed position. See Figure 17.

Do not assume that an open fuse position indicates the fuse to

be de-energized.

5. Reinstall grappler onto fuse assembly and while grasping

hotstick firmly, lift fuse assembly up and out of mounting.

See Figure 18.

6. If optional dual-purpose barriers are supplied, use grappler

to install into slide-in position to provide barrier between

Auto-jet®fuse interrupter and fuse bottom hinge. See

Figure 19.

Do not attempt to close main door unless open fuse has been

removed from unit.

7. Re-fuse using the procedures included with the replace-

ment fuse unit.

8. Remove optional dual purpose barriers, if supplied, using

grappler. See Figure 19.

9. Reinstall grappler onto fuse assembly and place fuse

assembly into fuse mounting in the 45° open (disconnect)

position. See Figure 18.

10. Insert grappler prong into fuse pull ring and push up briskly

on the fuse assembly, completing the closing stroke in one

motion. See Figure 17.

11. Before removing grappler from fuse pull ring, push firmly to

assure that the fuse is completely closed and latched.

12. Use grappler to return optional dual purpose barrier, if

furnished, to the normal, hanging position. See Figure 16.

13. Close the main door and padlock before leaving gear.

Illustration of Auto-Jet®Fuse Interrupter

3. Holder Parted, Auto-jet®Reset For Next Operation

2. Main contacts Have Parted, Puffer Spring Charged, and Interrupter

Parted

1. Closed: Hookstick Ready To Open

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 9

Figure 21.

Non-Load-break Fuse Operation

When non-load-break style fuse mountings are furnished, such

as the S&C type SM-5 or the clip style mountings to accom-

modate Cooper Type NX andType Q, the fuse replacement

procedure would be similar to those for the Auto-jet®fuse.

However, the following precautions should be observed when

work is performed on non-load-break fuses:

1. Any upstream device which could energize the fuse must

be opened and rendered inoperative to remove possibility

of inadvertently energizing the fuse.

2. Upon opening the fuse compartment door, the equipment

should be tested for the presence of voltage using a suit-

able voltage sensing device and hotstick arrangement.

3. If no voltage is present, the appropriate fuse terminal

should be grounded using proper device and technique.

4. Fuse(s) may then be removed and replaced using appropri-

ate fuse replacement procedures.

Optional Features

Standard options can be supplied that best serve the customer's

needs and operating practices. These are listed below:

Adapter Base

(Applicable to all models except 35kV))

3" non-compartmented to match S&C PMH dimension at pad.

Base Spacer

Non-compartmented or compartmented.

Barriers — Inner Door

Lift-off insulating barrier secured with penta-head bolt.

Fuse Storage Hooks

Finish Color and Special Cabinet Material

Ground Studs

Key Interlocks

Penta-Head Security Bolts

Distribution Surge Arresters

Cable Terminators

Cable Supports

Terminal Adapters

Fault Indicators

Copper Bus

Strip Heaters

Hinged Roof

Figure 21 shows a PSI-9 unit equipped with fault indicator with

viewing windows on associated doors, 24" base spacer to pro-

vide for increased cable terminating height, and shipping pallet.

Figure 17. Figure 18.

Figure 19. Figure 20.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 10

Fuse Ratings

*In conjunction with Auto-jet®Fuse Mountings.

† Three time fault-close rating: The Auto-jet®fuse mounting can withstand a fuseholder or fuse with end fitting being closed into a fault of the magnitude specified

three times when closed briskly without hesitation and remain operable and able to carry and interrupt the rated continuous current. (The fuse must be replaced

after each interruption. Refer to S&C instruction manual for SML-4Z holder and SML-20 end fitting maintenance required after each fault close or fault interruption).

14.4kV Nominal

SM-4 fused units require three S&C Cat. No. 92352 SML-4Z fuse-

holders and three S&C SM-4 fuse refills per fuse compartment. ††

SMU-20 fused units require three S&C Cat. No. 3097 SML-20 fuse

end fittings and three S&C SMU-20 fuse units per fuse compart-

ment. ††

SM-5 fused units require three S&C Cat. No. 86642R2 SM-5S fuse-

holders and three S&C SM-5 fuse refills per fuse compartment. ††

DBU fused units require three FP Cat. No. EFA-42 DBU end fittings

and three Eaton DBU fuse units per fuse compartment. ††

NX fused units: Auto-jet®fuse mountings will accommodate one

100 ampere Cooper Type NX current limiting fuse rated 8.3kV, one

100 ampere fuse rated 13.5kV, or one 80 ampere fuse rated 15kV.

Three sets of Auto-jet® end fittings and three appropriately rated

fuses are required in each fuse compartment. ††

Qfused units: Auto-jet®fuse mountings will accommodate one 100

ampere Cooper Type Q current limiting fuse rated 8.3kV or 15kV.

Three sets of Auto-jet®end fittings and three appropriately rated

fuses are required in each fuse compartment.

25kV Nominal

SM-4 fused units require three S&C Cat. No. 92353 SML-4Z fuse-

holders and three S&C SM-4 fuse refills per fuse compartment. ††

SMU-20 fused units require three S&C Cat. No. 3097 SML-20 fuse

end fittings and three S&C SMU-20 fuse units per fuse compart-

ment. ††

SM-5 fused units require three S&C Cat. No. 86643R2 SM-5S fuse-

holders and three S&C SM-5 fuse refills per fuse compartment. ††

DBU fused units require three FP Cat. No. EFA-42 DBU end fittings

and three Eaton DBU fuse units per fuse compartment. ††

NX fused units: Auto-jet®fuse mountings will accommodate one

100 ampere Cooper Type NX current limiting fuse rated 13.5kV,

one 80 ampere fuse rated 15kV, or one 40 ampere fuse rated 23kV,

or one 50 ampere fuse rated 27kV. Three sets of Auto-jet®end

fittings and three appropriately rated fuses are required in each

fuse compartment. ††

Qfused units: Auto-jet®fuse mountings will accommodate one 100

ampere Cooper Type Q current limiting fuse rated 15.5 kV, one 100

ampere fuse rated 23kV, or one 80 ampere fuse rated 27kV. Three

sets of Auto-jet®end fittings and three appropriately rated fuses

are required in each fuse compartment. ††

Ratings expressed in RMS amperes asymmetrical are 1.6 times

the symmetrical values listed.

Unit overall ratings are limited to the lowest component rating.

Load-break rating same as maximum continuous current rating.

†† For fuse application and ordering information refer to the current issue of:

• S&C Bulletin 252-31

• Cooper (McGraw-Edison) Cat. Sect. 240-60

• Eaton Cat. Sect. 4.4

• Eaton Cat. Sect. AD36-643

• Eaton Cat. Sect. PL36-609

Fuse

Manufacturer

and Type ††

Amperes RMS

3-Phase

MVA SYM

Max. Cont. Load-break* Interrupting SYM

Momentary &

3-Time Fault-Close†

ASYM

At 14.4kV Nominal Voltage • 95 kV BIL

S&C SM-4 200 200 12,500 20,000 310

S&C SMU-20 200 200 14,000 22,400 350

S&C SM-5 400 NLB 25,000 N/A 620

Eaton DBU 200 200 14,000 22,400 350

Cooper NX 50,000 40,000 620

Cooper Q 12,500 40,000 620

At 25kV Nominal Voltage • 125 kV BIL

S&C SM-4 200 200 12,500 20,000 540

S&C SMU-20 200 200 12,500 20,000 540

S&C SM-5 300 NLB 20,000 N/A 865

Eaton DBU 200 200 12,500 20,000 540

Cooper NX 50,000 40,000 1,080

Cooper Q 25,000 40,000 1,080

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 11

Maintenance

Federal Pacific switchgear does not require routine mechani-

cal or electrical maintenance. However, the following are some

recommendations for enhancing continued service of the equip-

ment.

1. Yearly mechanical exercising of the switch is recommended.

Warning: The switchgear must be completely de-energized from

all sources before any attempt is made to enter switchgear.

2. Check for cleanliness generally, but particularly for accumu-

lation of any foreign material on insulators.

Caution: Do not put grease on switch probe or puffer.

3. If the switch is closed on a short circuit within the making

capacity rating and the short circuit is cleared by circuit

breakers or fuses, the switch will not sustain damage which

would require major repairs. However, the switch should be

inspected before returning to service to determine switch

condition.

Figure 24.

Figure 25.

Auto-Latch Features

The automatic door latching feature furnished on the main

doors provides ease in opening and closing of the doors. Fea-

tures of the Auto-latch system are:

• Automatic 3-point latching upon door closure. See Figure 22.

•

After unlatching on opening, the door is automatically set for

latching upon door closure.

• A recessed, flush-mounted, stainless steel pocket contains

the padlock and security bolt.

• To discourage tampering, the padlock must be removed in

order to raise protective cover and gain access to security

bolt.

• A closed, latched, Auto-latch door can successfully with-

stand a "pull" greater than 600 pounds at any point on the

door.

Caution: It is not necessary to apply

torque on the bolt once the door is

unlatched. The bolt is not removable. A

force of 25 to 30 ft. - pounds will cause a

failure.

Auto-Latch Operation

Opening:

1. Remove padlock and raise protective cover exposing security

bolt. (Figure 24)

2. Using a standard 9/16 inch socket for hexhead security bolt or

standard pentahead socket for pentahead security bolt, rotate

the captive actuator bolt head 60° in either direction to release

latching mechanism. (Figure 25)

3. Open door and secure with door keeper. (Figure 23)

Closing:

1. Lift up door keeper and close door by pushing briskly. Mecha-

nism will automatically latch.

2. Install protective cover and install padlock.

Figure 23.

Figure 22.

601 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 669-1869 • www.federalpacific.com • ISO9001:2015

SECTION IB-1G-500

INSTALLATION & OPERATION INSTRUCTIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

REV. 1.6 - NOVEMBER 2017

PAGE 12

Minimum Clearance

from Energized

Parts to Barrier.

Minimum Clearance

from Terminator

Skirts to Barriers.

G. E. Type G. Termi-matic

Termination System Shown.

Phase-to-Phase or

Phase-to-Ground

with Barrier

Minimum Clearance

from Energized Parts

to Barrier

Typical Barrier-to-

Ground in Vicinity of

Energized Parts

Minimum Clearance

from Terminator

Skirts to Barriers

G. E. Type G. Termi-matic

Termination System Shown

Minimum Clearance from

Energized Parts to Electrical

Ground without Barrier.

Minimum Clearance

from Energized Parts to

Electrical Ground without

Barrier.

Minimum Clearance

from Energized Parts

to Electrical Ground

without Barrier.

Check clearances

for both normal and

alternate positions of

fuse termination bus.

ALTERNATE POSITION

NORMAL

POSITION

RECOMMENDED CLEARANCES

SEE TABLE BELOW

15kV, 25kV and

35kV

Pad-mounted

Unit Rating

kV, BIL

Recommended Clearances

(Minimum) in Inches

Phase-to-

Phase or

Phase-to-

Ground

without

Barrier

Phase-to-

Phase or

Phase-to-

Ground

with

Barrier

Energized

Bus (or

device) to

Barrier

Barrier to

Ground in

Vicinity of

Energized

Bus (or

device)

Terminator

Skirts to

Barrier

Note Note Note Note Note

95 5-1/2 3 1 3/4 1/2

125 7-1/2 5 2-1/4 2 1-1/4

150 10 6 3 2 2

Every effort is made to ensure that customers receive an up-to-date instruction manual on the use of Federal Pacific

products; however, from time to time, modifications to our products may without notice make the information contained

herein subject to alteration.

© 2014 Electro-Mechanical Corporation

Table of contents

Popular DC Drive manuals by other brands

HELVAR

HELVAR LL60/2-E-DA-iC manual

Lenze

Lenze L-force 8400 Series Mounting instructions

Unitek

Unitek TVD6.2-RS manual

YASKAWA

YASKAWA Z1000 CIMR-ZU*A Series User's manual supplement

Danfoss

Danfoss VLT HVAC Drive FC 102 operating instructions

Vatech

Vatech pDRIVE CX profi Operating and mounting instructions