FEDERAL PACIFIC PSE Installation instructions

1075 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 645-8206 • www.federalpacic.com • ISO9001:2015

SECTION IB-2B-800A

SUPPLEMENT TO INSPECTION AND MAINTENANCE RECOMMENDATIONS

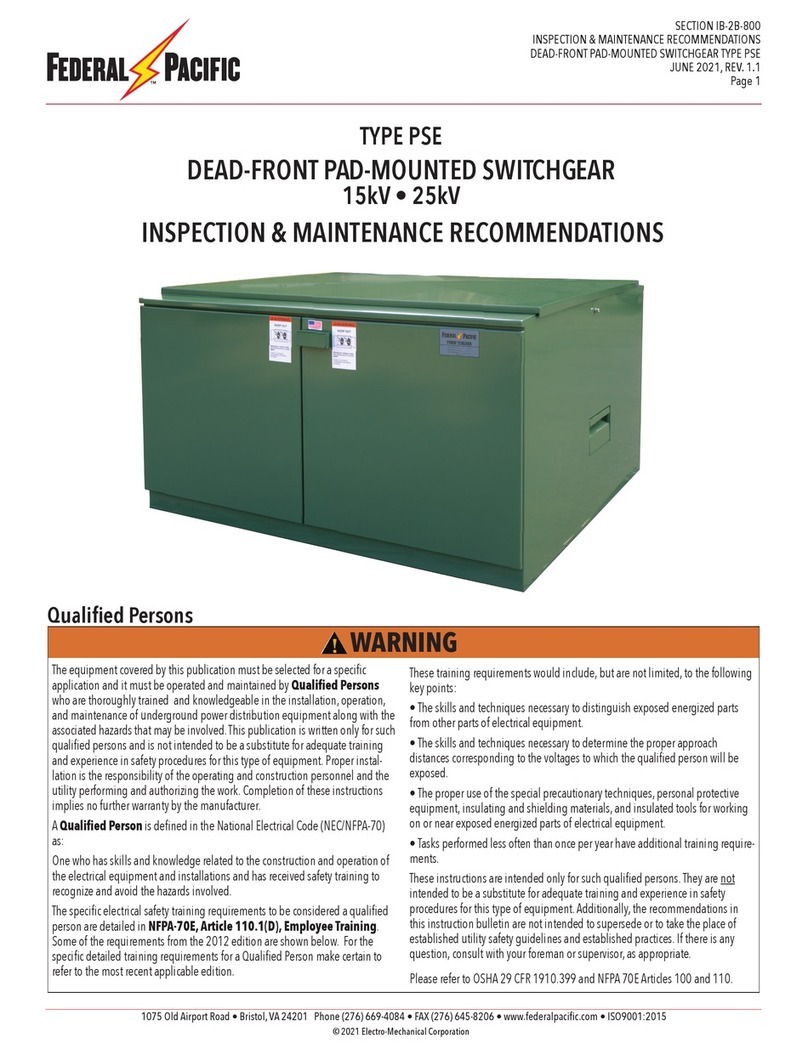

TYPE PSE DEAD-FRONT PAD-MOUNTED SWITCHGEAR

JUNE 2021

Page 1

Restoring Type PSE Dead-Front

Pad-Mounted Switchgear

Following Immersion in Flood Waters

Supplement to Inspection and Maintenance Recommendations

(Instruction Bulletin IB-2B-800)

© 2021 Electro-Mechanical Corporation

These training requirements would include, but are not limited, to the following

key points:

• The skills and techniques necessary to distinguish exposed energized parts

from other parts of electrical equipment.

• The skills and techniques necessary to determine the proper approach

distances corresponding to the voltages to which the qualied person will be

exposed.

• The proper use of the special precautionary techniques, personal protective

equipment, insulating and shielding materials, and insulated tools for working

on or near exposed energized parts of electrical equipment.

• Tasks performed less often than once per year have additional training

requirements.

These instructions are intended only for such qualied persons. They are not

intended to be a substitute for adequate training and experience in safety

procedures for this type of equipment. Additionally, the recommendations in

this instruction bulletin are not intended to supersede or to take the place of

established utility safety guidelines and established practices. If there is any

question, consult with your foreman or supervisor, as appropriate.

Please refer to OSHA 29 CFR 1910.399 and NFPA 70E Articles 100 and 110.

Qualied Persons

The equipment covered by this publication must be selected for a specic

application and it must be operated and maintained by Qualied Persons

who are thoroughly trained and knowledgeable in the installation, operation,

and maintenance of underground power distribution equipment along with

the associated hazards that may be involved.This publication is written only

for such qualied persons and is not intended to be a substitute for adequate

training and experience in safety procedures for this type of equipment. Proper

installation is the responsibility of the operating and construction personnel and

the utility performing and authorizing the work. Completion of these instructions

implies no further warranty by the manufacturer.

A Qualied Person is dened in the National Electrical Code (NEC/NFPA-70) as:

One who has skills and knowledge related to the construction and operation of

the electrical equipment and installations and has received safety training to

recognize and avoid the hazards involved.

The specic electrical safety training requirements to be considered a qualied

person are detailed in NFPA-70E, Article 110.1(D), Employee Training. Some

of the requirements from the 2012 edition are shown below. For the specic

detailed training requirements for a Qualied Person make certain to refer to the

most recent applicable edition.

WARNING

1075 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 645-8206 • www.federalpacic.com • ISO9001:2015

SECTION IB-2B-800A

SUPPLEMENT TO INSPECTION AND MAINTENANCE RECOMMENDATIONS

TYPE PSE DEAD-FRONT PAD-MOUNTED SWITCHGEAR

JUNE 2021

Page 2

This supplement is to be used in conjunction with Instruction Bulletin

IB-2B-800, “Inspection and Maintenance Recommendations for Dead-Front

Pad-Mounted Switchgear, Type PSE”. All Caution, Warning, Danger, and other

Notes in that document apply to this supplementary document.

Air insulated switchgear, be it Live-Front (PSI) or Dead-Front (PSE), is not

designed to be submersible. Once water touches, or comes in proximity

to, energized parts or interrupting components, there is a substantially

increased probability of immediate electrical failure or delayed electrical

or mechanical failure of the switchgear. This supplement addresses the

corrective actions to address exposure to a submerged condition.

When conditions warrant, barriers and insulators can be cleaned with a

non-alcohol and non-solvent based cleaner that does not leave a residue

when dry. Any residue must be removed. Any barrier showing swelling or

warping should be replaced.

When cleaning components, NEVER use any industrial strength cleaners.

NEVER apply lubricants to the probe contact or the tulip contact, which

aretheinterruptingcontacts.NEVER use any solvent-based or ammable

products on any components in the pad-mounted switchgear. Solvents

and ammable products can attack non-metallic components of the

equipment and reduce electrical and mechanical properties.

Before Opening the Switchgear

Thefollowinginspectionandmaintenanceproceduresmustbeperformed

with the current-carrying parts completely de-energized and isolated from

voltage. Any attempt to perform the inspection and maintenance with

the current-carrying parts energized may result in electrical arc ash that

can cause equipment damage, personal injury or death.

Initial Inspection after Flooding Event

1. If water has reached the oor-plate in the medium voltage compartment

of a PSE dead-front pad-mounted switchgear unit (the top of the base

spacer or bottom of the switchgear, if there is no base spacer), then action

must be taken to preserve and restore the switchgear.

The switchgear must be completely de-energized from all sources before

anyattemptis madeto enterswitchgear.Follownormal system operating

practices to de-energize the unit, test for voltage and ground the unit

before any work is performed.

2. If the switchgear has been submerged above the level of the switch

interrupters or the fuse-mounting interrupters, the user may want to

consider replacement, since it will be difcult to fully clean the interiors

of the interrupters, reassemble,and realign them by other than factory

personnel.

Standard Cleaning and Maintenance

3. Perform the Inspection and Maintenance functions recommended

in Federal Pacic Instruction Bulletin IB-2B-800, including cleaning

materials, lubrication, as well as the recommendations and procedures

contained in this supplement.

Barriers, viewing windows and insulators can be cleaned with a non-

alcohol and non-solvent based cleaner that does not leave any residue

when dry. Residue must be removed.

Flooded Switchgear - Additional Steps

4. PSE Dead-Front Switchgear which has been ooded and is deemed

suitable for restoration to service will require the additional inspection,

cleaning, and maintenance.

Current carrying parts must be completely de-energized from all sources

before any maintenance is performed on these parts. Follow normal

system operating practices to de-energize, test for voltage and ground

these parts before any work is performed. Any attempt to perform the

inspection and maintenance with the current-carrying parts energized

may result in electrical arc ash that can cause equipment damage,

personal injury or death.

a. Remove the roof. There are six sets of clamps and bolts (three on each

side) in the termination compartments.

b. Remove the internal barriers.Take care not to damage barriers during

removal or reinstallation.

When removing barriers, care must be taken to keep the barrier clean

and dry.Contamination on barrier can lead to tracking and arcing.Clean

off any contamination with a non-alcoholic and non-solvent based

cleaner that does not leave any residue.

c. Remove and clean or discard (and replace with new) the screened vent

screens at the bottom of the medium-voltage compartment.

d. Rinse the interior of the switchgear with low pressure clean water and

ush out any debris or water-soluble surface contaminants.

e. Clean the bus, the interrupters,the support insulators, and the barrier

boards.

f. Rinse thoroughly with clean water

g. Dry with compressed air or other similar approved means.

h. After cleaning and drying,inspect all insulators and bushings to make

certain there is no surface damage,including any imbedded perma-

nent discolorations or cracks.

• All damaged, discolored,or cracked insulators must be replaced.

i. After cleaning anddrying,inspect all barriers,make certain thatthere is

no surfacedamage,including any imbeddedpermanent discoloration

or warping.

• All discolored barriers must be replaced.

• Warped barriers must be inspected to make certain that correct

“Electrical Clearances” are met, as specied in Table 1, and replace

if necessary.

NOTICE

WARNING

WARNING

WARNING

WARNING

DANGER

1075 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 645-8206 • www.federalpacic.com • ISO9001:2015

SECTION IB-2B-800A

SUPPLEMENT TO INSPECTION AND MAINTENANCE RECOMMENDATIONS

TYPE PSE DEAD-FRONT PAD-MOUNTED SWITCHGEAR

JUNE 2021

Page 3

j. After cleaning and drying, inspect all metallic components of the

switches and fuse mountings for corrosion. Operating components

such as door latching mechanisms, springs, probes, switchblades,

contacts,bus, ground studs andground bars,and hardwareitems,such

as nuts, bolts, washers, etc. displaying corrosion must be replaced.

k. Lubrication of Non-Current Carrying Parts – Non-current carrying parts,

such as operating mechanisms,hinges and latches, may be lubricated

with anylubricants that theuser has determinedto be suitablefor such

applications.

l. Lubrication of Current Carrying Parts – NYE Reolube 363 is the only

approved lubricant for current carrying parts, as listed below. Apply

only a thin coat of lubricant.

• Fuse panel main contact stab.

• Contact interface at the fuse-mounting lower contact (hinge end).

• Contact interface at the fuse-mounting upper contact (receiver).

• Main-contact stab (stationary contact) on the Auto-jet®switches.

m.

Install new vent plugs (or re-install cleaned existing plugs) at the bottom

of the medium voltage compartment.

n. Verify that all bolts remain torqued for tightness and circuit continuity.

o. Reinstall the barriers.

p. Remove the old roof gasket and install a new roof gasket.

q. Ensure that the roof and interior are dry before re-installing.

r. Verify the integrity of terminations in accordance with the terminator

manufacturer’s recommendations. Replace any cable accessories or

other third party components as appropriate.

s. Verify the integrity of SML-20 components and end ttings, FP-3097

end ttings, SMU-20 and DBU fuse units/rell units and SML-4Z fuse

holders and rell units in accordance with the fuse manufacturer’s

recommendations.

• All fuses and fuse rell units in the switchgear which were not

sealed and known to be free of moisture must be considered to be

potentially damaged and are to be discarded and replaced.

• A silencerthat has beensubmerged mustbe replacedas anyresidue

inside may clog the exhaust path and cause a misoperation of the

fuse assembly when a subsequent fuse operation occurs.

t. Replace instruction manuals and any damaged or obscured name-

plates, ratings labels and hazard alerting signs (DANGER, WARNING,

and CAUTION) of the pad-mounted switchgear.

u. BEFORE RETURNING THE SWITCHGEAR TO SERVICE:

i. With the equipment de-energized, perform one or two mechani-

cal operations of each switch and fuse mounting to verify correct

operation and alignment as described in Federal Pacic Instruction

Bulletin IB-2A-210 – “Instructions for Installation and Operation,

Type PSE. Dead-Front Pad-Mounted Switchgear, 15kV – 25kV.”

ii. Verify the integrity of the insulation system in the equipment by

applying high potential testing in accordance with applicable

industry standards and the utility standard operating practices.

iii. As the combined effect of having many components submerged

in water, which may have been polluted with heavy levels of

contamination, and where there is a potential for hidden dam-

age or hazards to go unnoticed, it is recommended that the unit

be energized by a means the is initiated from a location OTHER

THAN by operating the components such as switches and fuses

in the specic switchgear unit being returned to service. For this

purpose, Federal Pacic has developed a CO2actuated Portable

Remote Operating Mechanism (PROM). Refer to Federal Pacic

for details on this product.

5. If there is any doubt or suspicion about any component, it should be

replaced.

Replacement Parts and Labels

If parts or labels are required, they may be ordered by contacting your local

Federal Pacic Representative. A directory of the representatives can be found

at www.federalpacic.com. You may also contact Federal Pacic directly

at 276-669-4084.

If parts or labels are ordered, the unit serial number must be provided along

with the part description.

Table 1 — Recommended Electrical Clearances

15kV, 25kV

Pad-Mounted

Unit Rating

kV BIL

Recommended Clearances (minimum, in inches)

Phase-to-Phase

or

Phase-to-Ground

Without

Barrier

Phase-to-Phase

or

Phase-to-Ground

With Barrier

Energized

Bus

(or device)

to Barrier

Barrier-to-Ground

in Vicinity

of

Energized Bus

(or device)

Terminator

or

Insulator

Skirts

to Barrier

95 5-1/2" 3" 1" 3/4" 1/2"

125 7-1/2" 5" 2-1/4" 2" 1-1/4"

CAUTION

Do not put any lubricant on switch probe or puffer contacts. Refer to

Inspection Bulletin IB-2B-800, section 10, "Lubrication of Current

Carrying Parts".

1075 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 645-8206 • www.federalpacic.com • ISO9001:2015

SECTION IB-2B-800A

SUPPLEMENT TO INSPECTION AND MAINTENANCE RECOMMENDATIONS

TYPE PSE DEAD-FRONT PAD-MOUNTED SWITCHGEAR

JUNE 2021

Page 4

Every effort is made to ensure that customers receive an up-to-date instruction manual on the use of Federal Pacic products; however, from time

to time, modications to our products may without notice make the information contained herein subject to alteration.

Notes:

© 2021 Electro-Mechanical Corporation

Other manuals for PSE

3

Other FEDERAL PACIFIC Tools manuals