FEDERAL PACIFIC PSI Installation instructions

1075 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 645-8206 • www.federalpacic.com • ISO9001:2015

SECTION IB-1G-805

INSPECTION & MAINTENANCE RECOMMENDATIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

JUNE 2021, REV 1.1

Page 1

The procedures required for operation of the Federal Pacic Auto-jet®II

Load-Interrupter Switches, the Non-Load-break Fuse Mountings, the

doors, the barriers and other accessory components are covered in

detail in the Federal Pacic Instruction Bulletin Section IB-1G-500.

The inspection and maintenance recommendations covered in this

bulletin are expected to be performed in conjunction with a review

of IB-1G-500. This bulletin does not cover all the detailed and specic

operational procedures and checks. In addition, these instructions are

not intended as a substitute for the user’s standard operating practices

and procedures. A copy of Instruction Bulletin Section IB-1G-500 can

be obtained by contacting Federal Pacic at www.federalpacic.com.

When cleaning components, NEVER use any industrial strength

cleaners. NEVER apply lubricants to the probe contact or the

tulip contact which are the interrupting contacts. NEVER use any

solvent-based or ammable products on any components in the

pad-mounted switchgear. Solvents and ammable products can

attack non-metallic components of the equipment and reduce

electrical and mechanical properties.

TYPE PSI

PAD-MOUNTED SWITCHGEAR

15kV • 25kV • 35kV

INSPECTION & MAINTENANCE RECOMMENDATIONS

Before Opening the Switchgear

The following inspection and maintenance procedures must be

performed with the unit completely de-energized and isolated from

voltage. Any attempt to perform the inspection and maintenance

with the unit energized may result in electrical arc ash that can

cause equipment damage, personal injury or death.

© 2021 Electro-Mechanical Corporation

INSPECTION & MAINTENANCE RECOMMENDATIONS

Qualied Persons

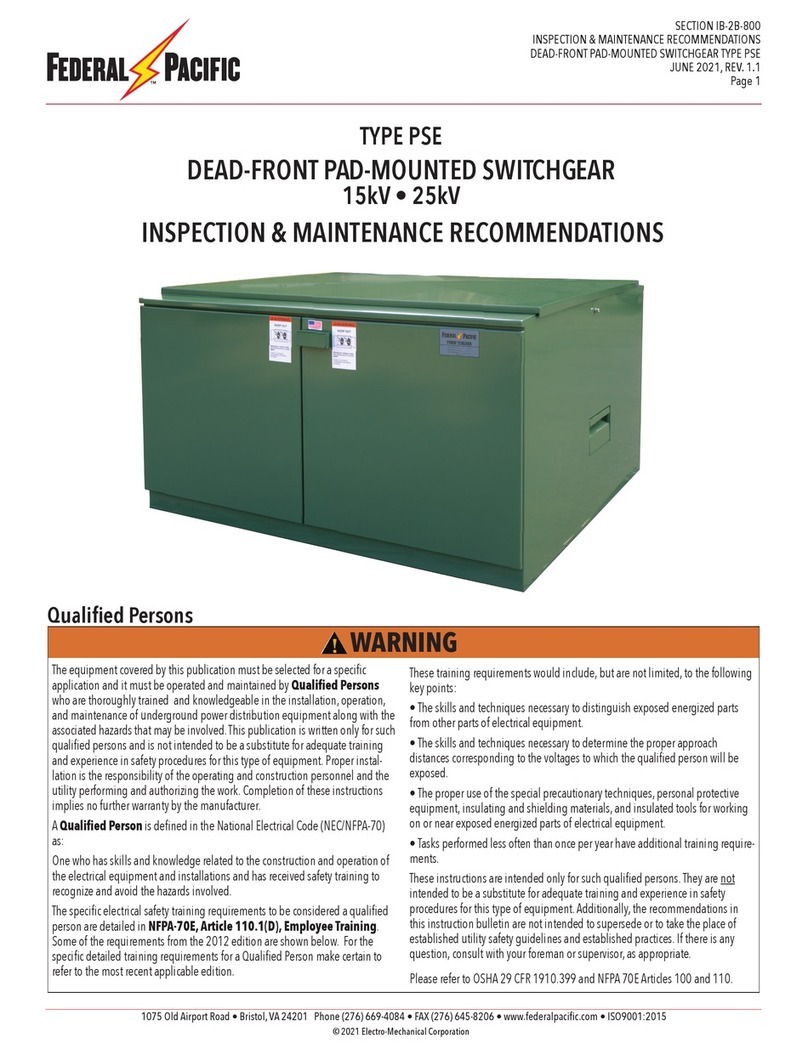

The equipment covered by this publication must be selected for a specic

application and it must be operated and maintained by Qualied Persons

who are thoroughly trained and knowledgeable in the installation, operation,

and maintenance of underground power distribution equipment along with

the associated hazards that may be involved. This publication is written only

for such qualied persons and is not intended to be a substitute for adequate

training and experience in safety procedures for this type of equipment.

Proper installation is the responsibility of the operating and construction

personnel and the utility performing and authorizing the work. Completion

of these instructions implies no further warranty by the manufacturer.

A Qualied Person is dened in the National Electrical Code (NEC/NFPA-

70) as:

One who has skills and knowledge related to the construction and operation

of the electrical equipment and installations and has received safety training

to recognize and avoid the hazards involved.

The specic electrical safety training requirements to be considered a qualied

person are detailed in NFPA-70E, Article 110.1(D), Employee Training.

Some of the requirements from the 2012 edition are shown below. For the

specic detailed training requirements for a Qualied Person make certain

to refer to the most recent applicable edition.

These training requirements would include, but are not limited, to the

following key points:

• The skills and techniques necessary to distinguish exposed energized

parts from other parts of electrical equipment.

• The skills and techniques necessary to determine the proper approach

distances corresponding to the voltages to which the qualied person will

be exposed.

• The proper use of the special precautionary techniques, personal protective

equipment, insulating and shielding materials, and insulated tools for

working on or near exposed energized parts of electrical equipment.

• Tasks performed less often than once per year have additional training

requirements.

These instructions are intended only for such qualied persons. They are not

intended to be a substitute for adequate training and experience in safety

procedures for this type of equipment. Additionally, the recommendations

in this instruction bulletin are not intended to supersede or to take the place

of established utility safety guidelines and established practices. If there

is any question, consult with your foreman or supervisor, as appropriate.

Please refer to OSHA 29 CFR 1910.399 and NFPA 70E Articles 100 and 110.

WARNING

WARNING

DANGER

Maintenance

Federal Pacic switchgear

does not require routine

mechanical or electrical

maintenance. However,

the following are some

recommendations for

enhancing continued

service of the equipment.

1075 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 645-8206 • www.federalpacic.com • ISO9001:2015

SECTION IB-1G-805

INSPECTION & MAINTENANCE RECOMMENDATIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

JUNE 2021, REV 1.1

Page 2

1. Exercising

Yearly mechanical exercising of the switch is recommended.

Refer to Instruction Bulletin Section IB-1G-500 for information

on operating the switch.

The switchgear must be completely de-energized from all sources

before any attempt is made to enter switchgear. Follow normal

system operating practices to de-energize the unit, test for voltage

and ground the unit before any work is performed.

2. Cleanliness

Check for cleanliness generally, but particularly for accumulation

of any foreign material on insulators and barriers.

Barriers and insulators can be cleaned with a non-alcohol and

non-solvent based cleaner that does not leave any residue when

dry. Residue must be removed.

Clean skirts of cable terminators and surge arrestors in accordance

with instructions provided by the manufacturers of those devices.

3. Barrier Removal

Fuse and Switch Dual-Purpose Barriers should not be left in

the slide-in position for more than one week. Accumulation

of contamination on the barrier may cause tracking that can

ultimately lead to a ashover. Clean any contaminated barrier per

"Maintenance" instructions above.

The use of interphase, phase-to-ground, and dual purpose front

barriers enhances the operation of pad-mounted switchgear by eld

personnel. The standard barrier system for Type PSI pad-mounted

switchgear includes a removable barrier assembly that allows removal

of phase-to-phase and phase-to-ground barriers from both the

switch and fuse compartments during initial installation and cable

termination or at any other time when the switchgear is de-energized.

When removing barriers, care must be taken to keep the barrier clean

and dry. Contamination on barrier can lead to tracking and arcing.

Clean off any contamination with a non-alcoholic and non-solvent

based cleaner that does not leave any residue.

Removal of the barriers is readily accomplished as follows:

a. Completely disconnect the unit from all power sources.

b. Open main door (see "Auto-Latch Features" and "Auto-Latch

Operation" on page 11 of Instruction Bulletin IB-1G-500) and

secure with door keeper.

c. Remove the dual-purpose barriers from their normal hanging

position (see instructions on pages 3 and 4 of Instruction Bulletin

IB-1G-500). If the optional B4/B5 barrier is provided, it must be

opened and secured before dual-purpose barriers may be accessed

(see page 4 of Instruction Bulletin IB-1G-500).

d. Test for voltage, and ground the unit using the user's standard

practice procedures and using grounding clamps suitable for the

short-circuit rating of the equipment.

e. See "Barrier System Removal" on pages 3 and 4 of IB-1G-500

for instructions on the procedure to follow when removing the

barrier system.

f. Barriers may be reinstalled by following the reverse procedure

to that described on pages 3 and 4 of IB-1G-500.

g. Dual purpose barriers may then be reinstalled.

h. Do not leave dual-purpose barriers in the slide-in position for

more than one week.

4. Switch Operation

Do not put any lubricant on switch probe or puffer tulip contacts. Refer

to section "11. Lubrication". Placing any lubricant on the probe or tulip

contacts (in the puffer assembly) will result in a disruptive event that may

cause equipment damage.

Check switch for proper operation refer to Instruction Bulletin IB-

1G-500. If the switch is closed on a short circuit within the fault

closing rating and the short circuit is cleared by circuit breakers or

fuses, the switch will not sustain damage which would require major

repairs. However, the switch should be inspected before returning

to service to determine switch condition. See Lubrication. Slight

arcing on switchblades and contacts can be burnished smooth

with an emery cloth or paper.

5. Fuse Operation

Open and close fuses and insure proper latching. Refer to

pages 8 and 9 in IB-1G-500. Inspect fuse contact interfaces for

damage and overheating, which will be evidenced by distortion

or discoloration of the contacts. Note that contacts are copper

and may be silver plated. There will be normal oxidation of these

parts. Slight irregularities can be burnished with an emery cloth

or paper. See "Lubrication".

6. Replacement Parts

If parts or labels are required they may be ordered by contacting

Federal Pacic at 276-669-4084 or your local Federal Pacic Sales

Territory Manager or Manufacturer's Representative. A directory

of the representatives can be found at www.federalpacic.com. If

parts are ordered, the unit serial number and date of manufacture

must be provided along with the part description.

7. Electrical Clearances

Check for proper electrical clearances as described in

Recommended Clearances.

NOTICE

WARNING

WARNING

DANGER

CAUTION

1075 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 645-8206 • www.federalpacic.com • ISO9001:2015

SECTION IB-1G-805

INSPECTION & MAINTENANCE RECOMMENDATIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

JUNE 2021, REV 1.1

Page 3

Check clearances for both normal

and alternate positions of fuse

termination bus.

Minimum clearance from

energized parts to electrical

ground without barrier.

Minimum clearance from

energized parts to electrical

ground without barrier.

Check clearances for both

normal and alternate positions

of fuse termination bus.

G.E. Type G Termi-matic

Termination System shown.

Minimum clearance from

terminator skirts to barriers.

Minimum clearance from

energized parts to barrier.

G.E. Type G Termi-matic Termi-

nation System shown.

Normal

Position

Alternate

Position

Minimum clearance from

energized parts to electrical

ground without barrier.

Recommended Clearances

15kV, 25kV

Pad-mounted

Unit

Rating

kV, BIL

Recommended Clearances

(Minimum) in Inches

Phase-to-

Phase or

Phase-to-

Ground

without

Barrier

NOTE

Phase-to-

Phase or

Phase-to-

Ground

with Barrier

NOTE

Energized

Bus (or

device) to

Barrier

NOTE

Barrier-to-

Ground in

Vicinity of

Energized

Bus

(or device)

NOTE

Terminator

Skirts to

Barriers

NOTE

95 5-1/2 3" 1" 3/4" 1/2"

125 7-1/2 5" 2-1/4" 1" 1-1/4"

150 10 6" 3" 2" 2"

Minimum clearance

from Terminator Skirts

to Barriers:

in Vicinity of Energized

Parts:

Minimum Clearance

from Energized

Parts to Barrier:

Typical Barrier to Ground

Phase-to-Phase or Phase-

to-Ground

with Barrier:

G. E. Type G Termi-matic Termination System Shown

DANGER

Failure to observe the electrical clearances specied in the

table and illustrated in the diagrams on this page may result

in electrical arc damage, personal injury or death.

1075 Old Airport Road • Bristol, VA 24201 Phone (276) 669-4084 • FAX (276) 645-8206 • www.federalpacic.com • ISO9001:2015

SECTION IB-1G-805

INSPECTION & MAINTENANCE RECOMMENDATIONS

PAD-MOUNTED SWITCHGEAR TYPE PSI

JUNE 2021, REV 1.1

Page 4

8. Maintaining the Exterior

The exterior nish can be maintained by periodic washing, touch up of any scratches

and abrasions, and waxing. For areas to be touched-up, clean the area removing all rust.

Feather the paint of areas adjacent to rusted areas to be painted. Apply a red-oxide primer,

available in spray cans from a local paint supplier or home improvement store. Spray cans

of the topcoat nish are available from Federal Pacic (specify the original color).

9.

Replacing Labels

Replace any missing, damaged or obscure labels. Replacement labels are available

from Federal Pacic.

10.

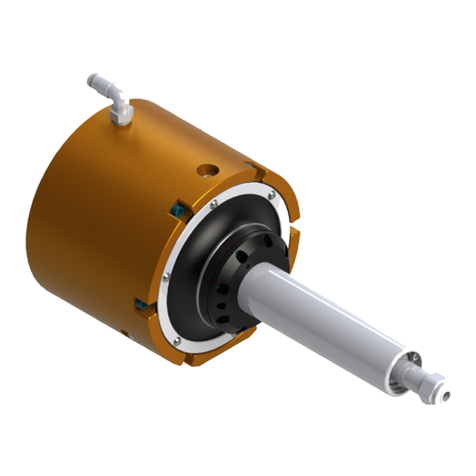

Lubrication

When maintenance is performed, check for lubrication at the following locations:

Figure 1. Lubricate only the interface between the main-

contact stab and the switch blade marked by arrows.

Figure 3. View shows present

cast fuse main contact at far

left and previous main contact,

which was a weldment, at right

(removed from load-break fuse

mounting).

LUBRICATE ONLY:

1. On the switch main-contact stab. See Figure 1.

2. On the contact interface at the fuse-mounting stationary main contact. See

Figure 2.

3. Fuse Mountings

a. Load-Break Fuse Mountings.

On the forward contact that engages the fuse contact rod and on the fuse

hinge contacts that engage the fuse contact ferrule. The contact rod on

the fuse end tting and the lower fuse ferrule on the fuse unit of the fuse

assembly. Refer to fuse manufacturer's instructions.

b. Non-Load-Break Fuse Mountings

On the upper main contact of the fuse mounting and the contact-rod of the

fuse-unit end tting or the upper-ferrule contact of the fuse holder, and on

the fuse hinge contacts that engage the lower ferrule of the fuse unit or fuse

holder.

4. DO NOT LUBRICATE ANY OTHER AREAS.

5. If lubrication is required apply a coating of NYE Rheolube 363, which is the

only approved lubricant.

11.

Verify Security Devices

Verify the operational integrity of security devices such as door latches, penta-

head bolts, hinges and key-interlock systems. Make certain padlocks are properly

installed on all doors and covers.

12.

Specication

Torque Value: For bus bar connections, apply 50 foot-pounds torque to 1/2-13

UNC 18-8SS (or equivalent) hex bolts. For other bolted connections, refer to factory.

High-Pot Test Value: After cleaning and restoring equipment, Per IEEE C37.74 — 75%

of 35kV for 1 minute.

Figure 2. Lubrication points on load-break fuse mounting (at top)

include three contact locations,namely,the main contact, forward

contact and fuse hinge contacts.Two lubrication points on non-

load-break fuse mountings (above).

Fuse-hinge contacts that

engage the fuse contact

ferrule

Contact interface at

stationary main contact

casting (or rod on main-

contact plate for older

designs)

Forward contacts

that engage the fuse

contact rod

© 2021 Electro-Mechanical Corporation

Lubrication is NOT required on any other surfaces than the locations identied

below. Applying lubrication in other areas may reduce mechanical and electrical

performance. DO NOT OVER LUBRICATE!

WARNING

Other FEDERAL PACIFIC Tools manuals