be sure the mounting surface can sustain the weight of the PS250. The mounting method must

also withstand external mechanical stresses that may be applied to the cabinet. The cabinet has

three holes located in the rear to accommodate #10 mounting screws. The user must supply all

mounting hardware.

The PS250 is shipped without the batteries installed. The batteries must be installed after the

unit is mounted.

Use the power supply enclosure minus the batteries as a template to mark the location of the

three mounting holes on the mounting surface. Mount the cabinet with the appropriate hard-

ware. Make sure that the unit is rmly secured to the mounting surface. Install all electrical

conduit at this time. Terminate the conduit for the 120 VAC or 240 VAC power at one of the

two knockouts located at the upper right side of the cabinet. These knockouts are located above

and to the right of the two transformers. Terminate the conduit for the 24 VDC or 12 VDC out-

put at one of the knockouts located at the top or the middle left side of the cabinet.

B. Electrical Connections.

NOTE

Make sure that AC power is OFF.

NOTE

The PS250 should be installed with the National Electrical Code NFPA 72 and

in accordance with any local regulations.

There are two conduit entry knockouts provided on the upper side of the power supply cabinet,

one on the lower right side, and one in the middle of the left side. Use one of the two knockouts

located at the upper right side of the cabinet, near the transformer, for 120 VAC or 240 VAC

power, Class I, conductors. Use one of the three knockouts in the top, either the middle or the

left side of the cabinet or the knockout in the middle of the left side for the power limited 24

VDC or 12 VDC output conductors. Make sure that all power limited re protective signaling

conductors are segregated from electric light, power, Class I, or non-power limited re protec-

tive signaling conductors by more than 1/4-inch inside the power supply cabinet.

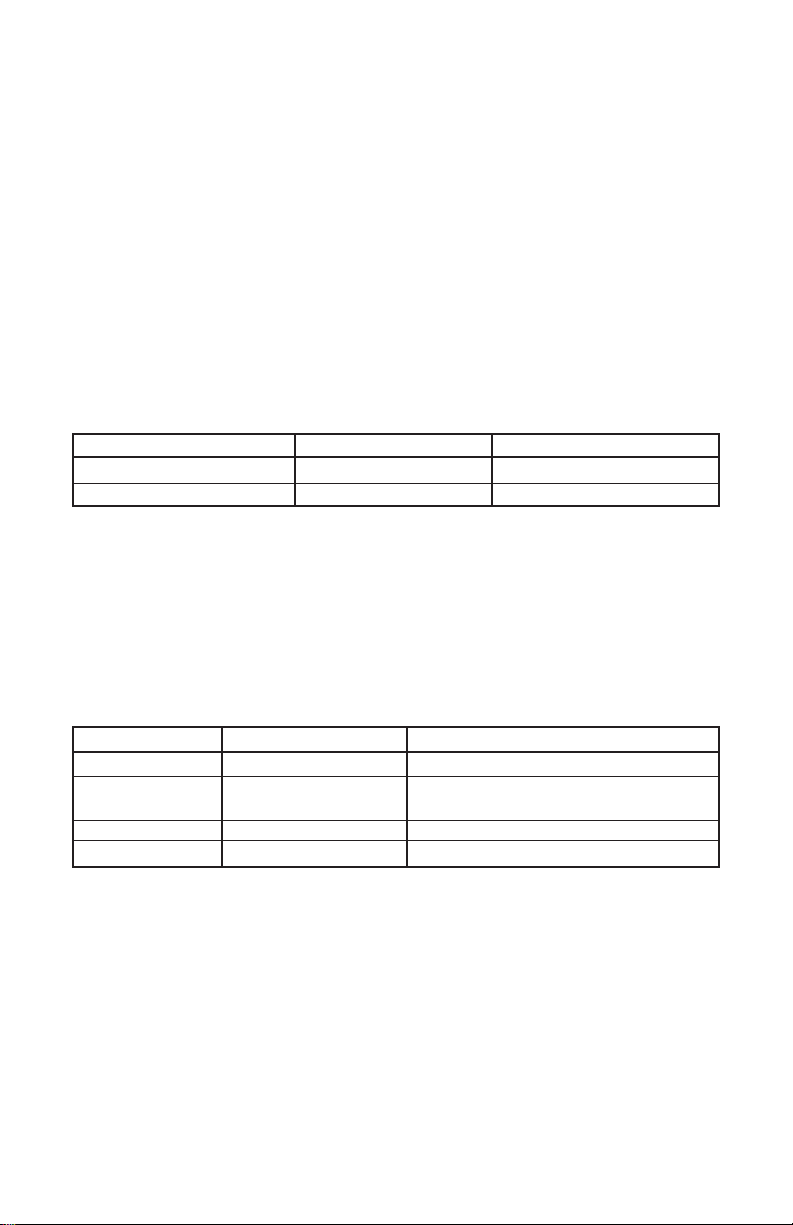

Install the electrical wiring for the input and output circuits, see gure 2. Use only 18 AWG

wire for all power connections (battery, DC output). Use 22 AWG to 18 AWG wire for sig-

naling outputs (AC and low battery supervision). Be sure to keep power limited wiring (su-

pervised AC and low battery signaling) separate from non-power limited wiring (120VAC @

50/60 Hz or 240 VAC @ 50/60 Hz input, battery wires and DC output). See gure 3 for trans-

former hook-up. Strip no more than 0.25 inch of wire insulation from the ends of the power

leads. Insert the stripped ends of the wire into the connector as far as they can travel. Make sure

the lead insulation is ush with the connector. If stranded wire is used, be sure that there are

no loose strands outside of the connector plug that could touch the adjacent lead and cause a

short circuit. Connect the 12 VDC or 24 VDC (output) circuits of the device to be powered, to

the two position terminal block located at the upper left side of the power supply PC board and

labeled “-DC+”. Observe the correct polarity. A wiring terminal screw can accommodate up

to two wires provided the wires sit under the terminal clamp on opposite sides of the terminal

screw.

Set the batteries next to one another at the bottom of the power supply cabinet. See gures 2

and 4. Connect the short yellow jumper wire provided between the positive (RED) terminal

of the rst battery and the negative (BLACK) terminal of the second battery. Connect the two

battery wires provided to the two position terminal block located at the lower left side of the

power supply PC board and labeled “-BAT+”. Observe the correct polarity. Connect the black

(negative) wire of the battery terminal block to the black (negative) terminal of the rst battery.

Then connect the red (positive) wire of the battery terminal block to the red (positive) terminal

of the second battery and close the cabinet door.

NOTE

For access control applications, batteries are optional. When batteries are not used,

the loss of AC will result in the loss of output voltage.

-4-