2

III. INSTALLATION.

IMPORTANT

Before proceeding, read and understand the

SAFETY NOTICES on pages iand ii of this

instruction sheet.

A. General.

During installation and before operation of all units,

steps 1, 2, and 3 must be performed.

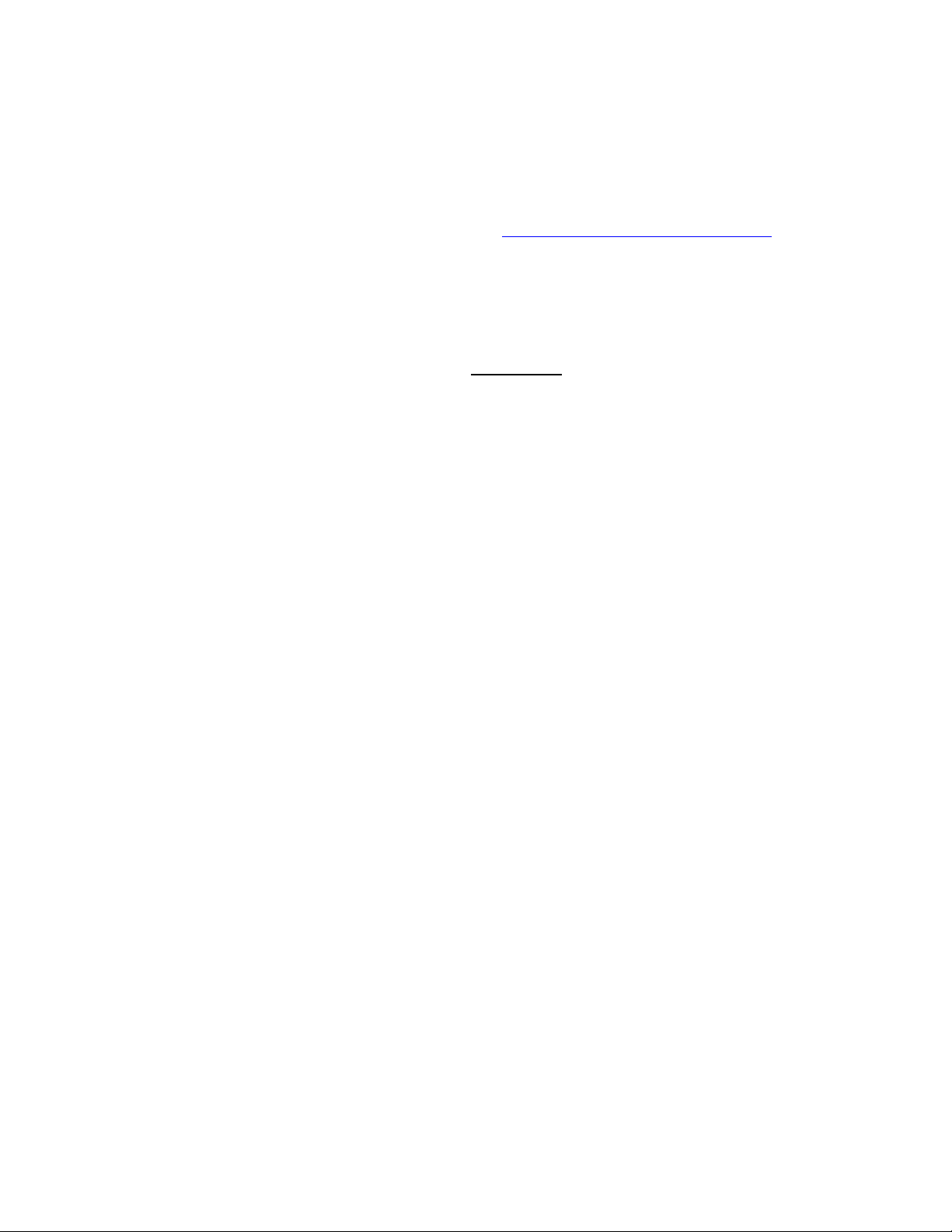

1. In order to control the rotation of the Speaker

Array, it is necessary to connect the wht/red wire from the

speaker array to JP25-1 on the motherboard (see figure 2).

CAUTION

To prevent damage to rotator assembly, steps

2 and 3 must be completed prior to operating

the unit.

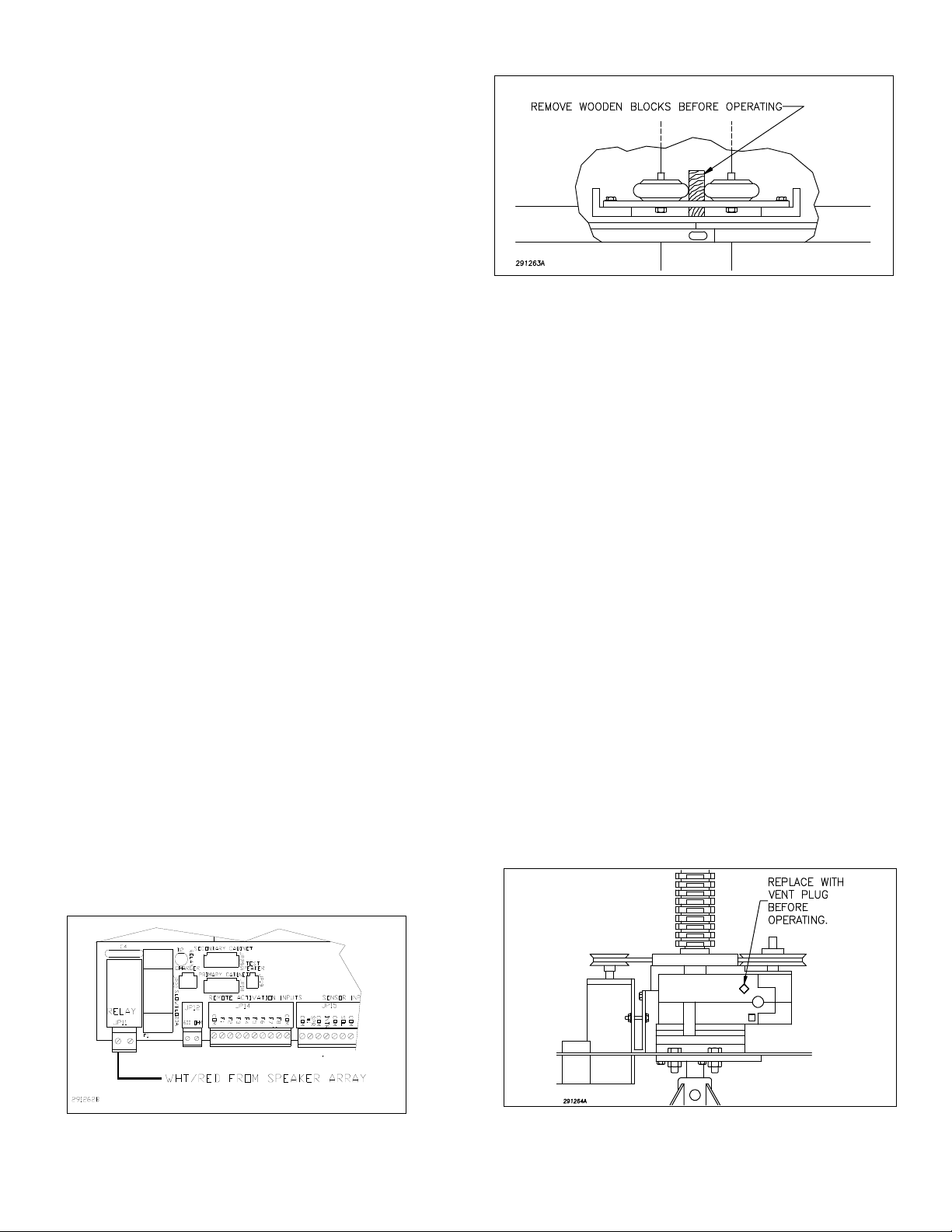

2. Remove the bottom rear panel of the Speaker

Array. In some units, wooden blocks may be installed

between the roller brackets (see figure 3). If installed,

remove the wooden blocks from the roller brackets. The

rollers should be adjusted for minimal clearance to the pole

(approximately 1/32-inch).

3. Remove the second rear panel from the top of

the Speaker Array. Remove the pipe plug from the upper

tapped hole in the rotator gear box and replace with the

supplied vent plug (see figure 4).

4. Speaker Array Positioning.

The Home Switch Assembly is located on top

of the commutator rings. It allows the Speaker Array to be

positioned in one of four zones. The switch assembly is

factory set to align the Speaker Array with an arrow on the

Speaker Array base plate indicating Zone 1 (Home or

North).

If Home Switch Assembly adjustment is necessary,

it may be performed now or after Pole Mounting

Figure 2. Motherboard Relay Connection

Figure 3. Wooden Block Removal

or Flat Surface Mounting is completed. Refer to paragraph

III.D. for a description of the adjustment procedure.

5. Replace both panels.

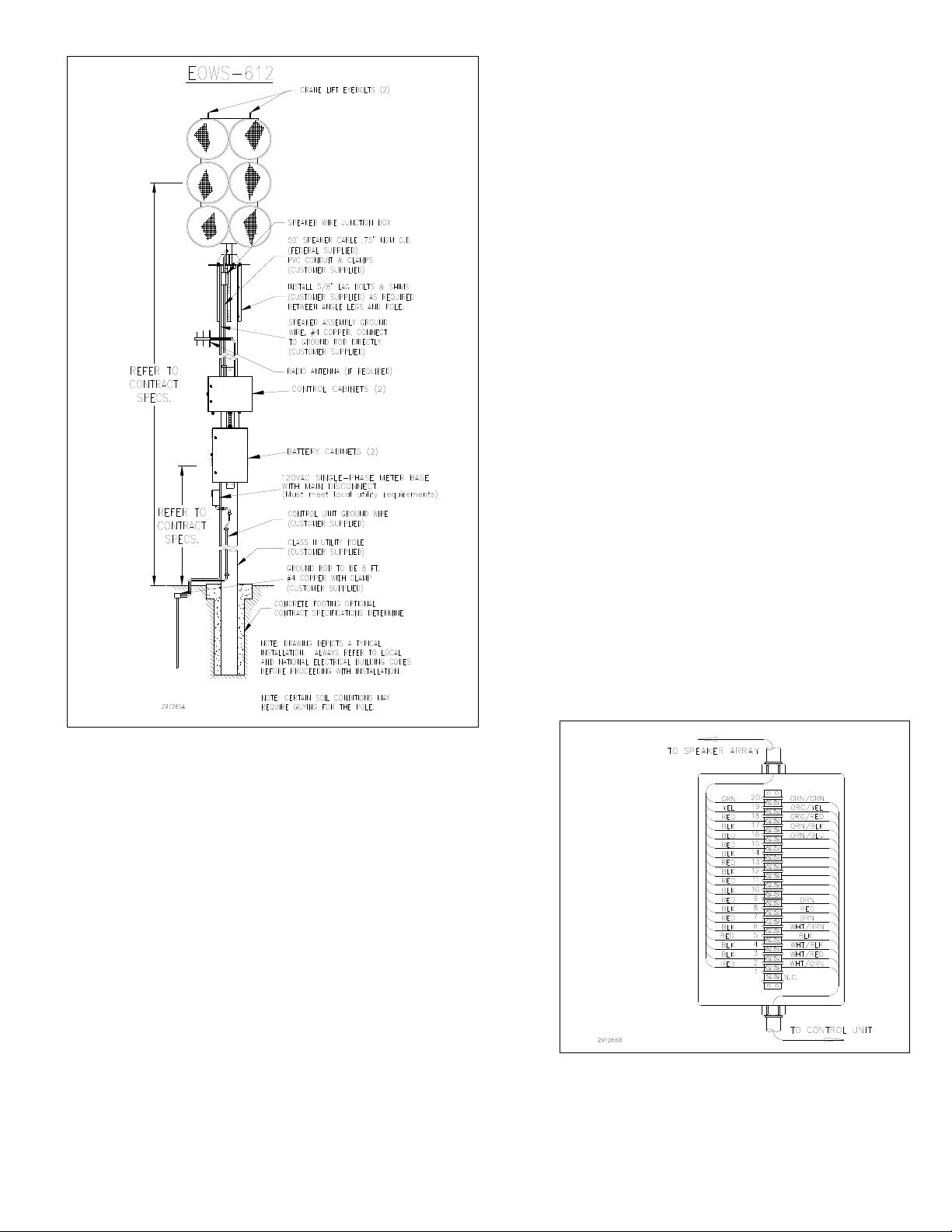

B. Pole Mount.

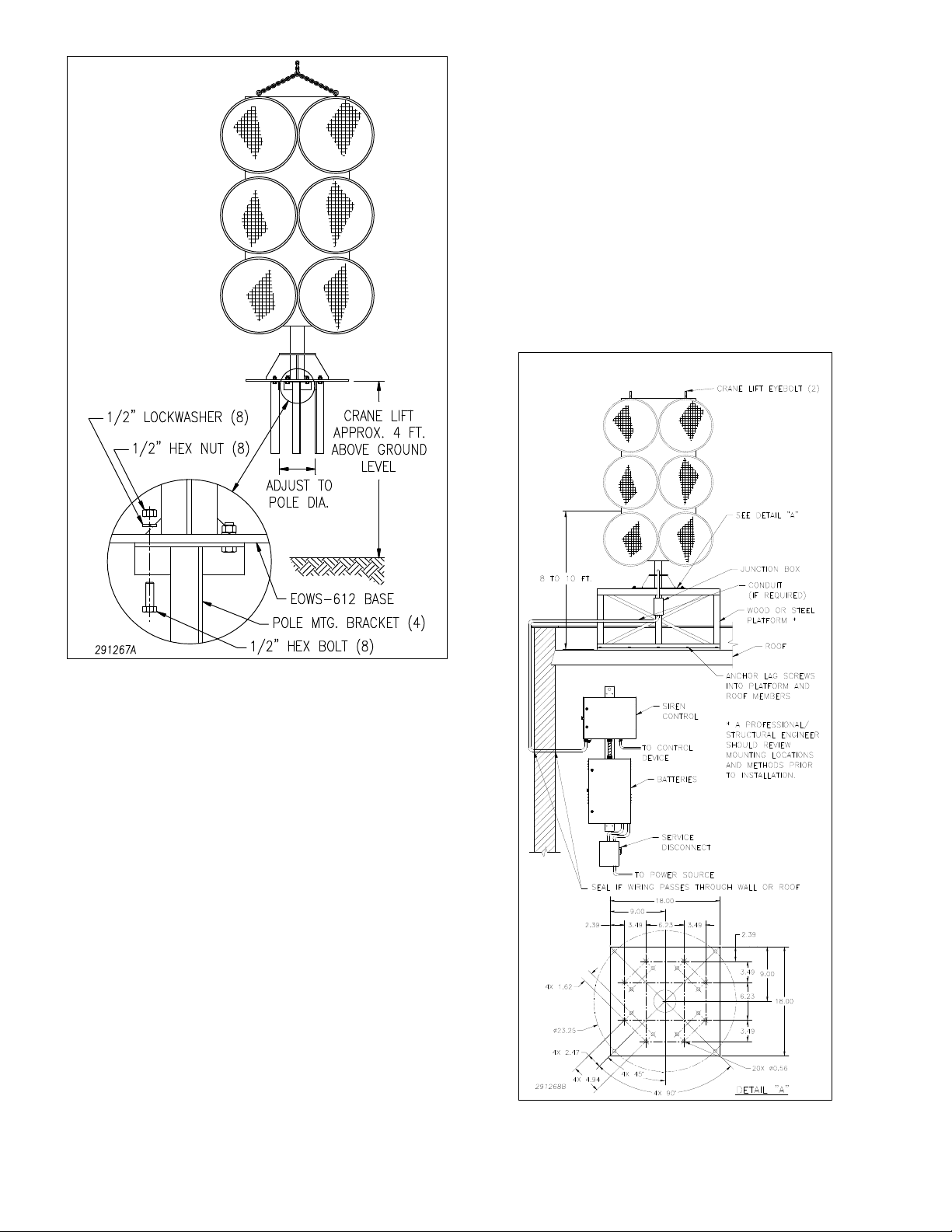

A typical pole mounted installation is shown in

figure 5. To provide optimum signalling effectiveness, the

siren must be mounted in accordance with FEMA standards.

Use a utility pole (ANSI Type 2 wooden pole or equivalent)

with a minimum horizontal ground stress rating of 3,700

pounds (1682kg).

The siren is attached to the pole by means of a

stand provided by Federal. The stand consists of four legs

which must be connected to the base plate. The base plate

serves as a vertical support for the Speaker Array while

adding rigidity to the stand. To install the Speaker Array on

a Class 2 utility pole, proceed as follows:

1. Install the Class 2 utility pole in accordance

with accepted standards and practices.

2. Federal recommends that the 50-foot (15.2m.)

interconnecting cable be routed through user-supplied

conduit to the Control Unit. The bottom of the junction box

is equipped with a hole to accommodate a 1" weatherproof

conduit fitting.

Figure 4. Vent Plug Installation