feedback MS150 User manual

MS150ModularServoWorkshop-GettingStarted

33-008-1M5

MS150 Modular Servo Workshop

Getting Started

33-008-1M5

Feedback

Feedback Instruments Ltd, Park Road, Crowborough, E. Sussex, TN6 2QR, UK.

Telephone: +44 (0) 1892 653322, Fax: +44 (0) 1892 663719.

Manual: 33-008-1M5 Ed02 991116

Printed in England by Fl Ltd, Crowborough

Feedback Part No. 1160–330081M5

Notes

MS150 MODULAR SERVO

Getting Started Preface

33-008-1M5 i

THE HEALTH AND SAFETY AT WORK ACT 1974

We are required under the Health and Safety at Work Act 1974, to make available to users of this equipment certain information

regarding its safe use.

The equipment, when used in normal or prescribed applications within the parameters set for its mechanical and electrical performance,

should not cause any danger or hazard to health or safety if normal engineering practices are observed and they are used in

accordance with the instructions supplied.

If, in specific cases, circumstances exist in which a potential hazard may be brought about by careless or improper use, these will be

pointed out and the necessary precautions emphasised.

While we provide the fullest possible user information relating to the proper use of this equipment, if there is any doubt whatsoever

about any aspect, the user should contact the Product Safety Officer at Feedback Instruments Limited, Crowborough.

This equipment should not be used by inexperienced users unless they are under supervision.

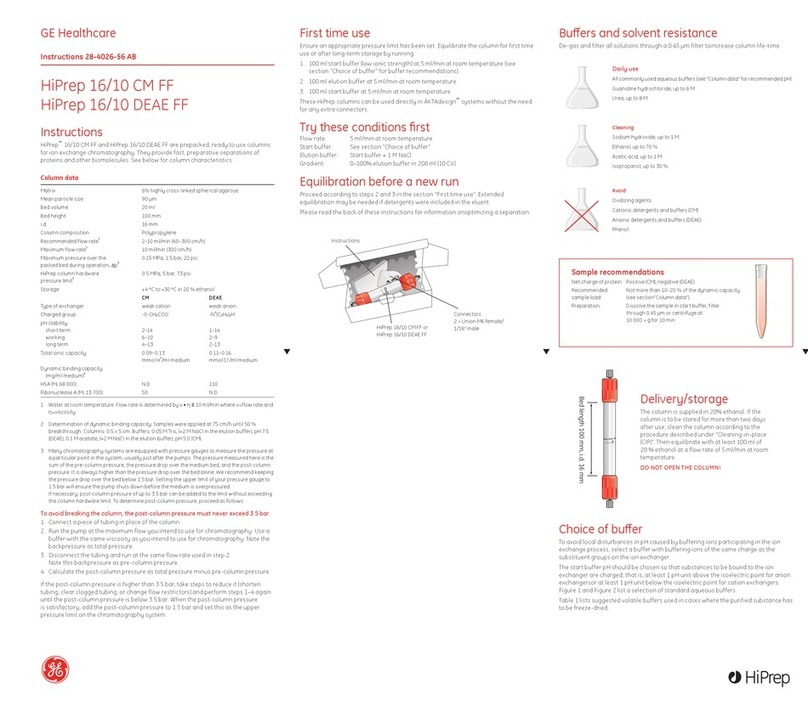

We are required by European Directives to indicate on our equipment panels certain areas and warnings that require attention by the

user. These have been indicated in the specified way by yellow labels with black printing, the meaning of any labels that may be fixed to

the instrument are shown below:

CAUTION -

RISK OF

DANGER

CAUTION -

RISK OF

ELECTRIC SHOCK

CAUTION -

ELECTROSTATIC

SENSITIVE DEVICE

Refer to accompanying documents

PRODUCT IMPROVEMENTS

We maintain a policy of continuous product improvement by incorporating the latest developments and components into our equipment,

even up to the time of dispatch.

All major changes are incorporated into up-dated editions of our manuals and this manual was believed to be correct at the time of

printing. However, some product changes which do not affect the instructional capability of the equipment, may not be included until it is

necessary to incorporate other significant changes.

COMPONENT REPLACEMENT

Where components are of a ‘Safety Critical’ nature, i.e. all components involved with the supply or carrying of voltages at supply

potential or higher, these must be replaced with components of equal international safety approval in order to maintain full equipment

safety.

In order to maintain compliance with international directives, all replacement components should be identical to those originally

supplied.

Any component may be ordered direct from Feedback or its agents by quoting the following information:

1. Equipment type

3. Component reference 2. Component value

4. Equipment serial number

Components can often be replaced by alternatives available locally, however we cannot therefore guarantee continued performance

either to published specification or compliance with international standards.

MS150 MODULAR SERVO

Preface Getting Started

33-008-1M5ii

DECLARATION CONCERNING ELECTROMAGNETIC COMPATIBILITY

Should this equipment be used outside the classroom, laboratory study area or similar such place for which it is designed and sold then

Feedback Instruments Ltd hereby states that conformity with the protection requirements of the European Community Electromagnetic

Compatibility Directive (89/336/EEC) may be invalidated and could lead to prosecution.

This equipment, when operated in accordance with the supplied documentation, does not cause electromagnetic disturbance outside its

immediate electromagnetic environment.

COPYRIGHT NOTICE

©Feedback Instruments Limited

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise, without the prior permission of Feedback Instruments Limited.

ACKNOWLEDGEMENTS

Feedback Instruments Ltd acknowledge all trademarks.

IBM, IBM - PC are registered trademarks of International Business Machines.

MICROSOFT, WINDOWS 95, WINDOWS 3.1 are registered trademarks of Microsoft Corporation.

MATLAB is a registered trademark of Mathworks Inc.

MODULAR SERVO

Getting Started Contents

33-008-1M5 TOC 1

TABLE OF CONTENTS

1. INTRODUCTION AND DESCRIPTION 1-1

1.1. Equipment and requirements 1-1

1.1.1. Knowledge Level Required 1-2

1.1.2. Minimum Hardware and Software Requirements 1-2

1.2. Principal system interconnections and software operation 1-3

2. MODEL AND CONTROL ALGORITHMS 2-1

2.1. PID control 2-2

2.2. State feedback control 2-2

2.3. Time - optimal control 2-3

2.4. Adaptive control 2-3

3. STARTING , TESTING AND STOPPING PROCEDURES 3-1

3.1. Starting procedure 3-1

3.2. Testing and troubleshooting 3-2

3.3. Stopping procedure 3-5

4. MENU DESCRIPTION 4-1

4.1. Tools 4-1

4.2. Design and identification 4-9

4.3. Models and experiments 4-16

5. FIRST EXAMPLES 5-1

5.1. Example 1. Closed-loop control system with state feedback gains 5-1

5.2. Example 2. Ziegler-Nichols method for designing PID controller 5-2

MODULAR SERVO

Contents Getting Started

TOC 2 33-008-1M5

6. CONNECTING THE PC AND THE SERVO 6-1

6.1. PCL-812PG acquisition board: 6-2

6.2. Switch settings - 16 bit board 6-2

6.3. Jumper Settings 6-3

6.4. Switch SW1 settings for 8 bit full length PCL - 812 board 6-4

6.5. Installation of PCL-812 Board 6-4

CHAPTER 1

MODULAR SERVO

Getting Started Introduction and Description

33-008-1M5 1-1

1. INTRODUCTION AND DESCRIPTION

The Modular Servo Workshop (MSW)

is an open-architecture software environment for

real-time control experiments using the Feedback

digital servomechanism. The main

concept of the Modular Servo Workshop was to create a rapid and direct path from

control system design to hardware implementation. The Modular Servo Workshop

supports the real-time design and implementation of advanced control methods, using

MATLAB

and Simulink tools, and extends the MATLAB

environment in the solution of

digital servomechanism control problems.

The integrated software supports all phases of a control system development:

•on-line process identification,

•control system modelling, design and simulation,

•real-time implementation of control algorithms.

The Modular Servo Workshop is intended to provide a user with a variety of software tools

to facilitate:

•on-line information flow between the process and the MATLAB

environment,

•real-time control experiments using embedded algorithms,

•development, simulation and application of user-defined control algorithms

.

The Modular Servo Workshop

uses standard PC hardware platforms and Microsoft

Windows operating systems. Version 1.02 of the software works with MATLAB

5.1 & 5.2

and Simulink 2.1 and 2.2. It is not compatible with earlier versions of MATLAB software.

1.1. Equipment and Requirements

The Modular Servo Workshop is distributed in compressed format on a CD-ROM.

Installation procedure is a standard one applied for Feedback MATLAB compatible

products (see The Software Installation Guide – 33-000 for details). A full set of software

and manuals consists of:

•CD-ROM,

•Getting Started 33-008-1M5 ( this manual),

•Reference Guide 33-008-2M5

•External Interface 33-008-3M5

•Advanced Teaching Manual, 33-008-4M5

•Software Installation Guide. 33-000M5

CHAPTER 1 MODULAR SERVO

Introduction Getting Started

1-2 33-008-1M5

1.1.1. Knowledge Level Required

The manual assumes that the user has a basic experience with one of the Feedback

digital servomechanisms, with MATLAB 5 & Simulink from MathWorks Inc, and with the

Microsoft Windows 95 or NT operating System. More experience in control is required for

experiments described in the ADVANCED TEACHING manual. Some practise in C-

language programming is expected for application of the EXTERNAL INTERFACE.

1.1.2. Minimum Hardware and Software Requirements

Modular Servo system - Feedback part numbers

OA150A Operational Amplifier

AU150B Attenuator

PA150C Pre-Amplifier

SA150D Servo Amplifier

PS150E Power Supply

DCM150F DC Motor

IP150H Input Potentiometer

OP150K Output Potentiometer

LV150L Magnetic Brake Load

GT150X Gearbox/Tachometer

MS150Z Accessories plus Magnetic Baseplate

33-301 Interface unit

33-300 Digital Encoder

PC and boards

486DX or above PC with 16 Mbytes memory, and 200 Mbytes available disk space, 16x

CD Rom, SVGA screen,

PCL-812PG or RT-DAC data acquisition board

Software

The MS150 uses a standard PC hardware platform and the standard Microsoft Windows

95 or NT operating system, and

minimum

MATLAB 5.1, Simulink 2.1, Control and Signal

Processing Toolboxes.from the Mathswork Inc. Certain specialised controllers, developed

in future Teaching Manual releases, may require the use of

additional

MATLAB toolboxes.

An appropriate C compiler is required for use of the External Interface.

CD-ROM with Feedback Modular Servo software

CHAPTER 1

MODULAR SERVO

Getting Started Introduction and Description

33-008-1M5 1-3

1.2. Principal system interconnections and software operation

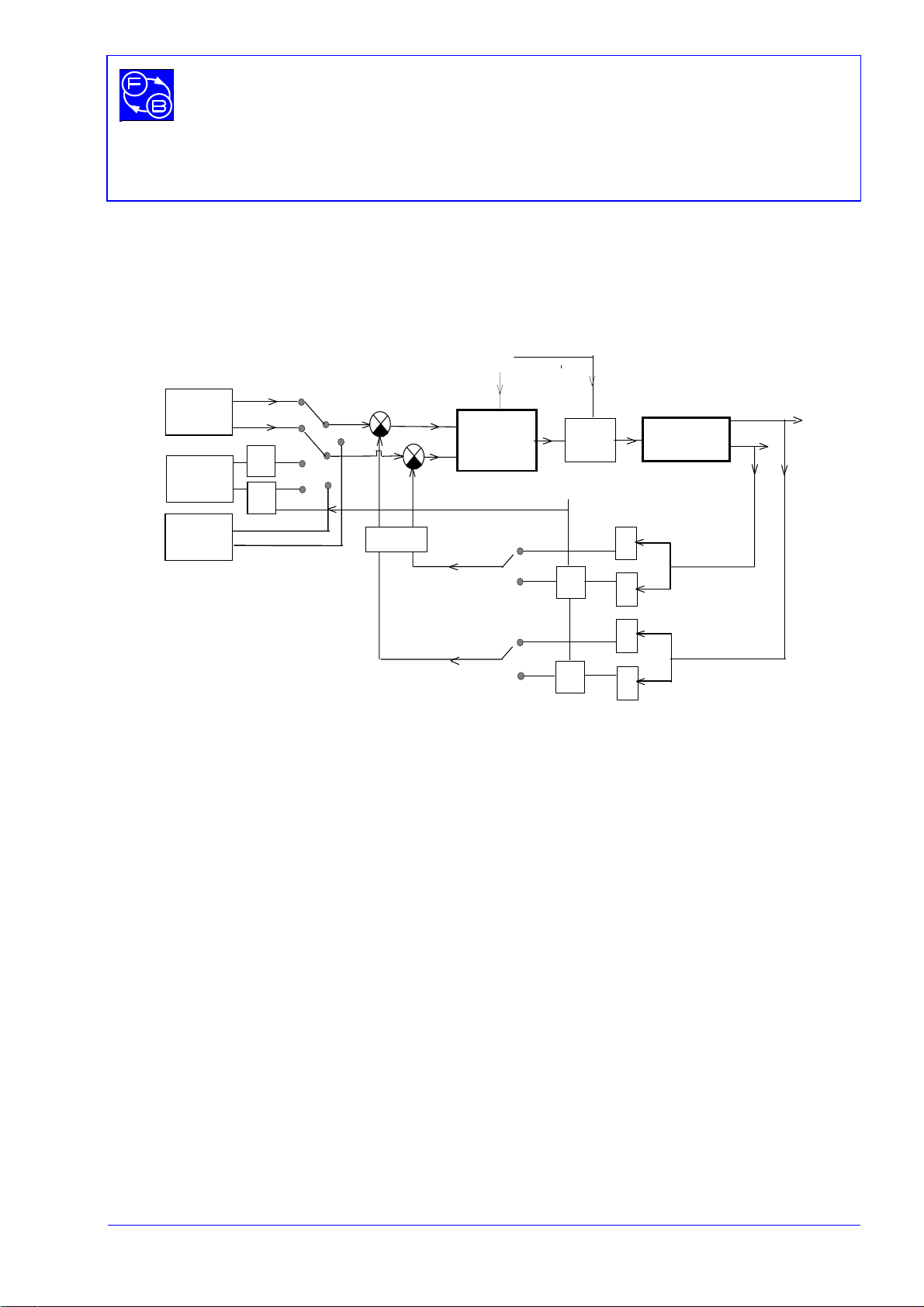

The control system applied for the servomechanism is given in a block diagram form in

Figure 1-1.

D/A

basic clock

controller

A/D

A/D

A/D

S

S

S

S

A/D

1

2

1

2

y

1

y

2

y

1d

y

2d

internal

excitation

source

excitation

source

external

auxiliar

y

clock

filter

uDC motor

Simulink

generator

sampling T0

Figure 1-1: Block diagram of the control system

Two process outputs are considered: the position y1 and the speed y2. Process outputs

can be measured as continuous signals (sensors S2) digitised by analogue-to-digital

converters (A/D) or a direct digital measurement technique can be used (sensors S1 -

encoder). The reference input (desired value) can be generated in a digital form using an

internal excitation source or, alternatively, an external MS150H Input potentiometer can

be applied. Additionally, the Simulink Signal Generator can be applied as a source of

excitation signal when the Simulink model is used.

The hardware and software connections of the

Modular Servo Workshop

are given in

Figure 1-2.

The software of the MSW

consist of the following main parts:

•

Real-time Kernel (RTK),

•

Modular Servo Toolbox.

CHAPTER 1 MODULAR SERVO

Introduction Getting Started

1-4 33-008-1M5

The Real-time Kernel is collection of real-time tasks supervised by a task manager.

Control algorithms, filtering procedures and outputs from the software generator of the

excitation signal, are activated by the timer interrupt. Notice, that, inside the real-time

kernel, the basic feedback loop of the control system is closed.

External

excitation

position

position

speed

PC - com

p

uter +MS-WINDOWS

RTK Data acquisition & control

y

1d

y

2d

filter

PCL-812PG or RT-DAC

buffer

p

rocess data

controller

selection&

parameters

M

ATLAB+SIMULINK

Internal

excitation Educational Servo Toolbox

to DC motor

- software

- hardware - software controlled

Modular Servo 150

from

Encoder

from

tachogenerator

embedded

controllers

commu-

nication

interface

(

*

)

(*)

(*)

(*) - user defined by External Interface software

3

3-301 Analogue Control Interface

DC Motor

Digital encoder Potentiometer

Gearbox/Tacho

brake

Figure 1-2: Closed-loop control system of the Modular Servo

The

Modular Servo Toolbox

, using MATLAB matrix functions, provides the functions

specialised for real-time control of the Feedback digital servomechanism. It is the general

assumption that the toolbox is an open system. This approach by its nature forces the

basic functions of the toolbox to be in the user domain. It enables the user to maintain his

own system, and to customise control algorithms to satisfy the requirements better.

In addition, however, in the

Main Control Window

typical "paths" through the toolbox are

provided, and typical control problems are introduced.

CHAPTER 1

MODULAR SERVO

Getting Started Introduction and Description

33-008-1M5 1-5

The collection of the toolbox functions can divided into two main categories:

•Real-Time Kernel communication functions,

•Real-Time Kernel configuration functions.

The toolbox functions and MATLAB functions can be used at different application levels.

In this manual the following convention is used:

•application level 1 - RTK communication and configuration functions, MATLAB

functions,

•application level 2 - menu-driven experiments and simulations,

•application level 3 - external interface software for advanced users to create his

own algorithms.

Application level 1 means a direct use of the toolbox functions controlling the information

flow between process sensors, RTK and MATLAB environment. The functions used at

this level configure a real time kernel, embedded controllers and excitation sources (see

Reference Manual – 33-008-2M5 for details).

At application level 2 the function

es

initialises the menu-driven part of the toolbox .

At application level 3 the EXTERNAL INTERFACE software allows the creation of user-

defined algorithms and the modification of communication functions (see the External

Interface Manual 33-008-3M5 for details).

CHAPTER 1 MODULAR SERVO

Introduction Getting Started

1-6 33-008-1M5

Notes

CHAPTER 2

MODULAR SERVO

Getting Started Model And Control Algorithms

33-008-1M5 2-1

2. MODEL AND CONTROL ALGORITHMS

In this section a brief review of the embedded control algorithms is given. For a detailed

description of control algorithms refer to the Advanced Teaching Manual ( 33-008-4M5 ).

The design process for the controllers listed below was performed assuming a linear

model of the DC motor in the form of two first-order linear differential equations. This

representation is generally known as a state-space model:

0

x=0)=t(x

DuCx=y

Bu+Ax=

dt

dx

+

For the DC motor we obtain:

0=D,

10

01

=C,

T

K

0

=B,

1

0

10

=A

s

s

−s

T

where: x is the vector with components x1(position of the DC motor shaft or angle) and

x2(the speed) and u is the control input.

The general solution of the state-space equations is:

Du(t)+)dBu(e+0x

At

eC=y(t) t

0

)-A(t

∫

ττ

τ

The discrete model of DC motor can be obtained by transformation of the continuous

system

dx/dt = Ax + Bu assuming a zero-order hold and sample time T0:

x[n+1]=Adx[n] + Bdu[n]

y[n] = Cdx[n]

The system can be classified as a multivariable (SIMO) because it has two measurable

states and one control variable.

CHAPTER 2 MODULAR SERVO

Model And Control Algorithms Getting Started

2-2 33-008-1M5

The following control algorithms are used for the first control experiments:

•PID

•state feedback controllers : LQ and deadbeat

•time-optimal

•adaptive controller

The user can develop and apply his own algorithm using the tools described in the

External Interface Manual - 33-008-3M5.

2.1. PID control

The PID controller has the form:

[]

uK kK kK k k

pi

k

n

d

=+ +−−

=

∑

(() () () ( ))

εεεε

11

011

1

where:

ε1is position error, Kpis gain coefficient, Kiis integration gain, and Kdis derivative

gain.

The constants Kp, Ki and Kd can be chosen according to the Ziegler-Nichols rule or

another controller designing procedure.

2.2. State feedback control

The state feedback controller has the form:

u = - (K1ε1+K2ε2)

where:ε1- is position error,

ε2- is speed error,

K1,K2are controller gains.

The LQ optimal feedback gain vector K = [K1,K2] can be calculated in such a way that the

feedback law u = -Kε; where ε= [ε1,ε2] minimises the cost function:

∫

∞

=0

Tdt)u+( RuQxxJ T, where Q and R are the weighting matrices,

subject to the state equation: dx/dt = Ax + Bu

CHAPTER 2

MODULAR SERVO

Getting Started Model And Control Algorithms

33-008-1M5 2-3

Another selection of state-feedback gains is based on 'dead-beat' principle. The feedback

gain vector K = [K1,K2] is calculated in such a way that eigenvalues of the state matrix of

the discrete closed-loop system are equal to zero:

eig(Ad - Bd * K) = 0

The controller has the property that he drives the states of the closed-loop system from an

arbitrary initial state to zero value in at most N-steps (N = dim(Ad)).

2.3. Time - optimal control

In this case typical for linear systems „bang-bang” control principle is used. A full

description and principles of operation of the time-optimal controller are given in the

Advanced Teaching Manual – 33-008-4M5.

2.4. Adaptive control

The adaptive controller is based on the reference model idea. A full description of the

controller is given in the Advanced Teaching Manual - 33-008-4M5.

CHAPTER 2 MODULAR SERVO

Model And Control Algorithms Getting Started

2-4 33-008-1M5

Notes

CHAPTER 3

MODULAR SERVO

Getting Started Starting, Testing and Stopping Procedures

33-008-1M5 3-1

3. STARTING , TESTING AND STOPPING PROCEDURES

3.1. Starting procedure

Perform all connections as described in Section 6 of this manual. They will ensure correct

communications between Computer – Advantech PCL812PG i/o board – 33-301

Analogue Interface unit and the rest of modular servo MS150 units.

Ensure that the Attenuator Unit AU150B has the top gain-pot set to a value around 8 and

the Pre-Amplifier Unit PA 150C has the pot to ‘zero set’. The connections to these units to

be made as shown in Section 6. There should be approximately ‘no motion’ noticed on

the motor unit.

If the motor is turning, then the output produced by the computer (i/o board) is set to high.

Follow the Calibration 33-301 routine in order to adjust offsets and gains for all 4

channels.

Note: Values stated in these manuals would not provide good performance on other

systems. The numbers should be around the ones shown in manual.

In the MS-WINDOWS environment invoke MATLAB by double clicking on the MATLAB

icon. The

Matlab Command Window

opens. Then type:

es

and then the

Main Control Window

of MSW opens (see Figure 3-1)

Figure 3-1: The Main Control Window

Then go through the following steps:

CHAPTER 3 MODULAR SERVO

Starting, Testing and Stopping Procedures Getting Started

3-2 33-008-1M5

•double click on the

Set base address

button. This set the base address of the i/o card.

•If the address of your data acquisition board agrees with the default value then accept

it, otherwise type the proper address. System may terminate if entered the incorrect

number.

Note: You can set the base address equal to zero. Then you can work with

the control software without a connection to the external hardware. In this

case the measurement data are produced by a built-in model of the DC

motor, which allows off-line testing of new control software.

Calibrate the 33-301 Analogue Control Interface Unit following step-by-step instruction

brought up by each individual window.

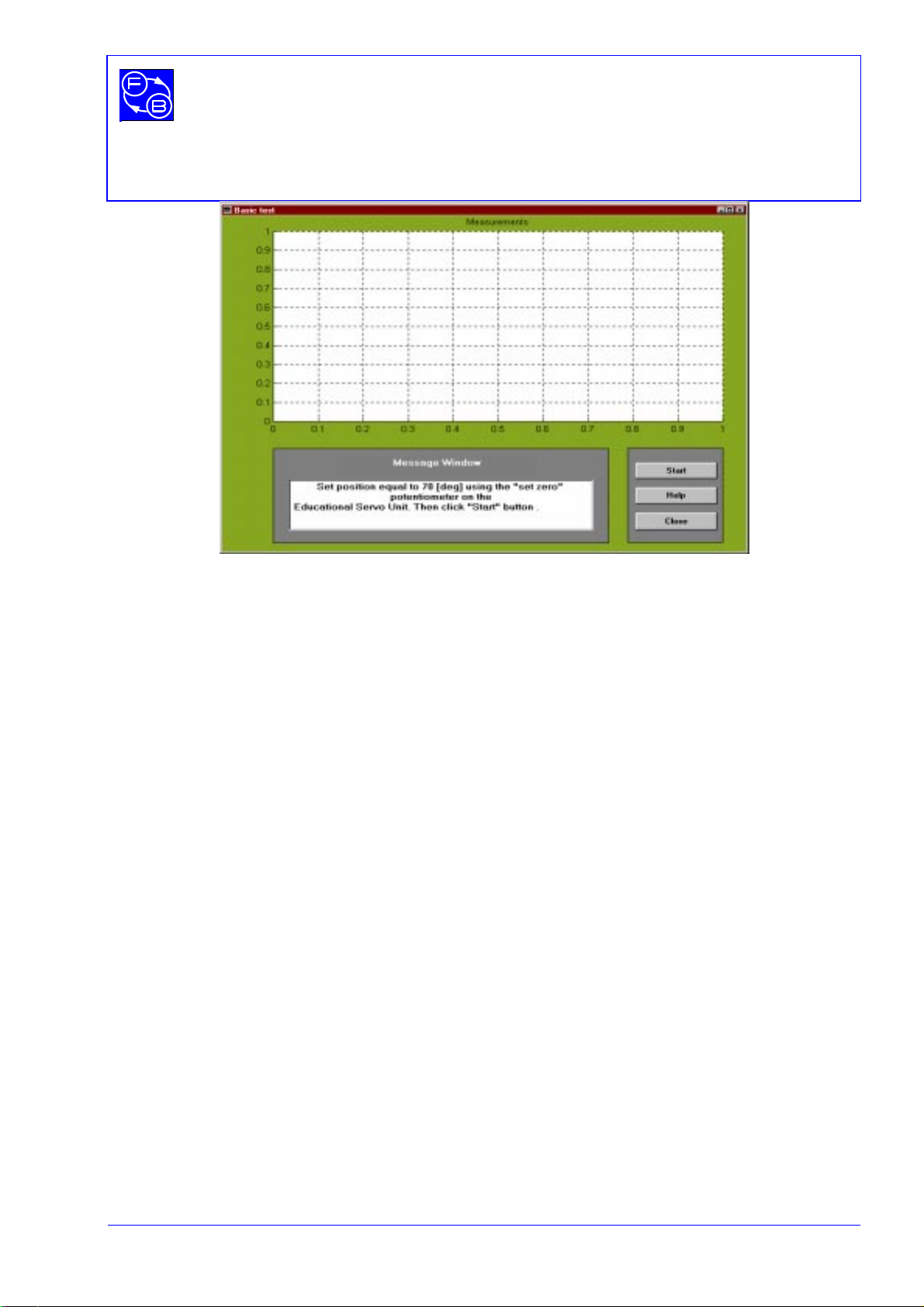

3.2. Testing and troubleshooting

Now you are ready to start an experiment. This will give an indication if the output

measurements are correct. First go through the following steps to check the proper

operation of your hardware:

•double click the

Basic test

button. The following window (Figure 3-2) appears:

CHAPTER 3

MODULAR SERVO

Getting Started Starting, Testing and Stopping Procedures

33-008-1M5 3-3

Figure 3-2:

Basic test

window

•set the position of the OP150K manually to 70 degrees anticlockwise. If this is not set

to 70 degrees, the Basic Test program will not provide results similar to the ones shown

in Fig. 3.3. This is because when applying a square wave (sudden reverse in the input

signal) the pot on the OP150K will rotate more than 180 degrees.

•click the

Start

button and wait for results.

This test performs the action in three steps:

1. sets the source of data as follows:

•Channel 1 - angle measured from A/D converter [deg] (using A/D1 channel of the

Analogue Control Interface),

•Channel 2 - angle measured from digital encoder [deg],

•Channel 3 - velocity measured from A/D converter [deg/s] (using A/D2 channel of

the Analogue Control Interface),

•Channel 4 - velocity calculated from encoder measurements [deg/s].

2. sends a step input to system, collects the data,

3. plots the results.

Typical results of the basic test are shown in Figure 3-3.

On the screen you will see the following colours: red-channel 1, blue-channel 2, green-

channel 3 and black-channel 4. In this case all components of the system are working

correctly.

Other manuals for MS150

1

Table of contents

Other feedback Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Buchi

Buchi Scrubber K-415 Operation manual

Nahita

Nahita 503 Series quick start guide

Sartorius

Sartorius Vivacon 500 operating instructions

Boekel

Boekel Slide Moat 240000 operating instructions

DENTAURUM

DENTAURUM Compact Megaplus Instructions for use

Simpnic

Simpnic SiMP UV-C Sterilizer Box Quick installation guide

Renfert

Renfert BASIC eco quick start guide

Kendro

Kendro HERAcell 150 operating instructions

Thermo Scientific

Thermo Scientific DensityPRO-T installation guide

ProteinSimple

ProteinSimple Jess user guide

Selecta

Selecta PRECISTERM 2L instruction manual

Agilent Technologies

Agilent Technologies 6890N Troubleshooting