Feeney Feeney DesignRail 24V LED Lighting V2, User manual

1-800-888-2418 | www.feeneyinc.com 1

Rev: 09/21

DesignRail®24V LED Lighng (v2)

General Notes:

Drivers are available in a variety of waages. In general a driver should not exceed more than 80% of its rated output capacity.

(Example: 60W Driver = 60 x 0.8 = 48W Max).

Strip Lights require 1.44 was per foot. Aer determining the necessary length of strip lighng, calculate the waage and ensure

the driver being used has adequate capacity (example: 10’ = 10 x 1.44 = 14.4W). The maximum length of strip lighng that can be

connected in one run is 55 feet.

Building codes vary by locaon and jurisdicon. Consult all applicable codes before installing DesignRail® LED Lighng.DesignRail®

LED Lighng may not be suitable for every applicaon and it is the sole responsibility of the installer to ensure that DesignRail® LED

Lighng is used for its intended purpose.

WARNING: ELECTRIC SHOCK IS ALWAYS POSSIBLE WHEN WORKING WITH ELECTRICITY. THIS CAN CAUSE SERIOUS PERSONAL

INJURIES OR DEATH. ELECTRICAL SHORTS CAN ALSO CAUSE FIRES AND PROPERTY DAMAGE. ALWAYS MAKE SURE THE

ELECTRICAL OUTLET YOU ARE PLUGGING INTO IS GROUNDED.

Installaon Instrucons

1-800-888-2418 | www.feeneyinc.com2

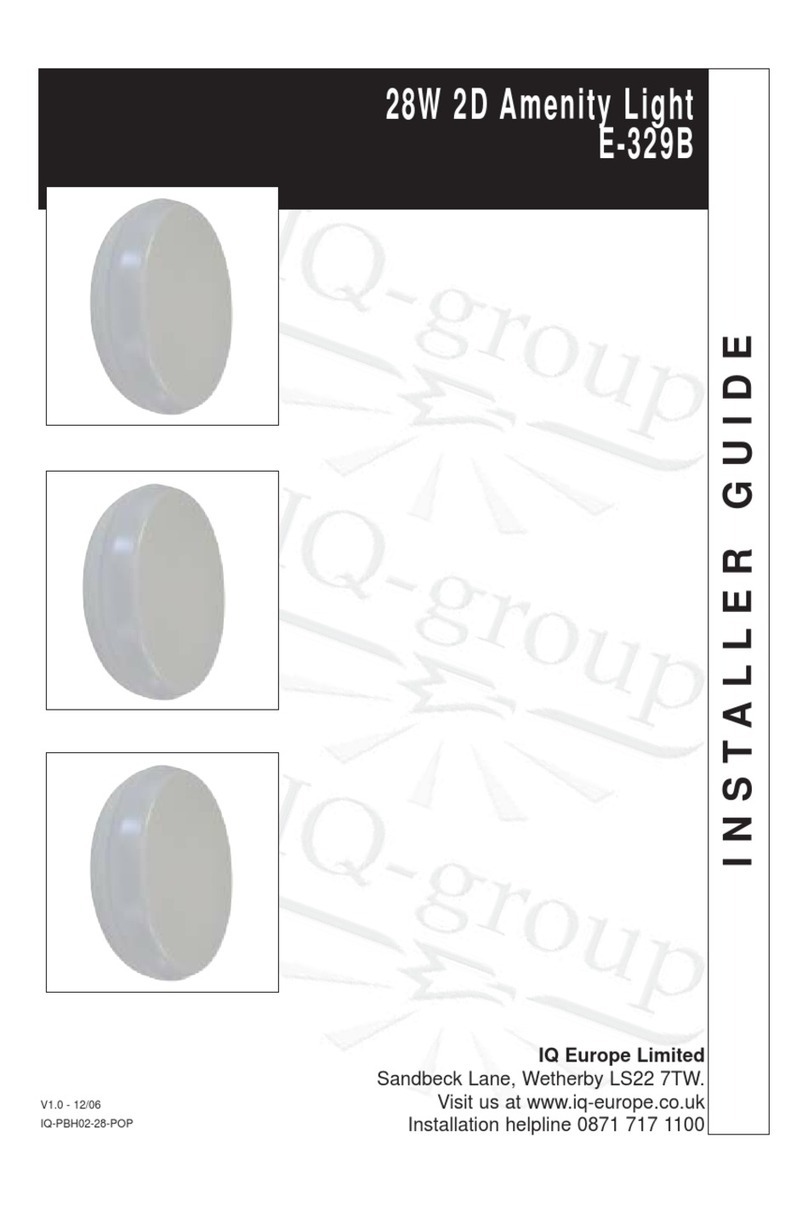

LED Lighng - Driver Kits

24V MAGNETIC DIMMABLE DRIVER

(SKU #LED : 40W, LED : 60W, LED : 96W)

ISOLATION

BUSHING

(SKU #1114)

WIRE NUTS

(PAIR)

(SKU #7670)

KIT CONTENTS

40W Driver Kit

(SKU #LED : 40W-DK)

1x 40 WaDimmable Driver

1x Starter Cable (20')

1x Wire Nuts (Pair)

1x Isolaon Bushing

60W Driver Kit

(SKU #LED : 60W-DK)

1x 60 WaDimmable Driver

1x Starter Cable (20')

1x Wire Nuts (Pair)

1x Isolaon Bushing

96W Driver Kit

(SKU #LED : 96W-DK)

1x 96 WaDimmable Driver

1x Starter Cable (20')

1x Wire Nuts (Pair)

1x Isolaon Bushing

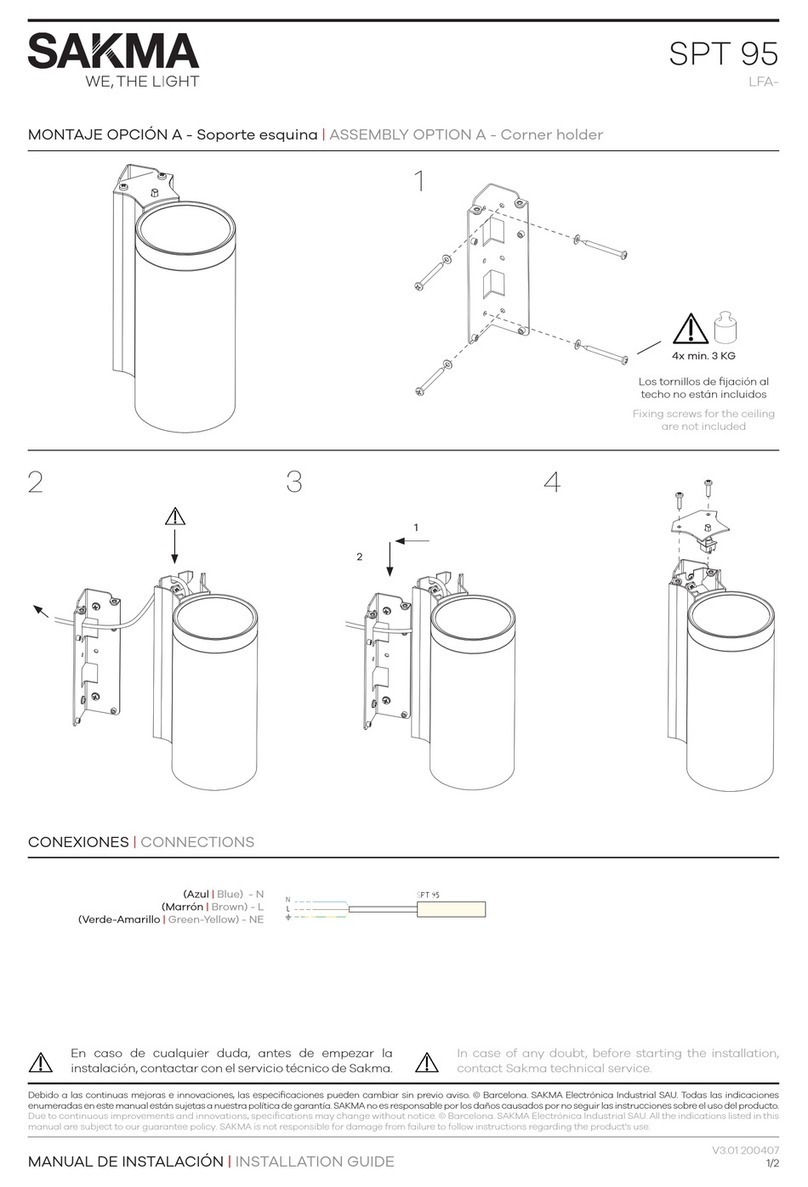

LED Light Strip

(SKU #LED : 05 to LED : 55)

LED EXTENSION CABLE (132")

(SKU #LED : EXT132)

LED CONNECTOR PAIR (includes tube of silicone)

(SKU #LED : CONN)

LED CRIMP CONNECTOR (8")

(SKU #LED : CC8)

LED SPLICE CONNECTOR (5-pack)

(SKU #LED : SPL)

LED END CAP (5-pack)

(SKU #LED : EC)

LED STARTER CABLE (20')

(SKU #LED : STC)

LED Lighng - Components

LED STARTER CABLE (20')

(SKU #LED : STC)

1-800-888-2418 | www.feeneyinc.com 3

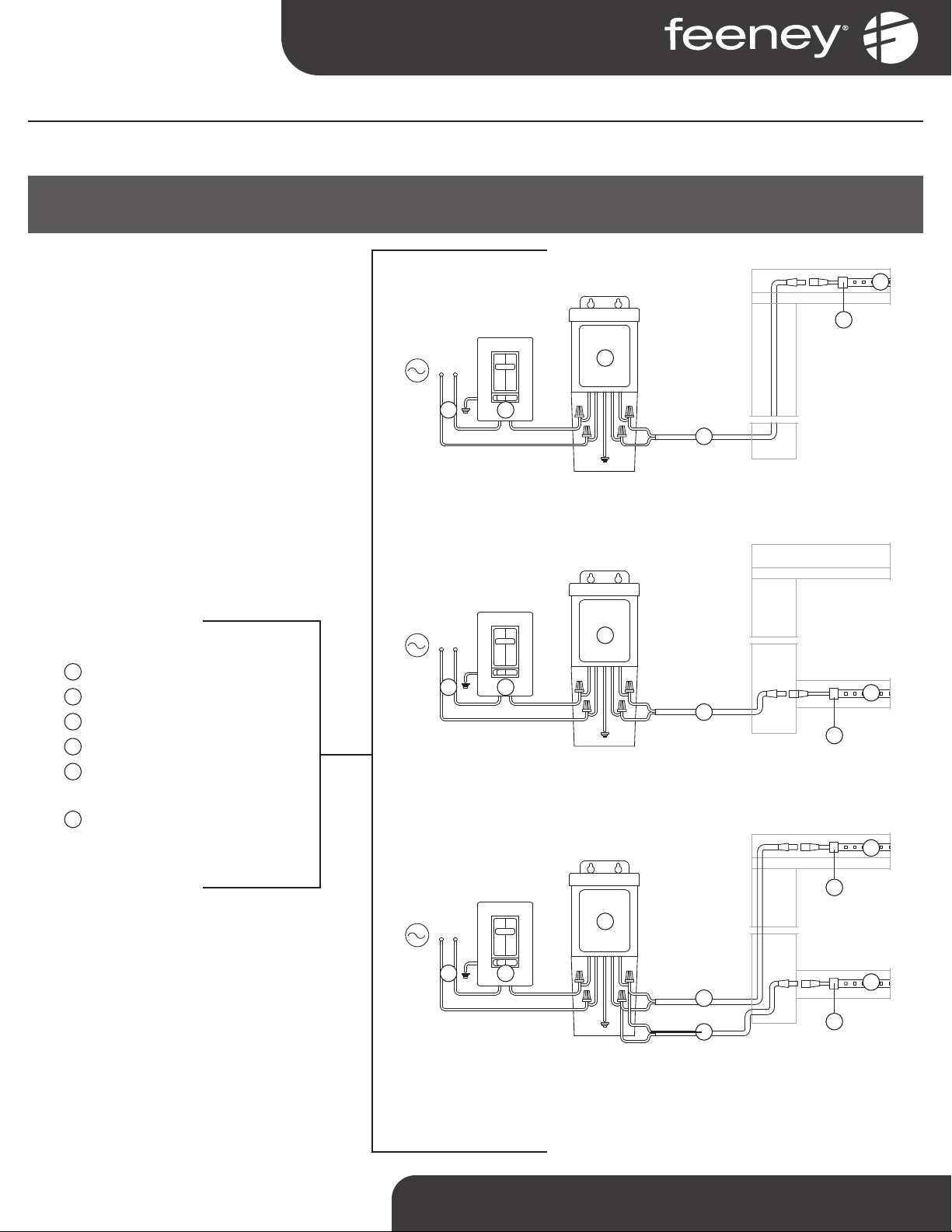

Step 1 - Install Drivers

Step 1A – Connect Source Power to Driver

IMPORTANT SAFETY NOTE: TO REDUCE RISK OF ELECTRICAL SHOCK, TURN OFF AC CIRCUIT BREAKER PRIOR TO COMMENCING ANY ELECTRICAL WORK AND

CONNECTING DRIVER(S) TO AC POWER SOURCE. VERIFY THAT LIVE POWER IS NOT PRESENT AT JUNCTION BOX WHEN MAKING CONNECTIONS.

Determine locaon of driver.

Note: It is best to locate the drivers as close as

possible to the lighࢼng to reduce the possibility

of voltage drop occuring. If possible, the driver

should be within 15 feet of the post that will

accept the 20' starter cable.

Route exterior rated wiring from compable

dimmer switch/AC power source to locaon of

driver.

Connect drivers to dimmer switch/AC power

source.

Connect 20' starter cable and route from driver

to post using supplied wire nuts.

1. Power (by customer)

2. Light Switch (by customer) 1

3. 24v Dimmable Driver 2

4. LED Starter Cable (20')

5. LED Connector Pair (Female

Connector)

6. LED Light Strip

LIGHTING COMPONENTS:

1. Mount vercally only. See Switch Compatabilty

Spec Sheet at www.feeneyinc.com

2. See Driver Spec Sheet at www.feeneyinc.com

3

4

1 2

5

6

TOP RAIL LIGHTING - WIRING DIAGRAM

BOTTOM RAIL LIGHTING - WIRING DIAGRAM

3

4

1 2

5

6

Note: If using both top and boom rail lighࢼng, run each with their own starter

cable aached to the driver.

Alternaࢼvely, a separate driver may be supplied for top and boom rail lighࢼng,

allowing for independent control of each circuit.

TOP & BOTTOM RAIL LIGHTING - WIRING DIAGRAM

3

4

1 2

5

6

5

6

4

1

2

3

4

5

6

1-800-888-2418 | www.feeneyinc.com4

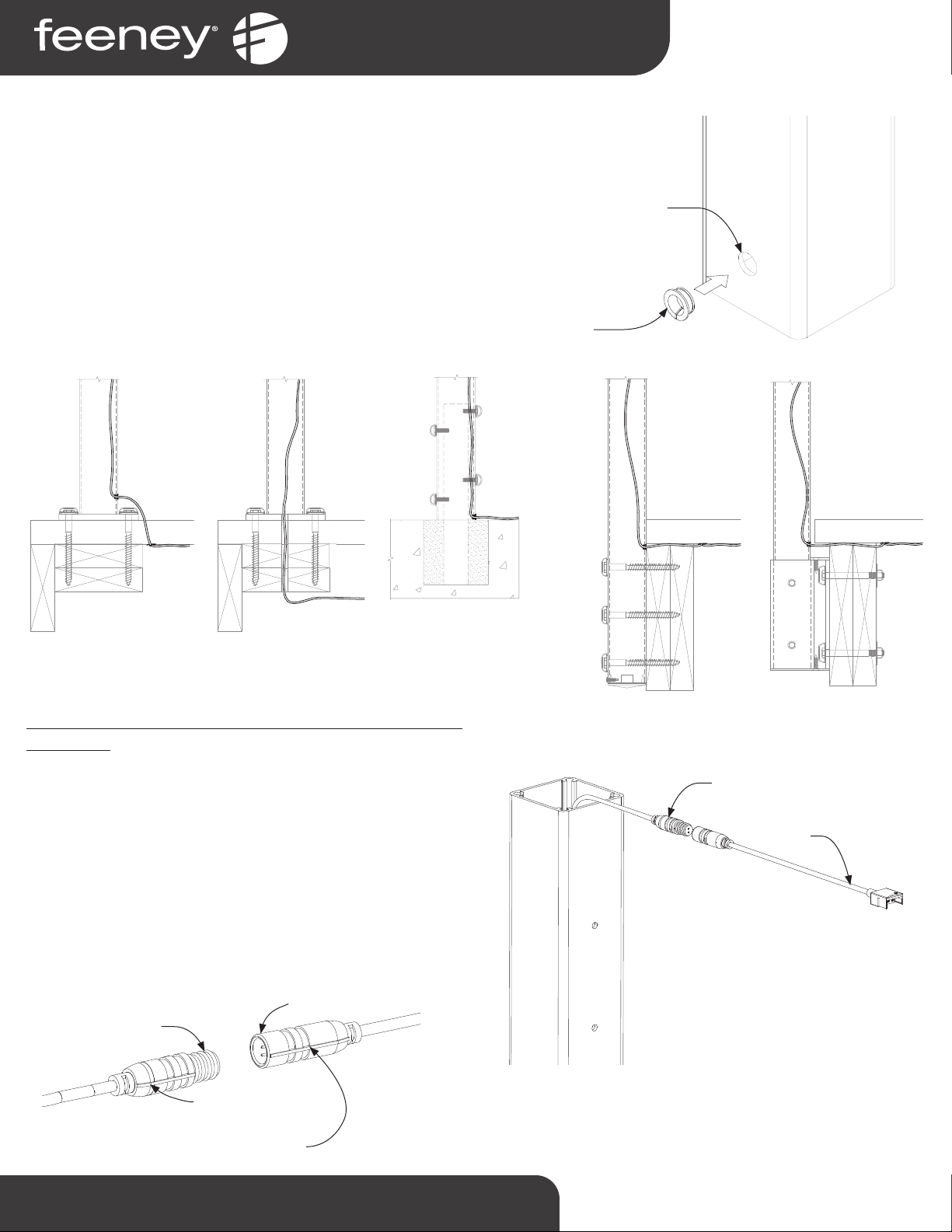

Step 1B - Drill Posts and Route Starter Cable

Determine the post that will act as the starng post, this will likely

be designated on the lighng layout schemac received with the

order. Installing the starter cable through the post is easiest when

done prior to mounng the post.

Determine the locaon that the starter cable will enter the starng

post.

Note: Depending on the post mounࢼng method, and driver locaࢼon

relaࢼve to the post, the starter cable entrance point may vary. (See

Figure 1.2 for typical recommendaࢼons)

Figure 1.1

1/2" DIA.

HOLE

GROMMET

PART #1114

For systems with lighng installed into Series 200, 300, 350, or

450 top rail:

Fish the connector for the starter cable through the post and out

of the top, and aach LED Connector (Female) to Starter Cable.

(See Figure 1.3).

IMPORTANT NOTE: Maintaining the polarity at all connec-

on points is crical. Constant alignment verificaon

of the of the posive and negave signs will guarantee

less problems and rework.

Use masking tape to temporarily secure starter cable to outside

of post to prevent retracng back into post.

WIRE COMES

UP THROUGH

DECKING AND

INTO POST.

WIRE CAN BE RUN

IN CONDUIT BURIED

IN CONCRETE, OR

RUN DIRECTLY

FROM ENCLOSURE

TO POST. WIRE

INSIDE POST RUNS

BETWEEN INSIDE

POST WALL AND

STANCHION.

WIRE RUNS UNDER

DECK THROUGH

FASCIA BOARDS

AND ENTERS POST

BELOW DECKING

SURFACE BETWEEN

FACSIA AND POST

FACE.

WIRE RUNS

UNDER DECK AND

ENTERS POST

ABOVE FASICA

BRACKET BELOW

DECKING.

WIRE RUNS UNDER

DECK THROUGH 3/4"

HOLE IN BASEPLATE

AND BLOCKING.

(3/4" HOLE DRILLED BY

CUSTOMER)

Figure 1.2

LED CONNECTOR

(FEMALE)

STARTER CABLE

Figure 1.3

MALE CONNECTOR

FEMALE CONNECTOR

Keep the straight line

on the outside maࢼng

connecࢼon aligned

1-800-888-2418 | www.feeneyinc.com 5

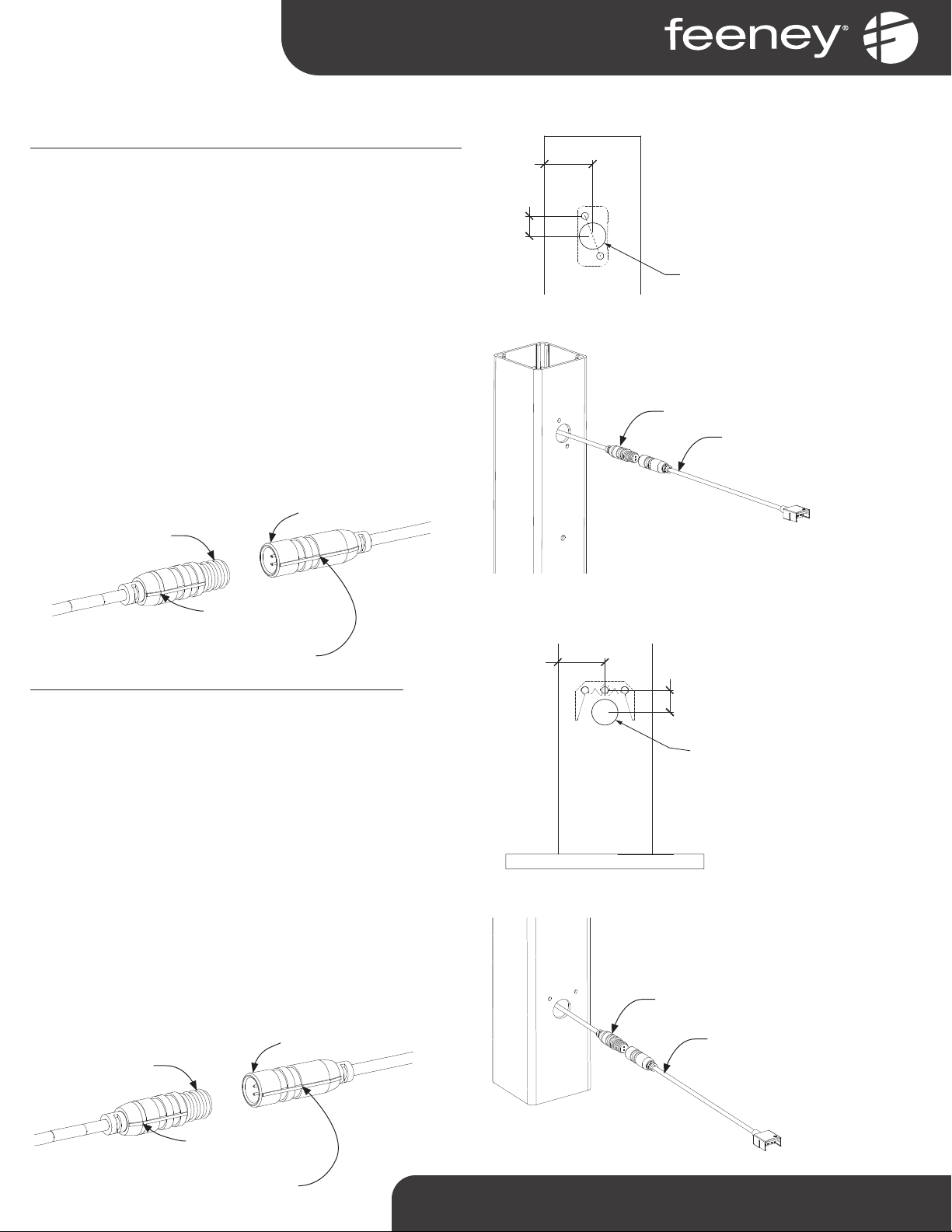

For systems with lighng installed into Series 150 top rail:

Drill an 11/16” diameter hole vercally centered between the

factory pre-drilled top rail RCB holes. This will allow the light

strip and connector to pass through the RCB hollow (See Figure

1.4). Repeat this step for each post which will have light strips

running through it. For stair posts, pre-drill top rail RCB holes as

needed, and then pre-drill 11/16" diameter hole.

Pull starter cable out through drilled hole between RCB holes,

and aach LED Connector (Female) to Starter Cable (See Figure

1.5).

IMPORTANT NOTE: Maintaining the polarity at all con-

necon points is crical. Constant alignment verifi-

caon of the of the posive and negave signs will

guarantee less problems and rework.

Use masking tape to temporarily secure starter cable to outside

of post to prevent retracng back into post.

For systems with lighng installed into Boom Rail: Drill an

11/16” dia. hole, at 9/16” below and centered between the

boom rail RCB holes (See Figure 1.6). Repeat this step for each

post which will have light strips running through it. For stair

posts, pre-drill boom rail RCB holes as needed, and then pre-

drill 11/16" diameter hole.

Pull starter cable out through drilled hole between RCB holes,

and aach LED Connector (Female) to Starter Cable (See Figure

1.7).

IMPORTANT NOTE: Maintaining the polarity at all con-

necon points is crical. Constant alignment verifi-

caon of the of the posive and negave signs will

guarantee less problems and rework.

Use masking tape to temporarily secure starter cable to outside

of post to prevent retracng back into post.

Step 1B - Connued

11/16" HOLE

1-3/16"

1/2"

TOP OF POST

Figure 1.4

1-3/16"

11/16" HOLE

9/16"

BOTTOM OF POST

Figure 1.6

Figure 1.5

LED CONNECTOR

(FEMALE)

STARTER CABLE

Figure 1.7

LED CONNECTOR

(FEMALE)

STARTER CABLE

MALE CONNECTOR

FEMALE CONNECTOR

Keep the straight line

on the outside maࢼng

connecࢼon aligned

MALE CONNECTOR

FEMALE CONNECTOR

Keep the straight line

on the outside maࢼng

connecࢼon aligned

1-800-888-2418 | www.feeneyinc.com6

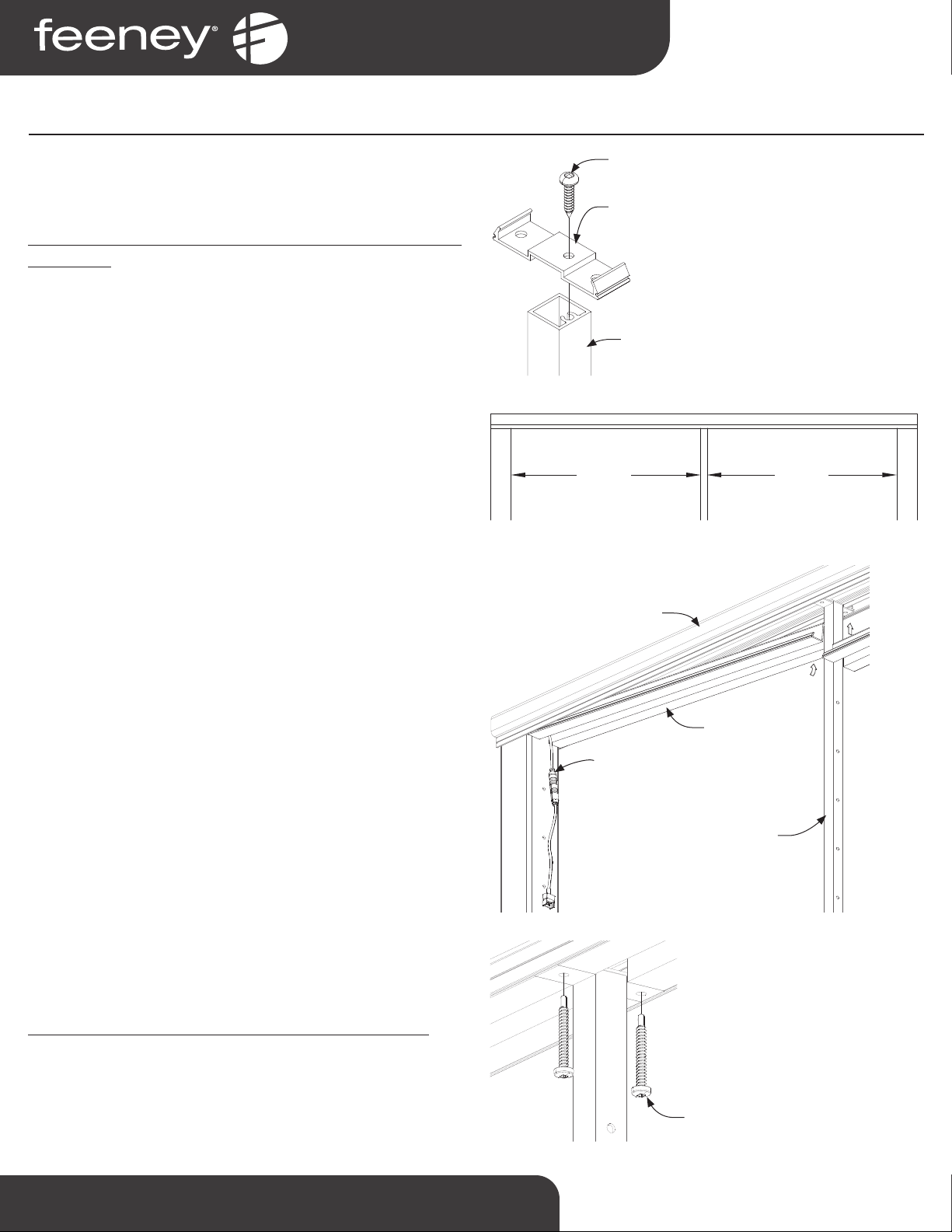

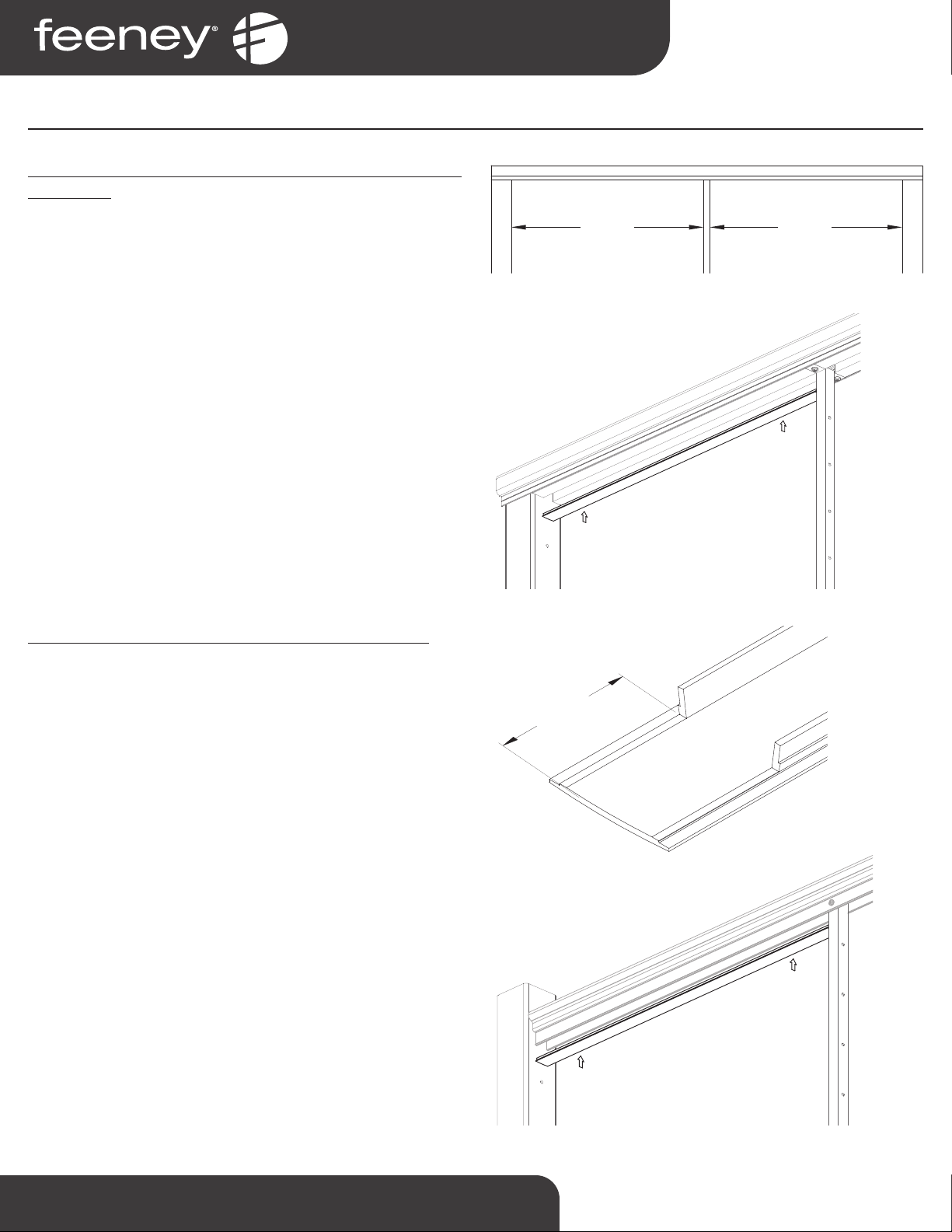

Step 2 - Prepare Railing Frame

Following driver installaon, and aer roung the starter

cable, install all posts and top rail per DesignRail Installaon

Instrucons.

For systems with lighng installed into Series 200, 300, 350, or

450 top rail:

Aach 3/4” wide piece of standard infill to top of intermediate

pickets using #10 x 3/4” screw (See Figure 2.1).

Follow standard DesignRail installaon instrucons for aaching

boom rail, or picket base plate, and install picket sub-assembly

panels.

Measure the opening between the picket and post face on each

side of the picket (See Figure 2.2). These dimensions should be

equal. Cut top rail insert for lighng, to fit on each side of the

picket.

Install top rail insert on each side of picket. Avoid pinching

starter cable by starng insert at a slight angle and rotang up

and snapping into top rail (See Figure 2.3).

Secure intermediate picket to top rail using (2x) #8 x 1” self-

tapping screws (See Figure 2.4).

For systems with lighng installed into Series 150 top rail:

Intermediate picket can be directly aached to flange of built-in

channel. Light strips will install directly into top rail, without an

addional insert

Figure 2.2

MEASURE MEASURE

Figure 2.1

#10 x 3/4"

SCREW

3/4" WIDE PIECE

OF STANDARD TOP

RAIL INFILL FOR

CABLERAIL

INTERMEDIATE

PICKET

Figure 2.3

STARTER CABLE

WITH LED CONNECTOR

TOP RAIL

INSERT FOR

LIGHTING

INTERMEDIATE

PICKET

TOP RAIL

Figure 2.4

#8 x 1" SELF-TAPPING

SCREW

1-800-888-2418 | www.feeneyinc.com 7

For systems with lighng installed into Boom Rail:

Measure opening between the post faces beneath the boom

rail (See Figure 2.5).

Cut channeled boom rail inert to fit between posts.

Trim channel poron of isert at both ends to clear RCBs. This can

be done by cung the ‘top’ of the channel to a point just above

the flanges, then ‘snipping’ the sides to remove (See Figure 2.6).

Install boom rail insert between posts (See Figure 2.7).

Figure 2.6

1-1/4"

Figure 2.7

BOTTOM RAIL

BOTTOM RAIL

INSERT

STARTER CABLE

WITH LED CONNECTOR

Figure 2.5

MEASURE

Step 2 - Connued

1-800-888-2418 | www.feeneyinc.com8

Measure length of strip light needed for run (face of post to

face of post). Reference lighng layout for approximate light

strip engths.

Cut light strip to length at nearest cut mark. Cut marks are

located approx. every 4-inches. Using scissors cut between

the 4 copper dots (See Figure 3.1).

Determine which end of light strip will be used at starng

post, by lining up the posve symbol on the light strip with

the posive symbol on the LED Connector. Be sure to

account for the back of the light strip (the side with the tape)

needing to face upwards. The light strip may need to be

flipped end for end in order to avoid twisng when properly

oriented (See Figure 3.2).

Roll back the adhesive tape at the end of the light strip just

enough so that it is out of the way of where the connector

will be placed. Use the provided silicone and affix the clear

plasc sleeve to the end of the light strip, make sure window

opening is oriented so that the copper dots are aligned in

opening (See Figure 3.3). The end of the light strip is now

ready to be snapped into the connector.

Snap the light strip onto the starter cable LED connector

assembly by firmly pressing the clear plasc sleeve into the

connector. The prongs of the LED connector will enter in

through the opening in the clear plasc sleeve and pierce

the light strip, contacng the copper dots (See Figure 3.4).

Step 3 - Install Light Strips

DC 24V DC 24V DC 24V DC 24V

Figure 3.1

LED CONNECTOR

CLEAR PLASTIC SLEEVE

LIGHT STRIP

Figure 3.2

POSITIVE

SYMBOL

LED CONNECTOR

CLEAR PLASTIC SLEEVE

LIGHT STRIP

Figure 3.4

Figure 3.3

CLEAR PLASTIC SLEEVE

LIGHT STRIP

LIGHT STRIP

ADHESIVE TAPE

1-800-888-2418 | www.feeneyinc.com 9

Peel back the adhesive tape protecve layer about 6 to

12 inches, enough to begin scking the light strip to the

underside of the channel.

Stuffstarter cable and connector back into post, so that light

strip starts as close to the face of the post as possible. Push

the light strip up and hold with firm pressure, allowing the

adhesive to bond to the aluminum (See Figure 3.5). Connue

peeling back the adhesive tape protecve layer and adhering

the light strip to the railing a few feet at a me.

For systems with lighng installed into Series 200, 300,

350, or 450 top rail:

Connue the enre light strip along the length of the top rail,

passing the light strip over the top of the posts and pickets.

For systems with lighng installed into Series 150 top rail:

Connue the enre light strip along the length of the top

rail, passing the light strip over the intermediate pickets,

through the pre-drilled holes and RCBs in the channel of the

Series 150 top rail.

For systems with lighng installed into Boom Rail:

Connue the enre light strip along the length of the boom

rail, passing the light strip through the pre-drilled holes and

RCBs in the channel of the boom rail insert (See Figure 3.6).

Corner post condions and newel post stair transions may

require addional connectors. See following details for

specific installaon condion soluons.

Figure 3.5

Figure 3.6

Step 3 - Connued

1-800-888-2418 | www.feeneyinc.com10

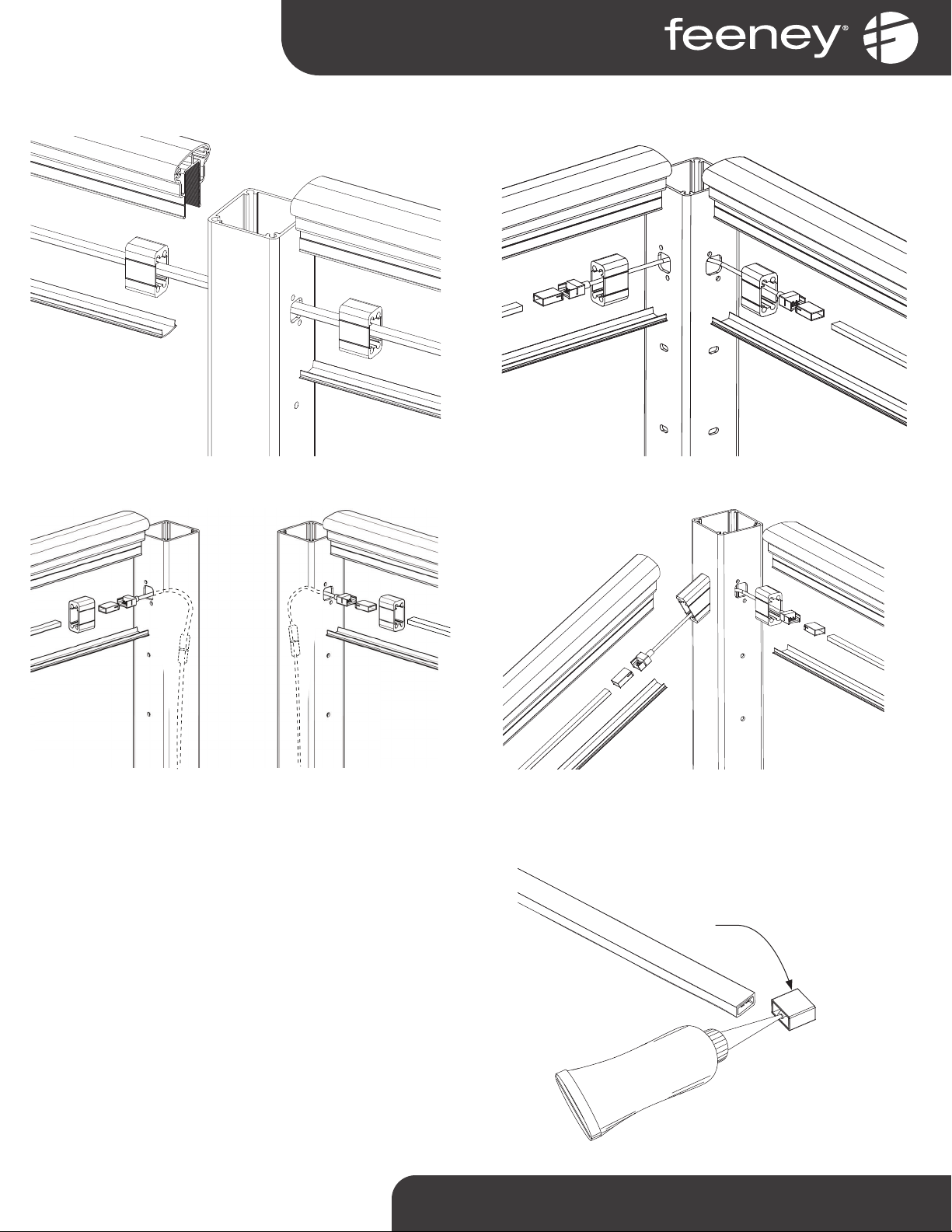

Intermediate Post with Series 200, 300, 350 or 450 top rail

and boom rail

Stair Newel Post with Series 200, 300, 350, 450 top rail and

boom rail on level and Series 150 and boom rail on stairs

Single Corner Post with Series 200, 300, 350, 450 top rail

and boom rail

Double Corner Post with Series 200, 300, 350, 450 top rail

and boom rail

Lighng in Series 200, 300, 350 or 450 Top Rail and Boom Rail Details

1-800-888-2418 | www.feeneyinc.com 11

Lighng in Series 150 Top Rail Details

Stair Newel Post with Series 150 top railDouble Corner Posts with Series 150 top rail

Single Corner Post with Series 150 top railIntermediate Post with series 150 top rail

At the exposed terminaon end of the light strip, where no more

connecons will be made roll back the adhesive tape. Use the

provided silicone and affix an end cap. (See Figure 3.4).

END CAP

Figure 3.4

1-800-888-2418 | www.feeneyinc.com12

For systems with lighng installed into Series 200, 300, 350, or

450 top rail:

Measure the opening between the picket and post face on each

side of the picket (See Figure 4.1). These dimensions should be

equal.

Cut diffuser lens to length to fit on each side of the picket, using

a sharp ulity knife, or heavy duty ulity scissors/shears.

Insert diffuser lens into top rail insert, or top rail flanges, as

shown. (See Figure 4.2).

For systems with lighng installed into Series 150 top rail:

Follow the same instrucons for measuring and cung diffuser

lens to length, as for other top rails (shown above).

Trim 1-1/4” of the ‘tension flanges’ at the end of the diffuser lens

that will be under the top rail RCB. Trimming is best done with

a small backsaw or sharp ulity knife. This will keep the diffuser

lens from interfering with the boom of the RCB. (See Figure 4.3).

Insert diffuser lens into top rail insert, or top rail flanges, as

shown. (See Figure 4.4)

Figure 4.1

MEASURE MEASURE

Figure 4.4

Figure 4.3

1-1/4"

Step 4 - Install Diffuser Lens

Figure 4.2

1-800-888-2418 | www.feeneyinc.com 13

For systems with lighng installed into Boom Rail:

Measure opening between the post faces beneath the boom

rail (See Figure 4.5).

Cut diffuser lens to length, using a sharp ulity knife, or heavy

duty ulity scissors/shears.

Depending on the length of the boom rail it may require more

than one piece of diffuser lens to fill the enre length. In this

case, insert the full 36” lens, then trim the second lens to fit the

remainder of the opening.

Insert diffuser lens into boom rail infill, as shown (See Figure 4.6).

MEASURE

Figure 4.5

Figure 4.6

Step 4 - Connued

LED Lighng - Troubleshoong

Scenario #1 - If all locaons do not illuminate, there could be a polarity issue

1. Turn offAC circuit breaker prior to connuing the next procedure.

2. Swap the wires at the driver terminals

3. Replace cover on driver unit

4. Turn on AC circuit breaker

5. Power up the driver and check all LED locaons for illuminaon

Scenario #2 - Some LED locaons are illuminated but others are not

1. Note which locaons are not illuminang

2. Turn offAC circuit breaker prior to connuing to next procedure

3. Rotate the connector 180 degrees at each noted locaon where the light strip is not illuminang

4. Repeat at all noted locaons that did not illuminate

5. Turn on AC circuit breaker

6. Power up the driver and check all locaons for illuminaon

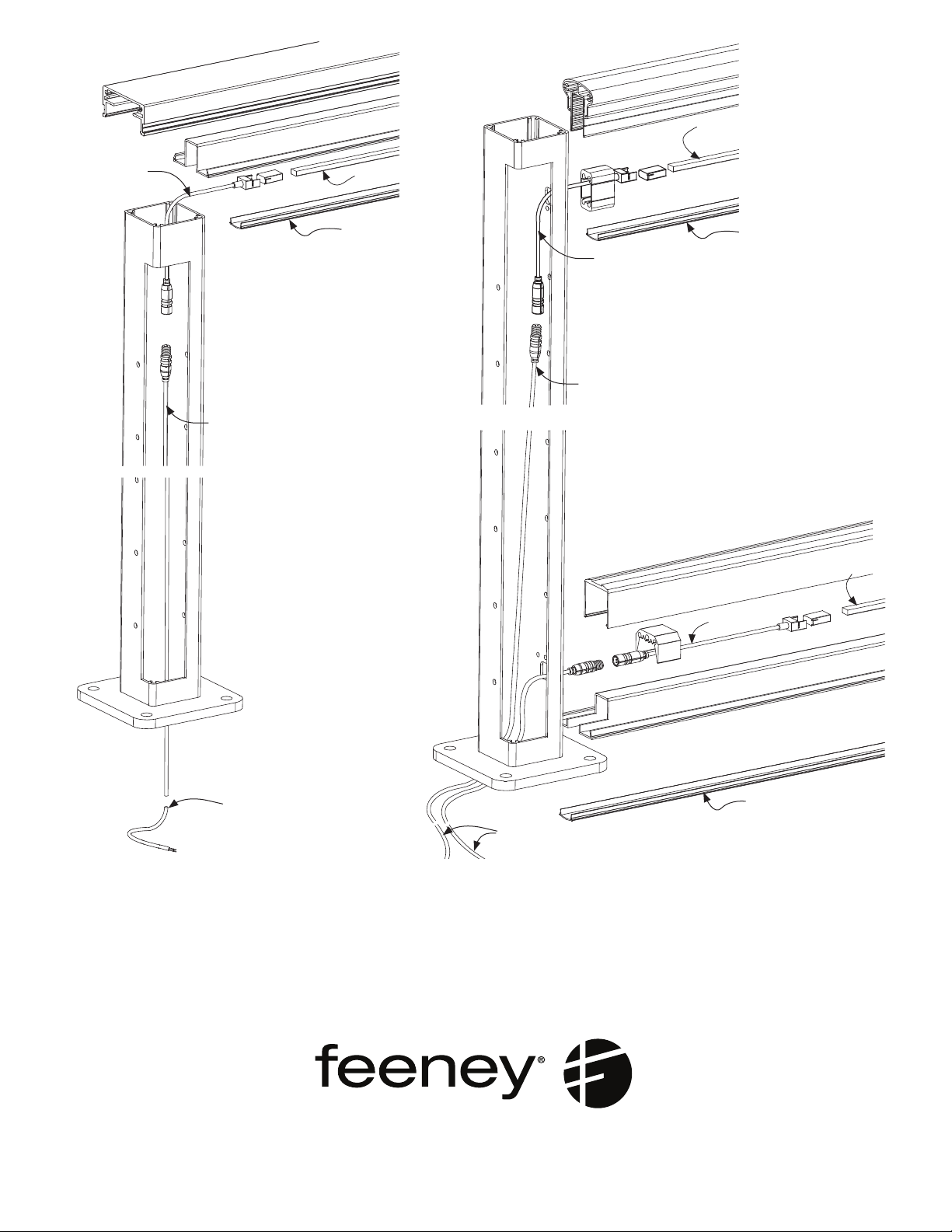

Starng Post with Top Rail Lighng, shown

with series 450 top rail (Series 200, 300, and

350 top rail similar)

Light Strip

Starter Cable (20')

LED Connector (Female)

Diffuser Lens

Top Rail

Bottom Rail

Starter Cable

Diffuser Lens

Light Strip

Bottom Rail Insert

LED Connector Pair

(Female)

Top Rail

Top Rail Insert

LED Connector

(Female)

Diffuser Lens

Starter Cable (20')

Starter Cable

Light Strip

www.feeneyinc.com

1-800-888-2418

©2021 Feeney, Inc. (09/21)

EXPLODED ISOMETRIC VIEWS

Starng Post with Top Rail and Boom Rail

Lighng, shown with series 150 top rail

Table of contents

Popular Lighting Equipment manuals by other brands

JONATHAN Y

JONATHAN Y JYL3050 instructions

Williams-Sonoma

Williams-Sonoma Hayes Assembly instructions

National Specialty Lighting

National Specialty Lighting LED Brick Star Gen I installation instructions

Lightmaxx

Lightmaxx VEGA DOT 60 user manual

Clas Ohlson

Clas Ohlson SCSYD001 quick start guide

Generac Power Systems

Generac Power Systems CTF 10mt owner's manual

Mania

Mania ILLUSIOLIGHT instruction manual

VisionAid

VisionAid StandBright 2 instructions

ADJ

ADJ INNO POCKET Z4 User instructions

Capital Play

Capital Play Trampoline MagicNight Lights Installation Manual & Safety Instructions

Cooper Crouse-Hinds

Cooper Crouse-Hinds 858 Series instruction manual

Terex

Terex Series AL4000 Operator's manual