(

DSk

658

To be handed to the workshop!

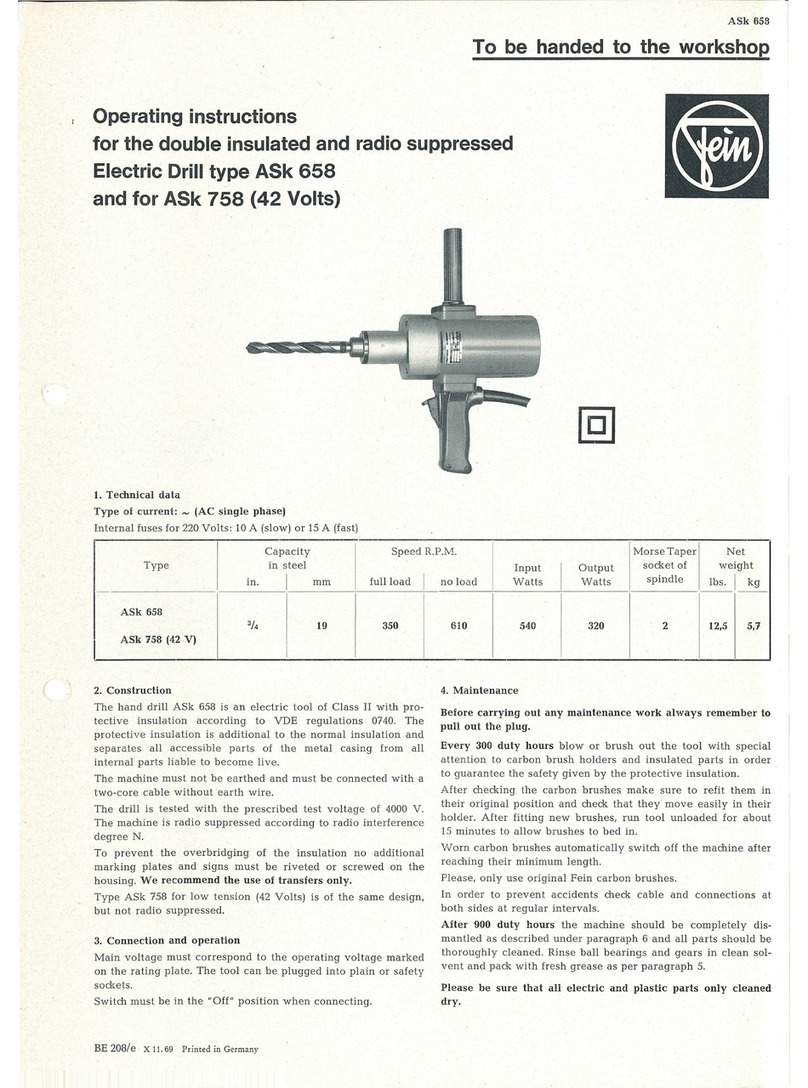

Operating instructions

for the Two Speed Electric Drill type DSk

658

and for DSk

758

(42

Volts)

and for DSke

658

(with electronic

sp~ed

control)

1.

Technical

data

Type

of

current:

~

AC

single

phase

Internal

fuses

for

220

Volts:

10 A (slow)

or

15

A (fast)

Capacity

in

steel

Speed

R.

P.M

.

Morse

Taper

Net

Type

Input

I

Output

Socket

of

weight

in

. I

mm

full

load

I

no

load

Watts

Watts

spindle

lbs

I

kg

DSk

658 l

'/,/

3

/4

13/19 420/200 720/340 540 320 2 13,42 6,1

DSk

758

{42

V)

DSke

658 1

/2fl/4

13/19 240-420/ 330-720/ 540 320 2 14,1 6,4 I

110-200

:l.

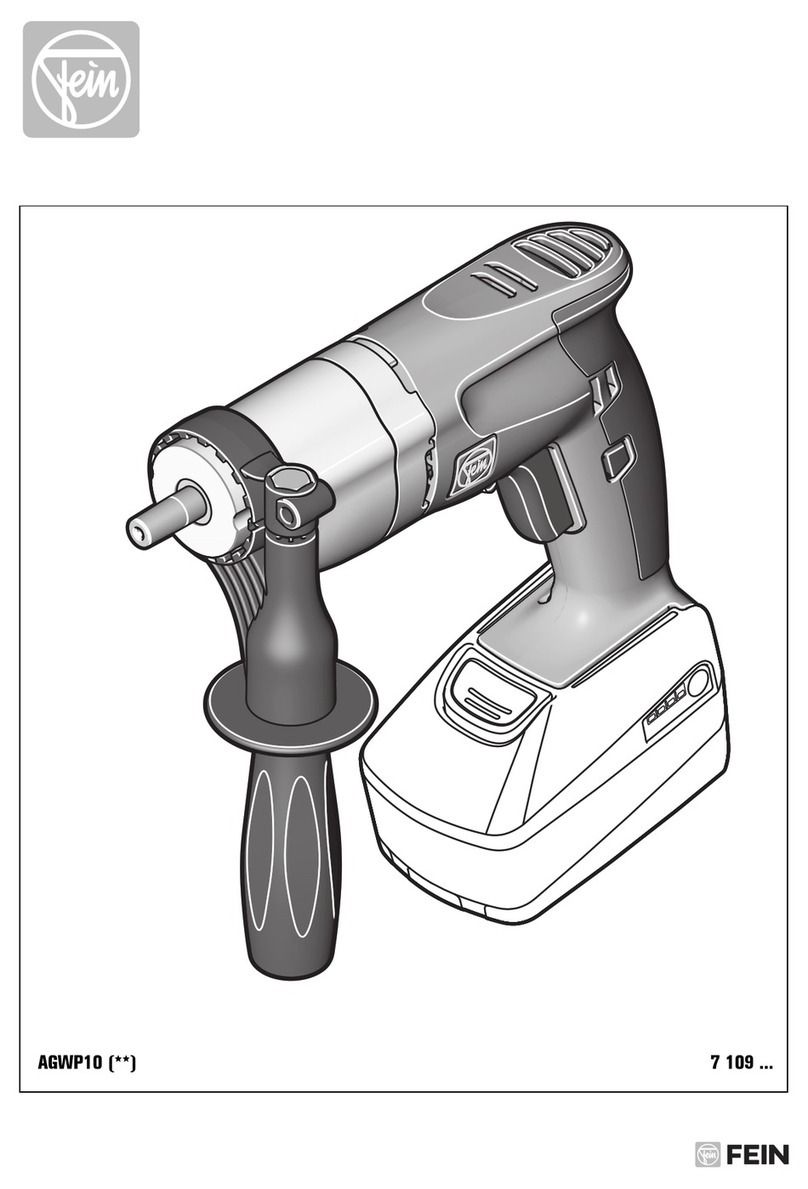

Construction

The

two

speed

hand

drill

DSk

658

is

an

electric

tool

of

Class

II

with

protective

insulation

according

to

VDE

regulations

0740.

The

protective

insulation

is

additional

to

the

normal

insulation

and

separates

all

accessible

parts

of

the

metal

casing

from

all

internal

parts

liable

to

become

live

.

The

machine

must

not

be

earthed

and

must

be

connected

with

a

two-core

cable

without

earth

wire.

The

drill

is

tested

with

the

prescribed

test

voltage

of

4000 V.

The

machin

e is

radio

suppressed

according

to

radio

interference

VDE 0875.

Type

DSk

758,

for

low

tension

(42 V)

is

of

the

same

design,

but

without

double

insulation.

To

prevent

the

overbridging

of

the

insulation

no

additional

marking

plates

and

signs

must

be

riveted

or

screwed

on

the

housing.

We

recommend

the

use

of

transfers

only.

BE 209/e X

1.

73

Prin

te

d

in

Germany

150-340

3.

Connection

and

operation

Main

voltage

must

correspond

to

the

operating

voltage

marked

on

the

rating

plate.

The

tool

can

be

plugged

into

plain

or

safet

y

sockets.

Switch

must

be

in

the

"Off"

position

when

connecting.

The

speed

of

the

machine

must

only

be

changed

at

stand-still

or

at

slowing

down

without

load

.

Release

switch

handle

(47)

of

its

longitudinal

position,

put

it

across

by

turning

it

out,

then

push

it

into

the

wanted

switch

direction

and

reset

the

switch

handle

in

opposite

direction

again

into

its

longitudinal

position.

The

type

DSke

658

has

an

electronic

speed

control.

The

speed

will

be

changed

by

turning

the

button

situated

on

the

handle,

when

the

machine

is

running

or

not.

The

speed

will

be

increased

by

turning

the

button

clockwise

and

reduced

by

turning

it

anticlockwise

.