Fein ASzx 736 User manual

Other Fein Drill manuals

Fein

Fein ABS 9 User manual

Fein

Fein HandyMaster ABS 12V Quick start guide

Fein

Fein Slugger JHM USA 101 X User manual

Fein

Fein BOS 16 User manual

Fein

Fein ASc 636 User manual

Fein

Fein BOP6 User manual

Fein

Fein Slugger JMU 404 M User manual

Fein

Fein KBC35 User manual

Fein

Fein AKBU 35 PMQ Series User manual

Fein

Fein ASz 648 d User manual

Fein

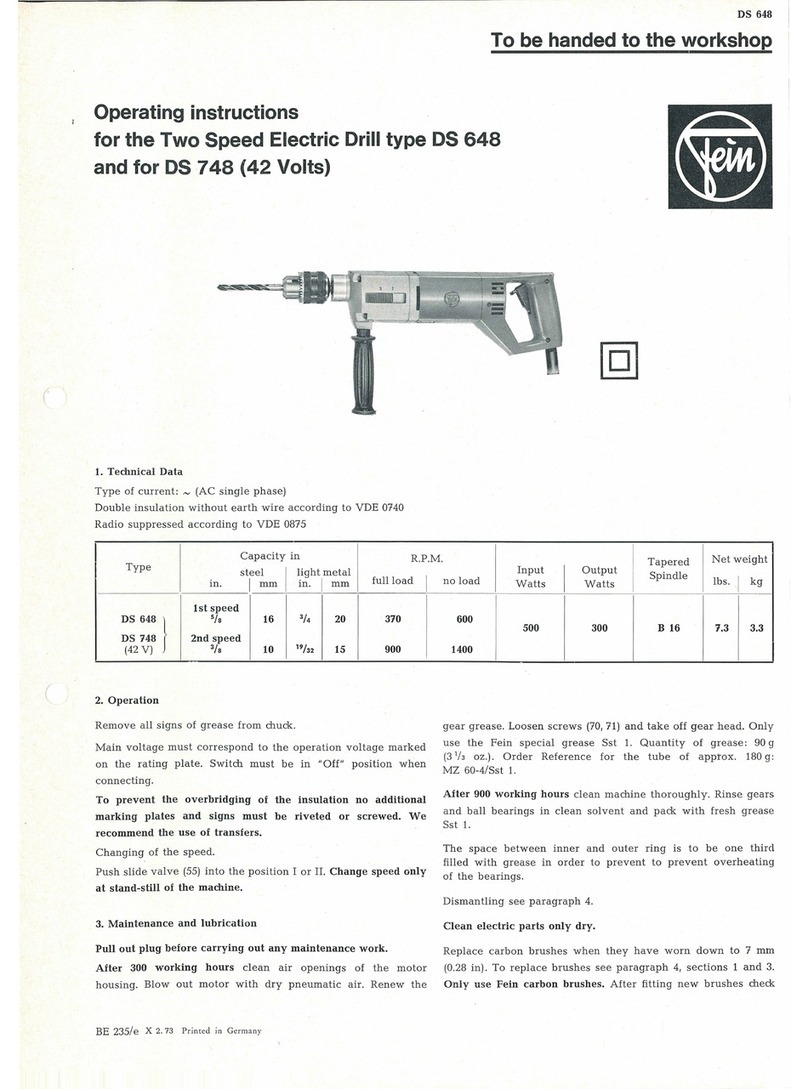

Fein DS 648 User manual

Fein

Fein HandyMaster ABS 14V Quick start guide

Fein

Fein KBM 50 Q User manual

Fein

Fein ASCD 18-200 W4 User manual

Fein

Fein Tapper ASge 636 User manual

Fein

Fein KBM 52 U User manual

Fein

Fein BOZ 32-4M User manual

Fein

Fein KBU 35 PQ Setup guide

Fein

Fein AKBU 35 PMQ Series User manual

Fein

Fein ABOP6 User manual