Felder RL 250 User manual

User Manual

Dust Extractor

RL 250/300

Keep this manual handy and in good condition for continual reference!

Dok.ID: 002-0-450_02 • Englisch • 2012-02-13

Translation

2

Dust Extractor

RL 250/RL 300

© Felder KG

KR-FELDER-STR.1

A-6060 Hall in Tirol

Tel.: +43 (0) 5223 / 58 50 0

Fax: +43 (0) 5223 / 56 13 0

Email: info@felder.at

Internet: www.felder.at

5th of November 2008

FELDER

Note: The machine must be inspected immediately on arrival. If the machine was damaged during trans-

port or if any parts are missing, a written record of the problems must be submitted to the forwarding

agent and a damage report compiled. Be sure, also to notify your supplier immediately.

For the safety of all personnel, it is necessary to conscientiously study this manual before assembly and

operation. This manual must be kept in good condition, as it belongs to the machine! Furthermore, keep

the manual at hand and in the vicinity of the machine so that it is accessible to personnel when they are

using, maintaining or repairing the machine.

A product of the FELDER GROUP

Note: Year of construction

The machine number of this machine will be printed on this operating manual.

The final two digits of the machine number show the year of construction of this machine.

z.B. XXX.XX.XXX.11 -> Year of construction 2011

3

Dust Extractor

RL 250/RL 300

Contents

Contents

02 • Englisch

1 General .......................................................................................................................5

1.1 Explanations of the symbols .............................................................................................5

1.2 Information about the manual ..........................................................................................6

1.3 Liability and warranty .....................................................................................................7

1.4 Copyright ......................................................................................................................7

1.5 Warranty notice .............................................................................................................7

1.6 Spare parts ...................................................................................................................7

1.7 Disposal ........................................................................................................................8

1.8 Important information .....................................................................................................8

2 Safety .........................................................................................................................9

2.1 Intended use ..................................................................................................................9

2.2 Manual contents ............................................................................................................9

2.3 Making changes and modifications to the machine.............................................................9

2.4 Responsibilities of the owner operator .............................................................................10

2.5 What is required of personnel ........................................................................................10

2.6 Work safety ................................................................................................................10

2.7 Personal safety equipment .............................................................................................11

2.8 Other risks ..................................................................................................................11

2.9 Machine hazards .........................................................................................................11

2.10 Fire hazards ..............................................................................................................12

2.11 Noise emission ..........................................................................................................12

2.12 Safety cover ..............................................................................................................13

2.13 Procedure in case of fire ..............................................................................................13

3 Declaration of Conformity ..........................................................................................14

4 Delivery and assembly ...............................................................................................15

5 Intended use ..............................................................................................................16

6 Technical specifications...............................................................................................17

7 Filter contents level monitoring ...................................................................................18

8 Explosion pressure proofness .....................................................................................18

9 General safety information ........................................................................................19

10 Vacuum hose port/casing ........................................................................................20

11 Electrical connection .................................................................................................20

12 Fire prevention and extinguisher...............................................................................21

13 Putting the dust extractor into operation ...................................................................21

14 Dedusting the filter...................................................................................................21

4

Dust Extractor

RL 250/RL 300

Contents

15 Maintenance ...........................................................................................................22

16 Removing the collected materials ..............................................................................22

17 Cleaning the filter ....................................................................................................23

18 Hazard prevention/Remaining risks ..........................................................................23

18.1 Mechanical hazard prevention measures .......................................................................23

18.2 Electrical hazard prevention measures ...........................................................................23

18.3 Dust hazard prevention ...............................................................................................24

18.4 Fire and explosion hazards prevention ..........................................................................24

19 Error recognition ......................................................................................................25

20 Spare parts list RL 250 .............................................................................................26

21 Spare parts list RL 300 .............................................................................................27

22 Pulse-jet cleaning pneumatic diagram .......................................................................28

23 Control system .........................................................................................................29

23.1 Indicator lamps and option switches in the equipment cabinet ..........................................29

23.2 Built-in equipment cabinet components ..........................................................................30

23.3 List of parameters for filter check: (factory settings) .........................................................31

23.4 Motor overload protector ............................................................................................31

24 Index ......................................................................................................................32

5

!

Dust Extractor

RL 250/RL 300

Note:

This symbol marks tips and information which should be observed to ensure efficient and failure-free op-

eration of the machine.

Attention! Risk of material damage!

This symbol marks instructions which, if not observed, may lead to material damage, functional failures

and/or machine breakdown.

Warning! Risk of injury or death!

This symbol marks instructions that must be followed in order to avoid harm to one‘s health, injuries, per-

manent impairment or death.

1 General

1.1 Explanations of the symbols

Important technical safety instructions in this manual are

marked with symbols.

These instructions for work safety must be followed. In

all these particular cases, special attention must be paid

in order to avoid accidents, injury to persons or material

damage.

Warning! Danger – electric current!

This symbol warns of potentially dangerous situations related to electric current. Not observing the safety

instructions increases the risk of serious injury or death. Required electrical repairs may only be carried out

by a trained electrical technician.

General

6

!

Dust Extractor

RL 250/RL 300

1.2 Information about the manual

This manual describes how to operate the machine

properly and safely. Be sure to follow the safety tips and

instructions stated here as well as any local accident

prevention regulations and general safety regulations.

Before beginning any work on the machine, ensure that

the manual, in particular the chapter entitled “Safety”

and the respective safety guidelines, has been read in its

entirety and fully understood. This manual is an integral

part of the machine and must therefore be kept in the

direct vicinity of the machine and be accessible at all

times. If the machine is sold, rented, lent or otherwise

transferred to another party, the manual must accompany

the machine.

Attention! This operating manual contains general guidelines on how to transport, set up, operate and

maintain the filter system.

The information contained in this manual is based on

practical experience acquired over many years. It is

recommended to comply exactly with the technical speci-

fications to guarantee the best possible results and a safe

operation of the machine. Read this operating manual

carefully and keep it in a safe place. If you have any

questions or are unclear about the instructions, please do

not hesitate to contact us. Please have the machine serial

number at hand when you contact us.

• This operating manual is designed for english spoken

technicians.

• If the instructions in this operating manual are not

observed, the guarantee claim is null and void.

• The filter system may only be operated, maintained

and put into operation by personnel who have read

and understood the operating manual and are famil-

iar with the applicable working safety and accident

prevention regulations.

• Keep this operating manual close at hand and en-

sure it is easily accessible to every operator.

• In addition to the operating manual, comply with

the local applicable accident prevention rules and

regulations.

Attention! This system was manufactured according to state-of-the-art technology and the safety standards

in force. This does not, however, exclude the risk of bodily injury, system damage or other material dam-

ages when used.

The system may only be used if it is technically defect-free and if the instructions in the technical operating

manual are followed and applied to the intended range of operations. The system may only be operated

by responsible personnel aware of the dangers and risks of operating the system. Malfunctions, in particu-

lar those, which affect the occupational safety must be eliminated immediately.

General

7

!

Dust Extractor

RL 250/RL 300

1.3 Liability and warranty

The contents and instructions in this manual were com-

piled in consideration of current regulations and state-

of-the-art technology as well as based on our know-how

and experience acquired over many years. This manual

must be read carefully before commencing any work

on or with this machine. The manufacturer shall not be

liable for damage and or faults resulting from the disre-

gard of instructions in the manual. The texts and images

do not necessarily represent the delivery contents.

The images and graphics are not depicted on a 1:1

scale. The actual delivery contents are dependent on

custom-build specifications, add-on options or recent

technical modifications and may therefore deviate from

the descriptions, instructions and images contained in

the manual. Should any questions arise, please contact

the manufacturer. We reserve the right to make technical

modifications to the product in order to further improve

user-friendliness and develop its functionality.

1.4 Copyright

This manual should be handled confidentially. It is desig-

nated solely for those persons who work on or with the

machine. All descriptions, texts, drawings, photos and

other depictions are protected by copyright and other

commercial laws. Illegal use of the materials is punish-

able by law.

This manual – in its entirety or parts thereof – may not

be transferred to third parties or copied in any way or

form, and its contents may not be used or otherwise

communicated without the express written consent of the

manufacturer. Infringement of these rights may lead to

a demand for compensation or other applicable claims.

We reserve all rights in exercising commercial protection

laws.

1.5 Warranty notice

The guarantee period is in accordance with national

guidelines. Details may be found on our website,

www.felder-group.com

1.6 Spare parts

Use only genuine spare parts supplied by the manufac-

turer.

Attention! Non genuine, counterfeit or faulty spare parts may result in damage, cause malfunction or

complete breakdown of the machine.

If unauthorised spare parts are installed in the machine,

all warranty, service, compensation and liability claims

against the manufacturer and their contractors, dealers

and representatives shall be rejected.

Note: A list of authorised genuine spare parts can be found at the end of this operating manual.

General

8

!

Dust Extractor

RL 250/RL 300

General

1.7 Disposal

If no agreement has been made with the supplier to take

back the packaging materials, help to protect the environ-

ment by reusing the materials or separating them accord-

ing to type and size for recycling.

• Scrap waste metal

• Recycle all plastic elements

• Sort all other components and dispose of appropriately.

Attention! Used electrical materials, electronic components, lubricants and other auxiliary

substances must be treated as hazardous waste and may only be disposed of by specialised,

licensed firms.

1.8 Important information

• Dust explosion-proof dust extractors of type 1 are from

a safety point of view, engineered to collect combusti-

ble dust particles (moist or dry) classified as dust explo-

sion classes St 1 and St 2 (Kst-value 300 bar x m xs-1)

in zone 11 (see Elex V §2(4)).

They may be used to vacuum individual dust sources.

• Dust collection is prohibited on woodworking machines

that may produce ignition sparks or smouldering em-

bers (e.g. multi-blade saws).

• When vacuuming oak or beech dust, the purified air

must be returned to the room from which it was extract-

ed. Positioning the dust extractor beside the woodwork-

ing machine will ensure this.

• When vacuuming oak or beech dust, the exhaust air

volume returned to the room by the dust extractor must

not exceed 50% of the air delivered.

For natural ventilation, assume an intake volume of 1x

the room volume (m3/h, air exchange index LW=1/h).

The Felder clean air devices RL 250/RL 300

• are designed to extract combustible dusts catego-

rised as ST1 and ST 2 of the dust explosion classes.

• and are not designed to extract objects which could

be active ignition sources.

• are not designed to extract potentially explosive

or similar materials according to §1 from the law

on explosives, nor dusts categorised as St 3 under

the dust explosive classes, nor combustible liquids

and mixtures of combustible dusts and combustible

liquids.

The required airflow capacity and collection quality is

guaranteed if the dust extractor has been connected

properly to either one or several wood working machines

and is operated according to the regulations.

If extracting dust from a «dust certified» machine with

a dust source, it is ensured that the TRK working place

concentration value remains 2 mg/m³.

We guarantee that the dust extractor was manufactured

with extreme attention to qualitative equipment and

manufacturing standards and that the supplied parts

were controlled thouroughly.

As can be seen from the enclosed docket, our employees

vouch with their names for meticulous workmanship.

We hope you will enjoy your new dust extractor and the

simplicity of its operation.

9

Dust Extractor

RL 250/RL 300

2 Safety

At the time of its development and production, the ma-

chine was built in accordance with prevailing technologi-

cal regulations and therefore conforms to industry safety

standards.

However, hazards may arise should the machine be

operated by untrained personnel, used improperly or em-

ployed for purposes other than those it was designed for.

The chapter entitled “Safety” offers an overview of all

the important safety considerations necessary to optimise

safety and ensure the safe and trouble-free operation of

the machine.

To further minimise risks, the other chapters of this

manual contain specific safety instructions, all marked

with symbols. Besides the various instructions, there are

a number of pictograms, signs and labels affixed to the

machine that must also be heeded. These must be kept

visible and legible and may not be removed.

2.1 Intended use

The dust extraction equipment should only be used to re-

move sawdust and woodshavings, as it is not suitable for

other materials. Suitable wooden materials are: all solid

woods, ply wood, medium density fibre boards (MDF),

highly compressed fibre boards (HDF) and chipboards.

Operational safety is guaranteed only when the ma-

chine is used for the intended purposes.

Attention! Any use outside of the machine‘s intended purpose shall be considered improper and is there-

fore not permitted. All claims regarding damage resulting from improper use that are made against the

manufacturer and its authorised representatives shall be rejected. The operator shall be solely liable for

any damage that results from improper use of the machine.

The term “proper use” also refers to correctly observing

the operating conditions as well as the specifications

and instructions in this manual.

The machine may only be operated with original manu-

facturer parts and accessories.

2.2 Manual contents

All those appointed to work on or with the machine must

have fully read and understood the manual before com-

mencing any work. This requirement must be met even

if the appointed person is familiar with the operation of

such a machine or a similar one, or has been trained by

the manufacturer.

Knowledge about the contents of this manual is a prereq-

uisite for protecting personnel from hazards and avoiding

mistakes so that the machine may be operated in a safe

and trouble-free manner. It is recommended that the op-

erator requests proof from the personnel that the contents

of the manual have been read and understood.

2.3 Making changes and modifications to the machine

In order to minimise risks and to ensure optimal perform-

ance, it is strictly prohibited to alter, retrofit or modify the

machine in any way without the express consent of the

manufacturer.

All the pictograms, signs and labels affixed to the ma-

chine must be kept visible, readable and may not be re-

moved. Pictograms, signs and labels that have become

damaged or unreadable must be replaced promptly.

Safety

10

Dust Extractor

RL 250/RL 300

2.4 Responsibilities of the owner operator

This manual must be kept in the immediate vicinity of

the machine and be accessible at all times to all persons

working on or with the machine. The machine may only

be operated if it is in proper working order and in safe

condition. All instructions in this manual must be strictly

followed without reservation.

Besides the safety advices and instructions stated in this

manual, it is necessary to consider and observe local ac-

cident prevention regulations, general safety regulations

as well as current environmental stipulations that apply to

the operational range of the machine.

The operator and designated personnel are responsible

for the trouble-free operation of the machine as well

as for clearly establishing who is in charge of install-

ing, servicing, maintaining and cleaning the machine.

Machines, tools and accessories must be kept out of the

reach of children.

2.5 What is required of personnel

Only authorized and trained personnel may work on

and with the machine. Personnel must be briefed about

all functions and potential dangers of the machine.

„Specialist staff“ is a term that refers to those who – due

to their professional training, know-how, experience, and

knowledge of relevant regulations – are in a position to

assess delegated tasks and recognise potential risks. If

the personnel lack the necessary knowledge for work-

ing on or with the machine, they must first be trained.

Responsibility for working with the machine (installation,

service, maintenance, overhaul) must be clearly defined

and strictly observed. Only those persons who can be

expected to carry out their work reliably may be given

permission to work on or with the machine. Personnel

must refrain from working in ways that could harm oth-

ers, the environment or the machine itself. It is absolutely

forbidden for anyone who is under the influence of

drugs, alcohol or reaction-impairing medication to work

on or with the machine. When appointing personnel to

work on the machine, it is necessary to observe all local

regulations regarding age and professional status. The

user is also responsible for ensuring that unauthorised

persons remain at a safe distance from the machine.

Personnel are obliged to immediately report to the opera-

tor any irregularities with the machine that might compro-

mise safety.

2.6 Work safety

Following the safety advice and instructions given in this

manual can prevent bodily injury and material dam-

age while working on and with the machine. Failure to

observe these instructions can lead to bodily injury and

damage to or destruction of the machine.

Disregard of the safety advice and instructions given in

this manual as well as the accident prevention regula-

tions and general safety regulations applicable to the

operative range of the machine shall release the manu-

facturer and their authorised representatives from any

liability and from all compensation claims.

Safety

11

Dust Extractor

RL 250/RL 300

2.7 Personal safety equipment

Protective clothes

Sturdy, tight-fitting clothing (tear-resistant, no wide sleeves).

When working on or with the machine, the following must always be worn by personnel:

Protective footwear

That protect the feet from heavy falling objects and prevent sliding on slippery floors.

Hearing protection

To protect against loss of hearing.

2.9 Machine hazards

The machine has undergone a hazard analysis. The

design and construction of the machine are based on the

results of this analysis and correspond to state-of-the-art

technology.

The machine is considered operationally safe when used

properly.

Nevertheless, there are some remaining risks that must be

considered.

The machine runs with high electrical voltage.

Warning! Danger – electric current!

Electrical energy can cause serious bodily injury. Damaged insulation materials or defective individual

components can cause a life-threatening electrical shock.

• Before carrying out any maintenance, cleaning and

repair work, switch off the machine and secure it

against being accidentally switched on again.

• When carrying out any work on the electrical equip-

ment, ensure that the voltage supply is completely

isolated.

• Do not remove any safety devices or alter them to put

them out of commission.

2.8 Other risks

Warning! Risk of injury or death!

• Hearing damage as a result of high noise levels.

• Health impairments due to the inhalation of airborne

particles, especially when working with beech and

oak wood.

Safety

12

Dust Extractor

RL 250/RL 300

Safety

2.10 Fire hazards

Warning! Fire hazard!

Incorrect installation and usage could result in a fire.

• The dust extraction hoses must be electrically conduc-

tive and grounded to prevent electrostatic loading.

Earth vacuum hose/pipes against any static electric-

ity that may accumulate.

• The vacuum hoses/pipes must be flameproof.

• All electrical connections must be installed correctly

by qualified persons.

• Electricity supply only in authorized region of

+/- 10% of mains voltage.

• Only vacuum sawdust and woodshavings.

• Do not vacuum spark-generating objects (e.g. nails,

screws etc.).

• Do not vacuum any inflammable waste (e.g. cigarette

ends, flying sparks, etc.)

2.11 Noise emission

The specified values are emission values and therefore

do not represent safe workplace values. Even though a

relationship exists between particle emission and noise

emission levels, an inference cannot be made about

whether additional safety measures need to be imple-

mented. Factors which can significantly affect the emis-

sion level that presently exists at the workplace include

duration of the effect, characteristics of the workspace,

and other ambient influences. The permissible workplace

values may also differ from country to country. Neverthe-

less, this information is provided to help the operator

better assess hazards and risks.

Depending on the location of the machine and other

specific conditions, the actual noise emission values may

deviate significantly from the specified values.

To keep the noise emission as low as possible, always

use sharpened tools and operate the machine at the

correct speed.

It is recommended to use protective ear equipment, this is

however not a substitute for properly sharpened tools or

the correct operating speed.

13

!

Dust Extractor

RL 250/RL 300

2.12 Safety cover

The safety cover simultaneously fulfills 2 functions:

1. Closes the vacuum connector if dust should explode.

2. Forwards the vacuumings towards the dust collecting

s a c k s .

Ensure that this cover is always easy to move.

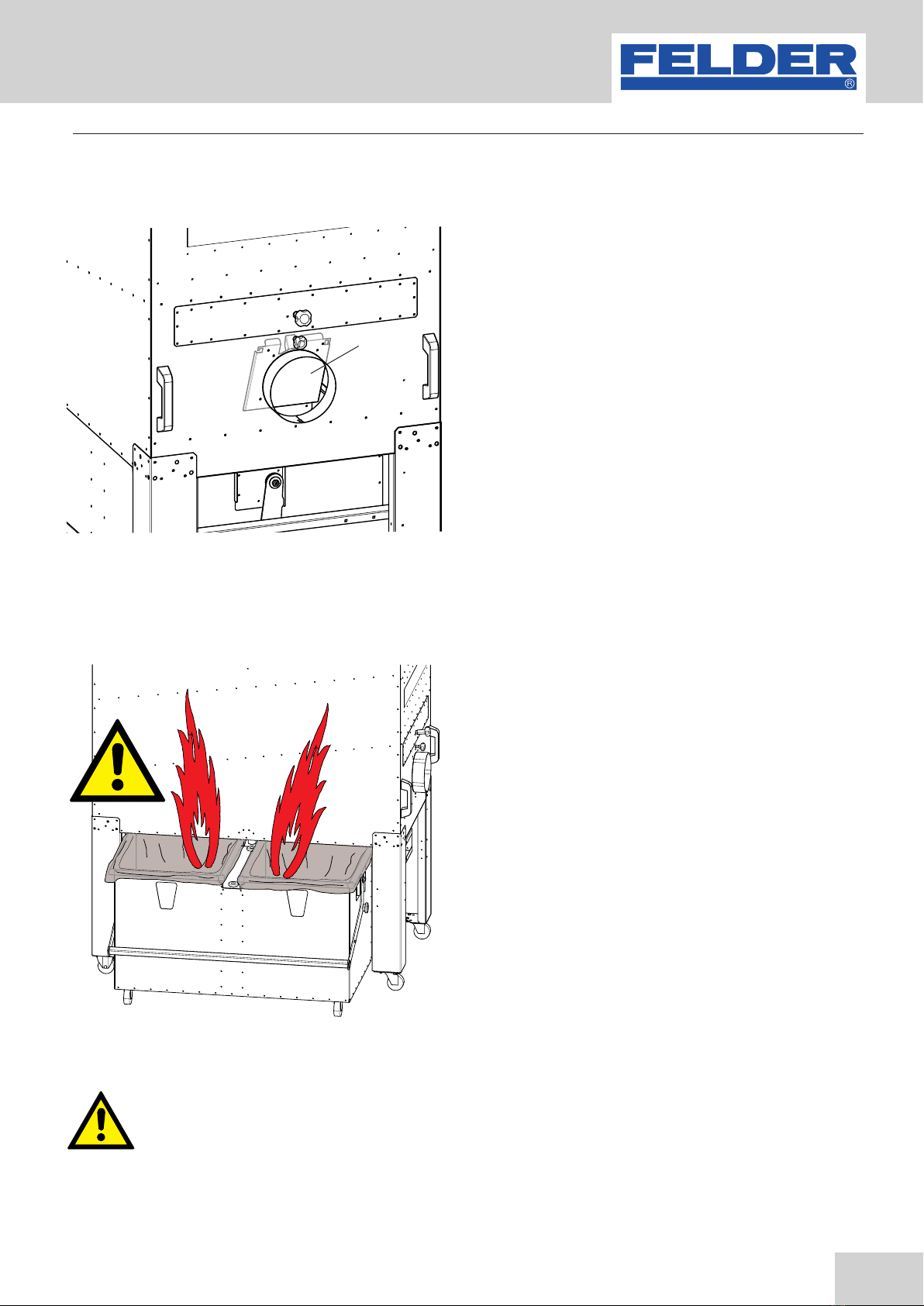

!Safety cover

Fig. 1: Safety cover

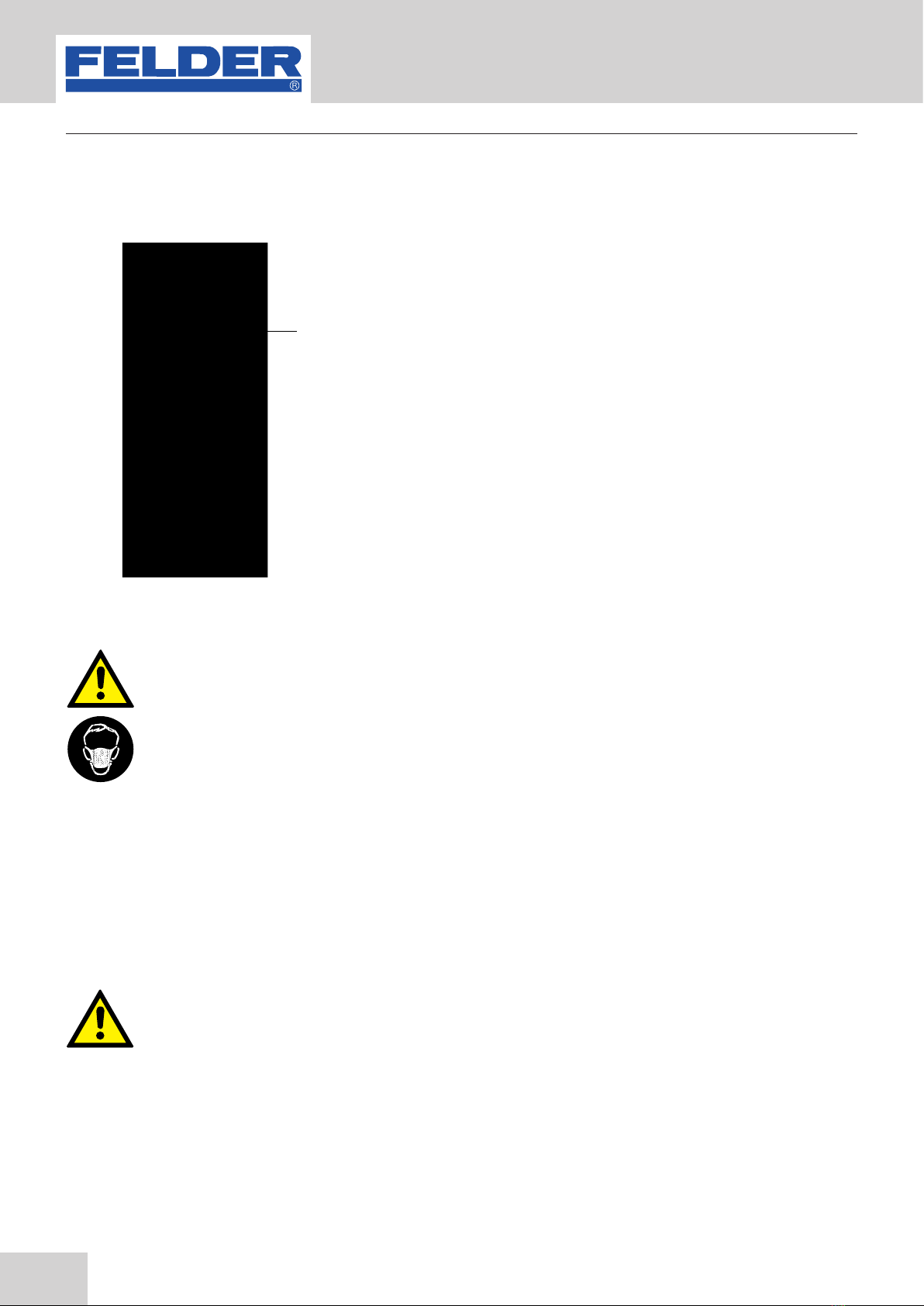

2.13 Procedure in case of fire

1. Pull out the mains plug.

2. Stop the pneumatic supply.

3. Call the fire-brigade.

Attention! When moving the chip container, flash fire can occur!

Fig. 2: Procedure in case of fire

Safety

14

Hall in Tirol, 1.1.2010

Dust Extractor

RL 250/RL 300

3 Declaration of Conformity

Declaration of Conformity

Manufacturer: Felder KG

KR-FELDER-STR.1

A-6060 Hall in Tirol

Product designation: Clean-Air Dust Extractor

Make: FELDER

Model designation: RL 250 / RL 300

The following EC guidelines were applied: 2006/42/EG

2006/95/EG

2004/108/EG

The following national norms have been applied: VDI 3677

GS-HO-14

EG-Declaration of Conformity

according to Machine Guidelines 2006/42/EG

We hereby declare that the machine indicated below, which corresponds to the design and construction of the model

we placed on the market, conforms with the safety and health requirements as stated by the EC.

This EC Declaration of Conformity is valid only if the CE label has been affixed to the machine.

Modifying or altering the machine without the express written agreement of the manufacturer shall render the war-

ranty null and void.

The signatory of this statement is the appointed agent for

the compilation of the technical information

Johann Felder, Managing Director FELDER KG

KR-FELDER-STR.1 • A-6060 Hall in Tirol

Dust Extractor

15

!

!

Dust Extractor

RL 250/RL 300

Delivery and assembly

4 Delivery and assembly

The dust extractor RL 250/RL 300 models are usually

delivered in a completely assembled state.

The dust extractor is shipped in a crate made of metal

sheets, and it is screwed down to the crate. Lift and if

necessary, transport the crate with appropriate hoisting

devices such as a stacker truck, crane or a lift truck.

Use the steering rollers to roll the dust extractor to its des-

tined location. There are two steering rollers with brake

blocks on the motor side to fix the position of the device

on a level floor surface.

Only set up and operate the duct extractor on an even

surface.

Insert a chip sack.

The container is then hermetically connected to the dust

extractor with a sealing clamp.

The dust extractor is assembled and ready to plug in. As-

semble the electrical connection as described in item 10.

To clean the filter, connect the dust extractor to the com-

pressed air supply with a 1/2 inch pneumatic hose.

Attention! The compressed air is free of oil and water!

Max. limit pressure: 7 bar

Operating pressure: 5 bar

Connect the duct extractor to the water-supply line or to

an appropriate water reservoir for the fire water supply.

Attention! The device may only be set up in a frost-free area!

Storage: keep dry and protect against unauthorised use!

16

Dust Extractor

RL 250/RL 300

Intended use

5 Intended use

The compact dust extractor was built according to the

inspection standards of the GS-HO-07 certificate (from

October 2006) and was inspected according to these

inspection standards by the German wood institute

for statutory accident insurance and prevention (Holz-

Berufsgenossenschaft), Vollmoellerstrasse 11, 70563

Stuttgart, Germany.

The dust extractor is thus appropriate to extract and to

separate dry (wood moisture < 30%) wood dust and

shavings, whereby the residual dust contents level of 3

“H3”, 0.1 mg/m3 will be adhered to.

The dust inspection applies to beech wood dust, with the

following specifications:

• Approx. median value 100 µm , 20 µm ≤ d90

≤ 300 µm

• Wood moisture 8 % ± 2 %

• The metered beech wood dust concentration amounts

to 5 g/m³ of air.

The dust extractor is tested for explosion pressure proof-

ness with an explosion pressure of 200 mbar (0.2 bar)

and therefore, can be set up in a working environment if

the necessary requirements are fulfilled.

17

Dust Extractor

RL 250/RL 300

6 Technical specifications

Technical specifications

Dimensions RL 250

Length 3015 mm

Width 970 mm

Height 2280 mm

Weight 700 kg

Motor power 7,5 PS (5,5 kW)

Motor voltage 400 V

Motor frequency 50 Hz

Power consumption 11,2 A

Minimum fuse amperage 32 A

Suction diameter 250 mm

Max. air flow rate 5000 m3/h

Nominal air flow rate 3530 m3/h

Interface vacuum 2100 Pa (for nominal air flow rate)

Dust collecting volume 500 l (3 bags each with 166 l)

Sealing grade IP54

Filter (surface) area 40 m2

Dust loading < 0,1 mg/m3

Air-to-cloth ratio 88 m3/m2/h (for nominal air flow rate)

Max. sound pressure 81 dB (A)/1 m distance/ 1,6 m height according to MRL

Ambient temperature 5–40° C

Compressed air consumption 12 l per filter cartridge and pulse

(Regular interval = 90 sec. = 40 Pulse/h = 2400 Litre/h

Dimensions RL 300

Length 3015 mm

Width 970 mm

Height 2280 mm

Weight 720 kg

Motor power 12,5 PS (9,2 kW)

Motor voltage 400 V

Motor frequency 50 Hz

Power consumption 17 A

Minimum fuse amperage 32 A

Suction diameter 300 mm

Max. air flow rate 6000 m3/h

Nominal air flow rate 5090 m3/h

Interface vacuum 2100 Pa (for nominal air flow rate)

Dust collecting volume 500 l (3 bags each with 166 l)

Sealing grade IP54

Filter (surface) area 40 m2

Dust loading < 0,1 mg/m3

Air-to-cloth ratio 127 m3/m2/h (for nominal air flow rate)

Max. sound pressure 82 dB (A)/1 m distance/ 1,6 m height according to MRL

Ambient temperature 5–40° C

Compressed air consumption 12 l per filter cartridge and pulse

(Regular interval = 90 sec. = 40 Pulse/h = 2400 Litre/h

18

!

Dust Extractor

RL 250/RL 300

Filter contents level monitoring/Explosion pressure proofness

Warning! The explosion pressure proofness is 210 mbar.

Warning! Danger of dust inhalation:

Always wear a dust respirator when cleaning the filter by hand (filter mask with a particle collector, Class 2).

Prevent people uninvolved with the process from being exposed to dust pollution. Avoid ignition sources,

open fire and electrostatic charging.

Dust and shavings must be disposed of according to the regulations of the country where the

machine is installed.

7 Filter contents level monitoring

If the filter resistance increases to a value which is not al-

lowed (filter clogging up), a warning lamp in the equip-

ment cabinet switches itself on. The filter component

cleaning process starts simultaneously. Once the device

is switched off, a manual cleaning process should start

(switch in the control cabinet). If, the warning lamp is

still on once the dust extractor is started anew, clean the

filter elements by hand using an appropriate industrial

vacuum.

!Differential pressure transducer

Fig. 1: Monitoring the filter system

8 Explosion pressure proofness

The RL 250/RL 300 clean air devices were tested for ex-

plosion pressure proofness by the FSA GmbH test centre.

The maximum explosion excess pressure, up to which the

dust extractor still withstood any form of damage, was

used as a proof pressure value, as detailed in the VDI

2263 Guidelines, Part 3.

Afterwards, to test the explosion pressure proofness, a

minimum of 1.1 x the proof pressure has to be attained

safely. Deformations are tolerated.

19

Dust Extractor

RL 250/RL 300

General safety information

9 General safety information

• The dust extractor may only be used by personnel

who are trained to handle the machine (instructions

and the operating manual).

• The machine may only be used in a dry and frost-free

environment and may not be used outside.

• Ensure that the current supply wire (power supply

cord) is not damaged by external influence (squash-

ing, driven over, tugged, etc.).

• Check the power supply lead regularly for signs of

damage or ageing.

• The device may only be used if the power supply cord

is free of defects.

• If replacing the power supply cord, only use HO7RN

5 x 4 mm2 rubber-insulated cable.

• If replacing the power plug, use a CEE plug SH/32

Amp. according to the VDE 0165 section 7.1.4 safety

standards. Adaptors are not authorised.

• Only qualified personnel may replace the power sup-

ply cord and the power plug.

• If the power supply cord and the power plug need to

be changed, comply with the replacement equipment

named by the manufacturer.

• The power plug may only be plugged into the power

source once the dust extractor has been set up at its

site of operation. Connection to CEE plug (i.e. wall

socket) with a delayed 25A fuse.

• Always unplug the dust extractor if it is not in use, or

if moving it from one place to another and before

cleaning or maintaining it or removing and replacing

removeable parts.

• Only use original spare parts when operating the

machine.

• If the device is to be stored (in a dry room) for a

long period of time, insert new chip sacks, switch the

machine off, roll up the power cord and ensure that

unauthorised personnel does not have access to the

machine.

• The filtered air from the dust extractor may only be

recycled into the room it was extracted from.

• The machine is only designed to extract dust from

woodworking machines which do not produce sparks

(Note: according to the BGI 739 (wood institute for

statutory accident insurance and prevention) such

machines are breakers, multi-blade circular saws and

wide-belt sanding machines used to manufacture

chipboards, doors, fillets and parquet flooring.

• Extracting other types of dust than wood dust is only

authorised with the express agreement of the machine

manufacturer.

• The machine may only be operated in non-explosive

areas. It is not authorised to use the machine in areas

where there is the danger of a gas explosion.

• It is not authorised to collect mixtures of combustible

dusts and liquids.

• The machine is not designed to extract liquids.

• Only sheet metal pipes and inflammable flexible

hoses with metal filaments, for electrostatical earthing,

may be used to connect to the machine. Ensure that

the electrostatical earthing is continuous.

• To avoid unauthorised heating, the direction of rota-

tion of the ventilating fan must be monitored.

• The machine is designed to extract combustible dusts

of Class 1 and 2 of the dust explosion classes (Kst-

value max. 300 bar m s-1), (see ElexV §3(4)).

• This device is not, from a safety point of view, de-

signed to absorb or extract explosive or similar materi-

als according to §1 from the law on explosives, nor

dusts categorised as a St 3 dust explosive class, nor

combustible liquids and mixtures of combustible dusts

and combustible liquids.

• The dust collecting container is always to be emptied

if full or after use. Only use original spare parts.

• If several machines are connected, the sum of the

opened cross-sections may not exceed the cross-sec-

tion of the dust extractor.

20

!

Dust Extractor

RL 250/RL 300

Vacuum hose port/casing/Electrical connection

10 Vacuum hose port/casing

If connecting a vacuum hose, only use electrical conduc-

tive and flame-resistant hoses. Ensure that the electrical

connection between the hose and the pipe connector is

free of defects.

If a so-called „coil hose“ is used, the metal coil must be

stripped and the hose pressed onto the wall of the con-

nector with a pipe wall clamp or a ring-tightener. Plastic

hoses must be flame-resistant.

Only use sheet metal pipes to connect to a pipe (pipe-

work). Use optimised flow lateral pipes and elbows (no

T-branches and/or 90° elbow fittings). The pipe fittings

have to be connected together hermetically and must

conduct electricity.

Use a sluice gate if the sum of the connected cross-sec-

tions is larger than the cross-section of the extraction

opening of the dust extractor.

We recommend the use of a qualified professional to

design and lay the pipework.

11 Electrical connection

Check if the power-supply indicated on the factory name

plate corresponds with the mains before connecting the

device to the mains supply available.

This device may only be operated if the mains has an

earthed neutral conductor!

Attention! Note the direction of rotation!

Check that the direction of rotation is correct before

starting the machine. The direction of rotation can be

determined by switching the motor on and off, by obser-

ving the cooling fan on the motor and comparing it to

the direction of rotation arrow.

If the direction of rotation is incorrect, change the polari-

ty. Change the polarity with the phase reverser built into

the plug. The direction of rotation of the ventilating fan is

changed by turning the pole pin built into the insulated

part of the plug with a screwdriver.

Attention! If the direction of rotation of the drive motor is incorrect, for example as a result of the incorrect

polarity, switch the machine off immediately, as the resulting suction output is not sufficient, and it prevents

the machine from heating up (prohibited).

Connect the converter coils in the connecting lead of

the appropriate woodworking machine as depicted in

the wiring diagram „Converter inputs“ in the annexed

Control operating manual.

This task may only be carried out by qualified profession-

als.

Other manuals for RL 250

1

This manual suits for next models

1

Table of contents

Other Felder Vacuum Cleaner manuals