FELIXrobotics FELIX 3.0 User manual

User Manual

FELIX 3.0, 3d printer

VERSION 8

Copyright Information

This document contains proprietary information that is protected by copyright. No part of this document may be photocopied,

reproduced, or translated to another language without the prior written consent of FELIXrobotics BV.

FELIXrobotics BV

Gessel 4a

3454MZ, de Meern

The Netherlands

Copyright © 2014 FELIXrobotics BV.

AUGUST 8, 2014

Page1

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

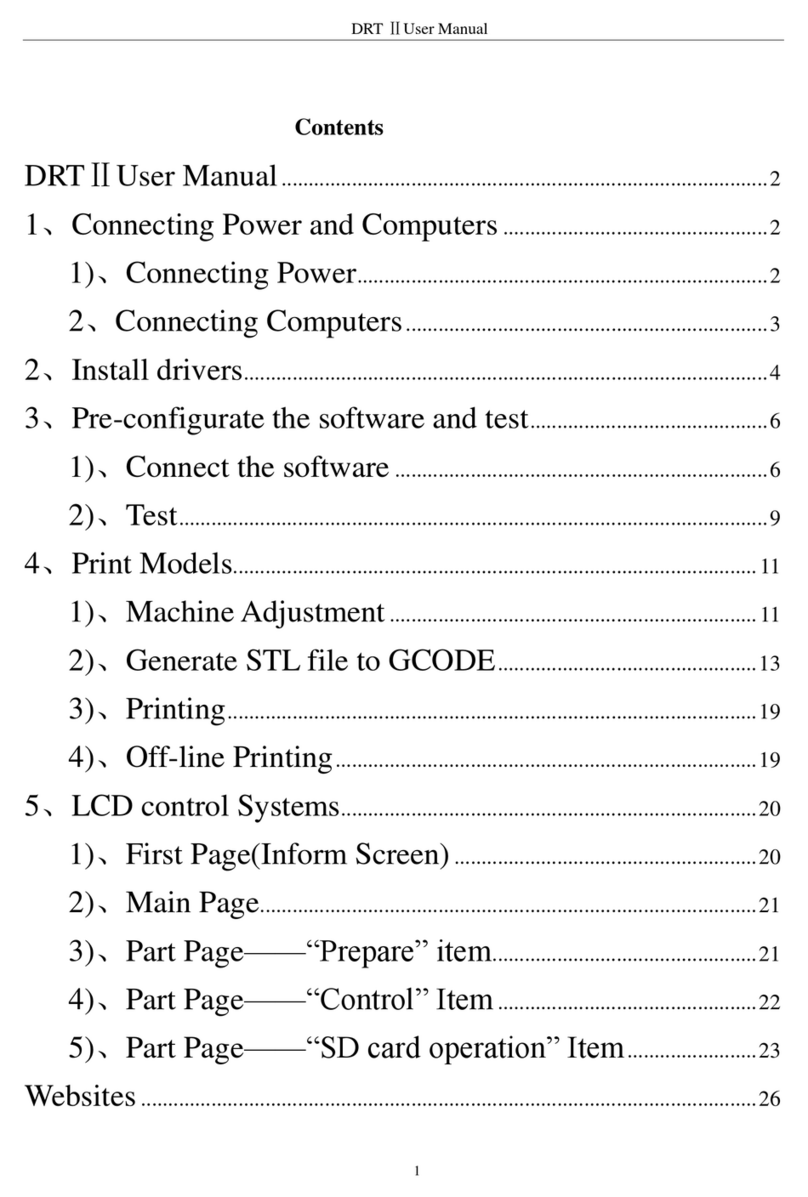

Contents

CONTENTS _________________________________________________________________________________________ 1

1INTRODUCTION ________________________________________________________________________________ 2

2SPECIFICATIONS _______________________________________________________________________________ 3

3MECHANICAL SETUP____________________________________________________________________________ 4

3.1 Calibration of table _________________________________________________________________________________________________________ 4

3.1.1 Step 1 __________________________________________________________________________________________________________________ 4

3.1.2 Step 2 __________________________________________________________________________________________________________________ 5

3.2 Extra calibration for dual extrusion printers ____________________________________________________________________________________ 6

4SOFTWARE INSTALLATION –MICROSOFT WINDOWS_______________________________________________ 7

4.1 Microsoft Windows _________________________________________________________________________________________________________ 7

4.1.1 Driver Installation ________________________________________________________________________________________________________ 9

4.1.2 Firmware installation –Arduino____________________________________________________________________________________________ 10

4.1.3 Printer Software –Repetier-Host ___________________________________________________________________________________________ 7

4.2 Software Installation –Mac OS ______________________________________________________________________________________________ 11

4.3 Calibrate the Z-Direction/Connect to printer __________________________________________________________________________________ 15

5PREPARE A CAD FILE FOR PRINTING - SLICING ____________________________________________________ 17

6YOUR FIRST PRINT ____________________________________________________________________________ 19

7SOFTWARE ___________________________________________________________________________________ 21

7.1 Repetier- Host_____________________________________________________________________________________________________________ 21

7.1.1 Slicers _________________________________________________________________________________________________________________ 21

7.1.1.1 CuraEngine ______________________________________________________________________________________________________ 21

7.1.1.2 SLIC3R __________________________________________________________________________________________________________ 24

7.1.1.3 SFACT __________________________________________________________________________________________________________ 25

7.1.2 Dual head printing _______________________________________________________________________________________________________ 27

7.1.2.1 Calibration _______________________________________________________________________________________________________ 27

7.1.2.2 Use second extruder for support material _____________________________________________________________________________ 30

7.1.2.3 Assign an extruder to an object. _____________________________________________________________________________________ 31

7.2 Kisslicer __________________________________________________________________________________________________________________ 34

7.2.1 Make a dual extrusion print _______________________________________________________________________________________________ 36

7.2.1.1 Support material with second extruder _______________________________________________________________________________ 36

7.2.1.2 Use second extruder for different object or part of an object. _____________________________________________________________ 38

8PRINTER CONTROL WITH OPTIONAL DISPLAY UNIT_______________________________________________ 40

8.1 Workflow to start a print. ___________________________________________________________________________________________________ 41

8.2 Workflow to stop or pause a print. ___________________________________________________________________________________________ 41

8.3 Switch filament. ___________________________________________________________________________________________________________ 41

8.4 Menu description __________________________________________________________________________________________________________ 42

9PRINTER ACCESSORIES ________________________________________________________________________ 43

9.1 Filament cleaner mechanism. _______________________________________________________________________________________________ 43

9.2 Filament roll off mechanism (vertical) ________________________________________________________________________________________ 44

9.3 Filament roll off mechanism (horizontal) ______________________________________________________________________________________ 45

10 FAQ__________________________________________________________________________________________ 46

11 SLICERS IN MORE DETAIL ______________________________________________________________________ 47

12 MAINTENANCE/OPTIMAL OPERATIONAL TIPS ____________________________________________________ 48

12.1 General tips for optimal operation ___________________________________________________________________________________________ 48

12.2 Cleaning __________________________________________________________________________________________________________________ 48

12.3 Regular maintainance ______________________________________________________________________________________________________ 48

13 TROUBLESHOOTING___________________________________________________________________________ 49

14 SAFETY ______________________________________________________________________________________ 52

15 APPENDIX: EXTRA CHECKS AFTER ASSEMBLING DIY KIT FOR OPTIMAL OPERATION __________________ 53

16 APPENDIX: ELECTRONIC SCHEMATICS ___________________________________________________________ 55

17 APPENDIX: MATERIAL DATA SAFETY SHEET______________________________________________________ 56

17.1 PLA ______________________________________________________________________________________________________________________ 56

17.2 ABS ______________________________________________________________________________________________________________________ 58

18 APPENDIX: SYMBOL- AND INDICATORLIGHTS EXPLANATION ______________________________________ 60

19 APPENDIX: TERMS OF SERVICE _________________________________________________________________ 61

Page2

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

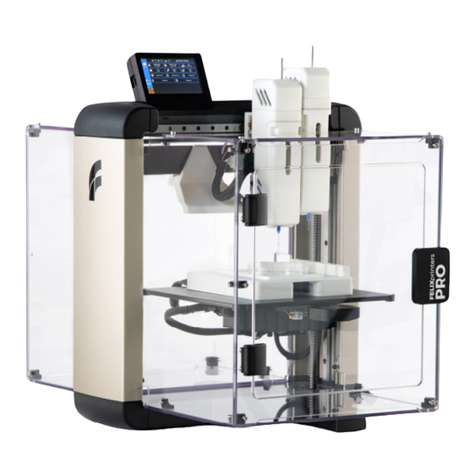

1Introduction

First of all, thank you choosing FELIXprinters! To get your Felix printer up and running as fast and

painlessly as possible please follow this manual carefully. Don’t compare this product with a television,

where a user manual is normally not required to get it working properly.

Please follow the instructions carefully and take your time to get familiar with the product. Please don’t

take any shortcuts unless you know what you’re doing. It’s better to spend a few minutes extra on

reading, than to wait a week for new parts.

When things are unclear or if you have any remarks or tips, please contact us at

support@FELIXprinters.com. We also recommend looking on our forum and getting yourself a forum

account. You will benefit from the ability to get downloadable and printable upgrades for your printer.

Also it is a great source to obtain and share knowledge about your 3d printer and 3d printing in general.

Page3

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

2Printer Specifications

Printing

Electrical

Print Technology

Fused Filament Fabrication

AC input:

100-240V, 50-60 Hz

Build Volume

25.5 x 20.5 x 22 cm

Power Requirements

12V DC, 15 Amps

Print Quality

Low

Normal

High

Very High

Extreme

250 microns

200 microns

150 microns

100 microns

50 microns

Connectivity

USB

Postioning Resolution

XY: 13 microns

Z: 0.4 microns

Power Usage

Max 250W

Filament Diameter

1.75 mm

Nozzle Diameter

0.35 mm

Mechanical

Chassis

Aluminum profiles

Software

Build platform

Aluminum sandwich plate

Software Bundle:

RepetierHost +

CuraEngine/Slic3r,Skeinforge/SFACT

Kisslicer

XY Bearings

Linear ball bearings

File Types:

.STL .gcode

Z bearing

Linear ball bearings

Supports:

Windows, XP and newer

Stepper Motors

1.8 deg angle

1/16 micro-stepping

Linux (Ubuntu 12.04+)

Mac OS X [10.6/10.7/10.8]

Physical Dimensions

Printer dimensions

40 x 44 x 52 cm

Weight

8.7kg single, 9kg dual head

Shipping Weight

11 kg

Shipping Box

50x30x30 cm, DIY kit

58.4x50.8x55.5 cm, Assembled unit

Temperature

Ambient operating

temperature

15-32 ˚C [60 – 90 ˚F]

Storage temperature

0 –32 ˚C

Warmup time

Heated bed (60 degC)

3 min

Nozzle (200degC)

1 min

Page4

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

3Mechanical Setup

3.1 Calibration of table

For a successful print it is important that the table is properly calibrated. The distance between the nozzle and table should

be the same at every x,y position. The leveling mechanism of the table can be adjusted by turning the 3 M4 nuts underneath

the heated bed. For the assembled units the calibration should be good right of the box, but due to shipment it could be

that the calibration is slightly off. Therefore it is important to check it first.

IMPORTANT NOTES:

!!The leveling should be done by moving the axes by hand, not via computer interface!!

!!Never move the axis at a high rate by hand, because the motors could act like a generator (similar to your bicycle and

potentially damage the electronics of the board.)!!

3.1.1 Step 1: Y-direction

Calibrate the table in the y-direction.

1. Move the X-axis carriage (extruder) close to the homing sensor as shown above, and move the table up until

approximately 1 mm from the hot-end.

2. Move the Y-axis (heated bed) back and forth slowly. While doing this check the distance between the tip and bed. It

should be the same over the whole movement.

If it is not, turn the 2 nuts underneath the bed as indicated in the picture below.

3. Move the table a little closer to the hot-end and repeat the previous step to more precisely determine the distance

between the hot-end and the table over the whole length.

Start with approx.

1mm distance

Adjustment nuts

Page5

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

3.1.2 Step 2: X-direction

Calibration in x-direction

4. Make sure there is at least 1mm separation between table hot-end.

5. Move the table to the middle of its movement range slowly.

6. Move the X-axis carriage over its movement range slowly. While moving check the distance between the hot-end and

bed. If the distance is not even, adjust it with the nut which supports the middle of the table.

7. Move the table a little closer to the hot-end and repeat the previous step to more precisely determine the distance

between the hot-end and the table over the whole length.

You have successfully calibrated the table.

Adjustment nut

Page6

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

3.2 Extra calibration for dual extrusion printers

NOTE:

This step is only intended for people who bought a dual head DIY kit. Otherwise skip to next

subchapter.

This section guides you through the process of mechanically calibrating your DUAL head setup. The following

checks make sure the hot-ends will have the same height with respect to the just-leveled heated bed.

1. Make sure the heated bed is leveled correctly.

2. Make sure the hot-ends have the same revision. Otherwise, mechanical adjustment might be required.

3. Make sure the bottom bolts are gently fastened with an equal amount of torque.

4. Is the height of both hot-ends equal? If not, do the following checks to see what could be the cause.

If the hot-end tips have a different height, it could be that during assembly of the hot-ends the parts were

not fastened with an equal amount of torque, or that the tolerances are out of spec with one of the two

hot-ends. Please check with steps 1 to 4 to see where the difference lies. If necessary, you can slightly

adjust the length by applying more torque to the parts of one of the hot-ends.

1. Verify that edge of top hot-end part

touches the bottom

2. Verify that the peek parts are

equally high

3. Check if heater barrels have the

same height

4. Check of tips have the same height.

Page7

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

4Software Installation –Microsoft Windows

4.1 Microsoft Windows

NOTE: Mac users should go to chapter 4.2

This chapter describes the steps how to make the printer communicate with your PC.

-Repetier-host

-Driver installation

-Firmware installation

4.1.1 Printer Software –Repetier-Host

Repetier-Host provides the following functions:

-Control your printer, move axes and set temperatures, monitoring etc.

-Process your CAD files (STL files) and make them printable.

To install Repetier-Host on your PC take the following steps:

1. Download the latest version of Repetier-Host from www.FELIXprinters.com/downloads

Navigate to the software folder and download setupRepetierHostFELIXprinters*.exe

2. Run the setupRepetierHostFELIXprinters*.exe file and follow the installation instructions.

-During installation it will ask to install a driver. This is recommended to do.

3. Make sure the power cable and USB cable of the printer are connected.

4. Start Repetier-Host.

5. Go to Config -> Printer settings.

6. Select your printer type, single or dual head

In the configuration window press the Refresh Ports button.

Page8

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

Choose the COM-port which belongs to your printer. If no port shows up, it could because of the

following:

-your printer might not be plugged into the USB port.

-The driver is not installed, or currently installing by windows.

If this is not the case, please install the driver manually according to next chapter.

Page9

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

4.1.2 Driver Installation

1. Plug in the power supply cable.

NOTE: The electronics board is NOT USB powered, so without the power cable the

electronics won’t work. It needs the voltage of the purple wire to drive the logic of the board.

The power to the rest of the board is controlled by the CPU when needed.

2. Plug the USB cable into the computer

3. Your operating system should find the correct drivers automatically, or download them automatically with

Windows update.

a. If the drivers are not found automatically, then download drivers from here:

http://www.ftdichip.com/Drivers/VCP.htm.

4. Windows 7: Right-click on "Computer" in the Start Menu, then select "Properties". In the left pane, click

"Device Manager". On Windows 8 the Device Manager is accessible directly from the Windows menu.

Note what COM-port is present. If there are more than one COM ports available, unplug the USB cable of

the printer and then re-plug it in again. Check what port number is appearing and disappearing. This port

number will be used for the next step.

NOTE: Sometimes Windows is still not able to find the port. To fix this follow this tutorial:

http://forum.arduino.cc/index.php/topic,107098.0.html

Page10

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

4.1.3 Firmware installation –Arduino

NOTE: Only continue with this subchapter if:

1. You have just assembled your DIY kit DUAL extruder 3d printer or

2. You want to update the firmware of your printer because there is new firmware

available.

This chapter explains how to update the firmware on the electronics board of your printer.

This step requires the following software:

-Arduino, http://arduino.cc/en/Main/Software platform to upload firmware to the printer.

-FELIXprinter firmware (check the revision of the printer). Contains printer settings for correct

operation of your FELIXprinter.

Steps to upload new firmware to the control board:

1. Download the latest firmware here:

http://www.felixprinters.com/downloads/index.php?path=firmware/

Be sure to download the printer firmware that matches your printer version.

Extract the firmware .zip file.

2. Install the Arduino software, and run it.

3. Open the firmware file from the extracted firmware folder.

In this case it is Repetier.ino, it could also be Marlin.ino.

4. Select the correct platform:

5. Select the correct Serial (COM) Port, which you noted earlier.

Page11

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

6. Press the upload button, and wait till the upload is complete. This normally takes between 1 to 2 minutes.

The new firmware is now on your printer.

4.2 Software Installation –Mac OS

1. Plug in the power supply cable.

NOTE: The electronics board is NOT USB powered, so without the power cable the

electronics won’t work. It needs the voltage of the purple wire to drive the logic of the board.

The power to the rest of the board is controlled by the CPU when needed.

2. Plug in the USB cable into the computer

3. Download Mac-drivers from: http://www.ftdichip.com/Drivers/VCP.htm.

4. Download repetier software (.dmg file) from: http://www.repetier.com/download/ or from

http://shop.felixprinters.com/downloads/index.php?path=software/

5. Open .dmg file and copy Repetier-Host.app to your Application folder

6. Download latest printer profiles from

http://shop.felixprinters.com/downloads/index.php?path=software%2Fsfact+slicing+profiles/

Page12

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

7. Extract sfact.zip file (containing 1 folder with 2 subfolders: “sfact” and “sfact_profiles”

8. Copy sub-folder “sfact_profiles” to Macintosh H

9. Copy the “sfact” sub-folder to Applications folder (where the Repetier-Host.app is as well)

10. Open the Repetier-Host Mac Application and go to Printer Settings

11. Configure printer settings:

Page13

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

12. Configure Skeinforge settings under Preferences -> Slicer -> Skeinforge

13. Click “Browse” to direct to the correct files

Application: /Applications/sfact/sfact.py

Craft Utility: /Applications/sfact/skeinforge_application/skeinforge_utilities/skeinforge_craft.py

Python Interpreter: /usr/bin/pythonw

Python Interpreter: /Applications/Repetier-Host Mac.app/Contents/Resources/pypy.app/bin/pypy

Profiles Directory: /sfact_profiles/profiles

Page14

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

Page15

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

4.3 Calibrate the Z-Direction/Connect to printer

To obtain good quality prints it is essential that the heated bed is level and that the distance between the hot-

end and the bed is close enough when printing the first layer.

The leveling was done prior to the software installation. So now it is time to calibrate the z-axis height with the

z-axis limit switch vane.

1. Connect to the printer. (The connect button should turn green)

Other checks to see if the printer is connected properly:

On the bottom of the Repetier-Host program the following should be displayed

If you see … commands waiting, press the reset button, which is on the side of the electronics case next

to the SD-card and USB sockets.

2. Go to the manual control tab. (This looks different on the Mac, but has the same functionality)

3. Now it is time to calibrate the z-height:

When doing the following steps, hold your hands on the power switch of the power supply. Flip the

switch if something goes wrong.

-Press the Power button. This will turn on the power circuit of the electronics board.

If you have built a DIY kit: Do the following checks to ensure you have connected the wires correctly.

oMake sure the fan which blows air on top of the hot-end is spinning

oMake sure the LEDs of the opto-sensors on the electronics board are reacting by checking to

see that the appropriate lights go out when they are triggered. When a limit switch vane goes

between the sensor flanges, the correct light should turn off.

Home X, Y and Z

button

Home All axes

button

Page16

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

-Make sure the bed is at least 5 cm from the hot-end, to give you enough reaction time to respond if

something goes wrong.

-Press Home X, then move the x axis back and forth.

-Press Home Y, move the y axis back and forth.

-Press Home Z

-The distance between the table and hot-end is probably too large.

-Turn the screw in such a way that the flexible vane mechanism goes downwards. Do this approx. till ¾

of the possible stroke. Move the complete part a little bit up and press Home Z again.

-Repeat this process until the table is approx. 3 mm from the nozzle. Now fix the bracket to the frame

and start homing again. Repeat this procedure to get the nozzle closer and closer by turning the little

screw as shown in the picture above.

-Do this a couple of times until the distance is less than the thickness of a piece of normal paper.

Example:

Too far: Big gap

Too close: Nozzle hits table

No airgap

No contact between nozzle

and table

In the manual control tab

-Check if the switchable fan mounted to the airduct is working.

Move the slider to 100% and press the fan button

1. Rough adjustment

2. Fine adjustment

Page17

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

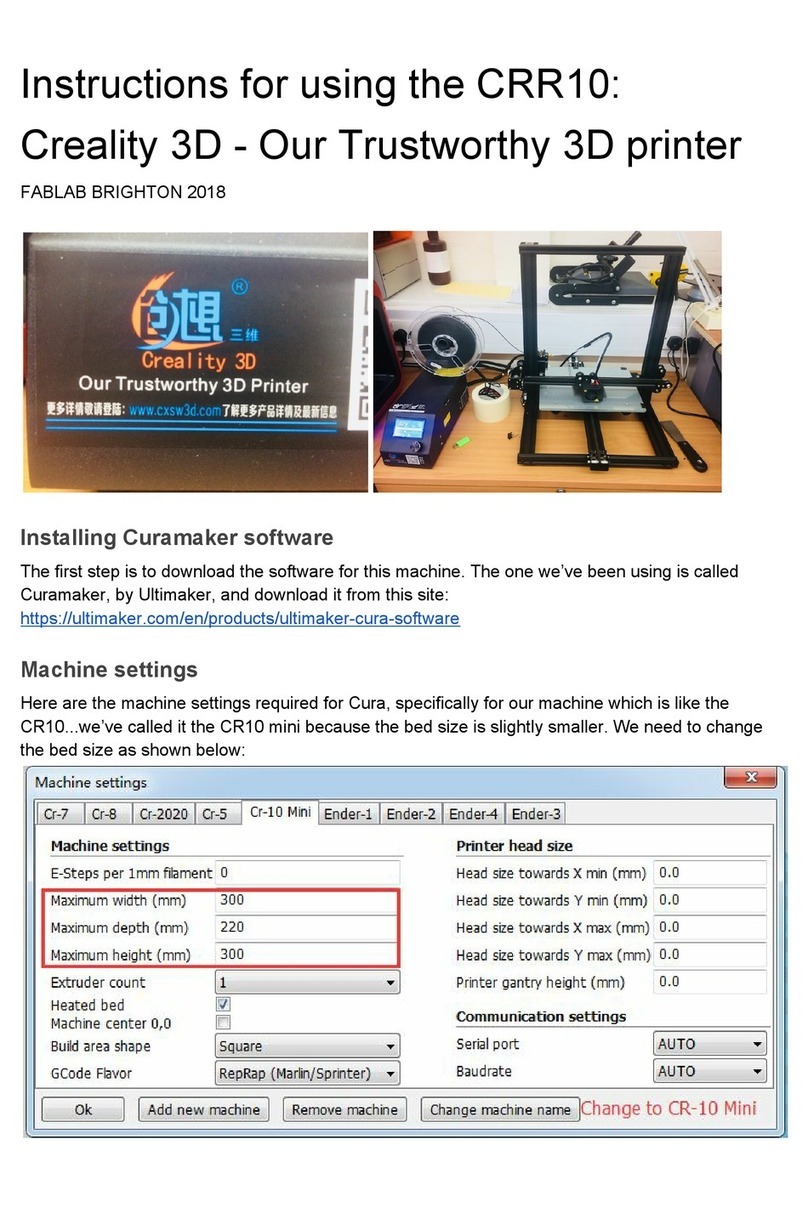

5Prepare a CAD file for printing - Slicing

This chapter will prepare a CAD file for printing. It basically converts an STL file to a gcode file. This process is

called slicing.

To keep things simple for your first print we recommend you get the test file from here:

http://shop.FELIXprinters.com/downloads/index.php?path=print_files%2Ftest_print_files/ .

Choose the file. FELIXprinters_gadget.STL.

For slicing there are several options available. All have their strengths.

In the Repetier-Host application there are three slicers embedded.

-CuraEngine (recommended)

-Slic3r

-SFACT(Used in the previous Repetier-Host versions)

Next to that we also recommend an external slicing program called Kisslicer. This program generates at the

time of writing the best gcode- files for dual extrusion and also very good code for single extrusion.

Go to the Slicer tab, you’ll see the three different slicers. For this demo we’ll take the recommended

CuraEngine. For your first print, we will take the default settings. Please match the settings in the picture

below.

Now load the downloaded STL file:

And press the Slice with CuraEngine button.

Page18

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

After slicing you’ll see a preview of the generated g-code. Also note the printing time, it will take approx. 15

minutes to finish this object.

You have now sliced your first object and are ready to go to the next step.

Page19

support@FELIXprinters.com

www.FELIXprinters.com

User manual FELIX 3.0 3d printer

6Your first print

At this stage all we’ve done all preparations and we’re at the final step to convert your idea or 3d file into

reality.

In the manual control window do the following.

-In case of dual extrusion, select the extruder of choice.

-Heat up the extruder to 195 degC

-Heat up the heated bed to 55 degC

-Move the table down 10mm

If the extruder and heated bed are warmed up, check or make sure that the following is true:

Printer axes can move without obstructions

Remove all plastic residues on the heated bed, preferably with the supplied tweezers

The heated bed surface is clean and degreased.

When all axes are homed, the hot-end is not touching the table.

Make sure the table is moved at least 10mm away from the extruder tip and insert the supplied PLA filament in

the extruder.

Run the extruder until a steady flow of plastic comes out.

NOTE: When there is not a continuous flow coming out of the nozzle, make sure the

extruder arm is properly tensioned. Turn the m4 bolt COUNTER CLOCKWISE to put more

tension on the filament, so the filament will be pulled into the hot-end better. But watch out,

too tight and the motor will have a hard time turning, and in the worst case the filament

might be squashed so wide that it gets clogged into the hot-end.

WARNING:EXTRUDER AND

HEATED BED GET HOT.WEAR

GLOVES WHEN OPERATING

YOUR FELIXPRINTER.

Other manuals for FELIX 3.0

1

Table of contents

Other FELIXrobotics 3D Printer manuals

Popular 3D Printer manuals by other brands

AmazonBasics

AmazonBasics B08895Y2CP manual

Stratasys

Stratasys J3 Series user guide

TRAK

TRAK Airwolf EVO-T Installation, Printing, Maintenance & Troubleshooting Manual

Dreve

Dreve phrozen Sonic XL 4K 2022 user manual

Creality 3D

Creality 3D Ender-3 Pro Instructions for assembly

Shining 3D

Shining 3D AccuFab-L4D user manual